In modern conditions, people are increasingly thinking about the rational use of resources. Electricity, water, materials. The world has come to saving all this quite a long time ago and everyone understands how to do it. But the main amount in the payment bills is heating, and not everyone understands how to reduce the cost on this item.

What is thermal engineering calculation?

Thermal engineering calculations are performed in order to select the thickness and material of the enclosing structures and bring the building into compliance with thermal protection standards. The main regulatory document regulating the ability of a structure to resist heat transfer is SNiP 23-02-2003 “Thermal protection of buildings”.

The main indicator of the enclosing surface from the point of view of thermal protection was the reduced heat transfer resistance. This is a value that takes into account the thermal protection characteristics of all layers of the structure, taking into account cold bridges.

A detailed and competent thermal calculation is quite labor-intensive. When constructing private houses, owners try to take into account the strength characteristics of materials, often forgetting about heat conservation. This can lead to quite disastrous consequences.

Features of the selection of radiators

Standard components for providing heat in a room are radiators, panels, underfloor heating systems, convectors, etc. The most common parts of a heating system are radiators.

The thermal radiator is a special hollow modular structure made of an alloy with high heat transfer. It is made of steel, aluminum, cast iron, ceramics and other alloys. The principle of operation of a heating radiator is reduced to the radiation of energy from the coolant into the space of the room through the “petals”.

An aluminum and bimetallic heating radiator replaced massive cast-iron batteries. Simplicity of production, high heat transfer, successful design and design have made this product a popular and widespread instrument for radiating heat indoors

There are several methods for calculating heating radiators in a room. The list of methods below is sorted in order of increasing calculation accuracy.

Calculation options:

- By area . N=(S*100)/C, where N is the number of sections, S is the area of the room (m2), C is the heat transfer of one section of the radiator (W, taken from the data sheet or certificate for the product), 100 W is the amount of heat flow, which is necessary to heat 1 m2 (empirical value). The question arises: how to take into account the height of the ceiling of the room?

- By volume . N=(S*H*41)/C, where N, S, C – similarly. H is the height of the room, 41 W is the amount of heat flow that is necessary to heat 1 m3 (empirical value).

- By odds . N=(100*S*k1*k2*k3*k4*k5*k6*k7)/C, where N, S, C and 100 are similar. k1 – taking into account the number of chambers in a double-glazed window of a room, k2 – thermal insulation of walls, k3 – ratio of window area to room area, k4 – average sub-zero temperature in the coldest week of winter, k5 – number of external walls of the room (which “extend” to the street), k6 – type of room above, k7 – ceiling height.

This is the most accurate option for calculating the number of sections. Naturally, fractional calculation results are always rounded to the next integer.

Why is the calculation performed?

Before starting construction, the customer can choose whether he will take into account thermal characteristics or ensure only the strength and stability of structures.

Costs for insulation will definitely increase the cost of building construction, but will reduce the costs of further operation. Individual houses are built to last for decades, and perhaps they will serve future generations. During this time, the cost of effective insulation will pay for itself several times over.

What the owner receives if the calculations are performed correctly:

- Savings on space heating. Heat losses of the building are reduced, and accordingly, the number of radiator sections in a classic heating system and the power of the underfloor heating system will decrease. Depending on the heating method, the owner’s costs for electricity, gas or hot water become less;

- Saving on repairs. With proper insulation, a comfortable microclimate is created in the room, condensation does not form on the walls, and microorganisms dangerous to humans do not appear. The presence of fungus or mold on the surface requires repairs, and simple cosmetic repairs will not bring any results and the problem will arise again;

- Safety for residents. Here, as in the previous paragraph, we are talking about dampness, mold and mildew, which can cause various diseases in people constantly staying indoors;

- Respect for the environment. There is a shortage of resources on the planet, so reducing the consumption of electricity or blue fuel has a beneficial effect on the environmental situation.

Thermal Load Concepts

Calculation of heat loss is carried out separately for each room depending on the area or volume

Heating a room is a compensation for heat loss. Through the walls, foundation, windows and doors, heat is gradually released outside. The lower the temperature outside, the faster the heat transfer outside. To maintain a comfortable temperature inside the building, heaters are installed. Their performance must be high enough to cover heat loss.

