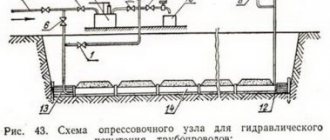

Pressure testing of a pipeline is a technological operation performed on a relatively small isolated section of the pipeline. This section is specially tested by applying high pressure, close in value to the maximum permissible. Carrying out pressure testing of pipelines allows you to verify the integrity of the line, the quality of installation work and installation of fittings.

Pressure testing is a necessary and important operation that allows you to identify weak points in the assembled pipeline

The concept of pipe crimping

Pressure testing means checking the readiness of an object for operation by applying increased pressure. The object of such a check may be a pipeline system, a container, an assembly or machine, or a separate mechanism. When we talk about increased pressure, we mean a value that is 2-3 times higher than the working pressure and is close to the maximum permissible. An object that has successfully passed pressure testing is considered suitable for use. Leaks identified during the inspection are repaired.

Important! The amount of pressure during pressure testing is regulated by regulatory documents for certain groups of objects.

Pressure testing must be carried out by a trained specialist. Relevant employees of industrial and utility enterprises are required to undergo certification. Upon completion of the tests, a report is signed indicating the date, pressure value, holding time and other information.

The pressure in the system for testing is created either by a standard pump or a special pressure tester. They check, as usual, with water. When its use, for some reason, is unacceptable, air pressure testing of pipes is carried out, which makes it difficult to detect leaks.

Price

The cost of crimping depends on several factors:

- length (internal volume) of the system;

- the age of the system and the condition of its constituent elements (amount of rust and dirt and salt deposits);

- type of equipment used.

Prices from different performers, even within the same city, may differ by 2–3 times. Private teams and craftsmen charge the cheapest for their services.

On average, for flushing and pressure testing the heating system of a building with an area of 400 sq. m (two-story) performers charge from 7 to 15 thousand rubles. As practice has shown, if you know how to bargain, you can agree to complete this amount of work for 4–5 thousand rubles. The work will be completed in 1 – 2 days.

The same work in a building of 5 thousand square meters. m (5 floors) will cost from 30 to 80 thousand rubles.

Some performers indicate prices per unit of volume (150 - 250 rubles / cubic meter) or time (500 - 1000 rubles / hour).

If you want to install the washbasin yourself, be sure to take care of connecting the water seal. Water seal for sewerage: types, purpose and installation features.

You will learn about the types of antiseptics for cesspools in this review.

When is pressure testing of pipelines carried out?

All new pipeline systems, tanks, etc. are subject to pressure testing before putting into operation. All objects that have undergone repair or replacement of some element are also checked. Since the joints with installed fittings are considered to be the most unreliable sections of the pipeline, sections where coupling was used are subject to mandatory inspection.

All types of pipelines, domestic and industrial, newly built and already in operation are subject to pressure testing

Testing is also carried out in other cases:

- if the pipeline has been idle for a long time or operates in seasonal mode (like a heating system in the summer);

- if scheduled inspections are provided. In this way, the polymer sewer system is checked when the integrity of the outlet pipeline is monitored. Pressure testing of a plastic water supply is one of the most popular operations carried out after any pipe cleaning, since mechanical damage is very likely, especially at the joints;

- after flushing the pipeline, especially with the use of aggressive chemicals, which could cause damage to fittings or pipe walls;

- Wells are tested in a special way - to check whether perched water (water from the surface layers) gets into its shaft, because consumers are concerned about the quality of water, especially drinking water.

Flushing heating systems

Hydropneumatic flushing of heating systems is a mandatory measure when preparing the heating system for start-up before the start of the heating season.

Water circulates through a closed circuit of the heating system during the heating period, and when heated and cooled, hardness salts are deposited. And this, together with the processes of corrosion of the internal walls of the pipes, leads to the deposition of scale on them. Scale significantly reduces the internal cross-section of pipelines, increases the hydraulic resistance of the system and reduces the heat transfer of radiators.

In high-temperature heating systems, scale leads to local overheating and further formation of fistulas. Scale deposits one millimeter thick lead to a reduction in heat transfer from the heating system by 15-20%. And on a global scale, this means colossal losses of thermal power and a significant decrease in the energy efficiency of the system with a significant increase in the cost of heating the building.

Flushing heating systems is the same necessary annual event as pressure testing, and is carried out before the start of the heating season or at the time of commissioning.

