A garage often performs several functions for its owner. In addition to its main purpose of storing the car from intruders and natural disasters, it also serves as a repair area and a warehouse for spare parts, fuel and lubricants, and often a resting place. If it's summer outside, there are no questions. Open the gate, turn on the carrier and repair as necessary. But if the temperature outside is very sub-zero, then you can forget about a comfortable pastime or work. And it’s worth thinking about how to build heating in a garage using antifreeze with your own hands, if no other decisions have been made.

How to make heating in a garage using antifreeze?

There are many ways to effectively heat your garage.

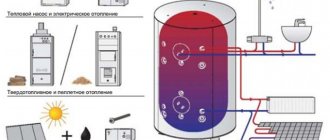

One of the most effective is the use of a water heating system. Due to their many advantages, the demand for them is quite high. But they have one big drawback - in severe frosts, the water in the pipes can freeze. To avoid this, many garage owners add various antifreezes to the complex. As practice shows, the garage heating system using antifreeze is quite effective. Types of equipping a garage with a heating system with antifreeze as a coolant:

- installation of the system from scratch, taking into account the properties of antifreeze;

- adaptation of the existing water heating system for the use of antifreeze:

- revision of technological connections and joints;

- installation of additional radiators;

- installation of exhaust ventilation.

Advantages and disadvantages

Attention: Antifreeze does not freeze in heating systems even in severe frosts. This is precisely its main advantage. The maximum that can happen to him is that he will turn into a jelly-like substance. But this will not affect the quality of heating in any way. After all, when heated, it will become liquid again.

Antifreeze can be used effectively in high-temperature circuits, as it has a high boiling point, which is 110-125 degrees. But when choosing a temperature mode, you need to take into account that it heats up more slowly than water.

Antifreeze has not only advantages, but also some disadvantages that should definitely be taken into account.

The disadvantages of antifreeze are:

- High viscosity compared to water. To pump it through pipes, additional power will be required. The circular pump will need to be replaced with a more powerful one.

- The heat capacity of this coolant is 1-15% lower than that of water. To compensate for this, it will be necessary to install additional radiator sections, heat exchangers, etc.

- High fluidity, which requires good sealing of all connections on the heating system. Rubber gaskets should be replaced with paronite gaskets.

- The service life of antifreeze, like many other antifreezes, is no more than 5 years. After which, it needs to be completely replaced.

- When stagnant, it forms white flakes, which, when settled, can ruin the heating structure.

Antifreeze has one more drawback. The most significant. It's poisonous. It is necessary to use this composition in the heating system so that it cannot enter the room. The heating system must not have any leaks and be sealed at the connections. After all, as already mentioned, the fluidity of this substance is greater than that of water, and it can leak even through a minor crack.

A leak of antifreeze is not immediately detected, and in order to avoid inhaling its vapors, which easily escape under the influence of high temperatures, you should carefully consider the condition of the heating system and inspect it from time to time for any damage.

Attention: If a leak is detected, you should immediately fix it, ventilate the garage and thoroughly wash the floor.

In addition, under no circumstances should it be poured into the heating system if a double-circuit boiler is used, since the substance can easily get into the hot water circuit and the consequences of this will be very unpleasant.

Filling the heating system

If you are not afraid that antifreeze is poisonous and you decide to pour it into the heating rack, you need to fully comply with safety precautions both when pouring and during subsequent operation.

Remember, before pouring, the antifreeze should be diluted. It should not be used in concentrated form, as it can cause damage to the heating boiler and circulation pump. When diluting antifreeze, you can independently choose the desired ratio of water and antifreeze. But first you should find out the lowest temperature at which its crystallization is possible. Most often, such information is available on the packaging.

Attention: Before pouring antifreeze, you should select the correct temperature conditions. Its name indicates the temperature at which its crystallization occurs. For example, A40-M (-40 degrees). Please note that the finished coolant should not be diluted with water. It is necessary to use concentrates that consist of 95% ethylene glycol. Using it for pouring, you can independently select the desired ratio of concentrate to water.

