Owners of private apartments and houses often hear sharp, distinct blows in the equipped heating pipeline. Many people do not pay due attention to this phenomenon, but the outcome of the situation can be very different. Specialists often have to eliminate the results of destruction of important parts.

In some cases, injury to residents cannot be ruled out. Water hammer in an equipped heating system is the main cause of most breakdowns and destruction of heating equipment. A high-quality and timely solution to this issue is of great importance for the stable and trouble-free operation of the system.

Classic consequences of an emergency

Short description

A very common water hammer in an equipped high-quality heating system is a unique phenomenon that is based on the dynamics of various substances. The manifestation itself differs in that with periodic changes in the flow rate of the working fluid, an increase in pressure indicators is observed. The main coolant is water, the main indicator of which is incompressibility. During the circulation of the charged coolant through pipelines and heating elements, various hydraulic obstacles may arise along its path. In most cases, these are turns, sudden changes in the diameter of pipelines, as well as shut-off and control valves.

Attention! Water hammer can only provoke the sudden appearance of large obstacles. In such a situation, the flow speed quickly decreases, and the pressure level in the obstruction zone increases significantly.

Under unfavorable conditions, the coolant can damage those elements that present strong hydraulic resistance to the flow. These can be convectors, pipe turns, various devices, radiators and even boiler heat exchangers.

An accident may well occur as a result of gradual wear and tear of the operating structure and its elements, or as a result of the sudden impact of a strong jump in performance. In all situations, the consequences of water hammer entail material waste to eliminate the leak. In order not to find yourself in such a situation, you should understand the basic reasons for the formation of water hammer. The consequences of an accident are always unpredictable, ranging from the most common breakdown of the circulation pump to large-scale flooding of the entire house. It all depends on the quality and power of the system.

The most common consequences of water hammer

Consequences of water hammer

Any incidents with the water supply are associated not only with material damage to the pipeline itself, but also with the costs of eliminating the consequences of water exposure to nearby objects. This is especially aggravated for pipelines with hot water and those under high pressure. In these situations, there is even a danger to the health and life of people and pets. They may be scalded or injured. In particular, this negative phenomenon may be followed by the following:

- destruction of pipe lines;

- flooding of residential, administrative and utility premises;

- failure of pumping equipment and shut-off valves;

- damage to furniture, household appliances, computers and the like;

- interruption of water supply;

- destruction of structures of buildings and structures (especially in winter, due to the force of expansion when moisture freezes);

- interruption of electrical supply;

- fires due to short circuit of electrical wiring.

Danger of consequences of damage to heating and water supply due to water hammer Source formp3life.ru

Accidents on highway networks can cause traffic congestion; in winter, icy conditions caused by gusts usually completely block the movement of cars for some time.

Main causes

Specific water hammer in a functioning heating system can occur for various reasons. A classic heating line for a private home necessarily consists of a variety of structural parts: pipelines of different sizes, as well as many other elements that have a great impact on fluid pressure drops. Experts have repeatedly noted that unprofessional assembly of devices and poor-quality installation of the heating system can be the main reason for large pressure surges. The main reasons include the following:

- The installed filters are clogged.

- During operation, a previously working pump experienced an unexpected failure.

- The master connected pipes of different diameters.

- The valve operated too quickly, which caused a strong water hammer.

- There are plugs in the heating system you are using.

The circulation unit may stop performing its basic functions due to poor quality parts, as well as for other reasons. This may be a decrease in the water level in an underground well or an incorrect determination of the basic operating parameters of the unit. To avoid negative consequences, experts recommend installing a source of guaranteed uninterruptible power supply.

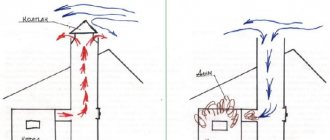

Air pockets in an operating heating system can occur not only in a classic country house, but also in a high-rise building. In the first case, this happens when not all the air has been bled out of the pipes. And in the apartment you can clearly hear the characteristic sounds of water hammer at the moment when hot water is supplied with the arrival of cold weather. To prevent burst pipes at a thermal power plant, the primary supply of non-hot coolant is carried out under low pressure. All parameters are increased only during the onset of cold weather.

The design of the ball valve is designed in such a way that this element will inevitably provoke a jump in the pressure level of the coolant involved. But the whole point is that the closure is not carried out gradually, as is the case with screw shut-off valves, but very abruptly. As a result, water inevitably encounters various obstacles.

