Often, for the installation of heating systems, hot water supply and hot water supply, domestic plumbers prefer to choose pipes made of metal-plastic or polypropylene. Each of these products has its own advantages. Both are characterized by high strength, corrosion resistance and flexibility. But which option is better?

In this article we will try to figure out what is better to take for independent installation of pipelines for various purposes - polypropylene or metal-plastic pipes, having examined their technical characteristics and features.

The information we provide is supplemented with visual photos and detailed videos with an overview of the differences and features of installing a pipeline made of metal-plastic and polypropylene.

Service life at different temperatures

For each material, manufacturers indicate a guaranteed service life of 50 years, provided that it is used for cold water supply. Practice has shown that this is so, and polypropylene (hereinafter referred to as PP) and metal-plastic (hereinafter referred to as MP) work without problems for up to 50 years without leaks in cold water. But with hot water it’s not so simple.

Many PP manufacturers indicate in the product data sheet that the pipes are capable of functioning normally in hot water supply and heating at temperatures not exceeding 70°C. However, in our radiator heating systems the temperature often reaches 80 - 90°C, which naturally reduces the service life of the PCB. When operating in such a temperature regime, the life of the PCB is halved to 20 - 25 years.

- Exploitation

6 disadvantages of plastic heating pipes that everyone should know about

In MP pipes, the maximum possible temperature of the pumped liquid, according to the passport data, can be 110°C. However, the service life in such conditions is also 20 - 25 years. From this we conclude that MP beats PP only in the temperature of the liquid with which it can work, and their lifespan is the same. But considering that our heating does not reach 100 - 110 ° C, we can say that PP and MP have the same service life in hot water supply and heating conditions.

Pipe features

The metal-plastic pipe consists of three layers. The outer one is made of protective polyethylene, the inner one is made of cross-linked polyethylene. And between them there is an aluminum layer. The layers are glued together with a special compound that secures them securely.

The inner layer easily withstands temperature changes and exposure to chemicals. It is antistatic, and the smooth surface does not interfere with the movement of liquid. Cross-linked polyethylene has molecular memory. This means that over time the material restores its original shape. This is a very important feature, since the pipe does not deform due to loads. There is no plastic slipping or clogging on corners.

The thickness of the aluminum foil layer is usually from 0.2 mm to 1 mm. The optimal value is 0.5 mm. This design minimizes expansion of the plastic due to heating.

Helpful information! Polyethylene and aluminum have different rates of thermal expansion. In low-quality pipes, temperature changes can cause layers to separate. Therefore, it is recommended to buy products from reputable manufacturers.

Pipeline installation method

PP pipes are connected by soldering: both parts are heated and connected to each other. Heating is carried out with a special soldering iron. Installation of PP pipes requires certain professional skills, since if the part is overexposed or underexposed when heated, the passage hole may become smaller or the parts will not connect well with each other and will leak. In addition, the process of connecting fittings and adapters is longer than that of MP.

MP pipes are also connected using fittings, but they only need to be pressed with press pliers. It is difficult to damage anything during the connection process, so even a beginner can handle the installation. If you plan to install the pipeline yourself and have never done anything like this before, we recommend installing MP. If you don’t want (or have the opportunity) to buy pliers, you can get by with collet connections - however, like any threaded ones, they will have to be tightened periodically.

Comparison of parameters

Metal-plastic and polypropylene pipes have different characteristics. Manufacturers have done their best, so even visually the materials are not similar to one another. Comparing the parameters will allow you to understand the difference between both models.

Performance characteristics

In terms of elasticity, polypropylene pipes are stiffer than types made of metal-plastic. Multilayer structures are easy to bend, making transportation and installation easier. With the same parameters, polymers have thicker walls than composites.

Installation of metal-plastic types Source dariusmehri.com

Number of connections

Here there is a clear advantage for metal-plastic, since the pipe itself does not come in pieces, but in a coil. Pipeline can be bent using a lever or spring bender to accommodate corners and curves. And although it is impossible to bend the pipe at an angle of 90°, in most cases this is not required. Due to this, the number of connections can be significantly reduced. In this case, the entire heating or plumbing system can be designed in such a way that the monolithic pipe is hidden in the wall, and the connections are accessible for maintenance.

Polypropylene pipes are sold in pieces of 2 m, so a large number of joints and fittings cannot be avoided. Taking this into account, PP pipes should not be installed under the wall, but rather routed outside so that the connections are always accessible. If any joint starts to leak, you will notice it in time and will not flood your neighbors.

General requirements for the operation of pipeline systems

During operation, a number of requirements are imposed on pipeline systems:

- mechanical strength of the structure;

- wide operating temperature range;

- chemical inertness of the materials used;

- resistance of the inner layer to mechanical abrasion;

- reliability and tightness of joints;

- convenience and ease of installation work.