The heat load is defined as the sum of heat losses of the building equal to the required heating power. By calculating how much heat the house loses and how it loses it, they will find out the power of the heating system. The total value is not enough. A room with 1 window loses less heat than a room with 2 windows and a balcony, so the indicator is calculated for each room separately.

When making calculations, be sure to take into account the height of the ceiling. If it does not exceed 3 m, a calculation is made based on the area. If the height is from 3 to 4 m, the consumption is calculated by volume.

Regulatory documents for performing calculations

The given resistance and its compliance with the standardized value is the main goal of the calculation. But to carry it out you will need to know the thermal conductivity of the materials of the wall, roof or ceiling. Thermal conductivity is a value characterizing the ability of a product to conduct heat through itself. The lower it is, the better.

When performing calculations, heating engineers rely on the following documents:

- SP 50.13330.2012 “Thermal protection of buildings”. The document was reissued based on SNiP 02/23/2003. Basic standard for calculation [1];

- SP 131.13330.2012 “Building climatology”. New edition of SNiP 23-01-99*. This document allows you to determine the climatic conditions of the locality in which the object is located [2];

- SP 23-101-2004 “Design of thermal protection of buildings” covers the topic in more detail than the first document in the list [3];

- GOST 30494-96 (replaced by GOST 30494-2011 since 2011) “Residential and public buildings” [4];

- A manual for students of construction universities E.G. Malyavin “Heat loss of a building. Reference manual" [5].

* - further in the text I will refer to regulatory documents and in order not to completely spell out their name, I will indicate only the number, for example [1].

Thermal engineering calculations are not complicated. It can be performed by a person without special education using a template. The main thing is to approach the issue very carefully.

Hydraulic calculation of water supply

Of course, the “picture” of calculating heat for heating cannot be complete without calculating such characteristics as the volume and speed of the coolant. In most cases, the coolant is ordinary water in a liquid or gaseous aggregate state.

It is recommended to calculate the actual volume of coolant by summing all cavities in the heating system. When using a single-circuit boiler, this is the best option. When using double-circuit boilers in a heating system, it is necessary to take into account the consumption of hot water for hygienic and other domestic purposes

Calculation of the volume of water heated by a double-circuit boiler to provide residents with hot water and heat the coolant is made by summing the internal volume of the heating circuit and the actual needs of users for heated water.

The volume of hot water in the heating system is calculated by the formula:

W=k*P , where

- W – volume of coolant;

- P – heating boiler power;

- k – power factor (number of liters per unit of power, equal to 13.5, range – 10-15 liters).

As a result, the final formula looks like this:

W = 13.5*P

Coolant velocity is the final dynamic assessment of the heating system, which characterizes the speed of fluid circulation in the system.

This value helps to evaluate the type and diameter of the pipeline:

V=(0.86*P*μ)/∆T , where

- P – boiler power;

- μ – boiler efficiency;

- ∆T – temperature difference between supply water and return water.

Using the above methods of hydraulic calculation, it will be possible to obtain real parameters that are the “foundation” of the future heating system.

An example of calculating a three-layer wall without an air gap

Let's take a closer look at an example of a thermal engineering calculation. First you need to decide on the initial data. As a rule, you choose the materials for wall construction yourself. We will calculate the thickness of the insulating layer based on the wall materials.

Initial data

The data is individual for each construction project and depends on the location of the object.

Climate and microclimate

- Construction area: Vologda.

- Purpose of the object: residential.

- Relative air humidity for a room with normal humidity conditions is 55% ([1] clause 4.3. table 1).

- The temperature inside residential premises tint is set by regulatory documents ([4] table 1) and is equal to 20 degrees Celsius.”

text — estimated outside air temperature. It is set by the temperature of the coldest five days of the year. The value can be found in [2], table 1, column 5. For a given area, the value is -32ᵒС.

zht = 231 days – the number of days in the period when additional heating of the room is necessary, that is, the average daily temperature outside is less than 8ᵒC. The value is looked for in the same table as the previous one, but in column 11.

tht = -4.1ᵒС – average outside air temperature during the heating period. The value is shown in column 12.

