Water-heated floors are gaining increasing popularity among residents of private houses, becoming a full-fledged alternative to traditional radiator heating. Installation of such a heating system is very complicated. It requires not only certain knowledge and skills, but also the use of high-quality materials that can last for decades.

Installation of water heated floor Rehau

For this reason, experienced installers, who have already encountered problems caused by incorrectly selected materials or errors during system installation, prefer to purchase products from trusted manufacturers. One of these manufacturers is the Rehau company, which began its work in the middle of the last century.

Thanks to its experience, the company is able to offer consumers Rehau heated floors - a system with all the components that greatly facilitate the work process.

Features of Rehau pipes

The main heating element in water-based floor heating options produced by Rehau is the Rautherm pipe. This element of the system is made of high-strength cross-linked polyethylene, the outer part of which is coated with an oxygen-protective material. Thanks to this combination, these pipes have certain advantages.

Characteristics and prices for Rehau pipes

- Rehau pipes are characterized by increased resistance to mechanical damage that occurs both during installation of the system and during its operation.

- Cross-linked polyethylene has high thermal conductivity, so it perfectly warms the floor surface.

- The pipes are very flexible, which eliminates the formation of kinks during their installation.

- This heating element is highly resistant to corrosion and internal deposits.

Rehau pipe structure - Cross-linked polyethylene is not exposed to chemicals, so during operation of the system, not only water, but also antifreeze can be poured into the pipes.

- The hydraulic version of floor heating, installed using a Rehau pipe, is not afraid of high temperatures and increased operating pressure.

This company produces pipes of the following diameters (wall thickness is indicated in brackets):

- 10.1 mm (1.1 mm);

- 14 mm (1.5 mm);

- 17 mm (2 mm);

- 20 mm (2 mm);

- 25 mm (2.3 mm);

- 32 mm (2.9 mm).

Rehau pipes

Types of heated floors

The pipe material does not react with chemicals in the water, so scale does not deposit on the walls.

Rehau offers 2 types of floor heaters: electric - Soletec, and water - Rautherm S and Rautitan. Both systems are economical, safe, and have an efficiency close to 100%.

Water

The basis of a water floor is pipes designed for an underfloor heater. They produce products with a diameter from 10.1 to 32 mm with a wall thickness from 1.1 to 2.9 mm. They have an additional oxygen-protective layer made of cross-linked polyethylene. This technology causes:

- high thermal conductivity - the pipe transfers heat to the floor surface with maximum high efficiency;

- outstanding operating parameters - the heater can withstand temperatures up to 90 degrees and pressure up to 6 bar;

- resistance to mechanical damage - the tubes are difficult to damage during installation, leakage is excluded;

- flexibility - when laying, they can be bent at any angle;

- no corrosion – cross-linked polyethylene is inert towards any chemically aggressive substances. No salts or clots are deposited on the walls of the pipes.

The pipes are connected to each other using moving sleeve technology, which guarantees complete tightness. O-rings are not needed, since they are provided in the design of the pipes themselves.

Rehau has developed all the joining and fixing elements for water heated floors: polystyrene mats, film panels, harpoon brackets, RAUFIX tires. The devices reduce installation time by 4 times.

Electric

Rehau cable flooring does not create magnetic radiation and can be installed in damp rooms.

Rehau cable flooring is devoid of the typical disadvantages of such a system. During production, a two-core cable reinforced with Kevlar is used. It can withstand higher loads and temperatures. Teflon insulation prevents overheating of the elements, and braided shielding protects the user from electromagnetic radiation.

The kit includes cables, laying mats, socket boxes, a protective tube for the sensor, rotation locks, and a corrugated pipe. The thickness of the cable is only 5.5 mm, and the thickness of the mat is 3.5 mm. Place the system in a screed or in a layer of tile adhesive directly under the tile. The heated floor practically does not change the height of the room.