The main sign of a “clogged” heating system is an increase in coolant consumption, an increase in warm-up time, or uneven heating of the radiators. In these cases, situations often arise when the pipelines are hot, but the radiators are not yet warmed up.

The hydropneumatic method involves filling the system with clean water and connecting an air compressor to it. Excessive air pressure increases the flow rate of the coolant and creates turbulent fluid flows. These flows in places of scale deposits create vortex vibrations, as a result of which contaminant particles are torn off the surface of the walls.

When supplying high pressure air, the valve on the air bleed valves must be closed, and a check valve must be installed to protect the compressor from water entering the system.

Also, for flushing the system, there are special solutions that break down the scale deposited on the walls of pipelines and thereby reduce their hydraulic resistance.

Preparation for work

Carrying out pressure testing is a responsible procedure that requires preparatory measures. Before starting pipeline testing, it is mandatory to:

- An inspection is carried out to identify visually detectable defects (corroded areas, missing parts, etc.). If violations are identified, they are eliminated. In cases where the system contains a working medium that is prohibited from being used for testing, it is customary to empty it (for example, the heating system is freed from coolant).

- The pipes are washed to remove rust, scale, and deposits of organic and inorganic origin. Some of the flushing methods require the use of a compressor. Upon completion of washing, the quality of its implementation is checked. The quality of flushing is checked by the condition of the inner surface of a half-meter section of the pipeline cut out at a randomly selected location.

To carry out work, a pressure gauge must be installed on the equipment to control the pressure.

If the injection device does not include a check valve that retains the working medium in the system, and a pressure gauge, then they are installed after completion of the tests.

It is important to know! Pressure testing of the heating system of an apartment building precedes an inspection of the work on preparing the associated heating unit. This is explained by the fact that the thermal unit is checked using high pressure values.

Call specialists or do it yourself

If for some purpose you require a pressure test certificate for your heating or hot water supply system, you have only one option - order this service from a specialized organization. The cost of heating pressure testing can only be quoted to you individually. It depends on the volume of the system, its structure, the presence of shut-off valves and their condition. In general, the cost is calculated based on the tariff for 1 hour of work, and it ranges from 1000 rubles/hour to 2500 rubles/hour. You will have to call different organizations and inquire with them.

Companies involved in hydraulic system testing have more serious equipment.

If you have upgraded the heating or hot water supply of your own home, and you know for sure that your pipes and equipment are in good condition, there are no salts or deposits in them, you can carry out pressure testing yourself. No one will demand hydraulic test certificates from you. Even if you see that your pipes and radiators are clogged, you can wash everything yourself and then test it again. If you just don’t want to do this, you can call specialists. They will immediately clean the system and pressure test it, and will also issue you a certificate.

Certificate of hydrostatic testing of the system (pressure testing)

Mechanisms for carrying out

Crimping operators, i.e. Special pumps for carrying out relevant tests differ in design. Based on this feature, they are classified into three types:

- Porshnev.

- Vane-rotor.

- Membrane.

If testing of a pipeline (or other object) of a relatively small volume is required (for example, in private housing construction), then it can be performed using an inexpensive and easy-to-maintain manual pressure tester. This mechanism allows you to pump up to three liters of working fluid into the system in a minute.

To check the systems of a multi-story building, you will need a more powerful mechanism driven by an internal combustion engine or electric. The domestic UGO-30 is equipped with a 16-liter tank and allows you to develop a pressure of up to 30 atm. Manual two-stage pumps UGO-50 and UGO-450 are used when performing more complex tasks.

In domestic conditions, compact devices are used that can be manually controlled.

German-assembled electrically driven crimpers produced by Rothenberger (model ROTEST GW 150/4, for example, designed for testing drinking water and gas supply systems with air) and Ridgid (for example, model 1460-E 19021 are used in systems filled with as a working fluid water, oil or ethylene glycol).

Equipment

If pressure testing is carried out in centralized heaters, then the staff uses standard devices. Private heating or water supply involves the use of slightly different devices. The electrical device used in the work is a special pump.

There are two pump options.

- The handheld device is a self-contained device. The system is controlled by pressure applied using the device lever. Pumps of this type are considered suitable for a small private house. Using a manual pump for volumetric systems is quite difficult, since at the same time you need to pump up pressure and monitor the indicators using the built-in pressure gauge in the unit.

