The classic heating scheme with one heat generator is well known to every home owner. However, by combining a gas and electric boiler in one system, a much greater practical effect can be achieved. They say that such a connection is much more economical than usual. Sounds tempting, doesn't it?

Logical reasoning raises doubts: how will electricity help save the budget, since its cost is much higher than gas? And why do this at all from the point of view of the feasibility of increasing the power of the units? Isn't it easier to just buy one productive boiler?

In fact, the project of such a combination is quite justified. We will tell you in detail how to assemble heating with electric and gas appliances. You will learn about the structure of this system and its feasibility. We will help you draw up a diagram and not miss the important nuances of arranging a combined heating line.

Why install two boilers at once?

The role of the leader in the gas + electric combination is usually performed by a gas unit. This is logical, if only because of the lower cost of the fuel used in the supply. But the word “save” was mentioned above, and it is not clear what the cost reduction is.

The fact is that in many regions the electricity tariff is based on the day/night system. In some cases, it turns out, at least a little, but more economical than paying for gas. The difference is doubtful, but it can serve as an additional reason to add arguments for the double connective.

Installing an electric boiler in conjunction with a gas boiler can play a backup or additional role in the overall organization of heat supply. When choosing equipment power, you should focus specifically on the purpose of its use.

Of course, this is not such a compelling reason to immediately design a heating system with 2 boilers. The main advantages of the circuit are power amplification and uninterrupted operation. When choosing and installing a heat generator, you must clearly understand that any device and fuel supply are not eternal.

The power supply is turned off, the gas line may be blocked due to a leak, the voltage in the network will drop, or a simple breakdown of the unit itself will occur. In this case, you risk being left without heat and hot water during the cold season.

To ensure uninterrupted operation of heating equipment or increase the power of the system as a whole, it is possible to allow 2 boilers operating on different fuels to operate at once

This is called connecting an additional (to enhance power) or backup power source, depending on the purposes and situations that arise.

Possibility of implementing joint connection

Designing a conventional gas-consuming heating system is not so easy. That is, it is easy to create a working scheme, but getting it approved is problematic. The situation with electric boilers is less dire in terms of costs, time and problems with obtaining papers approving the procedure.

And here is the combination of 2 different fuel units. It would seem that you won’t run into problems and will have to go through the authorities for literally years to get permits. But that's not true.

There are no restrictions on the joint use of gas and electric boilers in regulatory documents. However, it is still necessary to coordinate such a project with the gas service and obtain permission if your use of electricity exceeds the established limit in the total capacity of the equipment

In fact, building regulations are quite favorable to such schemes. To be more precise, there are no prohibitions.

Energy and fuel consumption meters are different. Resource consumption is not exceeded, an explosive situation is not provoked - install boilers in compliance with standard standards and installation instructions for each. There shouldn't be any problems.

We remind you that the installation of gas boilers should be carried out in accordance with SP 402.1325800.2018 (and this document is mandatory and not advisory).

How to connect 2 boilers in the system?

You can’t just randomly connect 2 devices, the system will either not work or will work incorrectly. It is necessary to use carefully designed and competently designed ones from an engineering point of view.

There are two main connection schemes, these are:

- Sequential , when all elements are connected to each other without additional nodes. In this case, one device will heat the coolant, and the second will reheat it;

- Parallel , in which the devices included in the circuit have 2 connection points and the boilers operate independently of each other.

The sequential system is more suitable for low-power boiler installations and is rarely used.

Serial connection is considered impractical, if only because it is impossible to remove one boiler without affecting the second. In fact, the problem is solved by installing bypasses and shut-off valves, but still parallel connection is preferable

Meanwhile, parallel connection in a single system of gas and electric boilers has many advantages. Therefore, it is used most often, despite the fact that this arrangement requires more materials and is considered more expensive.

In such a device, you can turn off one of the devices at any time and even remove it for replacement or repair, while the second one will continue to operate as normal.

Backup boiler paired with a diesel boiler

The best option for backing up liquid fuel heating would be either a second diesel boiler or a solid fuel boiler, as well as a gas boiler powered by a gas train - several cylinders connected to supply gas to the heat generator.

A second diesel boiler will work if your main unit fails. The backup will be powered from the same tank as the main heat generator.

If there are problems with the supply of diesel fuel or with the timely purchase and delivery of fuel, then a backup boiler using a different type of fuel will help out.

Features of parallel connection

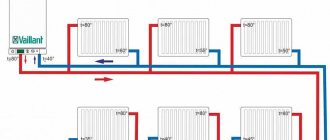

Let's take a closer look at what a standard parallel connection diagram for gas and electric boilers looks like:

- Each unit has coolant supply circuits. They join the common line.

- It is imperative that there are safety groups and shut-off valves.

- The return lines, also equipped with shut-off valves, are connected to the other line.

- A circulation pump is installed on the return line (or supply), in front of the unit for combining the piping circuits.

- The lines of both heating units are connected to the collectors.

