Gas tanks are subject to federal laws and codes of practice in the field of industrial safety of hazardous production facilities. Vessels intended for storing liquefied petroleum gas (LPG) in quantities from 1 to 20 tons belong to hazard class 4. This entails the requirements for all life cycle procedures of a gas tank, namely:

- Obtaining permission to install;

- Installation;

- Registration;

- Operation;

- Registration and supervision.

Individual entrepreneurs and organizations owning gas tanks must obtain permission to install and register them with Rostekhnadzor. If the owner of the vessel is an individual, then permission for installation is not required and it does not need to be registered.

The homeowner is responsible for safe operation. Concluding an installation and maintenance agreement with a contractor shifts responsibility to the contractor.

Installation of the gas tank and gas pipelines is carried out according to the project. To order a project, technical conditions for autonomous gas supply are required, which are issued by the regional gas distribution station. Project documentation is coordinated with the regional gas and electricity supply companies, fire inspection, architectural and environmental departments. If there is an installation contract, these concerns are taken over by the contractor.

What is a gas tank and why is it needed?

A gas holder is nothing more than a tank designed to store liquefied or natural gas. Connecting to a centralized gas main located several kilometers from the house will entail significant material costs. Using a gas tank for a private home will not only save money, but will also ensure complete energy independence and autonomy of home ownership.

Gas tanks are widely used in the European Union countries, where they are accustomed to using energy resources carefully and economically. Autonomous gasification, in practice, turns out to be much more economical than centralized gas supply.

Gas tanks are often installed in high-mountain resorts or hard-to-reach areas where it is impractical to extend a main gas pipeline for geological or economic reasons.

Owners of private houses do not resort to autonomous gasification out of desperation. This is a completely balanced and thoughtful decision. In Europe, in Poland alone there are more than 100,000 households equipped with an autonomous gas supply system. Using a gas holder allows you to save significant money on heating and domestic gas use.

If a gas tank installed on the territory of Russia is officially registered in the name of a legal entity, it must be registered with Rostechnadzor. If the tank is installed on private property and is registered to an individual, it is not necessary to register the equipment. In this case, all responsibility falls entirely on the homeowner.

What is a gas holder?

A gas holder is nothing more than a container designed to store liquefied natural gas. If you want, this is such a huge lighter. Around the world, the use of gas tanks on households is completely common. It would never occur to a prudent owner to pull a branch from a main gas pipeline several kilometers away.

Gas holders are widely used in Europe, where resources are used sparingly and the traditions of autonomous gasification are firmly entrenched in the minds of homeowners. Often such a large cylinder can be found at ski resorts, or northern territories where it is not possible to lay a gas pipeline for geological or economic reasons.

Autonomous gasification is not hopeless at all. This is a completely sensible, balanced and widespread decision throughout the world. In the European Union, for example, Poland alone, there are more than 100 thousand similar gas supply options. Installing a gas holder helps households experience the benefits of using liquefied gas at home, such as convenience and economic benefits.

Currently, at the end of 2022, the rules for operating a gas tank on the territory of the Russian Federation regulate the registration of installed equipment with Rostechnadzor, if it belongs to a legal entity. If the equipment belongs to an individual and is installed on private property, there is no such regulation of registration requirements. Of course, it is worth understanding that the owner is responsible for everything independently.

Types of gas tanks

All cylindrical gas holders can be divided into two groups:

- horizontal;

- vertical;

Let us consider in more detail the characteristic features of each of these modifications.

Vertical models

The shape of such tanks is similar to the shape of a large can. The main advantage of vertical gas holders is that they occupy a small area. On the other hand, due to the small area of evaporation of liquefied gas, such a container is not able to provide optimal pressure to equipment with increased gas consumption.

An increase in the evaporation rate of liquefied gas in vertical storage facilities can be achieved by installing a special electric heater. Such heaters are called evaporators. Although the use of EF increases the intensity of evaporation of the gas mixture, it entails additional material costs for paying for electricity.

Taking this fact into account, we can conclude that it is advisable to use vertical gas tanks for domestic needs or heating water in the warm season. To supply the heating system with gas, horizontal storage facilities, which have a much larger evaporation area, are more suitable. In addition, installing vertical equipment will require a deeper pit.

Horizontal models

Horizontal gas tanks are very popular in most of the European territory of Russia. This is due, first of all, to favorable climatic conditions that ensure intense evaporation of liquefied gas. In addition, horizontal storage facilities have a large evaporation area.

With a sufficient amount of gas-air mixture, a horizontal gas tank always has the opportunity to provide the required pressure in the heating system and hot water supply system. It is important to note the fact that the gas mixture evaporates randomly, without the use of electric heaters, which avoids unjustified material costs. Horizontal equipment can ensure efficient operation of the heating system even at low temperatures.

The disadvantages of a horizontal tank include the fact that it requires a large area to accommodate it.

Mobile models

This is a special modification of gas tanks, intended primarily for seasonal or emergency use. Mobile tanks are equipped with wheels, making them easy to transport, and have a small volume.

Such containers can be an excellent replacement for the well-known gas cylinder. A mobile gas holder is much safer and more spacious than a standard gas cylinder. Some models can hold up to 500 liters of liquefied gas. The presence of an autonomous electric heating system makes it possible to use mobile storage facilities regardless of the time of year.

It is not practical to use mobile storage facilities for permanent connection due to the small volume of the tank and the presence of additional costs for paying for the electricity required to heat the gas-air mixture in the cold season.

Ground models

Ground gas tanks are mounted above ground level. This greatly simplifies the maintenance process, but greatly tightens fire safety standards. The degree of protection of above-ground storage facilities is significantly lower than that of underground reservoirs.

Installing a gas tank above ground level leads to the fact that in the cold season the gas-air mixture can become supercooled, which will result in the cessation of evaporation. The consequence of these processes may be a cessation of gas supply.

In areas with cold climates, installation of ground-based models is impractical due to the significant costs of heating the gas mixture during the cold period. The use of such storage facilities is justified in mountainous areas or in places with difficult terrain, in other words, in places where it is not possible to dig a pit of the appropriate size.

