You often have to face questions: which hot water supply system - open or closed - is better, what are the differences between them, what to choose for a private home, etc. It is important to understand that the concept of "open" and "closed" (sometimes called "loop" ") does not refer to DHW systems, but to heat supply systems (HS), of which the DHW system is an integral part. Depending on how the hot water supply is organized in the heating supply system of the facility, this system is classified as either open or closed type.

Types of heat supply systems

There are many criteria for dividing ST into separate types. For example, depending on the coolant used, water and steam heat exchangers are distinguished; and depending on the location of the source of thermal energy - centralized and decentralized; according to the temperature regime - low-, medium- and high-potential ST. The number of pipelines also matters: systems can be single-, double- and multi-pipe. According to the method of providing consumers with heat, heating systems can be single- and multi-stage.

One of the fundamentally important criteria is the method of organizing hot water supply in the ST - according to GOST R 56501 of 2015 (see clauses 3.20 and 3.21) the use of open and closed ST is provided.

An open heat supply system (hereinafter we will use the more familiar and widely used term “open water supply system, DHW”) involves the selection of water for DHW from a common pipe system for heat supply. In this case, water is heated using the main source of thermal energy (CHP, boiler room or central heating point).

With a closed water supply system, water heating occurs at the consumer facility (in a multi-storey residential building, office building, production or industrial premises). Heating is carried out through a secondary circuit using plate heat exchangers. If you are planning to install a closed hot water system, you can buy a plate heat exchanger in St. Petersburg for these purposes in a specialized one.

The above figure on the right shows an open water supply system: the diagram shows that the same water flows into both the heating devices (batteries, radiators) and the drainage points (consumer taps).

Use of heating points

This is a separate room. It must contain thermal power plants connected to the heating network. Heat exchangers for hot water supply in an apartment building must have tools for regulating consumption, distributing hot water among apartments, and setting up the equipment itself.

An individual heating point in an apartment building is usually located in the basement. Previously, the system was installed in attics. In the event of a breakthrough, streams of boiling water spilled throughout the room and flooded the apartments. If an emergency occurred at night, it could lead to serious injuries or even casualties.

An alternative option is to build a heating station in a separate building next to the building. The purpose of the equipment is to convert the coolant, regulate the supply of hot water or heat, distribute the resource among apartments and turn off its supply.

Open heating system

The main thing you need to know about the open hot water supply system is that from January 1, 2022, it will be prohibited throughout the Russian Federation on the basis of the federal law “On Heat Supply.” All multi-storey residential buildings and organizations must switch to a closed-type system before this time.

Open circuit structure

The structure of the open type system is quite simple. It is built using the following elements:

- Pipeline;

- shut-off valves (ball valves, gate valves, etc.);

- instruments for measuring temperature and pressure in the system (pressure gauges and thermometers);

- temperature regulators.

Pipes must be insulated to prevent heat loss. Thermostats can be installed with or without valves.

Operating principle, advantages and disadvantages

The operating principle of an open hot water system is as follows:

- The heat source heats the coolant and transfers it to consumers through a pipeline.

- From the main pipeline, part of the coolant (in this case, water) enters the heating circuit (to consumers' heating appliances), the remaining is supplied to the hot water system, from which it is taken by consumers from intake points (taps).

- The water in the heating and hot water circuit circulates, returning through the return line to the source of thermal energy.

- The water used by consumers enters the sewer system, due to which the system is constantly, automatically, recharged with water.

There are pros and cons to open CT. Clear advantages include:

- Availability of this system.

- It is easy to install and maintain.

- Possibility of quick installation.

- There is no need to purchase additional equipment for heating water.

- Long service life of heating devices and pipes due to the high quality of the coolant.

However, this ST still has more disadvantages:

- High cost of centralized hot water preparation.

- The quality of the coolant must meet the requirements for drinking water. In practice, it often turns out that the water in consumers’ taps does not meet these requirements. Due to the presence of traces of fuels and lubricants, rust and chemical impurities, it can be harmful and have an unpleasant odor.

- Substances with a low crystallization temperature cannot be used as a coolant.