- Electric pumps are more complex and expensive. They are convenient for crimping, since they initially have the ability to create a certain pressure. The necessary indicators are entered by the operator, and it will be entered into the system automatically. It is not necessary to buy such a crimping machine if we are talking about private one-time use.

These devices are usually available from companies that provide professional crimping services. Home heating is rarely tested annually. If we compare the cost of devices, the difference will be about 25%. Companies that provide crimping services sometimes rent out their equipment. You can specify the price of services, but usually they are identical to the cost of the equipment itself.

Not in all cases the work can be carried out independently. If this work is needed as evidence of checking the integrity of the heating system, then a confirmation certificate is often needed. Such paper will be issued only if the work is carried out taking into account all regulatory requirements and by specialists who have special permission to do so. The cost of this activity is not specified in legislation; it is usually calculated individually. Company prices are related to the volume of systems, as well as the architectural features of buildings. Much also depends on the condition of the shut-off valves installed on the system.

Tariffs are taken into account based on the cost of work per hour, they vary from 1000 to 2500 rubles. However, if papers confirming the work are not required, but there is a desire to start pressure testing the system, then you can do it yourself. Moreover, hydraulic tests are possible even with clogged radiators and pipes. Hydraulic presses come in different capacities. Pumping units used to test systems are also called pressure testers.

Often, crimping equipment is confused with other types of devices, for example, a hydraulic electric press is used for pressing bearings, gears, shafts and other things. This tool is also used for stamping plastic and rubber products. The machine, which is a hydraulic press, is not used for crimping the heating system. This equipment is usually used in auto repair shops.

There is also a crimping press - this is a device that is used to tighten press fittings. This tool is also called press pliers, and its purpose, of course, is related to the arrangement of the heating system, however, this tool is not suitable for crimping.

SNiP and safety measures during crimp testing

The procedure for testing pipelines, technological diagrams of the pressure testing process and safety standards are determined by the relevant sections of SNiP:

- for internal sanitary systems - SNiP 3.05.01-85;

- for external drainage systems - SNiP 3.05.04-85;

- for heating, ventilation and air conditioning systems - SNiP 41-01-2003.

Industry regulations define the procedure for performing pressure testing on industrial pipelines.

The specified documents establish the pressure values permissible during testing. This value is determined by the material of the pipes, the minimum thickness of their walls, the difference in height between the lower and upper elements of the system under test and other factors. When conducting hydraulic and pneumatic tests, the pressure value can be (in atm):

- for pressure pipelines of water supply systems – 10-15;

- for cast iron sewerage – 1.5;

- for non-pressure polymer pipelines – 1.5 – 2;

- for heating systems of apartment buildings where cast iron radiators are installed - 2-5 (but not less than the value exceeding the operating pressure by 1.5 times);

- for input nodes of centralized systems – 10;

- for private houses - 2 (since the emergency valve is usually set to this level).

Pressure testing must be carried out in accordance with SNiP, taking into account the type of main line and the material of the pipes installed in it

Important! When conducting tests, the main safety requirement is to adhere to the recommended pressure limit. To avoid unpleasant consequences, it is recommended to use a crimping machine equipped with a special limiter when conducting tests.

Preparations

Before crimping pipes, you need to do certain work:

- The pipeline being tested is subject to inspection for specific faults (missing components, rusty fragments, etc.). Detection of disorganizations is eliminated. If the infrastructure is filled with some means, it must be emptied;

- Then the pipeline is washed. Here it is possible to eliminate scale, corrosion, and deposits of various types from the route. Cleaning can be carried out using a variety of technologies, some of which require the use of a supercharger. Adhering to the regulations, when finishing, you need to check the quality of its work by cutting off a half-meter part in a certain area and analyzing the position of its surface from the inside;

- Preparations end with the installation of a return valve and a pressure gauge, if they are not included in the design of the heating equipment. The reversible damper is needed to maintain the working area in the infrastructure;

General procedure for conducting pneumatic and hydraulic tests

The testing scheme for air and water is general. The procedure is as follows:

- Within the test object, a part of it is isolated and closed using shut-off (regulating) valves (the sewer pipes are plugged with rubber plugs or wooden plugs wrapped in rags).

- The test object is filled with water. When testing heating systems, when filled with water, air is discharged through special air vents in the upper part.