Consequently, in regions with cold winters, these installations require heating and are therefore unprofitable. In Russia, above-ground gas tanks are usually installed in places with difficult geological conditions, when it is not possible to dig a pit.

Underground models

Underground tanks are installed in specially dug pits. Since underground storage facilities are usually large in volume, digging a pit is a labor-intensive and expensive procedure.

However, installing a gas tank below the ground freezing level allows you to save significant money on heating the gas mixture. The fact is that even in the coldest winter, the liquefied gas stored in such a tank does not freeze and evaporates normally without any heating.

Another advantage of this installation is maximum storage security. The specific gravity of the propane-butane mixture is greater than the specific gravity of air, so in the event of a leak, the mixture does not rise into the air, but seeps into the ground, thereby eliminating the possibility of an explosion.

Gas holder safety

A gas holder is not very different from a regular household cylinder, except in size. Reviews from owners indicate the unpretentiousness of the equipment in general. Filling with gas, just like a cylinder, should not exceed 85% of its volume.

Evaporating, the gas phase enters the house through the gas duct and powers heating, hot water and other gas appliances. A mandatory safety principle during operation is the use of a group of special devices that monitor leaks of the gas mixture. Thermal shut-off valves block the gas supply to the house in the event of a fire.

Gas alarms paired with a solenoid valve during a leak and a gas concentration of 0.4% send a pulse to the valve and completely block the supply of the gas mixture to all appliances in the house.

A sensitive gas analyzer is installed near the floor, where possible leakage will accumulate; a wire runs from it to a valve fixed on the gas pipe. The critical concentration of propane-butane starts from 2% of its content in the air. Such a pair is not cheap, but it is a reasonable price for complete safety.

Classification

Gas tanks are classified by tank volume, installation method and fuel storage principle.

It varies from 2000 to 10,000 liters. The number of refills and refills depends on the size: with a small tank, the refiller will have to be called more often. The optimal number of refills is once every six months. The cost of the structure and installation of it also depends on the size: the larger the tank, the more expensive the excavation work will be, and the more space will be needed on the site.

According to the installation principle, there are vertical, horizontal and mobile tanks:

- Vertical models are compact, take up little space and have a small working area. The containers must have an insulating winding that will maintain the required rate of gas evaporation during the cold period. To speed up the process, heating units can also be used.

- In horizontal containers, the mixture turns into gas more efficiently. The working surface has a large area; the tanks are filled to 85% of the nominal value. The main thing is to choose the right size of the product.

- The third type is mobile, mobile gas tanks of small capacity (up to 500 liters). The advantage is that they are economical - they can be refueled at stations with a reduced price for liquefied gas. They do not require installation or installation underground. The disadvantage of mobile devices is that refilling must be constant.

There are gas holders of constant and variable volume. At a constant volume, the gas is stored at a pressure of up to 1.8 MPa. With a variable tank volume, the gas is stored inside at ambient temperature and atmospheric pressure with virtually no compression.

Factors affecting gas consumption

The gas holder has the form of a volumetric tank that is filled with liquefied petroleum gas (LPG). This is a mixture of two gases - propane and butane.

Autonomous heating schemes with gas extraction from a gas tank and a gas boiler in the system have become a modern alternative to heating houses from solid fuel or diesel boilers

Storing gas in such tanks, with its further use for heating the house, may be due to the following factors:

- the inability to tie into the main gas pipe or the high cost of such a connection;

- constant and unresolved by gas services problems with gas pressure in the central pipeline.

For normal operation of most gas boilers, the gas pressure in the pipeline must be at least 35 mbar. This standard is often not maintained in main gas pipelines and ranges only from 8 to 22 mbar.

To determine the volume of liquefied gas in a tank, there are mechanical level gauges or more modern remote telemetry systems. Such equipment can be supplied complete with the tank or purchased separately. The average daily gas consumption can also be determined by the difference in gas meter readings, if available.

But a more accurate answer to the question of how much gas in a gas holder is enough to heat a home, what its consumption is and how to minimize costs for it, mathematical calculations will help. And this despite the fact that objectively such a calculation will be of an average nature.

Fuel in an independent gas supply from a gas holder is consumed not only for heating. Although in much smaller volumes, it is also spent on heating water, operating a gas stove and other household needs.

It should be taken into account that gas consumption is influenced by the following factors:

- climate of the region and wind rose;

- square footage of the house, number and degree of thermal insulation of windows and doors;

- material of walls, roof, foundation and the degree of their insulation;

- number of residents and mode of their stay (permanently or periodically);

- technical characteristics of the boiler, the use of additional gas appliances and auxiliary equipment;

- number of heating radiators, presence of heated floors.

These and other conditions make the calculation of fuel consumption from a gas tank a relative value, which is based on average accepted indicators.

Gas holder device

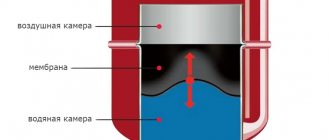

Gas holders are distinguished according to the principle of storing gaseous substances and are divided into two types: with variable and constant volume. In the variable type, the gas is stored at a pressure equal to atmospheric values. The volume of such a container changes linearly depending on filling or emptying, and the necessary pressure is created by a special bell in a cylindrical pool filled with water or by a piston in dry systems.

Second type: constant volume gas holder. That is, it is a container that does not change the internal volume depending on the amount of gaseous substance injected. As a rule, they look like a cylindrical tank. Their main advantage is the modern materials used for their manufacture, which are capable of containing gas under a pressure of 1.8 MPa.

Video description

For more information about autonomous gasification, watch the video:

If you want to buy a mobile gas tank, its price will be much cheaper than usual, and it will not require installation on site.

How to calculate the volume of a tank for a private house

Bigger does not mean better, so you need to calculate the volume of the gas tank correctly. This is done based on the technical characteristics of the heating boiler, the area of the house, and the number of cooking surfaces.

Horizontal gas tanks are selected with a margin of 15% of the calculated consumption indicators, and vertical ones with a margin of 10%.

Correct calculation of the tank volume allows you to choose a suitable gas tank for a private home; prices for them mainly depend on the volume, which means that you will not overpay for extra and unnecessary tank volume.