- It is prohibited to add chemical reagents to ST.

- There is a need for automatic and continuous replenishment of the coolant due to its selection by hot water consumers.

- Due to a single circuit, during service or repair, consumers are deprived of not only heating, but also hot water (closed-type systems can be easily repaired in the summer).

- In the warm season, more resources than necessary are used to ensure the functioning of the hot water supply system.

It was due to the presence of such significant shortcomings in Russia that the decision was made to abandon open-type ST.

Hierarchical and flat networks

The purpose of building corporate data networks (CDTNs), be it a network of a geographically distributed company or a data center network, is to ensure the operation of business applications.

KSPD is one of the most important tools for business development. In a company with a geographically distributed structure, business often depends on the reliability and flexibility of the joint work of its divisions. The construction of an ICSD is based on the principle of dividing the network into “building blocks” - each is characterized by its own functions and implementation features. Industry standards allow network equipment from different vendors to be used as such building blocks. Proprietary protocols limit customer freedom of choice, resulting in limited business agility and increased costs. By using standardized solutions, customers can select the best product in their area of interest and integrate it with other products using open, standard protocols. Today's large networks are highly complex, driven by multiple protocols, configurations, and technologies. Using hierarchy, you can organize all the components into an easily analyzable model. The hierarchical model helps you design, implement, and maintain scalable, reliable, and cost-effective interconnected networks.

Three-level corporate network architecture.

Traditional enterprise network architecture includes three layers: access, aggregation/distribution, and core. Each of them performs specific network functions.

The core layer is the basis of the entire network. To achieve maximum performance, routing functions and traffic management policies are moved to the aggregation/distribution level. It is he who is responsible for proper routing of packets and traffic policies. The task of the distribution layer is to aggregate/unite all access layer switches into a single network. This allows you to significantly reduce the number of connections. As a rule, it is to the distribution switches that the most important network services and its other modules are connected. The access level is used to connect clients to the network. Data center networks were built using a similar scheme.

Legacy three-tier network architecture in the data center.

Traditional three-tier architectures are focused on the client-server paradigm of network traffic. With the further development of virtualization and application integration technologies, the flow of network traffic between servers is increasing. Analysts talk (here too) about a paradigm shift in network traffic from the “north-south” direction to the “east-west” direction, i.e. to a significant predominance of traffic between servers, as opposed to exchange between the server and clients.

When considering the network architecture of a data center, the access level corresponds to the edge of the server farm. The three-layer network architecture in this case is not sufficiently optimized for transmitting traffic between individual physical servers, since instead of reducing the packet transmission path to one (or at most two) network layers, the packet is transmitted through all three, increasing delays due to spurious traffic in both directions.

That is, traffic between servers passes through the access, aggregation, and network core levels and back in a non-optimal manner, due to an unreasonable increase in the total length of the network segment and the number of packet processing levels by network devices. Hierarchical networks are not sufficiently adapted for data exchange between servers and do not fully meet the requirements of modern data centers with a high density of server farms and intense inter-server traffic. Such a network typically uses traditional loop protection, device redundancy, and aggregation protocols. Its features: significant delays, slow convergence, static nature, limited scalability, etc. Instead of the traditional tree-like network topology, it is necessary to use more efficient topologies (CLOS / Leaf-Spine / Collapsed), which reduce the number of layers and optimize packet transmission paths.

HP simplifies the network architecture from three-layer (typical of traditional Cisco network architectures) to two- or single-layer.

The current trend is that more and more customers, when building their networks, are focusing on building second-level (L2) data networks with a flat topology. In data center networks, the transition to it is stimulated by an increase in the number of server-to-server and server-to-storage system flows. This approach simplifies network planning and implementation, and also reduces operating costs and overall investment costs, making the network more productive.

In the data center, a flat network (L2) better meets application virtualization needs by allowing virtual machines to be moved efficiently between physical hosts. Another advantage that comes with effective clustering/stacking technologies is that there is no need for STP/RSTP/MSTP protocols. This architecture, combined with virtual switches, provides loop protection without using STP, and in the event of failures, the network converges an order of magnitude faster than using traditional STP family protocols.