When diluting it with water, it should be taken into account that if it freezes at a temperature of -40 degrees, then the ratio of water and concentrate should be 1:1. At freezing temperature - 30 degrees 2:3. And if freezing occurs at -20 degrees, the ratio is 1:2.

Before pouring it into the heating system, all existing coolant should be drained from it, and the radiators and pipes should be thoroughly rinsed. All internal contamination must be removed. It is best to wash several times to achieve better results. If any antifreeze was previously poured into the system, it must be completely drained. You should not mix it with the antifreeze you are pouring.

The system used to heat a garage using antifreeze requires sealing the heating system and replacing rubber gaskets. If necessary, detected violations should be corrected. Pressure testing must be carried out, which is necessary to check the heating system for possible excesses of normal pressure. Thanks to this procedure, hidden defects can be detected.

But first you should find out the quality of the concentrate to find out whether it can be poured into the heating system. To find out, make a solution in a small glass container and leave it for several days. The temperature should be room temperature. If no foam or sediment forms, it can be used. Otherwise it should not be used.

Only after all these procedures, using a special pump, should you start pouring antifreeze. This should be done carefully.

Attention: Be sure to use a protective suit, respirator and gloves. The garage should be well ventilated at this time. If it gets on your skin when pouring, you should immediately wash it off with water. If you have a chemical burn, consult a doctor.

Malfunctions associated with the use of low-quality antifreeze.

In recent years, Russian motorists have realized the importance of using high-quality consumables and oils when servicing their equipment. Unfortunately, this statement does not apply to the coolants used.

Many motorists are still fully confident that the use of low-quality antifreeze or antifreeze cannot seriously affect the performance of the car. You can often hear the following statement: “Previously, water was poured in and nothing…”. Meanwhile, according to the results of research by the world's leading automotive engineers, it was found that approximately 40% of all engine breakdowns are directly or indirectly related to improper maintenance of the engine cooling system.

The main types of malfunctions associated with the use of low-quality antifreeze and improper maintenance of the cooling system.

- Cavitation of the pump impeller Possible causes: Lack of anti-cavitation and anti-foam additives, impaired circulation of coolant in the system caused by deposits, increased operating temperature of the engine, lack of pressure in the cooling system, aeration of the coolant. Problems that arise: Pump failure, engine overheating, unplanned financial losses.

- Cavitation of a wet liner. Possible reasons: Lack of anti-cavitation and anti-foam additives, increased engine operating temperature, lack of pressure in the cooling system. Problems that arise: Engine seizure, antifreeze getting into the oil, engine overhaul, unplanned financial losses.

- Corrosion of parts of the engine cooling system. Possible causes: Lack of anti-corrosion and buffer additives or their imbalance, increased or decreased pH of the coolant, glycol oxidation due to overheating or ingress of fuel and lubricants, the presence of stray currents. Emerging problems: Destruction of engine parts, deterioration of heat dissipation/engine overheating, impaired coolant circulation/engine overheating/premature aging of oil, engine overhaul, unplanned financial losses.

- Deposits in the radiator and other parts of the cooling system. Possible causes: Use of hard water to dilute the coolant, excessive mineralization of the coolant, errors when adding additional additives. Emerging problems: Deterioration of heat dissipation/impaired coolant circulation/engine overheating/premature aging of oil, thermostat jamming, destruction of gaskets and seals, engine overhaul, unplanned financial losses.

- Formation of silicate gels. Possible reasons: Excessive mineralization of the coolant, errors when adding additional additives, lack of stabilizers. Emerging problems: Deterioration of heat dissipation/impaired coolant circulation/engine overheating/premature aging of oil, thermostat jamming, destruction of gaskets and seals, engine overhaul, unplanned financial losses.

And you still think you're saving money by using cheap, low-quality coolants?

Heating system

Heating your garage with antifreeze requires the installation of larger radiators and a more powerful circulation pump. In addition, attention should be paid to installed radiators and pipes. Since antifreeze and many similar antifreezes are made on the basis of ethylene glycol, you should find out in advance whether they can be used as a coolant in the presence of aluminum or bimetallic radiators and galvanized pipes.

Types of antifreeze: green, red, blue. Which one to choose - the differences and effects of each on the metal of the heating system and components.