Installation diagram of a gas tank for heating a private house Source resant.ru

The cost of a gas tank and its installation

When choosing gas tanks for a private home, prices in the Moscow region can take a long time to review, since they depend both on the manufacturing company and on the volume of the tank itself. At first glance, everything is simple: the larger the tank, the higher the price, but the economic benefits of small storage facilities are sometimes deceptive. After all, a small tank needs to be refilled more often, which means additional costs for gas delivery. Therefore, you should choose a gas tank after first calculating the volume of the tank required for heating the house.

If you have already chosen and purchased a gas tank, the cost of installation will be calculated specifically for you by a specialist who comes to the work site. Typically, prices vary depending on the distance of the site from the city where the installation will take place, the size of the tank and its type, as well as the length of the gas pipeline. The cost of installation can vary from 40,000 to 100 thousand rubles. This includes everything (earth and installation work, reinforced concrete slab, set of materials, delivery), except the cost of the gas holder itself.

Installation of two gas tanks for heating a private house Source svoigaz.ru

Principle of operation

The operation of an autonomous gas system is similar to a conventional one.

The main difference is the gas supply source and piping layout. Evaporating, the mixture of propane-butane fraction enters the reactor, where it acquires the required pressure. The gas is then distributed through the gas pipeline junction to the fuel consumer. The frequency of refilling the gas tank depends on the degree of gas consumption and the volume of the gas storage. If the volume of the gas tank is correctly selected, the gas should be enough for at least one year. Liquefied gas can be stored in a container for a large amount of time without changing its composition or quality. To install a gas holder, it is necessary to take into account the distance to residential buildings. The main condition for the correct location of the container is the availability of free space in front of the house or cottage.

Please note: according to safety requirements, the minimum distance from the gas tank to any building must be at least 10 meters.

Storage container

A gas tank is a container for storing gas, and in a specific situation of heating a country house, it is a container into which LPG, liquefied hydrocarbon gases, a mixture of butane and propane are poured. LPG is not at all the same gas that is supplied to houses through main gas pipelines - it uses methane-based fuel.

A gas holder differs from a conventional gas cylinder in size and stationarity; it is installed on the site for several decades and is periodically refueled from a special refueling machine. An underground gas pipeline is laid to the house from the reservoir (it must be at a certain distance), through which the evaporated gas flows to the boiler.

Gas tanks are made of steel and treated with special anti-corrosion compounds. The device is equipped with sensors that help control gas flow and indicate the pressure in the tank.

The history of gas holders began in 1781 in the laboratory of the French chemist Lavoisier. To store gas in his laboratory, he made a rectangular container with a capacity of 100 liters, and after a few years he realized that the gas holder should be cylindrical. Further, gas holders were used mainly in science, industry and urban utilities (for gas lamps).

Over time and the development of science, gas tanks changed, modified, and finally a variety appeared that is used for heating private houses. These are cylindrical tanks of constant volume that can withstand high pressure: there are tanks in which gas is stored at a pressure of up to 18 atm.

Types of tanks

The ground type of device is located in a designated area. With this arrangement, you don’t have to worry about problems related to maintenance, because you can approach the tank at any time. Corrosion and other excesses harmful to metal are also quite easy to detect; the only nuance will be weak evaporation in winter.

Underground types of construction will lead to additional costs for site preparation; it may be necessary to call in special equipment, it all depends on the size of the equipment. Protection against cold in this situation remains at a high level, which will affect the practicality of the device.

Experts advise burying the tank to a depth of at least 60 cm. Vertical models are very similar to ordinary cans; they are installed to save free space on the building site. For large quantities of consumption, such containers will not be practical. Horizontal types of structures are considered the most common, but they occupy a large area.

Tips for saving gas

You can reduce gas consumption from a gas tank by performing the following energy-saving measures:

- insulation of walls, roofs, attics, basement floors;

- replacing old window units with modern double-glazed windows with frost-free profiles;

- optimal setting of boiler parameters;

- installation of an energy-efficient condensing-type gas boiler for heating;

- the use of a collector heating system, which has a higher efficiency and the ability to regulate the coolant supply on each heating device;

- equipping heating radiators with thermostats.

A good gas saving effect is achieved through the installation of controllers that automate the process of heat supply control.

The controller, depending on the specified settings, automatically controls autonomous heating, which allows you to significantly minimize the consumption of LPG from the gas tank and reduce heating costs by up to 25%.

Moreover, modern controllers are, as a rule, smart devices with which you can remotely control the boiler from a mobile phone.

An inexpensive alternative to such remote-controlled devices are programmable or daily thermostats, which also allow you to save energy.

A modern solution for saving gas from an autonomous storage facility is the “smart home” system.

Along with a large range of useful functions that make life easier, the use of smart home technology allows for automatic climate control

The climate control function in the house can be installed separately or integrated into a general set of “utilities”.

Such technologies make it possible to economically use gas for heating throughout the day in individual rooms. You can configure the system to operate in heating mode when there are no residents and turn on full heating remotely before arriving home.

The main problem with implementing a “smart home” climate control system is the relatively high cost of the issue and the need for design before installation of the heating system.

Gas holder for a private home: pros and cons

The advantages of owning a gas holder in a personal household are obvious, we just have to state the facts:

pros

- autonomy - the consumption of gas resources becomes available to you in full. Your personal gas pipeline system does not depend on pressure in the mains. You are not afraid of accidents of the common gas pipeline. In addition, such equipment significantly affects the capitalization of your home;

- environmental component - do you want to walk on snow-white snow in your country house, creaking on the paths? Then urgently give up fuel oil, diesel fuel and coal. The almost complete absence of sulfur compounds in liquefied gas, and its complete combustion with sufficient air, guarantees snow-white snow and clean air. Even if the gas tank fails and gas escapes, nothing terrible will happen. Liquefied gas quickly passes into the vapor phase and evaporates into the atmosphere. You don't have to worry about harming the ground cover or seedlings;

- increased service life of your entire farm. Boiler equipment running on gas fuel always has an undeniable advantage in the form of a long service life over solid fuel or liquid fuel boilers. The fact is that the absence of sulfur has a beneficial effect on interaction with metal. Having no reaction with sulfur, gas equipment will work faithfully 30% longer compared to traditional heating units;

- odorless combustion - modern gas equipment is everywhere located in high-rise apartments. The combustion processes of blue fuel in devices occur without the release of pungent odors, and harmful products are removed outside through a chimney.