- A pressure tester is connected to the system, pumping a certain amount of working fluid to create the pressure required by regulatory standards.

- Having reached the required pressure value, recorded by the observer on the pressure gauge, the pressure tester turns off.

- The system is left under pressure for a certain time (for heating systems - at least half an hour; in some cases, the holding time can be 6-8 hours).

- At the end of the designated holding time, the observer again takes the pressure gauge readings. A difference in pressure gauge readings is evidence of a leak in the system that needs to be detected and eliminated.

You can connect the pressure tester to the heating system by removing one of the taps

Note! After the leak has been eliminated, the pressure test is carried out again.

Need for hydraulic tests

Pressure testing allows you to identify leaks in the system.

The operation is performed on a small section of the line, which is isolated from the main line and subjected to testing with increased pressure bordering on critical. A large volume of compressed air is pumped into the branch or a water flow is started under pressure. If the branch passes this test and maintains its integrity, it is considered suitable for further use. A breakthrough will be indicated by a drop in pressure on the pressure gauge.

The following must be subjected to hydraulic tests:

- newly created highways;

- repaired networks;

- plastic pipelines after cleaning;

- pipe sections after replacing a damaged section or installing a coupling or tee;

- water pipes in the apartment after connecting water meters;

- heating systems before the heating season.

Pressure tests of wells are carried out in order to check that there is no contact of the transported liquid with the upper layers of water in the mine. This is necessary to accurately determine the depth of water intake.

Pressure testing of pipelines with air and water

To test the performance of a heating, water supply or sewerage system, you will need a pump (special or one that circulates liquid in the system). It is connected to the heating system either:

- directly to the tap designed to drain the working fluid from the heating system;

- to any of the radiators. To do this, the Mayevsky tap is removed, and in its place an adapter is installed, to which the hose from the compressor is connected.

The water supply test is carried out through the connection pipe of the taps through which cold or hot water is supplied. To connect to the sewerage system, you will need to insert the sediment fitting into one of the revisions, special tees mounted in the outlet pipeline every 40-50 m.

Purchasing a crimping machine for personal use that will be used once a year is hardly advisable. Which pump to use to pump air or water into the system is determined based on the pressure that needs to be created for the test (and it should be 2-3 times higher than the working pressure). To pressurize the heating system of a private household, a car compressor or an electric pump should be sufficient.

Which method should I choose?

Many people have a question: which testing option is best for warm water floors? The air method is more convenient, since it is not always possible to put the system into operation in time when cold weather sets in, so there is a danger of freezing the entire pipeline.

With air pressure testing such problems will not arise. This is important for heating floors, since the coolant can be easily drained from the radiators, but this is quite difficult to do from floor circuits.

But with the air method, it is visually difficult to determine a leaky connection or a section of pipe through which air will escape. There will be no such problems with water, and you will immediately determine the right place.

In addition, when choosing a method for testing a heating system, you should take into account the type of pipes from which the water heating is made.

Adviсe

Even in a new apartment building with a newly commissioned system, about 10% of effective heating is lost during the first months. Sludge and corrosion appear in the connecting nodes, which causes scale and sediment to appear. Settling dirt reduces the efficiency of systems. The scale layer can be so massive that it interferes with heat transfer. Because of this, the elements wear out.

The first sign of scale deposits is uneven heating of the pipes. Usually in this case the bottom of the batteries is cold. You can also tell about the presence of scale by the characteristic crackling sound of the batteries. This effect occurs due to water vapor that enters the scale. At the same time, the power of boiler equipment decreases, and fuel costs increase.

The system is descaled using a chemical or physical method. Physical methods involve the use of special equipment - compressors. The chemical method is carried out using special preparations. In both cases, cleaning costs will be less than they would be if the node connections were replaced.

In a private apartment, flushing the heating system is possible using improvised means, for example, citric acid. Home craftsmen advise adding detergent with citric acid to the system. The aqueous solution with the products should be left in the system for a day. The soapy water from the system should then be drained, and the system itself should be flushed with a product like Calgon. You can also consider ready-made compositions offered in stores for flushing heating. Purchased funds can be used according to the method described above.