Otherwise, the antifreeze used may have a negative impact on the heating system, for example by causing metal corrosion.

Before pouring antifreeze, be sure to make sure that it will not cause harm to your heating system. Also, consider the risks and costs associated with its operation. Please note that the lower the concentration of coolant, the less likely it is to get burned if it gets on your skin.

Antifreeze can be used quite effectively for heating a garage. Its use allows you to achieve warmth in it and avoid freezing of the system even in severe frosts. But it should be used with caution, as it is very toxic. When using it, you must follow safety rules. Do not use it under any circumstances if you have a double-circuit boiler.

Main types of garage heating

The choice of heating system and type depends on the location of the garage. If the building is located near the house or on site, with a gas pipeline connected, in this case everything is simple; by installing a gas boiler, you can install a pipeline and install heating devices.

If you need to install heating in a garage cooperative, such a system can be equipped using:

- an expensive system with electrical appliances or a boiler;

- heating from a gas boiler powered by cylinders. This is not the cheapest method; you will need to spend money on refilling cylinders;

- using wood or coal as fuel will require the allocation of space in the garage for fuel storage. But this scheme is the cheapest and it is possible to make a furnace with a water circuit yourself if you have skills in electric welding;

- An expensive universal means for heating a garage - an electric - wood-burning boiler for heating. This scheme is available when installed in several bays of car repair shops;

- The cheapest and most accessible way to heat a garage with water is a homemade or industrial stove that runs on used motor oil. Such fuel is available, does not take up much space in the garage, and a system filled with antifreeze will not defrost even at significant sub-zero temperatures.

In any case, if you need to make water heating, it is better to fill the system with antifreeze. We'll talk about its positive and negative sides in the next chapter.

It is important to know! In the worst case, at a very low, prohibitive temperature, antifreeze turns into a jelly-like mass. It easily turns into liquid when the boiler is turned on.

The main advantages and disadvantages of a system filled with antifreeze

The advantages of the method include:

- The boiling point of antifreeze is 1100-1250, so it is preferable to use it in individual heating systems with high fuel combustion temperatures. At the same time, the air in the room will heat up more slowly, so this feature of the coolant must be taken into account;

- prevents the formation of scale on the walls of boilers, and accordingly increases the service life of the equipment;

A heating system in a garage filled with antifreeze has its negative aspects, which include:

- a higher level of viscosity will require the installation of a powerful circulation pump;

- Antifreeze has a low level of heat capacity; to achieve a level of room heating similar to water heating, it will require the installation of additional sections on radiators;

- high penetrating ability of antifreeze requires tightness of all wiring connections;

- for gaskets you will have to use expensive paronite;

- water heating of a garage using antifreeze as a coolant will require a complete replacement of antifreeze in 4-5 years;

- the most important disadvantage is its toxicity to humans. Therefore, it is important to make the heating circuit completely sealed and monitor this constantly.

Important! For optimal, safe operating conditions of a boiler with a water circuit filled with antifreeze, it is important to choose the right coolant according to its composition. It is not recommended to dilute the finished antifreeze with plain water before filling the system. In this case, the freezing point of the liquid changes. Only special concentrates can be diluted, but strictly according to the instructions. Concentrated antifreeze consists of 95% propylene glycol.

Air heating

Air heating of a garage is based on the use of special heat guns, heat fans and curtains. They all work on a simple principle: the device is connected to the network - the built-in fan blows air - it passes through the built-in heating device - the room is heated.

Such devices allow you to warm up rooms of a wide variety of sizes in the shortest possible time. There are both electric models that operate from an ordinary household network, and fan heaters. using a variety of fuels for their work.

- quick heating of rooms;

- maintaining the temperature at the required level;

- ease of connection and use.

The only disadvantages include the relatively high cost of maintaining the system in the case of using electrical appliances. Also, under the influence of air flow in the room, dust will rise and settle on various objects. Therefore, you will have to regularly clean the garage.

The main way to properly prepare coolant for a garage heating system

The most popular for heating is concentrated antifreeze, with certain characteristics. In this case, using the instructions, you can prepare the antifreeze that is most suitable for your climate zone. Another advantage of this solution is that counterfeit ready-made antifreezes and antifreezes are most common on the market. But you should remember - the coolant is diluted only with distilled water.