The network architecture of modern data centers must effectively support the transmission of large volumes of dynamic traffic. Dynamic traffic is due to a significant increase in the number of virtual machines and the level of application integration. Here it is necessary to note the increasing role of various technologies for virtualizing information technology (IT) infrastructure based on the concept of software-defined networks (SDN).

The SDN concept is currently widely extended not only to the level of network infrastructure of individual sites, but also to the levels of computing resources and storage systems both within individual and geographically distributed data centers (examples of the latter are HP Virtual Cloud Networking - VCN and HP Distributed Cloud Networking - DCN).

A key feature of the SDN concept is the combination of physical and virtual network resources and their functionality within a single virtual network. It is important to understand that despite the fact that network virtualization solutions (overlay) can work on top of any network, the performance/availability of applications and services largely depends on the performance and parameters of the physical infrastructure (underlay). Thus, combining the advantages of optimized physical and adaptive virtual network architectures makes it possible to build unified network infrastructures for the efficient transmission of large flows of dynamic traffic based on application requests.

Closed heating system

A closed heat supply system is built using special equipment for heating water: a plate heat exchanger or a boiler. Thus, it turns out that the heating circuit is separated from the DHW circuit and water of different quality can be supplied to them: higher quality in the DHW circuit and technical water in the heating circuit.

Due to the fact that it is the closed heating system that fully complies with the requirements of sanitary standards and at the same time provides comfort to consumers, it is considered more modern and is widely used in the design of new buildings and the reconstruction of old housing stock.

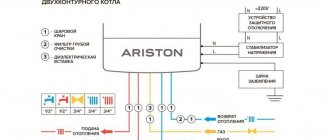

The schematic diagram of a closed type ST is as follows:

Advantages of a closed hot water system

Like the open CT, the closed one has its advantages:

- Proper quality of hot water is ensured.

- To supply hot water, you do not need to use the entire CT infrastructure; only a small circuit is used.

- Fuel savings are ensured due to the absence of the need for centralized heating of water for hot water supply.

- For the heating system, you can use a coolant with low crystallization temperature.

- The hot water system flows water with a temperature of no higher than 60 degrees, which guarantees safety to consumers.

Disadvantages of a loop network

The main disadvantage of a closed hot water system is the significant capital costs for its creation and repair. Due to the use of special equipment for heating water, the design of such a system becomes technically more complex and involves the use of a larger number of communications.

In addition, the disadvantages of a loop network include:

- Increased costs for laying pipes due to actual duplication of pipelines.

- The need to use additional equipment to control the temperature of the water supply.

- The need to allocate space for the installation of water heating equipment, for example, a plate heat exchanger.

- At large heating stations, according to SanPiN 2.1.4.2496, it becomes necessary to perform vacuum deaeration at a water temperature of 100°C or more.

- The need for regular maintenance of water heating equipment and related communications.

- The need to constantly recharge the DHW circuit.

- The use of electricity to connect the necessary equipment and the associated difficulties in its absence.

HP FlexNetwork Architecture

To build flat networks, vendors are developing appropriate equipment, technologies and services.

Examples include Cisco Nexus, Juniper QFabric, HP FlexFabric. The HP solution is based on the open and standardized HP FlexNetwork architecture. HP FlexNetwork includes four interconnected components: FlexFabric, FlexCampus, FlexBranch and FlexManagement. HP FlexFabric, HP FlexCampus and HP FlexBranch solutions optimize the network architectures of data centers, campuses and branch offices, respectively, allowing you to gradually migrate from traditional hierarchical infrastructures to unified virtual, high-performance, converged networks or build such networks based on reference architectures as you grow. , recommended by HP.

HP FlexManagement provides comprehensive monitoring, automation of deployment/configuration/control of multivendor networks, unified management of virtual and physical networks from a single console, which speeds up the deployment of services, simplifies management, increases network availability, and eliminates the complexities associated with the use of multiple administration systems. Moreover, the system can manage devices from dozens of other network equipment manufacturers.

