Lithuanian-Russian solid fuel boilers "Stropuva" have a patented combustion chamber design with top ignition, which provides standard burning time for a single load of fuel:

- firewood - up to 30 hours

- coal - up to 5 days

Two types of units are produced - universal for all types of solid fuel, and operating only on wood. Solid fuel boilers "Stropuva" have a rated power range of 7-40 kW. To meet the needs of large rooms, a cascade operating mode is provided. The units are equipped with an automatic combustion control system, thanks to which the amount of fuel required for a given temperature regime is consumed.

The design of solid fuel boilers in Stropuva has many advantages that ensure continuous and long combustion , efficiency and safe operation of the heating system as a whole. These advantages include: a large loading chamber, a bi-thermal draft regulator (control of combustion intensity and fuel consumption), the presence of a special economizer, as well as vertical loading. Stropuva boilers are characterized by extremely low ash content, they need to be cleaned only once every two weeks, and it is only necessary to remove the ash; no tar is formed in the boiler. Due to their high environmental performance and operational safety, these boilers have been awarded the prestigious European CE certificate.

Now let’s learn more about the operation of these boilers. Stropuva engineers created heating boilers with the goal of improving their ease of use, reducing energy and labor costs, while maintaining high efficiency. Thanks to these developments, we have original heating equipment that can operate on one load for up to 5 days!

Depending on the wood and coal used, the Stropuva long-burning boiler can operate without refilling for up to 30 hours, and the new series of Universal boilers can operate for up to 5 days.

Fuel ignition in Stropuva boilers occurs from above. The built-in bi-thermal regulator monitors the combustion process of the fuel layers from top to bottom, while the gas distributor, which regulates the air supply, descends to the very bottom of the loading chamber. Thanks to this scheme, only as much fuel is used as is required to maintain the set temperature, regardless of external conditions. Fuel costs for such combustion are significantly lower than those of conventional solid fuel boilers.

All products are certified and have a 5-year warranty on the body, 2 years on components!

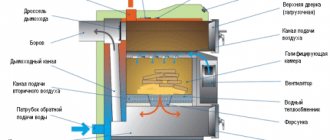

How the device works

Stropuva boiler with a fuel storage tank

The operating principle of Stropuva heating equipment is based on burning fuel in its upper part. This effect is achieved by supplying oxygen to the top layer of wood waste, coal or briquettes. As it burns out, the hearth moves to the lower part of the firebox until all the material is exhausted.

The efficiency and high efficiency of the equipment is due to slow combustion and smoldering, in which almost all the thermal energy is used to heat the water in the circuit. Due to the fact that the flame in the firebox is not intense, in most cases overheating and boiling of the coolant is impossible, so in a heating system of this type you do not need to use an expansion tank.

If firewood is used as fuel, on average the supply in the combustion bunker needs to be replenished once every 30 hours. With a more powerful energy source - coal - it is enough to fill the firebox once every five days.

How does the Stropuva boiler work?

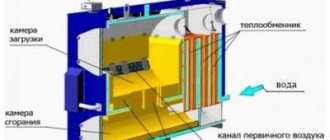

Structural features of the unit

The Stropuva boiler has an original design, which is built on the following elements:

- Housing with water jacket. This is the load-bearing part of the apparatus, equipped with a double wall with an internal space filled with coolant. At the bottom and top of such a tank there are supply and return pipes.

- Firebox. A cylindrical container in which firewood or other flammable material is placed. There are two shafts with doors leading into it: one for supplying wood, the second for removing ash, as well as a smoke removal channel.

- Air heating chamber. It is necessary so that oxygen coming from the street into the fire burning area does not reduce the temperature and does not cool the heat exchanger.

- Oxygen distributor. The element is made in the form of a nozzle with stops, in the middle of which there is a hole connected to the air heating chamber using a telescopic pipe. The distributor is controlled by a ring and a cable.

- Manual air damper. It serves to reduce or increase the flow of oxygen into the combustion chamber.

- Thermometer and pressure release sensor.

The Stropuva long-burning solid fuel boiler is installed on a concrete base that has a strictly horizontal position.

Design and principle of operation of Stropuva boilers

Loading fuel into the Stropuva furnace is possible only from above. For better ignition, the main fuel is mixed with sawdust; you can add flammable liquid. Ignition also occurs through the top door, which must be closed tightly after all actions.

The chimney will form a draft, the fire will flare up from the top of the fuel. Quickly igniting the firewood will ensure good air flow. Fire and smoke rush through the inner housing structure to the smoke hole. Some of the hot gases also rush upward, simultaneously heating the metal and water.