Compliance with all these requirements is not mandatory, but they directly affect the reliability of the system and ultimately increase the duration of the trouble-free operating interval.

Narrowing of the section on fittings

This is where the main drawback of pipes made from MP appears - they have a strong narrowing in metal fittings. If you took a ¾ pipe, then you will have ½ inch in the metal corner (see picture). A smaller cross-section than that of the inlet pipe leads to hydraulic shocks, which in turn affect the rate of failure of the joint. Of course, at normal (not exceeding permissible values) pressure, for example, in heating pipes, you can not be afraid of getting a water hammer, and the fittings will work fine for many years. But with pressure drops in the water supply, the destruction of connections will occur faster.

PP does not have this problem, and the cross-section of the fittings is equal to the cross-section of the pipes being connected. Therefore, when purchasing material, we simply take pipes and all connecting elements of the same section.

Rating of meat grinders

- Material – food grade plastic, metal, combined body;

- Power – rated from 130 to 850, maximum up to 3000 W;

- Knives – quality steel, anti-corrosion coating, self-sharpening;

- Motor protection - automatic shutdown;

- Productivity - the amount of meat per unit of time;

- Attachments – vegetable cutter, juicer, etc.;

- Reverse – to remove stuck particles without disassembling;

- Noise level – the quieter the better;

- Stability – tendency to vibration, noise;

- Dimensions – compact or bulky models.

When choosing, much depends on the purpose of such a unit. For many buyers, an important criterion is the price tag. Therefore, when creating the top list, the ratio of price and quality was taken into account. Feedback from experts, real user feedback, their experience and advice helped identify the strengths and weaknesses of each nominee.

The best pans for an induction cooker

Linear expansion

Linear expansion is the deviation of the pipeline axis from the norm under the influence of temperature. For MP pipes, linear expansion is about 0.02 mm per linear meter when heated to 1°C. That is, when operating in a heating system with a water temperature of about 90°C, the expansion will be only 1.8 mm per linear meter, which will not even be noticeable. Therefore, the pipes will always be smooth and look aesthetically pleasing.

For PP, the linear expansion is greater and is about 2.5 mm per linear meter. As temperature increases, linear expansion will naturally increase. This can cause the pipeline to become wavy. To make it even, you have to mount it to the wall with a smaller pitch, using more fasteners, which makes the structure more expensive.

True, if the pipeline is made outside, for example, for watering a greenhouse, and there is a possibility of freezing of the remaining water, then due to the large linear expansion, the PP will simply expand and contract, and the MP will rupture.

What is better to choose

When choosing the type of pipes, pay attention to the purpose of the future structure. To organize a cold water supply, polypropylene models (PN10) are sufficient. If they are installing a hot water supply, they are guided by the financial capabilities of the owners. With a small construction budget, preference is given to inexpensive plastic (from PN16 and above). In a compact system, elements with aluminum foil in the mid-price segment can be used.

It is better to make a “warm floor” from metal-plastic pipes. The flexible material is easy to bend without fear of damaging the seal. According to the technology, the maximum step is 0.35 m, otherwise cold zones will arise. The absence of a large number of connecting parts eliminates emergency situations in the future.

Where is metal-plastic used? Source zonapola.ru

The combination of polymers and aluminum foil provides strength to the entire circuit. Due to the low coefficient of expansion of metal-plastic pipes, the screed is very strong. The pipeline holds its shape even during cement pouring. Due to its inertness to chemicals, there is no fear of corrosion and destruction.

It is better to use metal-plastic pipes when creating heating wiring in a private house. The material will withstand temperatures up to 110 C without losing its shape. The aluminum foil inside does not allow oxygen to pass through, so the coolant will not harm the radiators.

Professionals do not advise installing metal-plastic pipes in houses that are often idle in winter. Freezing and thawing of water in the system will lead to delamination of expensive raw materials. Polyethylene types are less capricious to low temperatures, so they are suitable for dachas.

Where to put plastic pipes Source 1-teplodom.ru

Polypropylene can be used to install a heating system in high-rise buildings. An assembled structure made from PN25 will be cheaper in price than composites. The finished structure is easy to install, so you don’t have to hire a professional.

Price

MP is an order of magnitude more expensive than PP pipes. For example, PP pipes with a cross section of 25 mm cost about 40 - 50 rubles per linear meter . MP pipes of the same section will cost 100 - 110 rubles . If the pipeline is long, this is a significant cost overrun. Among other things, there is a big difference in the cost of the installation tool. If for polypropylene you need a soldering iron, the price of which is 1500 - 3000 rubles depending on the company, then press pliers for metal-plastic will cost 9000 - 12000 rubles. So if your budget is limited, we recommend installing a polypropylene pipeline. The only thing you can save on when installing MP pipes is on fittings. If you make more turns with a pipe bender, the number of fittings can be reduced to a minimum.