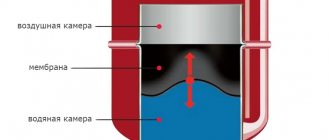

- An expansion tank is installed on one of the distribution manifolds. A make-up circuit is also connected to its pipe, equipped with a check valve and shut-off valves.

- From the distribution manifolds there are main branches to the heated floor, radiators, boiler, each with circulation pumps and valves for draining the coolant from the system.

This is not a schematic diagram, but only its main features. It gives a general idea of how best to connect an additional electric boiler to the main gas boiler. The assembly option can be complicated and improved, for example, with an automation system and a servo drive.

With a parallel connection, you can also install a hydraulic arrow and an automation unit, but before doing this, carefully consider this decision; installing them is not always advisable

Implemented standard solutions (main heating system + backup):

• with a gas boiler;

• with a gas boiler and a backup electric boiler;

• with wood/coal boiler;

• with a wood/coal boiler and a backup electric boiler;

• with a gas boiler and a backup solid fuel boiler.

Building a system solely on an electric boiler is not economically feasible. Especially if the private house is large enough (from 100 sq.m. or more). Utility bills may be too high. If gas is unavailable, we recommend installing a solid fuel boiler and an electric one as a backup.

Manual/automatic control options

Control of the boiler backup system or shutdown of failed ones can be carried out manually or automatically. It is not advisable to leave the system running with one boiler turned off, since the water will continue to circulate.

Imagine what will happen when the cooled return flows in the opposite direction and begins to mix with the supply, cooling the coolant and causing the pump to work in vain.

If for some reason you do not want to equip the boilers with complex devices, you will start the unit yourself. That is, everything is standard: you need to turn on the device - turn all the necessary valves and turn it on. When disconnecting, perform the steps in reverse order.

If you want the backup equipment to start automatically, the system is equipped with automation, thermostats, indoor and outdoor air temperature sensors, coolant temperature sensors, and servos.

In the circuit diagram of the automatic backup start of the heating unit, all shut-off valves must be in the open position. According to the counter scheme, the system is equipped with check valves to avoid parasitic circulation of coolant through a boiler that is not operating at a certain time.

However, despite the convenience, the system can cause certain problems, for example, hydraulic resistance of check valves, causing stress on the pumps, contamination and wear of the devices themselves.

To automatically turn on the heating boiler, the system is equipped with a thermostat, which sends commands to the control unit, depending on the temperature in the house. The switch-on time for night standby use is set on a timer. The circulation pump is turned off using a magnetic starter.

Automation for electric boilers can be built-in, homemade, or purchased separately. However, you should not install it yourself using advice from the Internet, without having the proper skills. Invite a specialist for installation and correct system settings

When choosing a control that will be equipped with an electric boiler installed in parallel with a gas boiler, you should opt for automation if:

- The backup boiler is turned on at night, when it is inconvenient to start it manually.

- In case of long trips from home during the heating season.

- If the gas boiler is unreliable.

In other cases, it is quite possible to use the simplest manual scheme.

Hydraulic arrow in a parallel connection system

A hydraulic arrow is a device that provides hydraulic isolation of flows supplied to individual circuits of the heating system. It plays the role of a buffer tank, receiving the flow of coolant heated by the boilers and distributing it to consumers in a branched system.

Often the volume of coolant required for them differs, the speed of movement of the heated water and its pressure differ. And in the situation under consideration, the movement of heated water from each of the boilers also stimulates its own circulation pump.

When the powerful pump is turned on, the coolant is unevenly distributed throughout the circuits. So, the task of the hydraulic gun is to equalize this pressure. Due to the fact that there is virtually no hydraulic resistance inside it, it will freely receive and distribute coolant flows from both boilers.

Let’s figure out whether it is really necessary in a parallel system for connecting 2 boilers, especially since if you buy and install a hydraulic separator with the help of a specialist, and not with your own hands, the total amount will be unpleasantly surprising.

The device is a piece of pipe with pipes, hollow or with filter meshes to remove bubbles and filter out incoming contaminants. It can be placed in any position, but more often vertically, with an air vent on top and a shut-off valve on the bottom for cleaning. A hydraulic arrow is installed between the boiler and heating circuits

In the classic connection scheme, a hydraulic separator is usually not required, since the conflict of 2-3 pumps can be equalized without this device. Accordingly, if you have 2 boilers that are used exclusively as a backup and there are no more than 3-4 pumps in the system, there is no particular need for it.

But if there are more forced circulation circuits or heating boilers operate simultaneously at full power, it is best to install this device. Again, it is unknown whether you will use the second boiler permanently or only in backup mode, so it is better to be safe.

Rating of the best models of electric boilers for the home in 2022

Protherm Skat 9 KR 13

This is a single-circuit boiler with the ability to connect a boiler, but it is not included in the kit and will have to be purchased separately. Such a unit can be installed in country houses, cottages, private houses and even in apartments. This device belongs to the luxury equipment, it is convenient to use and easy to maintain.