The disadvantages that a gas tank can give us are not so obvious. For the most part, they are all connected in one way or another with the increasing financial burden on home ownership:

Minuses

- Price – financial costs for a full range of services for connecting a gas tank, which is called “turnkey”, will cost the owner starting from $3,500. Additionally, you will have to buy control valves, gas analyzers and other metering devices. Ensuring the access of a gas carrier so that gas delivery and gas holder refilling can be carried out without hindrance. Add here the annual maintenance;

- Increased responsibility - the gas in the tank is an explosive substance. You should remember safety measures and, if possible, bury the gas tank in the ground at the maximum distance from residential buildings. The minimum distance is considered to be 10 meters; the depth, as a rule, corresponds to the lower level of soil freezing. As we wrote above, limit yourself to filling the storage tank to no more than 85% of the volume. Remember, gas is a substance that can expand, especially in the summer.

- Routine check – the gas tank requires regular maintenance. Taking into account the passport data of the tanks, in accordance with the current rules and standards, only specially trained persons who have passed certification are allowed to perform maintenance. The entire system must be constantly monitored for gas leaks. Monitor the amount of it in the tank so as not to end up in a situation where the tank is empty and then the heating system stops. A telemetry module can be an assistant in solving many problems. As you might guess, this pleasure is not free, but the installation monitors and transmits information about the status of the equipment via the Internet or cellular communications;

- condensation formations - evaporation occurs inside the gas tank, particles fall onto the walls in the form of condensation, the process destroys the equipment and can gradually damage the tank.

Autonomous gasification and gas supply to a private home - watch the video:

Heating autonomous gas supply gas holder private house

Why is a gas tank needed?

In order to save their costs and make more profits, developers are not willing to extend highways to new buildings. The owner of a private house may, in this case, think about autonomous gasification of his home. If the mainline is significantly removed, a gas tank becomes an alternative solution. Why is this necessary? For three reasons: convenience, economy and ecology. Of course, you can heat your house with coal, fuel oil, diesel fuel or even wood.

If any of the above options are comparable in cost, then they are definitely not environmentally friendly. As for the economy, if you consider that the price of a kilogram of liquefied gas at the time of 2022 is about 30 rubles (on average = 0.5 dollars). An eight-month heating season for a house with an area of 150 square meters. will require from 3000 to 4000 kilograms.

Thus, the total financial costs for heating, heating water to a hot state and cooking food are approaching 90-120 thousand rubles per year. Or 7 – 10 thousand rubles per month, for complete energy independence. However, we will make a reservation that the actual amount of costs depends on the materials used to build the house, the insulation used and the area.

The nuances of installing a gas tank

In the CIS, gas tanks are not as popular as in Europe. The rules for their installation are also somewhat different. If in European countries they mainly use above-ground tanks, in the CIS this option is not always acceptable. There are more stringent requirements for the distance from the gas tank to various objects.

If they are carried out, in most standard areas there is simply no room for an above-ground tank, and in Europe they are installed even close to the house.

In Europe, gas tanks are filled with pure propane, but here we use a mixture of propane and butane in a ratio of 1:1 or 7:3. In order for the LPG mixture to work, evaporation must occur, and at low temperatures this is not possible. In order not to be left without heat in winter, the tank must be equipped with a special evaporation unit.

The cost of the equipment itself and its installation depends on the model of the tank, the volume of excavation work, and additional equipment. Questions about how much domestic and imported gas tanks will cost need to be clarified in advance.

Note that prices do not vary much. Containers produced by our manufacturers, unlike European products, as a rule, have a high neck.

The design without it is cheaper, but then the position of the platform with the reinforcement will not be so convenient. Its location on a hill allows it to be protected from moisture, especially during spring floods. If water enters the reducer, the gas supply will stop.

To reduce the pressure acceptable for boiler operation, the tank has a valve and a reducer, which performs this task. In winter, the gearbox may stop performing its functions due to freezing. It is very simple to correct the situation by heating it with boiling water, but subject to first disconnecting the line

Recently, gas tanks without a neck have appeared. Instead, the design includes a series of tall tubes covered with a metal casing. This solution made it possible to reduce the cost of the product and place the fittings at a safe height.

Structurally, the gas tank is designed to prevent both gas leaks and ignition. Its monolithic structure resists pressure from the inside and various influences from the outside.

LPG tanks are sold complete with valves that ensure the selection of the gaseous phase, filling valves that shut off the gas supply when the tank is filled to a set level

In addition to valves, the tank is equipped with safety valves designed to relieve excess pressure, and ball valves with which the fuel flow is regulated.

Some companies offer to buy refurbished tanks at a price significantly lower than new ones. Don’t be tempted by the cheapness; the consequences of such savings can be the most unpredictable.

When installing a tank, there are several nuances that need to be monitored during the installation process. Everything that will be hidden in the ground must be reliably protected from corrosion. In this case, conventional fasteners are not suitable; they are made of stainless steel or provided with anti-corrosion protection.

When backfilling, make sure that there is no loam or stones in the sand. The sand is covered with geotextiles, otherwise clay soil will get into it, which over time can cause heaving with all the consequences dangerous for the gas tank.

Contractors often consider cathodic protection as an additional service. In fact, without this option, the metal tank, as a result of exposure to stray currents, salts and water, will collapse much faster than its allotted service life.

When concluding an agreement, you must insist that it include a clause on the installation of electrochemical protection.

You should know that there are two types of such protection - active and protective. The first of them is used in conjunction with Russian-made tanks made of 09G2S steel. This material has little resistance to rust.

To increase the service life of the tank, a 0.75 kW cathodic protection station is installed that consumes electricity. For this reason, this method of protection is expensive.

Imported gas tanks are made from higher quality material. They are protected from corrosion by a protective anode-cathode system. It consists of aluminum elements with electronegative potential, connected by wire to an underground gas tank.

The consequences of negative influences affect the protector - it oxidizes, and the surface of the metal container is restored.