The Rehau electric floor does not dry out the air, does not create an electromagnetic field, and does not overheat the coating. Installation is allowed in bathrooms, toilets, kitchens, and children's rooms. Any covering: linoleum, wood, ceramics, laminate, even carpet.

Floor heaters are equipped with digital programmable thermostats and analogue ones. The cost of the former is higher, but such a thermostat allows you not only to lower or increase the temperature, but also to create a heating mode, which reduces costs by 15–30%.

If the heated floor is the main heater, the thickness of the screed is less than 35 mm. Concrete accumulates heat: the thicker its layer, the longer the heated floor cools down.

Additional items

Installation of the Rehau water heated floor pipeline is carried out using special fasteners.

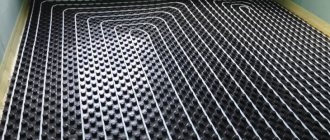

- Varionova mats are made of polystyrene foam and are equipped with clamps designed for securing pipes. In addition to the main function of facilitating installation, these elements are equipped with heat and sound insulating properties. The mats are fastened together using a connecting strip using the seam method. Mats with clamps and thermal insulation Rehau Varionova

- The Varionova panel is a film equipped with bosses and fasteners. Installation of the pipe on the film panel is carried out by laying it between the bosses. Panel with Varionova fasteners without insulation

- RAUFIX tires are made of rigid polypropylene and are an alternative to the previous elements, reducing the cost of the hydraulic floor heating option. The underside of the tires is equipped with special brackets that allow these elements to be securely fastened to any floor surface. The busbars are connected to each other by a locking connection. The advantages of using Raufix tires lie in their design features

Rehau water heated floor is a ready-made system, equipped with all the necessary fasteners designed for fixing mats and pipes on mats and panels. These include:

- harpoon clamps designed for fixing pipes; Tece harpoon bracket for heated floors

- clips for fixing mats. Insulating nails and clips for underfloor heating

Hydraulic underfloor heating from Rehau is controlled using a distribution manifold, available in various modifications. The most popular among consumers is the assembled manifold, equipped with a thermostat and a flow meter.

Fasteners

To secure the pipeline transporting the coolant, fastening systems are used. There are several such products.

Varionova fixing mats

The rigid polymer material from which they are made provides the mats with excellent mechanical stability. For example, they are able to withstand the load from the weight of an adult man, even if the top layer of the screed has not yet been poured. They provide greater speed of installation of Rehau floors compared to models from other manufacturers. Each product is equipped with clips designed for installation over pipes. Mats can be cut along special lines into individual fragments. They are then joined together using connecting elements. Pipes ø 14–17 mm are laid with a minimum step of 5 cm.

Specifications:

- The thickness of the coating is 2 mm; it is possible to choose products with or without a thermal insulating foam backing.

- Designed for laying pipelines with a diameter of 14 to 17 mm.

- The minimum laying step is 5 cm.

- To optimize installation, the surface of the mats has cutting lines and connecting elements for joining individual parts to each other.

RAUFIX tires

This is the best way to install an inexpensive heated floor. Tires made of rigid polypropylene, thanks to special brackets on the underside, are attached to almost any base. Such products have a small thickness, which is why the floor height increases by only 5 mm. The installation of the main line is carried out in increments of multiples of 5 cm. The tires are 1 meter long and 4 or 5 cm wide. The tires must be mounted on top of the thermal insulation layer.

How to install a Rehau underfloor heating system

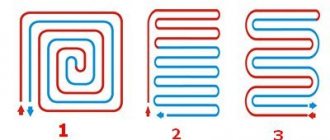

Before installing a Rehau water heated floor, it is necessary to draw up a project, which includes calculating the system power for each specific room, and choose a pipe laying method - snail or snake.

Pipeline layout diagrams

The floor structure must be installed in such a way that temperature changes are not felt during operation. The optimal step is the distance between the loops equal to 11-18 cm.

Depending on the diameter of the pipe, the maximum length of the circuit should not exceed 120 meters. Otherwise, the coolant will reach the farthest sections of the pipeline already cooled, which will directly affect the quality of heating.