Wall materials

All layers should be taken into account (even the plaster layer, if there is one). This will allow you to calculate the design most accurately.

In this version, we consider a wall consisting of the following materials:

- layer of plaster, 2 centimeters;

- the inner verst is made of ordinary solid ceramic brick, 38 centimeters thick;

- a layer of Rockwool mineral wool insulation, the thickness of which is selected by calculation;

- the outer verst is made of facing ceramic brick, 12 centimeters thick.

Thermal conductivity of adopted materials

All properties of materials must be presented in the manufacturer’s passport. Many companies provide complete information about their products on their websites. For convenience, the characteristics of the selected materials are summarized in a table.

| No. | Material | Layer thickness, δ, mm | Thermal conductivity, λ, W/(m*ᵒС) | Density, ρ, kg/m3 |

| 1 | Complex plaster solution | 20 | 0,87 | 1700 |

| 2 | Masonry of ordinary ceramic solid bricks | 380 | 0,48 | 1600 |

| 3 | Rockwool mineral wool slabs | Unknown | 0,038 | 90 |

| 4 | Solid face ceramic brick masonry | 120 | 0,48 | 1600 |

Calculation of insulation thickness for a wall

Energy saving condition

Calculation of the heating period degree-day value (HSDP) is carried out using the formula:

Dd = (tint - tht) zht.

All letter designations presented in the formula are deciphered in the source data.

Dd = (20-(-4.1)) *231=5567.1 ᵒС*day.

We find the standard heat transfer resistance using the formula:

Rreq=a*Dd+b.

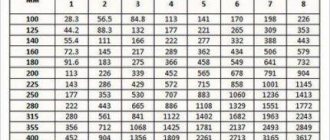

Coefficients a and b are taken according to Table 4, column 3 [4].

For the initial data a=0.00045, b=1.9.

Rreq = 0.00045*5567.1+1.9=3.348 m2*ᵒС/W.

Calculation of thermal protection standards based on sanitation conditions

This indicator is not calculated for residential buildings and is given as an example. The calculation is carried out when there is an excess of sensible heat exceeding 23 W/m3, or the building is used in spring and autumn. Also, calculations are necessary at a design temperature of less than 12ᵒC indoors. Use formula 3 [1]:

Coefficient n is taken according to Table 6 of the SP “Thermal Protection of Buildings”, αint according to Table 7, Δtn according to the fifth table.

Rreq = 1*(20+31)4*8.7 = 1.47 m2*ᵒC/W.

Of the two values obtained in the first and second paragraphs, the largest is selected, and further calculations are carried out based on it. In this case, Rreq = 3.348 m2*ᵒС/W.

Determining the thickness of insulation

The heat transfer resistance for each layer is obtained by the formula:

Ri = δi/λi,

where δ is the thickness of the layer, λ is its thermal conductivity.

a) plaster R pcs = 0.02/0.87 = 0.023 m2*ᵒC/W; b) ordinary brick R row.brick. = 0.38/0.48 = 0.79 m2*ᵒC/W; c) facing brick Rth = 0.12/0.48 = 0.25 m2*ᵒС/W.

The minimum heat transfer resistance of the entire structure is determined by the formula ([5], formula 5.6):

Rint = 1/αint = 1/8.7 = 0.115 m2*ᵒС/W; Rext = 1/αext = 1/23 = 0.043 m2*ᵒС/W; ∑Ri = 0.023+0.79+0.25 = 1.063 m2*ᵒС/W, that is, the sum of the numbers obtained in point 3;

Rtro = Rreq.

R_tr^ut = 3.348 – (0.115+0.043+1.063) = 2.127 m2*ᵒC/W.

The thickness of the insulation is determined by the formula ([5] formula 5.7):

δ_tr^ut = 0.038*2.127 = 0.081 m.

The found value is minimal. The insulation layer is no less than this value. In this calculation, we assume the final thickness of the mineral wool insulation is 10 centimeters, so that we do not have to cut the purchased material.