The joints between pipes of different sizes are themselves a weak link. These fragments are exposed to rapid fluid flow, causing them to constantly experience enormous stress. Even clogging of the filter with various microparticles prevents the stable operation of the pump, which is fraught with a large pressure drop.

Impact of common negative factors

The batteries gurgle

The next cause of noise in metal heating pipes is air. If something is continuously seething and gurgling in the battery, like in the stomach of a sick cow, that’s it, darling. Soundproofing heating pipes, even if it were done, would not give anything - the sound will be heard through the walls of the radiator.

Are you on the top floor of a house with bottom drain (where both the heating system supply and return pipes are located in the basement)? Then look for a Mayevsky tap on the radiator or jumper between adjacent rooms - a device that helps bleed air.

In all other cases, it is worth looking for a counter-slope (of course, if the heating system works normally in all other respects, except for noise). A radiator hanging skewed or a section of the supply line to it, which is lower near the riser than near the battery itself - this is what you have to fix, most likely in the summer - stopping the heating system in winter for a long time, especially in the harsh climate of Siberia or the Far East, is unlikely would be a good idea.

Protecting the installation from negative influences

Experts are accustomed to using time-tested methods of protection against water hammer. Even at the first stage of design, experts provide for the presence of all the necessary working units and parts, which are used only as a whole. The final choice of protection elements depends on the characteristics of the equipped heating system: the area of the home, the type of pump, the length and diameter of the pipes. Only a professional who has previously studied all the nuances of the property can select the entire set of devices as rationally as possible.

The video provides useful information on how to properly and effectively deal with water hammer:

Where and how to install: installation recommendations

The water hammer compensator is small in size; only a small amount of water can fit into the housing (usually less than 200 ml). It is installed in close proximity to the source of water hammer: a ball valve, a water comb, on a hose to a washing machine or dishwasher, after a circulation pump, on a heated floor comb.

The water hammer compensator is installed close to consumers or on the comb

You can attach it in any position: up, down, to the side. For membrane models, it is only important that there is free access to the nipple. Regardless of the design, it is not recommended to install the device on long branches from the main line. The supply pipe section should be as short as possible.

Rules for installing a water hammer compensator

When choosing, pay attention to the maximum operating and compensated pressure. The second point is the connection diameter. Usually it is 1/2 inch, but there are also 3/4 and inch.

When connecting a washing machine and/or dishwasher, a tee is installed on the hose. One free outlet of the tee goes to the machine, and a water hammer compensator is installed on the second.

Gradual shutdown of the system

This is one of the most important requirements when starting and subsequently shutting down a heating installation. All optimal parameters are described in detail in the basic accompanying documents. The whole reason is that the accumulated energy of the water hammer, due to the increased strength of the pipe walls, may not act with all its power.

This feature is achieved due to lightning-fast bending in the desired direction. With the same final impact force, the power of influence on a certain area of the system will be significantly reduced. Thanks to the smooth switching on, specialists are able to significantly extend the rate of pressure build-up, minimizing the likelihood of damage to the heating system of a cottage or apartment building.

Advice! Those valves whose design provides for a fairly large gap until the final moment of shutting off the water flow are installed at the first stage of installing pre-prepared equipment.

Classic pipe burst

The relevance of using automatic elements

Such devices must be prepared to gradually adjust the static pressure. You can achieve the desired result if you install pumps with automatic speed adjustment that is understandable even for beginners. Installing electronically controlled units, which the manufacturer has equipped with a built-in converter, can also help.

Those pumps that are equipped with automatic speed control of an electric motor differ favorably from all analogues in that they can smoothly increase and decrease the pressure in the operating pipeline. High-precision software performs two important functions: it independently regulates the intensity of the pressure supply, and also monitors changes in liquid indicators in the water supply.

The relevance of using automation in heating

Introduction of shock absorbers

Hydraulic accumulators and dampers sold today are capable of simultaneously performing several important functions. They not only collect liquid, but also eliminate excess water from the system, and also help prevent various undesirable manifestations. Hydraulic accumulators perform all the functions of compensating units. They are installed only in the direction of the main water flow in those sections of the heating circuit where the likelihood of a sudden decrease or increase in the level of measured pressure is especially high.