Overview of installation of heated floors using Rehau technology

[ads-mob-1][ads-pc-1]

Design

The design of any heated floor begins with its calculation.

First of all, calculate the best possible power of the system using the calculated data of its specific heat capacity. On a note

The specific heat capacity of the heating complex in rooms provided with a good level of thermal insulation is about 70–150 watts per square meter. m.

The Rehau floor heating system consists of a number of elements:

- pipes with increased resistance to high pressure, which are made from cross-linked polyethylene. They are equipped with couplings and fittings that ensure reliable fastening;

- mounting elements, say, a mat with clamps;

- control units - combs, thermostats and temperature sensors.

Then select the installation scheme for the pipeline, laid in increments of 11–18 cm.

Attention

Please note that if the total length of the pipes being laid exceeds 15 m, then due to the temperature difference at the starting and ending points, the uniformity of heating in the pipeline will be disrupted.

After the layout plan has been drawn up, the elements of the water heated floor are selected.

Its configuration begins with the selection of pipes.

Installation process

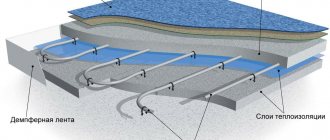

To prevent such heating from causing trouble in the future, its installation should begin with leveling the subfloor by applying special solutions and laying a damper tape, or a special profile for an expansion joint around the perimeter of the room and between the contours of the water-heated floor. In this way, it will be possible to compensate for the expansion that occurs during the heating of the pipe and avoid cracking of the concrete screed.

Laying scheme for water heated floors

When the base dries, thermal insulation in the form of sheets of expanded polystyrene is laid on it. And a polyethylene film is laid on top of it, on which the functions of waterproofing will be assigned. Moreover, thermal insulation is required only if the Rehau heated floor is planned to be laid on a film panel or tires. If mats are purchased, then the need for additional thermal insulation disappears.

Now you can begin installing the distribution manifold, which is connected to the heating boiler. Next, mats or panels with tires intended for securing the pipeline are laid. Pipes begin to be laid by connecting to the collectors. During the installation process, the pipes are secured to the mats using special fasteners.

Advantages and disadvantages of Rehau underfloor heating systems

Durable material - Kevlar, which covers the Rehau electric cable.

Any option of underfloor heating has the following advantages:

- Reliability - the cable is reinforced with Kevlar, and the water tubes are protected by a sheath made of cross-linked polyethylene. Both heating elements can withstand high loads and heat with a large margin - + 90 and +95 C at operating temperatures of +60 C.

- Overheating and destruction are excluded. Insulation and cross-linked polyethylene prevent mechanical damage;

- Flexible tubes and cables are laid according to different patterns and uniform heating of the entire area is achieved.

- No contamination – when the surface is evenly heated, there is no excess air circulation. Dust and dirt do not move around the room.

Rehau warm floors can be installed in apartments where allergy sufferers live.

There are also disadvantages:

- Installation of the system is technically simple, since the kit includes all the necessary elements for installation. However, connection diagrams and calculations are far from simple and require experience.

- Laying under the screed is a complex and messy process. But here the problem is not in the floor heater, but in the screed itself.

- Installation is carried out on a prepared floor.

Repairing an underfloor heater is difficult. To remove the damaged fragment, you need to remove the finishing coating, remove the screed or adhesive layer and replace the pipes or cables. This happens rarely: it is not for nothing that the manufacturer gives a guarantee on heating elements for a period of 10 years.

Pouring concrete screed

To ensure that the system works flawlessly and the floor warms up evenly, the pipes are filled with a cement-sand composition. To increase the strength of the structure, a reinforcing mesh is laid on top of it.

Scheme for pouring a concrete screed for a water heated floor

Before you begin finishing the floor, you need to wait until the screed has completely dried and gained strength. This process lasts 28 days. All this time the heating system must be turned off. Otherwise, the concrete may crack.