No power supply is required to the protector, but the protector itself must be changed periodically. To do this, make a hole next to the gas holder to insert another protector into it, then connect the wires to it

On gas tanks made in Europe with a complete epoxy coating, the protectors are replaced on average after 5 years. The steel from which Polish Avtonomgaz tanks are made is practically non-corrosive. The protection here is updated every 15 years.

On domestic tanks with a bitumen coating, and on imported ones with an epoxy coating that was not tested during installation, the protectors are replaced annually. In this case, the protective anode is consumed very quickly, because due to the increased permeability of the coating, he has to actively restore the surface of the container.

Installation of a ground gas tank

During ground installation of the unit, mandatory fastening to the base is carried out, which ensures the most stable position of the container in space. It is also necessary to protect the tank from direct exposure to sunlight, lightning, and corrosion. Otherwise, an emergency may occur.

In winter, operation of ground-based installations is possible exclusively with the use of evaporators.

Installation of a ground gas tank is possible only if:

- It is necessary to ensure low gas consumption.

- Inability to carry out excavation work (close groundwater, mountainous terrain).

Installing and connecting a gas tank is the most acceptable solution for providing residential premises with an uninterrupted gas supply. The lifespan of such a system depends entirely on the quality of the equipment and the installation process of the system.

an autonomous gasification system on your site

much easier than connecting main gas. But any gas networks are an object of increased danger, therefore their installation and operation must strictly comply with officially accepted standards. The list of main documents (SNiP) regulating the construction of autonomous gas supply systems includes:

Their full and current text can be found on the official websites of government agencies. We will present the basic requirements for the placement and installation of gas tanks. We will also talk about the standards for the construction of an external gas system, which is mounted together with the tank and connected directly to it.

Calculation of model parameters

When choosing the volume of a gas tank, it is customary to proceed from the full heating season (the coldest 6 months). This is done so that one maximum permissible refueling is enough for all needs in winter. Thus, based on the price of gas in your region and the volume of full filling of the tank, it is easy to calculate the cost of the heating period.

First of all, you need to calculate the exact area of the heated premises. Take into account, if necessary, other structures - bathhouse, swimming pool, garage. The average consumption is usually calculated based on the formula 30 liters of gas per 1 square meter of area (for one season). Thus, it is easy to calculate the size of the tank for your premises. For example, for a house with an area of 150 sq.m. A gas holder with a volume of 4.5 cubic meters is sufficient.

Of course, these calculations are approximate. But at least they make it possible to present a general picture of an autonomous gasification system, the key link of which is the gas tank. And since it is installed once and for decades, there is no need to skimp on it.

Approximate cost of a gas holder, depending on the area of the heated room. Prices are valid for 2022 for Moscow and the Moscow region:

- 2.7 cu. m (sufficient for an area of up to 120 sq. m) – 120 thousand rubles;

- 4.8 cu. m (for an area of up to 260 sq. m) – 140 – 200 thousand rubles;

- 6.4 cu. m (for an area of up to 500 sq. m) – 180 – 240 thousand rubles;

- 10 cu. m (for an area of up to 900 sq. m) – 250 – 320 thousand rubles.

Of course, the price also depends on the manufacturer of the gas tank.

What volume of gas tank is needed for a country house with an area of 100 square meters? m, 150 sq. m, 200 sq. m

A new, well-insulated house with an area of 100 m2 requires a storage capacity of 2,627 liters, with two refills per year. Typical gas tanks are produced with a volume of 2,700 liters.

It is impossible to carry out calculations with an accuracy of up to a liter, since no two houses are identical - each has its own heat losses, boilers, consumers, heating systems. Statistical data is used for approximate calculations. On average, the annual consumption of LPG is 27 - 30 liters per 1 m2 of heated area. The table shows the results of calculating the volume of a gas tank based on statistics for houses of different sizes.

| Heated area of the house, sq.m | Volume of LPG consumed, liters | Volume including filling K = 0.85, liters | Volume at two refills per year, liters | Volume of a typical gas tank, liters |

| 100 | 3 000 | 3529 | 1765 | 2 700 |

| 150 | 4500 | 5294 | 2647 | 2700 |

| 200 | 6000 | 7059 | 3529 | 5000 |

The results of these calculations can be used when choosing a heating option for your home, but to develop a project and select equipment, you must contact a specialized organization. In this case, the following will be taken into account: the location of the site, the individual properties of the house, and your priorities.

What you need to know before buying a gas tank - features and selection criteria

Of course, first of all you need to know the amount of gas that you will consume during the year. The continuity of gas supply and the frequency of its refilling depend on the correctly selected tank volume. Experts recommend making calculations and developing a gas supply project at the stage of building a house.

When choosing the volume of the tank, you need to pay attention to an important point. The gas tank is never filled to the brim; its useful volume is usually no more than 85%.

It is enough to equip private residential buildings (country cottages, dachas) with tanks with a volume of up to 10 cubic meters. On average, the size of gas tanks for private use varies from 2.7 to 10 cubic meters.

The choice of a sufficient tank size is influenced not only by the area of all heated rooms. But also, importantly, the level of insulation of the building, the minimum and average annual temperature in the region. And also the power of the installed heating equipment and the presence of panoramic windows.

The frequency of refilling the tank directly depends on its volume. However, if the house is planned for permanent residence, the storage will have to be refilled at least twice a year. This is due to the fact that summer gas has a different proportion of butane and propane from winter gas. And in order to stay warm in winter, you need to use the gas composition intended for this season.

Calculation of gas flow from a gas tank

Calculating the heating consumption of the mixture from the gas storage used in the heating system of the house has its own characteristics and differs from calculating the consumption of main natural gas.

The predicted volume of gas consumption is calculated using the formula:

V = Q / (q × η) , where

V is the calculated volume of LPG, measured in m³/h;

Q—calculated heat losses;

q is the smallest specific value of the heat of combustion of the gas or its calorie content. For propane-butane this value is 46 MJ/kg or 12.8 kW/kg;

η – efficiency of the gas supply system, expressed in absolute value per unit (efficiency/100). Depending on the characteristics of the gas boiler, the efficiency can range from 86% - for the simplest ones, to 96% - for high-tech condensing units. Accordingly, the value of η can range from 0.86 to 0.96.