Flushing radiators separately from the system is possible if special taps are installed on them. The device includes a ball valve and a battery plug. A hose is connected to the device, the free end of which is discharged into the sewer. In addition to cleaning the system itself, sometimes it may be necessary to clean the boiler itself if we are talking about heating in a private apartment. When flushing equipment, water must be supplied in the opposite direction from the coolant flow.

In the case of equipment, mechanical or chemical methods can also be used. Boilers must be flushed separately from pipe systems. During cleaning, the equipment must be completely disconnected from the pipes. If the work is done correctly, most of the impurities will be removed. The heating system will operate at its full efficiency. There are no ways to completely eliminate corrosion of metal pipes, because the metal will in any case turn into rusty dust if the system is left without washing and cleaning.

Tests for tightness and strength are required regardless of the installation conditions of the system and the technologies used. When testing modern systems, this technology involves releasing the supplied pressure to the operating value while checking for possible leaks. If defects are found, they are eliminated and the test procedures are repeated again.

Modern techniques make it possible to find even small leaks. However, any problems require a visual inspection. Therefore, specialists checking systems in apartment buildings must have access to the apartments. To clarify the timing of work in your homes, you should contact the relevant housing and communal services service.

See below for tips on performing pressure testing of an air heating system.

Price category

It depends on the following reasons:

- Lengths (internal dimension) of the structure;

- The age of the structure and position of the segments included in the structure (the amount of corrosion, as well as mud and salt deposits);

- Class of equipment being used;

The cost of this operation among different manufacturers, even in the same city, can vary by about three times. Cheaper, it will be carried out by private groups or specialists.

Typically, for cleaning and pressure testing a structure with an area of about 400 square meters (2-storey), contractors charge from 8-16,000 rubles.

Some contractors determine the price category per unit of size (200-250 rubles/cubic meter) or time (800-1000 rubles/hour).

This is how the procedure is performed.

Video

- What is a heating point?

- Repairing leaks

- UUTE with VIS.T

- TO No. 1 of the thermal point

- TO No. 2 of the thermal point

< >

Air crimping

The essence of the process comes down to analyzing the state of the heating system: its tightness and resistance to coolant pressure. Pneumatic testing is carried out by pumping air. This method is used in low-rise buildings and private houses in the absence of the technical ability to conduct hydraulic tests.

Select a calculator to calculate the cost of work

- Calculation of the cost of a contract for hydraulic testing

- Calculation of the cost of chemical flushing of the heat exchanger

- Calculation of the cost of maintenance (TO) of ITP and TsTP

- Calculation of the cost of installing UUTE

- Calculation of the cost of designing a heating point

- Calculation of the cost of operating engineering systems

- Calculation of the cost of chemical flushing of central heating pipelines

- Calculation of the cost of diagnosing pipeline damage

Sequencing:

- Using shut-off valves, the circuit is cut off from the main heating pipeline, and the coolant (water or antifreeze) is drained from it.

- Pumping equipment is installed at the inlet (or outlet) of the circuit. Its functions can be performed by a mechanical pump or an electric compressor equipped with a pressure gauge.

- The system creates an excess - compared to the working - pressure of the environment, not exceeding 1.5 atm.

If the quantitative characteristic of the parameter is higher, depressurization of the pipeline may occur. This is fraught not only with its mechanical damage, but also with injury to those conducting testing.

- The readings of the pressure gauge indicate the time when the pressure of the medium has stabilized throughout the entire circuit. From this moment, observation of environmental parameters begins for half an hour.

- If the pressure in the pipeline does not drop, a conclusion is drawn that it is tight and ready for use in winter.

- If after 30 minutes the devices detect a decrease in pressure, the process stops.

Then a visual inspection of the pipeline is performed to identify mechanical damage. Once a breakdown is detected, the element is repaired or replaced. When installation is completed, the system is again checked for leaks.

Comments

April 28, 2017

_

How to pressurize a section of pipe at home? how to calculate the maximum pressure that a pipe can withstand - based on the diameter and wall thickness

0 0 Reply

April 28, 2017

Mikhail (o-trubah.ru) ➜

Pressure testing is also possible at home. To do this, a section of the pipe is cut off from the rest of the pipeline, and a special pressure testing pump is connected to it. After this, cold (!!!!) water is supplied to the area at a pressure exceeding the working one. As for the calculation, the withstand pressure depends not only on the dimensions, but also on the material. So the best way to find out is to study the tables provided by the pipe manufacturer.

0 0 Reply