HP FlexFabric supports switching in networks up to 100GbE at the core level and up to 40GbE at the access level, using HP Virtual Connect technology. By implementing FlexFabric architecture, organizations can gradually move from three-tier networks to optimized two- and single-tier networks.

Customers can gradually migrate from proprietary legacy networks to HP FlexNetwork architecture using HP Technology Services. HP offers migration services from proprietary network protocols such as Cisco EIGRP (although Cisco calls this protocol an "open standard") to truly standard OSPF v2 and v3 routing protocols. In addition, HP offers FlexManagement administration services and a suite of lifecycle services for each modular HP FlexNetwork building block, including planning, design, implementation and maintenance of enterprise networks.

HP continues to improve the capabilities of its equipment, both at the level of hardware platforms and based on the Software Defined Network (SDN) concept, introducing various protocols for dynamic management of switches and routers (OpenFlow, NETCONF, OVSDB). To build scalable Ethernet factories, a number of HP network device models have implemented technologies such as TRILL, SPB, VXLAN (the list of devices supporting these protocols is constantly expanding). In addition to standard protocols of the DCB category (in particular VPLS), HP has developed and is actively developing proprietary technologies for effectively combining geographically distributed data centers into a single L2 network. For example, the current implementation of the HP EVI (Ethernet Virtual Interconnect) protocol allows up to 64 data center sites to be connected in a similar way. The combined use of HP EVI and the HP MDC (Multitenant Device Context) device virtualization protocol provides additional expansion opportunities, increasing the reliability and security of distributed virtualized L2 networks.

Differences between closed and open hot water systems

To summarize, we can say that the key and fundamental difference between these STs is the price of hot water for the end consumer. If in an open system the total cost for hot water is paid, then in a closed system the cost of cold water and the thermal component are paid separately. When installing meters, utility bills with a closed station are significantly lower than with an open one, and people have the opportunity to save.

It is also important to evaluate the level of comfort and convenience: with a closed CT, these parameters are significantly higher. In particular, autonomous hot water supply allows consumers to flexibly regulate indoor air and hot water.

Calculation and recycling procedure

In order for the DHW system to be designed correctly, the following must be kept in mind.

- The drawing shows the circulation rings. They close at the thermal unit.

- There are 2 pipelines: supply and circulation.

- On the longest section of the hot water supply route, zones of maximum circulation heat consumption are noted.

- The diameter of the pipes cannot be less than 1.5 cm. Moreover, they must be 1-2 sizes larger than the diameter of those in the supply section. This is done to avoid air locks.

When calculating a heating installation, you need to keep in mind that an open system will be effective only at a short distance from the intake site and when the valve supplying boiling water is opened frequently. Otherwise, the consumer will receive cooled water.

conclusions

The open hot water system is an obsolete scheme, which is being widely abandoned not only because of legal requirements, but also because of its key disadvantages, especially the low quality of water in the system. Closed CTs are installed in new buildings, private houses, industrial enterprises and production facilities. When using modern and energy-efficient thermal equipment, in particular plate heat exchangers, a closed-type system is the most economical, convenient and easy-to-use tool for creating an optimal indoor microclimate and providing consumers with hot water. You can purchase heat exchangers at the best price and order their installation services at: specialists will offer profitable solutions and provide after-sales service for the purchased equipment.

Myth 1: classification according to the type of expansion tank

Closed systems are heating systems that use a closed (membrane) expansion tank.

Open systems are systems with an open expansion tank.

An expansion tank is needed in order to absorb excess coolant during its expansion, since as the temperature rises, the liquid increases in volume.

Without devices that absorb excess coolant, the pressure in the system increases, which sometimes leads to dire consequences, for example, a pipeline rupture and shut-off and control valves may fail.

An open expansion tank (Fig. 1) is not sealed - it is connected to air. It is mainly used in gravity heating systems of private houses. In such systems, liquid circulates without a pump, due to temperature differences.

Fig.1. Open expansion tank in a gravity heating system

A closed (membrane) expansion tank (Fig. 2) is a hermetically sealed metal container divided into 2 chambers by an elastic membrane. Hence the name “membrane”.

Rice. 2. Closed (membrane) expansion tank in the heating system