To calculate the heat losses of a building, which are performed for the design of heating systems, it is necessary to find the actual value of heat transfer resistance with the found insulation thickness.

Ro = Rint+Rext+∑Ri = 1/8.7 + 1/23 + 0.023 + 0.79 + 0.1/0.038 + 0.25 = 3.85 m2*ᵒС/W > 3.348 m2*ᵒС/W.

The condition is met.

Standards for room temperature conditions

Before carrying out any calculations of system parameters, it is necessary, at a minimum, to know the order of the expected results, and also to have standardized characteristics of some tabular values that need to be substituted into formulas or be guided by them.

By calculating parameters with such constants, you can be confident in the reliability of the desired dynamic or constant parameter of the system.

For premises of various purposes, there are reference standards for temperature conditions in residential and non-residential premises. These standards are enshrined in the so-called GOSTs

For a heating system, one of these global parameters is the room temperature, which must be constant regardless of the season and environmental conditions.

According to the regulations of sanitary standards and rules, there are differences in temperature relative to the summer and winter periods of the year. The air conditioning system is responsible for the temperature regime of the room in the summer season; the principle of its calculation is described in detail in this article.

But the room temperature in winter is provided by the heating system. Therefore, we are interested in temperature ranges and their deviation tolerances for the winter season.

Most regulatory documents stipulate the following temperature ranges that allow a person to stay comfortably in the room.

For non-residential office premises with an area of up to 100 m2:

- 22-24°C – optimal air temperature;

- 1°С – permissible fluctuation.

For office-type premises with an area of more than 100 m2, the temperature is 21-23°C. For non-residential industrial premises, temperature ranges vary greatly depending on the purpose of the room and established labor protection standards.

Each person has their own comfortable room temperature. Some people like it to be very warm in the room, others feel comfortable when the room is cool - it’s all quite individual.

As for residential premises: apartments, private houses, estates, etc., there are certain temperature ranges that can be adjusted depending on the wishes of the residents.

And yet, for specific premises of an apartment and house we have:

- 20-22°С – living room, including children’s room, tolerance ±2°С –

- 19-21°С – kitchen, toilet, tolerance ±2°С;

- 24-26°С – bathroom, shower, swimming pool, tolerance ±1°С;

- 16-18°C – corridors, hallways, staircases, storerooms, tolerance +3°C

It is important to note that there are several more basic parameters that affect the temperature in the room and which you need to focus on when calculating the heating system: humidity (40-60%), concentration of oxygen and carbon dioxide in the air (250:1), air movement speed mass (0.13-0.25 m/s), etc.

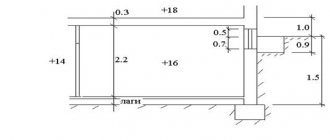

Influence of the air gap on thermal protection characteristics

When constructing a wall protected by slab insulation, it is possible to install a ventilated layer. It allows condensation to be removed from the material and prevents it from getting wet. The minimum gap thickness is 1 centimeter. This space is not enclosed and has direct communication with outside air.

If there is an air-ventilated layer, the calculation takes into account only those layers that are located before it on the warm air side. For example, a wall pie consists of plaster, internal masonry, insulation, an air gap and external masonry. Only plaster, internal masonry and insulation are taken into account. The outer layer of masonry comes after the ventilation gap and is therefore not taken into account. In this case, the external masonry performs only an aesthetic function and protects the insulation from external influences.

Important: when considering structures where the air space is enclosed, it is taken into account in the calculation. For example, in the case of window fillings. The air between the glasses plays the role of effective insulation.

House ventilation losses

The key parameter in this case is the air exchange rate. Provided that the walls of the house are vapor-permeable, this value is equal to one.

The penetration of cold air into the house is carried out through supply ventilation. Exhaust ventilation helps warm air escape. The recuperator-heat exchanger reduces losses through ventilation. It does not allow heat to escape along with the outgoing air, and it heats the incoming air flows

There is a formula that determines heat loss through the ventilation system:

Qv = (V x Kv: 3600) x P x C x dT

Here the symbols mean the following:

- Qв - heat loss.

- V is the volume of the room in mᶾ.