A kind of damper, as well as a hydraulic accumulator, in practice, is a capacious steel flask that can easily hold up to 35 liters of liquid. They include two sections separated by a durable rubber partition. In the event of an increase in pressure, all water hammer is redirected to the reservoir. Thanks to the bending of the involved membrane at the moment of a sharp increase in indicators, specialists are able to achieve the effect of forced expansion of the circuit.

The shock-absorbing elements are pipes made of heat-resistant reinforced rubber or elastic plastic. To achieve the desired effect, it is enough to use a product 35 centimeters long. If the pipeline is long, then the shock absorber section must be increased by at least 12 cm.

High-quality water hammer absorber

Manufacturers, characteristics, prices

It is best to buy a water hammer compensator from well-known companies. This is not the area where it is appropriate to save money. The most popular are several companies:

- FAR. The compensator from this company is without a membrane, with a spring and a locking disc. Connecting thread 1/2″, maximum pressure 50 Bar, nominal pressure 10 Bar. Withstands temperatures up to 100°C. Price from 30 $.

- Uni Fitt. The same design with a spring-loaded disk. There are two body options: brass and nickel plated brass. Connection 1/2 inch. Maximum temperature 90°C, nominal pressure - 10 Bar, peak pressure - 20 Bar. The length of the protected pipeline is 10 m. Price from $15.

The same models are sold at different prices in different stores - Valtec (Valtek). This is a membrane type hydraulic shock absorber. There are models connected through a small ball valve with a pressure gauge. If necessary, open the ball valve and check the pressure in the compensator. The pressure in the chamber is 3.5 Bar, the maximum operating pressure is 10 Bar, the maximum compensated pressure is 20 Bar. Price from $25.

- CALEFFI (Caleffi). This company produces disk compensators. There are regular ones - with a 1/2″ connection, and there are 3/8″ ones for the sink. The parameters can be called good: the working pressure is no more than 10 Bar, they can compensate up to 40 Bar (for washing up to 30 Bar).

There are other companies, but they are not so popular. some due to being overpriced, others have not gained trust. At least for now.

Application of protective elements

The diaphragm type of this unit is mounted on a pipeline outlet as close as possible to the pump. Due to this, when the pressure increases, the required amount of coolant can be released freely. In many ways, activation of the safety valve depends on the model and manufacturer.

This could be an electrically powered function or an innovative, fast-acting device. The device is triggered when the pressure exceeds a safe threshold. This approach protects the modernized pumping unit in case of accidental shutdown of the unit. A large pressure surge is dangerous for the system, which is why the valve opens completely, and after a gradual decrease in performance, the regulator gradually closes.

A safety element in demand today

A little about the renovation

With constant overvoltages occurring in pipelines, the need for repairs to the heating system often arises.

Coolant leaks from the circuit occur through threaded connections, ruptures of the pipe or radiator elements along the seam. There are 3 types of repairs:

- emergency. The need for it arises when the elements of the thermal circuit gradually wear out or in cases of a sharp increase in pressure. Performed in conditions where it is necessary to quickly restore the heat supply to the facility;

- current . It is carried out at the end of the heating season based on inspections by specialists of repair services and residents of residential premises. Worn parts are replaced, defects noticed during routine pressure testing of pipelines are eliminated;

- capital _ Complete or partial replacement of pipes, heating registers, circulation pump and other elements of the heating system is carried out.

Compliance with the operating rules of the heating system will avoid its premature breakdowns. So, the circulation pump should smoothly accelerate and stop.

To avoid water hammer, taps should be turned off gradually, without abruptly interrupting the flow of water.

Retrofitting a thermostatic valve

This auxiliary part is a compact tube. The final clearance can vary from 0.2 to 0.6 millimeters. The shunt is mounted in the direction of the circulating fluid. The main task of the part is to gradually reduce the pressure when overloads are detected. When designing autonomous systems, the shunting method must be used, since only in this case can the new pipeline be protected from failure.

This effect is due to the fact that worn-out pipes contain rust and other debris, which is a serious obstacle to achieving the desired result. It is for this reason that when using a shunt, it is advisable to install high-quality water filters at the very outlet of the equipped heating circuit.

Application of a professional thermostat with super protection

This device is a kind of fuse that continuously monitors the pressure in the system. This element does not allow the installation to function after the main indicator has reached the critical limit. The thermostat is equipped with a kind of spring mechanism, which is placed between the valve and a heavy-duty thermal head.