First of all, you should determine the required maximum subzero temperature, after which the composition thickens and crystallizes. This can be achieved by proceeding according to the following scheme:

- when combining antifreeze and water in a ratio of 1/1 – the freezing point is 400 degrees below zero;

- if it is required that the coolant does not crystallize at -400 - in this case, the mixture is diluted 2/3;

- taking 1 part of the concentrate, adding 2 parts of the distillate - we get a coolant that does not freeze at -200.

To check the quality of the concentrate, you can do the following:

- dilute a small volume of the mixture in a certain proportion;

- pour it into a transparent glass container;

- leave the solution in the garage for several days at above-zero temperatures;

- inspect the solution if sediment has formed or foam has formed - it is not recommended to pour such antifreeze into water heating in the garage. Such formations indicate low quality of the concentrate.

When using a combination stove or boiler for a garage with antifreeze filled, it is important when replacing not only to properly dilute the concentrate, but also to fill the system with it.

Pour antifreeze into the garage water heating

To do this, you will need to prepare a garage heating system with your own hands. This is not a difficult, but responsible operation. We remove water from pipelines and registers. It is important to note that waste coolant cannot be poured under plants or onto the ground. It is better to collect it in containers and drain it into the storm drain.

Further operations are performed in the following order:

- It is important to rinse the pipes and radiators thoroughly; to do this, close the drain valve and fill the system with clean water. You can add citric acid, this treatment removes alkaline scale from pipes. After starting the boiler, heating the water, let it cool slightly and drain. The operation should be repeated several times.

- When filling with water for the last time, be sure to check all pipes, joints and registers for leaks and fistulas. When they are detected, such places are cleaned and boiled or crimped with clamps with paranitic gaskets. At all connections where there are rubber seals, it is necessary to replace them with paranit.

- After these operations, having filled the system, turn on the boiler, bring the temperature to operating temperature and check the tightness of the connections. Some experts advise pressure testing of the heating, but this is unnecessary, we do not have prohibitive pressures.

- Now pour liquid into the heating. It is important to do this evenly, in a small stream. You already know the optimal volume of antifreeze to fill the garage heating system. Remember that after filling the system, it is necessary to remove any air pockets from it. This is done at the top point of the system using a tap or it is equipped with an expansion tank.

Now you can start the boiler and once again check the tightness of the joints and the absence of air in the liquid heating system of the garage. It is important to remember that antifreeze is a toxic material. If the substance gets on the mucous membranes, they should be immediately rinsed with water. Carry out work with the gates of the box open.

In conclusion, some advice.

You can heat a garage using a potbelly stove or stoves, but fumes, smoke and space for storing firewood make this method costly and inconvenient. You don’t have to be smart and install an electric convector or boiler, but this technique significantly increases the figures on your electricity bill.

Regardless of the choice of types of liquid heating in the garage, we recommend using antifreeze as a coolant. Good luck.

Heating Requirements

You should not try to make cheap garage heating with your own hands - after all, the desire for cheapness can result in serious problems. Moreover, there are not so much cheap as economical options that will allow you to create the required temperature conditions with minimal energy costs.

When organizing heating in a garage, the following parameters must be observed:

- reliability;

- resistance to sudden changes in ambient air temperature;

- relative autonomy, allowing you to continue heating the room even when disconnected from the power supply.

It is important to fulfill the following conditions:

- ensuring maximum heat retention in the room - when insulating walls, roofs and gates, heat loss will be minimal;

- create a well-thought-out ventilation system.

Without providing thermal insulation and proper ventilation, it will not be possible to create an effective and thoughtful, economical heating system!

For a garage, a temperature of +100C is quite enough to maintain the car, start its engine without problems and guarantee normal humidity.

Antifreeze garage heating system

A garage often performs several functions for its owner. In addition to its main purpose of storing the car from intruders and natural disasters, it also serves as a repair area and a warehouse for spare parts, fuel and lubricants, and often a resting place. If it's summer outside, there are no questions. Open the gate, turn on the carrier and repair as necessary. But if the temperature outside is very sub-zero, then you can forget about a comfortable pastime or work. And it’s worth thinking about how to build heating in a garage using antifreeze with your own hands, if no other decisions have been made.