Let's assume that the heating system is planned to be equipped with a modern condensing boiler with an efficiency of 96%.

Substituting the values we accepted for calculation into the original formula, we obtain the following average volume of gas consumed for heating:

V = 9.6 / (12.8 × 0.96) = 9.6 /12.288 = 0.78 kg/h.

Since the LPG filling unit is usually considered to be a liter, it is necessary to express the volume of propane-butane in this unit of measurement. To calculate the number of liters in the mass of a liquefied hydrocarbon mixture, it is necessary to divide kilograms by density.

The table shows the test density of liquefied gas (in t/m3), at various average daily air temperatures and in accordance with the ratio of propane to butane expressed as a percentage

The physics of the transition of LPG from liquid to vapor (working) state is as follows: propane boils at minus 40 °C and above, butane - from 3 °C with a minus sign. Accordingly, the 50/50 mixture will begin to transition into the gaseous phase at a temperature of minus 20 °C.

For middle latitudes and a gas tank buried in the ground, such proportions are sufficient. But, in order to protect yourself from unnecessary hassle, it is optimal in winter conditions to use a mixture with at least 70% propane content - “winter gas”.

Taking the calculated density of LPG as 0.572 t/m3 - a 70/30 propane/butane mixture at a temperature of -20 °C), it is easy to calculate the gas consumption in liters: 0.78 / 0.572 = 1.36 l/h.

Daily consumption with such gas selection in the house will be: 1.36 × 24 ≈ 32.6 l, during the month - 32.6 × 30 = 978 l. Since the obtained value was calculated for the coldest period, adjusted for weather conditions, it can be divided in half: 978/2 = 489 liters, on average per month.

The duration of the heating season is calculated from the moment when the average daily outside temperature does not exceed +8 degrees Celsius for 5 days. This period ends in the spring, with stable warming

In the area we took as an example (Moscow region), this period averages 214 days.

Gas consumption for heating during the year when calculated will be: 32.6/2 × 214 ≈ 3488 liters.

Installation placement and operational safety

The first thing they do when installing an autonomous heating system is to install a gas tank. Depending on its type, its location is determined. Usually buried in the ground at a distance from residential premises. The volume of the device is calculated based on the parameters of the house or room. The location is selected so that the gas carrier or other vehicle has easy access to the installation.

Gas is delivered with the help of supplying companies in bulk gas carriers. The depth of installation also depends on the characteristics of the gas tank. The installation of the entire system should be entrusted to specialists who will carefully calculate all the parameters for installation. When choosing parts for the system, special attention should be paid to the service life (can reach 20 years) and to the neck of the container. It should be tall and wide.

When operating the system, you should remember that the cylinder must contain no more than 85% of the gas of the total volume of the container. You should also have instruments that can detect leaks and monitor gas consumption.

It is necessary to acquire thermal shut-off valves that will shut off the gas supply in the event of a fire, and gas alarms with solenoid valves. The gas analyzer operates shut-off valves, which prevent leaks and provide greater safety.

With all the nuances, a system equipped with a gas holder is today the most convenient and environmentally friendly solution to the problem of individual gas supply.

Gas holder placement rules on the site

An autonomous heating system using a gas holder today requires large one-time investments. That is why it is not advisable to use a gas tank for a private house with an area of less than 150 square meters, due to the long payback period of the project.

The basis for gasification of the facility is the gas tank. Or, as we found out, a liquefied gas storage facility. Gas is delivered by special gas carriers, which pump it into the tank. The volume of the required gas tank is calculated based on the size of the house.

Practice shows that normal household use is limited to a size of 2.5 - 5 cubic meters. The tank is buried in the ground, at a certain distance from the house, so that the gas holder can be refilled without hindrance, and the gas carrier can park without any difficulties.

The depth of the container is also important. Preference should be given to manufacturing companies that manufacture gas holders taking into account the freezing depth. The design must have a high neck.

Please note that European manufacturers do not always make a high neck, since it is not necessary in southern latitudes. We can only envy that not all of Europe is familiar with the concept of “freezing depth”.

Many consumers buy a container without a neck, saving a small amount of money, and then, when faced with difficulties, begin to heroically overcome them. After installation, deepening the gas tank is not an easy and costly task, but expanding the neck becomes more difficult and many times more expensive.

In any case, it will not be possible to leave the gas holder near the surface. The physical properties of propane-butane do not allow for high-quality operation of the device at subzero temperatures, preventing the liquefied phase from effectively evaporating.

In addition, pay attention to the service life of the container. Often a gas tank with no neck has a limited service life and does not exceed 20 years. After this time, the container simply needs to be replaced, since there is no way to diagnose it.

Bury the gas tank in a horizontal position. This achieves two goals. Firstly, it is much easier to dig a hole and ensure inexpensive installation of the structure. Secondly, the gas evaporation surface expands. Evaporation occurs naturally, and its quantity is enough to provide a country house with the vapor phase of gas. Otherwise, it would be necessary to use separate mechanisms - so-called evaporators.

Which is more profitable: a gas holder or bottled gas?

The convenience of small containers cannot be ignored; they can be placed literally anywhere, because their size allows this to be beneficial for saving free space. Most owners decide to install this type of device under the gas stove or in another place.

But the cylinders run out quite quickly; the same cannot be said about a gas tank for a private home; mini-version options are also very practical, so the demand for other types of storage has decreased somewhat. Many houses are adjacent to a plot of land of various sizes, which is most suitable for installation; there are often no problems with space in private buildings.

The cylinder is refilled by weight, which directly affects the difference in cost with servicing the gas tank; a stationary installation is much more profitable in this regard. After simple calculations and comparisons, you can understand that the cost will be higher; in some situations, refilling one liter will cost up to 100 rubles.

Most consumers have already encountered a similar nuance and can confidently say that stationary containers are more practical, thanks to them you can significantly save the family budget; every consumer needs to know the pros and cons of a gas tank for a private home.