Its operation occurs at the moment when the pressure parameter exceeds the permissible thresholds. In such a situation, the valve simply will not be able to close completely. Thermostats must be mounted exclusively in the direction indicated on the housing.

Popular model of hydraulic shock absorber

Basic preventive measures

In addition to strict compliance with all established operating rules, an accident can be prevented if a number of preventive actions are carried out promptly and regularly. The whole reason is that in the main heating or water supply system, absolutely all processes are closely interconnected. A water hammer unexpected by the user is just the final destructive stage, which may well lead to various negative consequences. All this happens against the background of the relatively poor technical condition of pipes that have been used for years.

Changes in pressure and resulting vibrations only contribute to the formation of various cracks in the thickness of the metal. Over time, more serious defects arise, which, after the onset of water hammer, immediately appear in areas of too high internal stress. These can be various bends, mechanical connections and even welds.

Preventive manipulations include the following steps:

- Timely check of the pressure behind the elastic membrane of the expansion vessel in use. If during this procedure the technician discovers unsatisfactory results, then it is prohibited to operate the system without quality adjustments.

- Checking the functionality of the involved security groups. This applies to the air vent, safety valve, as well as the classic pressure gauge.

- Monitoring the position of the valves of the involved shut-off and control metal fittings.

- Periodically check the condition of all filters. These elements are responsible for retaining fine sand, classic scale, and rust fragments. If necessary, the technician will need to clean and then rinse the filters.

- Testing the system used for leaks. You also need to check the degree of wear of all elements.

Many experts recommend replacing the classic rigid pipe with a plastic product. It is more flexible in use and can expand quickly under pressure. But you need to be careful, as depressurization of the joints is possible.

A professional approach to prevention, which is aimed at overall maintaining the optimal condition of the heating and water heating system, necessarily includes basic types of work. It is not recommended to ignore this stage. This is due to the fact that heating repairs in a private house entail a large expenditure of finances and free time. All the described protective measures will be effective if you approach the work comprehensively. Only in such a situation can various undesirable consequences be neutralized and the life of the coordinated operation of the system extended.

Installing a high quality backwash filter

What is water hammer?

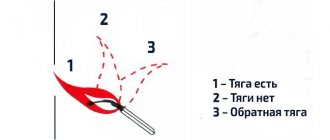

When the coolant passes from a pipeline of one diameter to another, when the tap is abruptly closed or when the liquid collides with an air lock, a process of excess pressure occurs - this is a water hammer in the heating system. This phenomenon lasts a fraction of a second, but its strength can be unpredictable - the pipeline is already under constant pressure, and during a water hammer it can jump many times, and if it does not damage the pipeline, it will constantly reduce the working life of organs and devices heating system. In water supply and heating systems, the causes of this phenomenon can be very different and the level of consequences is also unpredictable.

If we try to give an unambiguous definition of water hammer, the formulation may sound like this: a liquid moving in a pipeline has kinetic energy and, after colliding with an obstacle, directs its energy in the opposite direction, creating high pressure. This pressure acts on the pipeline and when it encounters any obstacle, it also affects it. This is water hammer. Obstacles may include transitions from pipelines of one diameter to another, valves and Sharkrans.

Water hammer occurs constantly in plumbing systems when we open and close the water supply tap. The same thing happens in heating systems, but not as often. It is worth noting that the liquid is able to maintain its pressure and accumulate energy. Because of this, accidents occur in private houses and apartments. Especially where systems use rubber hoses in a metal winding. Probably, many of us have noticed that such hoses serve for some time and then break. This occurs due to pressure that accumulated in the system and did not flow into the general water supply due to the check valve. Over time, the pressure exceeded the strength of the hose, and it began to leak.

What is water hammer in a heating system?

Water hammer in the heating system of an apartment building does not happen often. For apartment residents, the problem of water hammer is not as acute as for owners of private houses, because the repair and maintenance of these facilities is carried out by competent services. But it’s still worth paying attention to flexible hoses when installing a water heater, because responsibility and material costs fall on the shoulders of residents of city apartments.

Water hammers in the heating system of a private home occur much more often, so residents of the private sector should pay special attention when designing and installing a heating system in their home. And also use means of protection against this phenomenon, which will be described below. I hope I explained clearly: what is water hammer in a heating system.