Installation of a water version of floor heating is much more expensive than its electric counterparts. However, its installation allows you to heat the room more evenly and create a healthier microclimate. In addition, the operation of such a floor is much cheaper than electric options. And after a few years, such heating completely pays for itself. [ads-pc-2][ads-mob-2]

Control elements

The main control device of the set is the comb. Rehau offers the consumer several modifications of the distribution manifold. The best option is a comb assembly, which includes a thermostat and a flow meter installed, respectively, on the inlet and outlet manifold. There are, of course, other options, since you can connect a water heated floor through a pumping and mixing unit. In this case, the components, say, a circular pump, are purchased separately.

Selection of mats for heated floors

Fixing tire for underfloor heating pipes brand Rehau

There are 3 types of substrate:

- Mats for warm water floors Rehau Varionova are made from foamed polystyrene. This model replaces the thermal insulation layer, as the material retains heat perfectly. The surface is embossed and includes fasteners of complex shape. The tubes are placed between the clamps.

- Varionova panels are a profiled polystyrene foam backing with square or cylindrical bosses. Heating pipes are placed between the projections. The panel also retains heat and dampens sound.

- RAUFIX tires – rigid polypropylene backing. There are sharp brackets on the underside so that the tire can be secured to any surface. Does not have thermal insulation properties.

The company also produces clips and harpoon clips for fixing heating elements.

If a heated floor is installed in a room above an unheated cellar, thermal insulation cannot be avoided.

System design development

In order for the floors to work as economically and efficiently as possible, before carrying out installation work it is necessary to draw up a project for the future heating system.

Before laying a Rehau heated floor, the calculation is made taking into account the required power of the heating system, using data on its specific heat capacity as a basis:

In rooms with high-quality thermal insulation, this figure is 70 – 150 W per m2.

Rehau water floor consists of the following components:

- A set of pipes made of cross-linked polyethylene, with increased resistance to high pressure levels, supplemented with fittings and couplings for mounting connections.

- Additional mounting elements (fasteners, etc.).

- Devices that control the system (combs, thermostats and temperature sensors).

Laying of system elements can be done according to several schemes:

- Spiral.

- Serpentine.

- In the form of a double spiral.

The pipeline is laid in increments of 11-18 cm. In this case, the length of the pipes should not exceed 15 m, since otherwise, due to the temperature difference between the starting and ending points of the pipeline, its heating will be uneven.

When completing the system, Rehau pipes for heated floors are first selected . They play a leading role in the functioning of heating, acting as the main link of the entire heating complex.

RAUTHERM pipes made of cross-linked polyethylene with enhanced strength for this purpose For greater reliability and durability, their walls have an ethylene vinyl alcohol layer. Their characteristics:

- High resistance to mechanical stress.

- Low level of heat transfer resistance.

- Elasticity , ensuring the absence of creases and kinks.

- Neutrality to chemical media , due to which the pipes do not lose their performance even when in contact with alkalis and other chemicals.

- High temperature resistance.

To fasten and join the pipeline, the system uses Rehau push-in couplings and fittings, equipped with fittings with a ribbed surface, which in normal condition are unable to pass through the inner diameter of the pipes.

To install the connection, special expanders are used, with the help of which the internal diameter of the pipe expands.

In practice this happens as follows:

- First of all, a sliding coupling is put on the pipe , after which the socket is expanded using an expander in several stages.

- Then a fitting of a suitable fitting is placed on the pipe and, using a press, the sleeve is pushed onto the fitting over the pipe.

A connection of this type guarantees complete sealing of the pipeline, making the pipes as resistant to high temperatures and pressure as possible.

Advantages of using fittings:

- Simplicity and convenience of installation of connection points using special devices.

- The absence of rusting and rubber seals , which reduce the service life of pipes.

- Possibility of visual control during the installation process.

- After crimping, the fittings can be mounted into walls and screeds.