Safety precautions

To avoid unpleasant consequences, you should adhere to the following recommendations:

- equip a high-quality ventilation system;

- do not store fuels and lubricants in large volumes;

- do not smoke indoors;

- purchase a fire extinguisher;

- install smoke detectors;

- refuel the car only outside the garage;

- dispose of unnecessary rags immediately;

- do not carry out any hot work indoors;

- do not install homemade electrical units;

- nearby, arrange a place to store sand and water containers.

Advantages and disadvantages of using antifreeze in a heating system

The main reason why antifreeze is poured into the garage heating system is that in this case there is no need to worry about the batteries defrosting during severe frosts. The crystallization threshold of antifreeze is much lower than that of ordinary water. Depending on the brand, it does not freeze at -20, -30 and even -40 degrees. Antifreeze, of course, may thicken somewhat, but this will have absolutely no effect on its qualities and when heated it will quickly turn into a liquid state again. At the same time, its boiling point is higher than that of water, so in this respect it is safer.

However, there are many more disadvantages, or more precisely, some inconveniences, of using antifreeze in a garage heating system installed with your own hands. It’s worth mentioning right away that these inconveniences relate rather to the process of assembling the system, during which it is necessary to observe certain safety measures and take into account the properties of this non-freezing liquid. All of them are worth listing and explaining a little:

- Viscosity. This property of antifreeze, which is much higher than that of water, requires the installation of a more powerful circular pump.

- The heat capacity, on the contrary, is much lower. That is, when the water heats up to 30 degrees, the antifreeze under the same initial conditions will only reach 20-25 degrees. And this can only be compensated for by installing additional radiators.

- Fluidity. This component is also high-grade, which means you will have to carefully check the system for cracks in order to avoid the slightest leak.

- With a long absence of circulation, in other words, stagnation of liquid, flakes can form, which, settling, can render the entire heating system unusable.

- Lifetime. Antifreeze will serve as a garage heating liquid for no more than five years. After this, you will have to drain it, thoroughly rinse the entire system and fill in a new one.

- And the main disadvantage of antifreeze is that it is poisonous. And not only the liquid itself, but also its vapor. And under the above-mentioned condition of increased fluidity, the possibility of it leaking and entering the atmosphere of the garage is very possible. If this problem is detected, you should immediately eliminate the cause of the leak, thoroughly rinse and ventilate the room.

There are many more disadvantages. However, this does not mean at all that you should forget about a garage heating system using antifreeze, installed by yourself. It’s just that all work on the installation of heat exchangers, heating radiators and pipes needs to be carried out more carefully and in compliance with all safety regulations.

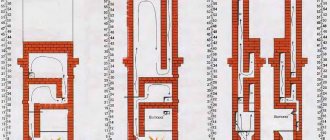

Heating in a garage using antifreeze - installation details

Installation of the entire heating system begins from the stove.

- Based on our preferences and capabilities, we install a heating device in the selected location. Electric or gas boiler. A stove that runs on wood, exhaust or another type of fuel.

- We hang aluminum or cast iron radiators in such a way that the heating of the entire room is uniform.

- Pipes for connecting radiators to the stove should be selected taking into account the viscosity of the antifreeze. That is, their diameter must be at least 1.5 times larger than for water heating.

- The circular pump is installed in the system at a distance of at least 1 meter from the heating device. It is recommended to install shut-off valves on both sides. This is done so that it is possible, if necessary, to remove the pump, without having to drain the antifreeze from the entire system. The pump itself should be selected so that it is twice as powerful as when used in a similar heating system operating on water.

- We install the expansion tank as high as possible. The ideal option would be to take it to the roof

- Carefully connect all elements. It is better not to use threaded connections. This is due to the increased fluidity of antifreeze, which easily seeps through such connections. But a high-quality welding seam will easily hold it.

- Filling the antifreeze system is carried out as follows:

- Approximately 2/3 of the required volume is poured into the expansion tank.