Conclusions and useful video on the topic

Briefly and succinctly about autonomous gas supply to private households:

Judging by the description of the design and installation process, it is quite possible to provide a private home with an autonomous gas station with little effort and at a cost acceptable to the family budget. And quite a few owners of suburban real estate, remote from centralized gas communications, use this opportunity. The result is obvious - convenience and increased living comfort.

Do you have practical experience in using and installing gas tanks? Or would you like an article on the topic? Please leave comments, ask questions, and share your experience in the block below the article.

Installation of a gas tank in a private house

Such work is carried out by turnkey specialists, but you should order services only from trusted organizations; today there are quite a lot of companies dealing with these issues.

It is forbidden to perform manipulations on your own; this is worth looking at first. Certified workers are involved in installation, wiring and connection to the boiler.

Such a process directly depends on the status of the applicant for registration; the situation is different for individuals and legal entities. The device is included in the list of containers that are not subject to registration with Rostechnadzor, since the volume exceeds 100 liters.

And also if the device is not the property of an individual entrepreneur, and an ordinary citizen is responsible for its installation, then no documents will be required. You just need to adhere to all safety rules; you can easily find them and examine the papers in person.

Underground models of devices will be most practical in private buildings, because taking into account the climatic conditions in most regions, it is possible to accurately determine the minimum temperature regime.

The regasification process slows down when their indicators are below “0”; this point is worth looking at when choosing equipment. Small areas will require maintaining free space.

One of the important tips from experts in this matter would be to prohibit the purchase of containers that have been used.

Such specimens are often only tidied up on the outside, but if you look inside the product, you will find rust deposits there.

Since such an opportunity will not arise, you should take the advice as seriously as possible; damage reaches 40-50% of all walls of the device, which can be called a good reason for refusing to purchase.

Large units cannot be called the most practical; it is necessary to make correct calculations for each country house. The following nuances are taken into account:

- Boiler characteristics.

- Building area.

- Quantity of equipment.

If we take into account horizontal instances of devices, then it is better to make a reserve of 15% of consumption indicators; vertical designs allow you to reduce the figure to 10%.

Prices for different products will also differ, so each owner needs to choose a suitable container. Extra volumes are not needed in this situation; each building requires an individual approach to calculations.

There are several rules of SNiP and other control bodies, they include the minimum permissible distances to the nearest objects and safety standards, the summary looks like this:

- Residential buildings, at least 20 m for underground and 10 m for above-ground types of fixtures.

- Heating mains and sewer pipes should not be closer than 3.5 m.

- Engineering communications and water supply at 5 m.

- Wells will also need to withstand 5 m.

- Category 5 and 4 roads are removed by 10 and 5 m, respectively, for above-ground and underground types.

- Water supply sources, distribution points, transformer substations, power lines no closer than 15 m.

For the practicality of fuel delivery, it is better to maintain a distance of 30 to 50 meters from the nearest vehicle parking lot; this nuance is pre-agreed with the company that will replenish supplies.

Upon completion of the preparatory stages, it is worth moving on to the actual installation; the storage facility is carefully unloaded and placed in a pre-designated place. Often a concrete pad is poured under the container to avoid subsidence of the soil during filling; the level may also be lost.

Fixation is mandatory; for this you will need to purchase special paws with bolts. Otherwise, you should not count on accurate readings of the remaining liquid in the tank.

The next stage of work involves the installation of a blue fuel supply system; for this, plastic pipes or specimens with an anti-corrosion coating are used.

The trenches are filled with sand, and all workpieces and fittings are fastened by welding; do not forget about the warning tape, it is needed as a warning, otherwise damage to the gas pipeline cannot be avoided during excavation work, which is fraught with leakage and explosion.

Above ground or underground

Based on the type of occurrence, reservoirs are divided into above-ground and underground. In most cases, Russian homeowners choose underground ones. This is a dire necessity. How a gas tank works: at positive temperatures, the liquefied fuel in it evaporates and turns into gas, the valve opens, and the gas flows through the gas pipeline into the house, to the boiler. Under the ground around the walls of the container there are always positive temperatures - this is the main advantage of an underground gas tank. And the ground-based one may need to install special evaporators.

CrimsonFORUMHOUSE Member

That’s why large gas tanks are buried to prevent them from freezing. And preferably with a high neck, so that the gas itself is deeper - it’s warmer there.

But some owners of gas tanks believe that all tanks, regardless of the type of location, need additional heating of the gearbox.

StanspbFORUMHOUSE Member

In winter, it can freeze to very low temperatures, crack and stop regulating the gas supply. So I consider it necessary to heat the gearbox.

There is another type of gas holder - mobile or portable.

Usually this is a gas tank for the country - a cylinder with a capacity of about 700 liters on a car trailer that can be transported to a gas station. Mini gas holders cope with their tasks quite well.

MosKvachFORUMHOUSE Member

The mobile is placed on the base or works directly from the trailer. Moreover, there are also winter kits to prevent freezing in cold weather.

How is a gas tank filled?

Fuel reserves are replenished on average once every 2-3 years. Moreover, this service should be ordered when the residual gas level in the tank is about 20-25%. The refueling itself is carried out by special machines equipped with hoses 30-40 m long. The whole process consists of the following stages:

- Clearing the area around the equipment and preparing the neck.

- Checking data from measuring equipment showing the exact filling level.

- Connecting the tank nozzles to the special equipment hose.

- Resetting automatic measuring counters.

- Fuel supply and gas tank refueling supported by pumps or compressor unit.

- Removing gas residues by blowing the channels with compressed air.

- Dismantling of connected equipment.

The entire procedure takes on average from 30 to 60 minutes. This depends on the fuel injection technology and the capacity of the gas tank. Reviews from equipment owners note that it is cheaper to order large volumes at a time. For example, filling 30% will cost approximately 20-22 rubles. for 1 liter, and 70% - respectively, 15-17 rubles.

Gas boiler power calculation

The main share of fuel consumption is heating. An important parameter of any house or apartment that affects the amount of gas spent on heating is the heat loss indicator. The task of heating is precisely to correctly compensate for these losses, creating conditions for comfortable living.

In order to calculate the need for liquefied gas, it is necessary to determine the amount of heat loss at home or the thermal power required for full heating. The rated power of the heating system - gas boiler - depends on this indicator

As a standard for calculations, we will take a house located in an area with an average climate, in satisfactory condition and insulated in accordance with technology. The area of the house is 80 m2.