The internal chamber of the air duct increases as the fuel burns. An afterburning chamber is formed in the increased space, which has a positive effect on efficiency. In this case, the fire will not flare up too much, the protection will work in the device. Thanks to the device, the air damper either opens or closes, increasing or decreasing the draft or combustion temperature.

Sources

- https://www.tproekt.com/kotel-stropuva/

- https://kotlydlyadoma.ru/kotel-dlitelnogo-goreniya-stropuva.html

[collapse]

Types of boilers

The manufacturer produces Stropuv equipment, like other types of devices operating on solid fuel, of different capacities. In addition, there are simpler models that work on wood and waste of this material, and there are more universal ones. The combustion chamber of the latter allows you to burn different grades of coal (except for those used in blast furnaces), as well as various fuel briquettes and pellets.

Long-burning conventional solid propellant

Types of fuel for the universal solid fuel boiler Stropuva

The devices operate only on firewood and wood waste. Technical characteristics of the medium power device:

- Thermal energy output is 10 kilowatts.

- The recommended heating area is no more than 100 square meters.

- Efficiency is about 87%.

- The volume of the water jacket is 34 liters.

- The capacity of the firewood hopper is about 25 kg.

- The length of the log is no more than 0.35 meters.

- The parameters of the firebox are 0.350X0.210X0.250 meters.

- Weight and dimensions – 1.92 meters height, 0.45 meters diameter, 185 kilograms.

The original models of devices are produced in the Republic of Lithuania.

Long-burning boilers Stropuva universal

A separate combustion chamber must be allocated for the unit.

These units are floor-mounted and can operate on various fuels of natural origin: wood materials, coal, peat and briquettes. The models are equipped with a forced air fan and a spacious combustion chamber, which allows fuel to be stored for a long time. Technical characteristics of high power equipment:

- Heat transfer power – 20 kilowatts.

- Heated space – 200 square meters.

- Efficiency is within 85%.

- The heat exchanger capacity is 45 liters.

- The volume of the coal bunker is 130 kilograms.

- Weight and dimensions – 2.1 meters height, 0.56 meters diameter, 246 kilograms.

Due to its compactness, the device can be placed in a small furnace room.

Long-burning solid fuel boilers Stropuva

- We offer to buy Stropuva solid fuel boilers with delivery in the Tavago online store.

- The price of Stropuva solid fuel boilers is from 90,000 rubles.

- Read instructions and reviews about Stropuva solid fuel boilers.

The Stropuva long-burning solid fuel boiler differs from a traditional type boiler operating on solid fuel by a special combustion process. Ignition of the loaded fuel occurs in the upper part of the boiler and the combustion front slowly moves from the top of the load downwards. This design allows fuel to be burned in a slower mode without reducing heat transfer parameters. The time of continuous operation from one load of coal can be up to 5 days. Nowadays, when we are all spoiled by automation, which is present in literally every device and mechanism, it is quite strange to get a Stropuva wood-burning boiler where it is completely absent. But, as the 1st law of technology says: the simpler it is, the more reliable it is. And it is unlikely that it will be possible to automate the process of loading the firebox - there is no way around manual labor. In addition, unnecessary automation and electronics will only increase the price of the product. Another interesting feature of these boilers is the absence of a bottom in most models. It was decided to produce “bottomless” boilers after consultations with heating engineers who carried out an expert assessment of the design for compliance with EU safety standards. Such boilers are installed on a concrete pad. This year, the production of boilers with bottoms for installation on tiled floors began. Stropuva solid fuel heating boilers are produced by 2 factories - the main one in Vilnius and a subsidiary in Kyiv. The lineup includes two types of equipment:

- wood-burning boilers Stropuva S7, S10, S20, S40 – fuel used: sawdust briquettes, wood chips with a moisture content of up to 25%, firewood

- universal boilers Stropuva S10, S20U, S40U – fuel used: wood chips, firewood, coal, pellets – the ability to use fuel with a moisture content of more than 25%, wood, sawdust and peat briquettes, pellets

The Stropuva single-circuit solid fuel boiler can only be used for heating. If autonomous hot water supply is required, then a water boiler must be connected. To select the correct model, you need to take into account the correspondence of the power of Stropuva long-burning solid fuel boilers to the area of the heated room:

- 7 kW – 20 – 80 m2

- 10 kW – 50 – 100 m2

- 20 kW – 100 – 200 m2

- 40 kW – 180 – 400 m2

The heating area, as well as the power of the heating system, is not limited by the parameters of the boilers, since cascade assembly of several devices into one network is possible. An additional advantage that a cascade connection provides is the organization of a semi-automatic operating mode with sequential reloading of boilers. The advantages of Stropuva solid fuel boilers, which distinguish them from products with a traditional combustion method:

- long period of fuel combustion from one load

- energy independence

- ergonomic design

- economical fuel consumption

- low operating costs (cheaper than gas)

- high efficiency – 91%

- high degree of reliability

- safety in operation

- lack of energy storage capacity

- 5-year warranty on heat exchanger

Disadvantages of Stropuva heating boilers using solid fuel:

- the need to equip an efficient chimney

- Requires competent wiring and adjustment by qualified specialists

- “manual control” - loading fuel, cleaning the firebox

- quite high cost

If it is possible to use solid fuel for heating and you are not afraid of the need to sometimes roll up your sleeves to add firewood or coal to the firebox, then the Stropuva solid fuel boiler will be an excellent choice, and also very inexpensive to operate. The Tavago store will help you with choosing the model that is optimal for performance, as well as with strapping and installation work.

Advantages and disadvantages

The advantages of such models of heat generators include:

- High efficiency of about 87%.

- Long-lasting action on one tab and the absence of excessive heat leading to boiling of water in the system.

- The frequency of cleaning the ash pan is 3-1 times a month.

- The wood-burning version of the equipment is completely energy-independent; it is controlled by a bimetallic plate. Universal models require electrical power of only 20 W.

- The height of the chimney pipe for such devices can be from 4.5 meters.

- The equipment is safe; at critical temperatures, the structure contracts and does not explode.

Boiler power depending on design

In practice, Stropuva devices reliably serve for over 10 years.

Disadvantages of the Stropuva boiler:

- The duration of combustion of the unit specified by the manufacturer on different types of fuel is possible only under certain conditions. This includes good insulation of the house and a properly assembled heating system, and this is rarely the case in practice.

- You cannot throw firewood into the firebox during the combustion process - you need to wait until everything burns out, as a result, the effect of cold batteries is always observed.

- The bimetallic regulator does not allow you to accurately adjust the temperature in the system.

The unit is considered energy-independent, but the system to which it is connected requires forced circulation by a pump.

Experts recommend not adhering to the rule of 1 kilowatt of thermal energy per 10 square meters of room, but choosing top-burning boilers that are twice as powerful as the design option. This approach is guaranteed to provide greater efficiency of the device and the certified duration of operation on one tab.

Types and technical characteristics

At the moment, Stropuva is available in three varieties: wood-burning, pellet and universal. Each of these three varieties is designed for a specific type of fuel, but can work on any other, albeit with less efficiency. In total, the line includes 4 standard sizes: 10, 15, 20, 40 kW and a Mini version with a power of 8 kW.

The Stropuva wood-burning boiler is equipped with a special air distributor, which allows efficient burning of wood, and has the following characteristics:

ModelMini SS10S15S20S40

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Firewood capacity, dm³ | 120 | 150 | 200 | 230 | 360 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Burning duration, h | 31,5 | ||||

| Price, rub | 65 000 | 87 150 | 92 348 | 97 545 | 107 730 |

The pellet version is equipped with a distributor for fuel pellets and an air supply manifold. Boilers operating on pellets have the following data:

ModelMini SPS10PS15PS20PS40P

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | |||

| Burning duration, h | 72 | ||||

| Price, rub | 65 000 | 91 350 | 97 072 | 102 795 | 112 980 |

The last representative of solid fuel boilers is universal. These devices can operate on coal, wood, fuel briquettes and pellets. The delivery set includes distributors for all types of fuel, as well as an air supply manifold. They have the following technical characteristics:

ModelMini SPS10PS15PS20PS40P

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,8 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Duration of coal combustion, h | 130 | ||||

| Price, rub | 65 000 | 102 700 | 114 608 | 121 380 | 127 995 |

As you can see, from the presented model range you can choose a solid fuel boiler for any room, type of fuel and available budget.

System piping

Piping the boiler is no different from other solid fuel units.

When piping the device, in addition to conventional heating radiators, you need to include a safety battery in the system, on which you do not need to install a thermostat. This convector must be embedded first on the jacket supply pipe through a balancing valve and mounted in such a way that the coolant can move in it by gravity in the event of a power outage.

All other radiators go through a different circuit through regular valves and are connected by return to the circulation pump. The pump itself is bypassed through a three-way valve, which is connected through a second channel to the return pipe of the unit and is controlled by a temperature sensor installed on the return pipe of the batteries.

Among the most popular models of solid fuel boilers Stropuva are the wood-burning unit Stropuva 10S and the universal device Stropuva 20U, with 10 and 20 kilowatts of power, respectively, intended for heating country cottages.