- Due to the dismountable nature of this system, the fittings can be reused .

To fasten the pipeline in Rehau heated floors, various fasteners are used . For example, Varionova fixing mats, which are plates made of hard polymer material, equipped with special clips for installation on top of pipes.

Along the marking lines, they are cut into fragments of the required area and joined together using the connecting elements included in the kit. The minimum step for laying pipes with a diameter of 14-17 mm in such a system is 5 cm.

Another fastening option is RAUFIX tires , made of high-rigidity polyethylene, on the reverse side, equipped with special brackets that allow you to secure the pipeline to almost any type of base.

Their advantage is their small thickness, which is why the total thickness of the floor increases by no more than 5 cm. Tires, having a length of 1 m and a width of 4 or 5 cm, are attached on top of the heat-insulating layer in increments of multiples of 5 cm.

The main control element of the system is a comb or collector - a device that collects flows and distributes them through pipes. Rehau manifolds for heated floors are available in several modifications, the optimal of which is the comb assembly, with a thermostat and flow meter installed on the inlet and outlet manifolds.

Do-it-yourself heating system for a private house, read how to do it correctly. Solar panels for home heating are an environmental solution to the problem. No fuel costs!

Choose the right induction heating boiler, recommendations in our article.

Installation and installation of a water floor

Installation of Rehau heated floors includes the following operations:

- Preparation of the base . Work on laying a heated floor system is carried out only after the completion of the main finishing work in the room, including plastering of surfaces. The old covering is dismantled along with the baseboards and cleaned of dust and debris. If necessary, it is leveled using a cement-sand screed. The heated floor is laid on a dry surface, the differences on which should be no more than 5 mm.

- Waterproofing layer devices . For this purpose, you can use thick polyethylene film, laying it overlapping and taping the seams.

- Gluing damper tape . It is laid where the floor meets the walls.

- Laying the thermal insulation layer . To create it, you can use penofol, which has good fire resistance, environmental friendliness and moisture resistance.

- Installation of fastening elements (fixing mats or tires). Their assembly is carried out by analogy with laminate: “into a lock”.

- Installation of the comb . It is installed in a distribution cabinet connected to a boiler or heating system, after which the mounting mats are laid. Places of hidden connections are additionally wrapped with a special fixing tape.

- Main line laying . It starts with connecting to the collector.

- Screed fillings . It is poured onto the pipeline in a thin layer, no more than 30 mm. For additional strength of the structure, reinforcing mesh is used.

- After the screed has completely hardened, the heated floors can be turned on.

More detailed information on how to lay Rehau heated floors can be found in the video:

Prices and tips for choosing

It is necessary to take into account that the price for Rehau heated floors is quite high. And it depends on the type of system and its operational characteristics. For example, electrically heated floors, represented by the Rehau Solelec model, consisting of two-core mats, will cost about 1,600-5,000 rubles per square meter.

The price of brand heating cables is slightly lower . On average it ranges from 1100 to 3300 rubles. Here you need to add the cost of installation services: from 400 rubles per square meter.

Rehau water floors will cost less . The cost of collectors, depending on the number of flow meters, will be:

| Number of flow meters | ||||||

| 7 | 8 | 9 | 10 | 11 | 12 | |

| Rehau | 15250 rub. | 16900 rub. | 18400 rub. | 19800 rub. | 21500 rub. | 22500 rub. |

Prices for components:

| Protective polyethylene film | From 62.42 rub. per square meter |

| Profiled wall insulation | From 79.90 rub. |

| Pipe rotation clamps | 86 – 260 rub. |

| Guide bends with rings | 167 - 270 rub. |

| Profiles for expansion joints | 665 rub. |

| Varionova mats | 729 – 1300 rub. |

| Couplings | 50-100 rub. |

Infrared heated floors: pros and cons of this modern heating system. Read how to properly install a heated floor under a laminate on a wooden base.

Is it possible to lay linoleum on a warm floor on a wooden base, how to choose a quality material.