The average values of heat loss and boiler power can be determined by the quadrature of the area.

The formula looks like:

Q = S × Рр /10 , where

Q—calculated heat losses (kW);

S is the area of the premises that are heated (m2);

Рр - specific power of a gas boiler (kW/m2) - power for every 10 m2.

The specific power for heating an area of 10 m2 has already been approximately established, taking into account adjustments for regions with different climates. For our reference house, located, for example, in the Moscow region, Рр = 1.2 - 1.5 kW.

Taking into account a house area of 80 m2, the optimal power of the heating system will have the following value:

Q = 80 × 1.2 / 10 = 9.6 kW.

Although simplified, this formula reflects the most accurate results.

Often, for convenience in carrying out calculations, unit is taken as the value of specific power. Based on this, the power of the heating system is taken at the rate of 10 kW per 100 m2 of heating area.

Since the gas supply system of your home includes not only heating, but also water heating and other equipment, the boiler power is determined by adding 20-25% of the reserve to the calculated heat losses

The second option, but accepted with a greater degree of error, is to calculate the cost of thermal energy for the heat loss of a building by cubic capacity - the volume of heated premises. Depending on the climate zone, 30 - 40 W are allocated for heating one cubic meter of a room with a ceiling height of up to 3 m.

Operation and service

Scheduled technical inspection is carried out every 2 years, the package of measures includes:

- External inspections of the housing, connection system, control devices and shut-off valves.

- Pressure and fluid level.

- Individual components, if necessary, are repaired or replaced.

Sources

- https://masterok-remonta.ru/otoplenie-i-ventilyatsiya/gazgolder-dlya-chastnogo-doma-plyusy-i-minusy.html

- https://ProUteplenie.com/otoplenie/gazgolder-dlya-chastnogo-doma

- https://positroika-doma.ru/otoplenie/chto-takoe-gazgolder-i-dlya-chego-on-nuzhen-v-zagorodnom-dome

- https://kotle.ru/gazosnabzhenie/chto-takoe-gazgolder

- https://domsgazom.ru/gasholder/gazgolder-chto-eto-takoe-i-kakova-ego-rol-v-sisteme-avtonomnoj-gazifikatsii

- https://zapodlico.ru/chto_takoe_gazgolder_i_dlya_chego_on_nuzhen_v_zagorodnom_dome

- https://delta-instrument.ru/otoplenie/gazgolder-eto.html

How many liters of gas are in the gas tank?

First, let’s figure out what tank volume a gas tank can have. Most often, gas tanks with a volume of 2700 and 4800 liters are used for gasification of private houses. Of course, there are tanks of larger volume, but they are used less often for domestic purposes.

To determine what tank volume is right for you, it is better to turn to professionals, since there is a high risk of making a mistake when choosing on your own. Experts determine the required tank volume taking into account various factors, including the characteristics of your garden plot and the square footage of your house.

Installation rules

The list of installation work for installing a gas tank includes digging a pit of the required depth, installing gravel and sand backfill, installing a reinforced concrete slab or installing a concrete foundation. After this, the contractor will bring the gas pipeline to the house and bury the tank.

The container is attached to the slab in the pit, and this attachment must be protected from corrosion. It is also necessary to have cathodic protection for a longer service life of the container.

Installation of the gas tank must be carried out in accordance with all norms and rules

Liquefied gas is heavier than air, so when there is a leak, it sinks down, so that ventilation will not be able to remove the gas, hence it is imperative to install ventilation holes 30 cm from the floor level and a gas leak alarm.

According to building regulations, a gas storage facility must be located at least 15 meters from a public building. For residential buildings, other standards are provided - at least 10 meters. The gas tank should be located no closer than 5 meters from the well or well, at a two-meter distance from utilities (sewerage, water supply, etc.).

Installation cost

Important! Installation companies often do not include cathodic protection, a gas analyzer with a gas leak alarm, etc. in the price. Find out these nuances right away.

Typically, the installation cost is included in the price of the gas tank. The manufacturer, tank volume, and service life are of decisive For example, products of the Czech company Deltagaz, which manufactures gas tanks with a volume of 2.7 m3, 4.8 m3, 6.4 m3, cost from 175 thousand rubles.

Gas holder from the Czech company Deltagaz

Gas tanks from the Polish manufacturer Chemet, made of steel, with a polymer protective coating and stiffening ribs, are distinguished by their increased cost. The price of a tank with a volume of 4850 liters starts at 330,000 rubles.

The Bulgarian company Syty-gas produces gas tanks with a volume of 2.7 m3; 4.85m3; 6.4m3 and also 9.15m3. Such tanks are operated at temperatures from -40 to +40 degrees and have additional protection. The price of the kit includes installation of the tank and gas connection. The price starts from 330,000 rubles.

House connection diagram

The gas tank connection diagram is regulated by the provisions of building codes and regulations. The installation of tanks, as well as the supply of fuel to the house, should be carried out by specialists who have access to this type of work.

Installation of a gas tank according to SNIPs

When supplying gas from the storage facility to the house, the following requirements of SNIPs must be observed:

- The minimum depth for laying gas pipeline pipes is 1.5 meters;

- 1% pipeline slope;

- The need to process metal parts that are underground;

- Installation of a condensate collector;

- After entering the building, the gas pipeline is connected to the gas boiler, then to other consumers.

Big or small

If you want to install a large gas tank and thereby provide yourself with liquefied propane-butane for a couple of years, you should remember that too large a volume is not beneficial because:

- A significant area of the site will be occupied, on which nothing except a lawn can be placed.

- Significant financial costs will be required, both for the tank itself and for the work on its installation.

- fill the gas tank not once, but twice a year: once with summer fuel, and the second time with winter fuel. Summer cannot be used in winter. Winter ones are more expensive, so it’s better to buy them only for winter. You can save up to 20,000 - 30,000 rubles on the price difference.

A tank that is too small has one significant drawback - it will have to be frequently refilled with propane-butane gas . And if you forget about the next refueling, you can be left without heat at the most inopportune moment.