Diameters

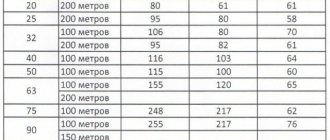

To properly install a PP or metal-plastic pipeline, you must select the correct diameter.

The most common diameters of MP pipe products are 16, 20 and 26 mm. Manufacturers offer options of 50 mm and more, but they are not often used at home.

To install water supply in an apartment, 16 and 20 mm products are used. For the second option, the cost of fittings is significantly higher, therefore, if the pressure in the network is low, then it is quite possible to limit yourself to a 16 mm range. System performance will not be affected at all.

You also need to be able to choose the diameter of polypropylene pipes. To do this, use a special hydraulic calculation. Purchasing pipes with a large cross-section will be expensive, but with a small cross-section, the water pressure in such a network will be low.

PP assortment is manufactured with a volume from 16 to 1200 mm. The household system works perfectly with products from 16 to 32 mm. And internal sewerage will require pipe rolling of 40, 50 or 110 millimeters.

Conclusion

Metal-plastic significantly exceeds polypropylene in service life at high coolant temperatures, has less linear expansion and fewer connections, so it can partially be mounted into a wall. It is easy to install even for a beginner. If you want a durable heating system, then it is better to take metal-plastic.

If the budget is limited, then it is better to use polypropylene, which in cold water supply is not inferior in service life to metal-plastic. At the same time, the costs of its installation, as well as the installation equipment itself, will be significantly lower.

Practical tips for the home handyman:

- Induction cooker errors: we can repair it ourselves

- How to find phase and zero: simple and effective ways

Advantages and disadvantages of metal-plastic

The basic set of advantages of metal-plastic is practically indistinguishable from the advantages of PP fittings. Here you can find low roughness, which guarantees high cleanliness of the inner walls of the pipe, low thermal conductivity, and even low weight.

However, in these parameters, metal-plastic loses to PP pipes. Moreover, in the case of thermal conductivity, the loss can be called significant - the metal-plastic pipe is covered with perspiration. In addition, it is heavier than its polypropylene counterpart. And its service life is measured in years.

Metal-plastic pipes are easy to bend, cut and connect

However, these discrepancies are compensated by the high heat resistance of the metal-plastic pipe. It can withstand even 110 degrees Celsius. Therefore, such fittings are readily purchased not only for plumbing, but also for the installation of heating systems, including heated floors.

Another advantage of metal-plastic is its high flexibility, thanks to which you can refuse to use corner fittings. True, such flexibility is demonstrated only by those pipes that use polyethylene as a polymer shell.

Among the disadvantages of metal-plastic, one can note the traditionally low resistance to thermal deformation for polymer reinforcement, although it is eight times less than that of pure PP pipes. In addition, if the pressure is exceeded, such a pipe does not burst in one place, but delaminates - the metal layer peels off from the polymer shell and insert. Therefore, the consequences of water hammer for the owner of metal-plastic fittings can be very serious.

Criterias of choice

Correctly answer the difficult question “what is better: plastic pipes or metal-plastic?” can be done by taking into account the following aspects:

- Purpose of using pipe assortment. For cold water, polypropylene is more profitable; there will be no problems with leakage. For heated floors, metal-plastic with press fittings is more convenient. For hot water and heating, information from experienced craftsmen will help you decide which is better: plastic pipes or metal-plastic ones.

- Material. Confidence in the quality of the material largely determines the lifespan of the pipeline. Requires attention to the availability of product certificates, documentation with technical data, and appearance.

- Performance characteristics. The material must be suitable for use in the required conditions (temperature, pressure, house with autonomous systems or central highway). The linear expansion of one meter of pipe with an increase in t by 1°C for metal-plastic will be 0.0002 cm, for polypropylene 0.015 cm.

- Assembly method. Both types of products can be easily assembled yourself if you have confidence in your knowledge and have the necessary tools. Remember, a connection using a threaded element must be accessible.

- Construction budget. The cost of materials varies, the main thing is to find an option for yourself with a price/quality balance. You can combine products, for example, make interfloor risers in polypropylene or prefer it for cold water risers.

Over time, more and more new plastic products with innovative characteristics appear. Useful information in the field of construction/repair, accumulated through trial and error, will help, casting aside doubts, make a responsible choice and decide which is better: metal-plastic or polypropylene pipes.