- The circulation pump turns on.

- You should drive the system a little, carefully monitoring the antifreeze level.

- Add if necessary.

- After making sure that everything is working properly, there are no leaks and the antifreeze level is appropriate, you should carefully seal the expansion tank.

- Now you can start the stove for the first time.

- During the first month or two, it is recommended to conduct a daily visual inspection of the entire system, especially the joints and connections for leaks and other faults.

When installing a heating system in a garage using antifreeze, special attention should be paid to ensuring that all elements are made of materials that are neutral to the substances contained in this non-freezing liquid. Aluminum meets these requirements, but it is quite expensive and much more difficult to install. You can use thick-walled iron pipes, especially if your system includes a homemade stove.

What to think about at the preliminary stage

Rarely lucky people are lucky enough to have a centralized heating system in their garage. This is possible if you have a shared indoor parking space or the garage is located directly in the structure of a country house.

In the remaining 99%, the stall for the iron horse is located in a garage cooperative and is a brick or metal bunker without any amenities

Therefore, the heating system must be autonomous. Before you consider purchasing a heating device, do your homework. What should be done:

- The garage needs to be insulated. Simply heating an iron bunker is literally throwing money away. Brick, metal or sandwich - all this needs additional insulation. You need to make sure that all cracks are securely caulked. It is better to place the heat insulator on the outside of the walls, but if this is not possible, the inner layer will also work. Particular attention should be paid to the floor - this is also a large area for heat loss. It should be covered with insulating material.

Don’t forget about the roof - otherwise all the heat will escape through it - It is necessary to provide high-quality ventilation. Sad statistics show that most tragic incidents in garages occur in winter. Careful insulation of the room does not allow for normal air exchange. Simply warming up the car for a few minutes before leaving can end very sadly. What can we say about the situation when the boiler is constantly running in the room.

For car boxes, it is better to use ventilation systems that combine natural and forced ventilation

Other garage heating options

For regions with frosty and long winters, antifreeze in the garage heating system is the most acceptable option. However, there are other ways.

- Water heating. The system is identical to the one described above. Only instead of antifreeze, water is poured into it. Heats up faster. Among multi-level homemade products, one of the simplest. But in case of untimely start-up, it can lead to defrosting of the pipes and complete failure.

- Air heating. Probably the only system that does not have significant drawbacks. Installation is no more difficult. Can be left indefinitely without needing to reheat.

- Electric heating. Using air heaters, air guns and other devices. Practically safe, but very expensive.

- On liquefied gas. A gas heating boiler is required, to which a propane cylinder is connected. Quite an economical option, but there is a risk of fire. It is not recommended to leave a running installation unattended.

- Potbelly stove. A small iron stove that consumes all types of solid fuel. Fast heating, good heat dissipation. The disadvantages include the mandatory construction of a chimney and increased fire hazard.

Whatever type of heating system you install in your garage, the main thing is to understand that safety should always come first. Choose a place for the stove away from reserves of fuels and lubricants.

Types of heated floors

Warm floors come in water and electric types; they differ in heating method, design and construction technology.

Below we will analyze each type in detail, their advantages and disadvantages, and provide instructions on how to install them yourself.

Mermen

A water floor is a structure made of pipes (metal-plastic or steel - find out which pipes are best to choose and why) through which the heated coolant moves. The structure is connected to a central heating system or to an autonomous power source (gas, electric or solid fuel boilers).

There are two technologies for installing a water system:

- by pouring a concrete screed;

- in a flat way.

Such heating is capable of heating concrete evenly, without spending on electricity. However, there are additional costs - for the purchase of a pump and boiler (with an autonomous connection). And if the device does not turn on for a long time, the liquid in the pipes will freeze, and this will lead to failure of the entire structure.

Article on the topic: What is the best way to make an exhaust hood in a sauna when the firebox is from the street - pros and cons

Electrical

Electrical systems run on electricity. They are:

- cable - the heating element is a cable, single or two-core, or self-regulating;

- infrared film, heat source - carbon emitter that emits infrared rays.

The advantage of electric types is that there is no danger of leakage. When installing an infrared model, it is also easy to install. Disadvantages include energy costs.