- P is the air density. its value is taken equal to 1.2047 kg/mᶾ.

- Kv - air exchange rate.

- C is the specific heat capacity. It is equal to 1005 J/kg x C.

Based on the results of this calculation, it is possible to determine the power of the heat generator of the heating system. If the power value is too high, a ventilation device with a recuperator may be a way out of the situation. Let's look at a few examples for houses made of different materials.

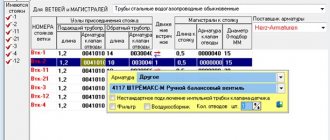

Teremok program

To perform calculations using a personal computer, specialists often use the “Teremok” program for thermal engineering calculations. It exists in an online version and as an application for operating systems.

The program makes calculations based on all necessary regulatory documents. Working with the application is extremely simple. It allows you to work in two modes:

- calculation of the required insulation layer;

- checking an already thought-out design.

The database contains all the necessary characteristics for the settlements of our country; you just need to select the one you need. It is also necessary to choose the type of construction: external wall, attic roof, ceiling over a cold basement or attic.

When you click the continue work button, a new window appears, allowing you to “assemble” the structure. Many materials are available in the program memory. They are divided into three groups for ease of search: structural, thermal insulation and thermal insulation-structural. You only need to set the layer thickness; the program will indicate the thermal conductivity itself.

If the necessary materials are not available, you can add them yourself, knowing the thermal conductivity.

Before making calculations, you must select the type of calculation above the wall structure plate. Depending on this, the program will display either the thickness of the insulation or report the compliance of the building envelope with standards. After completing the calculations, you can generate a report in text format.

“Teremok” is very convenient to use and even a person without technical education can understand it. For specialists, it significantly reduces the time for calculations and preparing reports in electronic form.

The main advantage of the program is the fact that it is able to calculate the thickness of insulation not only of an external wall, but also of any structure. Each of the calculations has its own characteristics, and it is quite difficult for a non-professional to understand them all. To build a private house, you just need to master this application, and you don’t have to delve into all the complications. Calculation and checking of all enclosing surfaces will take no more than 10 minutes.

Types of thermal loads

Calculations take into account average seasonal temperatures

Thermal loads are of different nature. There is a certain constant level of heat loss associated with the thickness of the wall and roof structure. There are temporary ones - with a sharp drop in temperature, with intensive ventilation. The calculation of the entire thermal load takes this into account.

Seasonal loads

This is the name given to weather-related heat loss. These include:

- the difference between the outside and indoor temperatures;

- wind speed and direction;

- amount of solar radiation - with high insolation of the building and a large number of sunny days, even in winter the house cools less;

- air humidity.

Seasonal load is distinguished by a variable annual schedule and a constant daily schedule. Seasonal heat load is heating, ventilation and air conditioning. The first 2 types are classified as winter.

Constant thermal

Industrial refrigeration equipment generates large amounts of heat

Year-round services include hot water supply and technological devices. The latter is important for industrial enterprises: digesters, industrial refrigerators, and steaming chambers emit enormous amounts of heat.

In residential buildings, the load on hot water supply becomes comparable to the heating load. This value changes little throughout the year, but fluctuates greatly depending on the time of day and day of the week. In summer, the consumption of hot water decreases by 30%, since the temperature of the water in the cold water supply is 12 degrees higher than in winter. During the cold season, hot water consumption increases, especially on weekends.

Dry heat

Comfort mode is determined by air temperature and humidity. These parameters are calculated based on the concepts of dry and latent heat. Dry is a value measured with a special dry thermometer. It is affected by:

- glazing and doorways;

- sun and heat loads on winter heating;

- partitions between rooms with different temperatures, floors above empty space, ceilings under attics;

- cracks, crevices, gaps in walls and doors;

- air ducts outside heated zones and ventilation;

- equipment;

- People.

Floors on a concrete foundation and underground walls are not taken into account in the calculations.

Latent heat

Room humidity increases the temperature inside

This parameter determines the air humidity. The source is:

- equipment – heats the air, reduces humidity;

- people are a source of moisture;

- air currents passing through cracks and crevices in walls.