The boiler is quite easy to install and has a high efficiency that will not decrease during operation. It does not make any sounds during operation. The adjustment is made quite quickly, accurate to the degree, the boiler operates from a 220 V network. The design has a circulation pump and an expansion tank. All basic information is displayed on a liquid crystal display; the boiler can be used not only for a traditional heating system, but also for heated floors. There are several levels of protection: from freezing, from leaks, short circuits, and so on.

- Attractive appearance;

- Good quality;

- Easy to use;

- All key controls are located next to the LCD display;

- Economical - maximum power is only 9 kW;

- Possibility of connecting a boiler to provide the home with hot water.

- There is no remote temperature control system;

- Boiler is not included.

Vaillant eloBLOCK VE 9

This equipment is perfect for making an individual heating system in a private home. The boiler has high power, thanks to which the room warms up to the set temperature within just a few hours. It can be used not only for residential, but also for industrial premises, the area of which is no more than 120 square meters.

If necessary, it can be connected to a heating system of the “warm floor” type; it is possible to connect a storage boiler. The body is made of thin sheet stainless steel. On its front side there is a convenient and extremely clear external control panel, equipped with an LED display, where you can easily adjust the temperature. The design includes a powerful and efficient microprocessor that ensures the accuracy of all changes in the heating system.

To extend the service life of the unit, the manufacturer equipped it with a number of protective systems - protection from overheating, from too high pressure in the system, from freezing, etc. The power changes smoothly, which prevents overloads. The kit includes an external temperature sensor that will transmit data to the microprocessor. This, in turn, will increase or decrease the temperature of the coolant.

- Significant heating area;

- Possibility of connection to the “warm floor” system;

- You can additionally purchase a hot water boiler;

- The expansion tank is equipped with a mechanical pressure gauge;

- Operates exclusively on 200 V.

- Expensive service;

- High price.

Buderus Logamax E213-10

A reliable and durable model, the boiler body is made of welded sheet metal and is additionally equipped with a heat-insulating layer. The casing is painted with comaxit compounds. All main fuses are located on the top of the device. These include an air valve, a control system fuse and a coolant temperature limiter. The unit has a three-stage pump, thanks to which water quickly circulates throughout the system. The boiler thermostat prevents the housing from overheating.

The product is small in size, has a frame for mounting to a wall, and the equipment power is about 10 kW. The boiler has all the key functions. Its power can be adjusted on the device itself or through a room thermostat, which comes with the equipment. Inside there is also an expansion tank with a volume of about 7 liters. The maximum system pressure is 2.5 bar - which is quite enough for a house with an area of about 100 square meters.

- High efficiency;

- It works absolutely silently, due to the fact that the boiler has a power switching relay;

- Easy to install and maintain;

- Reliable thermal insulation that minimizes heat loss during operation;

- Small overall dimensions and long service life.

- There is no possibility of connecting a boiler to provide the house with hot water.

EVAN EPO 4

This domestic product is one of the most budget models presented in our rating of the best electric boilers. The main distinguishing feature of the unit is the absence of a housing, but at the same time it retains all the basic qualities and functions. The temperature range is from 30 to 85 degrees - which is quite enough even for the most severe climatic conditions. If necessary, you can connect an external thermostat with a remote control module to the device, but you will have to purchase it separately.

The thermostat is automatic - it is activated when the coolant temperature drops below the set value. There is an overheat protection system: the boiler will turn off when the water warms up to 92 degrees. The heating element is made of thick-walled stainless steel, characterized by a long service life. The device weighs only 15 kg, the maximum pressure in the system is about 4.5 bar, and is designed for connection to a single-phase line with a voltage of 220 V.

- Reliable stainless steel heating elements;

- Does not require maintenance during the entire service life;

- Simple device;

- Low price.

- The need to purchase additional devices such as a thermostat;

- Lack of housing.

RusNIT 209M

Medium power equipment - consumes only about 9 kW, takes up little space, and is mounted on the wall. The boiler can be used both for heating and for a hot water supply system due to the additional installation of a boiler. When installing heating equipment, you will have to install an expansion tank and a circulation pump, since these elements are missing in the boiler.

Conclusions and useful video on the topic

Synchronization of operation and shutdown of boilers in a parallel installation:

Installing 2 heating boilers, gas and electric, is a wise solution to increase the power of heating equipment, as well as for backup heating of the building. Parallel installation of units is not as difficult as it might seem at first.

The main thing is to correctly select the arrangement scheme and correctly calculate the total or reserve power of the equipment. If you are not confident in your abilities and cannot cope on your own, it is best to contact plumbers. They will help you quickly and efficiently install a system for reliable and comfortable heating of your home.

Heating system with wood/coal boiler:

The most common solution in the absence of gas is to use a solid fuel boiler.

For a house with an area of 100 square meters, the minimum tank capacity is 250 liters. For a more accurate calculation, you need to know the parameters of the wood-burning boiler and the duration of fuel combustion.

An electric heating element can be installed in the storage tank, which will maintain the temperature when the solid fuel boiler is not in use. If you have an electric boiler, then it can be used instead of a heater.