An electric boiler is the most modern, practical and safe way to heat a home. Only electricity is used to heat the coolant, so no harmful substances, soot or resins are released during its operation. Consequently, such equipment does not require a chimney, which greatly simplifies the design of the heating system and its installation.

But, like any complex technical device, it can break. Despite the fact that the principle of operation of an electric boiler is similar to gas and solid fuel, they have differences, and therefore repairs occur in their own way.

Types of faults and methods for their elimination

Malfunction:

the boiler does not turn on

The boiler does not turn on:

The thermostat does not turn on.

—

Remove the cover from the boiler control unit. Using a screwdriver with an indicator light, check the presence of electricity from the phase supply cable at the boiler input circuit breaker. If the indicator shows the presence of current, check that the cables are connected correctly and the polarity is observed (according to the instructions), the wires are tightened in the terminal connections and the electrical current is supplied to the thermostat.

— If power is supplied to the thermostat and it is working, check in the thermostat menu (according to the instructions) whether the temperature control sensor is selected correctly. In the settings, the liquid temperature control sensor must be selected as the main one, and the air sensor must be turned off. Also, the temperature on the thermostat should be set manually (not automatically). See the instructions for the thermostat

— If the starter relay turns on, then you need to check the presence of voltage at the terminal contacts from the starter to the boiler, as on EOU series boiler models. On Dachanik-type boilers, after the starter there are automatic switching units for power steps; it is necessary to check the presence of mains voltage at the terminals of these automatic units when they are on, as well as the tightness of the supply cables to them and the cables going from them to the boiler.

Malfunction:

The boiler does not heat enough due to a drop in network voltage

Signs:

The boiler is working, but the coolant temperature does not rise to the set value on the thermostat

— A typical problem for electrode boilers is a voltage drop in the network - the so-called “voltage sag”. This phenomenon usually occurs when there are a large number of consumers on one electric cable and is more common for single-phase boilers.

— It is necessary to check, using a tester, the voltage of the supply cables at the input circuit breaker into the house. It must correspond to 220V for one phase and zero for a single-phase network or 220V for each phase and zero for a 3-phase network, respectively. If the voltage drops less than 210 volts, there may be a drop in power at the boiler, and hence, as a consequence, the boiler’s insufficient ability to heat the heating system to the required temperature.

— A temporary solution may be to limit the use of some heating radiators by closing them using control valves until the voltage in the network stabilizes.

— Transfer the boiler (if you are using a single-phase boiler, and the house has a 3-phase network) to another less loaded phase.

— A more effective solution to this problem, if it occurs frequently, is the need to install a stabilizer. The stabilizer must be selected with a margin of 40-50% of the boiler power. So, for example, for a 5 kW boiler it is better to choose a stabilizer of 10-12 kW; stabilizers of lower power will have a shorter service life.

Question:

How can you yourself measure the power produced by an electrode boiler?

Solution:

To do this, you will need a multimeter with current clamps (Sold at any electrical goods store.)

Step 1. Measure the voltage in the network.

Before measuring power, first make sure that there is no voltage drop in the network and that it is 220 volts or close to it. To do this, use a multimeter to measure the voltage between the phase wire and the neutral terminal. A voltage drop can affect the drop in thermal power produced by the boiler, as a result of which the boiler may not heat up to the set temperature.

Evan NEXT - 5

Electric boiler Evan NEXT 5 is one of the simplest heating units made in Russia. It is used for heating private households, country houses, industrial and commercial premises. The model is easy to operate and has a long service life. Boiler features:

- Heating elements made of stainless steel;

- Universal power supply;

- Possibility of connecting a thermostat;

- Ability to work with heated floors;

- Monoblock design.

The boiler is made in a compact metal casing for wall mounting.

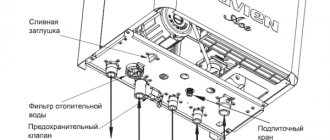

Boiler design

The wall-mounted electric boiler Evan NEXT 5 is built on the basis of Czech-made stainless steel heating elements. It is resistant to corrosion and low quality coolant. The temperature in the circuit ranges from +30 to +85 degrees with a permissible pressure of up to 3 bar. Water or certified antifreeze liquids are used as a coolant. With a boiler power of 5 kW, the maximum heated area is 50 square meters. m.

The boiler is made in the form of a monoblock. It combines blocks of heating elements and a simple mechanical control panel - here the power and temperature of the coolant are selected. To reduce heat losses, the housing is supplemented with a layer of thermal insulation. Due to its compactness, the boiler will not take up much space in the boiler room. There is no built-in piping, but the design of the unit provides terminals for connecting a circulation pump.

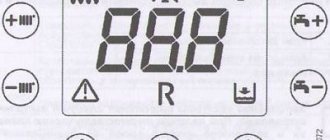

Microclimate control

The Evan NEXT 5 electric boiler is characterized by its simplicity of design, which has a positive effect on its reliability. The microclimate in the premises is controlled using a simple thermostat with an accuracy of one degree. A room thermostat - simple or programmable - will help automate the operation of the boiler. It is connected via a two-wire circuit and controls the operation of the heating elements. The user just has to choose a comfortable temperature - a boiler with a thermostat will ensure its stable support.

Power supply and options

The electric boiler is powered from a single-phase or three-phase electrical network. An emergency self-resetting switch is used as the main protection system. It operates at a temperature of +92 degrees, preventing overheating of the coolant in the heating system. After the coolant has cooled, the switch returns to its original position without user intervention.

The electric boiler is easy to operate and does not require frequent maintenance. It is mounted on the wall; pipes with a diameter of 1 inch are provided for connecting the heating circuit. An interesting option will be the ability to connect a GSM module for remote control of the boiler via mobile Internet or SMS channel - an excellent solution for country housing or a summer house. If necessary, the boiler can work with heated floors.

How does a boiler work?

To understand the situation more clearly, you need to understand the principle of operation of the boiler. Double-circuit gas wall-mounted boilers such as Baksi or Ariston consist of several components. In the gas part, the incoming fuel is burned, the water part ensures the supply of heated water from the heat exchangers to the heating system, and the smoke removal part is responsible for removing combustion products outside the home.

Depending on the user settings, temperature sensors adjust the water heating mode. A sensor on the return pipeline turns off the boiler, depending on the achievement of the required temperature set for the return. However, the system pump does not stop running until the heat exchanger temperature drops.

This is provided to prevent the water from boiling in it. As soon as the coolant cools down to the maximum level, the electronics will send a signal to turn on water pumping and the gas valve. The whole process will start again. When you open the tap in the mixer in a double-circuit boiler, a flow sensor reacts, which informs the electronics about the need to switch the three-way valve to the mode of heating water for DHW.

Briefly about the main thing

To understand why a double-circuit boiler does not heat hot water well, you should diagnose not only the unit itself, but also the entire heating system. The most likely causes of such failures are scale on the walls of the boiler equipment, problems with the gas supply and burner operation, as well as violations in the automatic settings of the programmable module. If the boiler does not heat the heating well and the consumer has found out the reason, it is necessary to eliminate it.

Have you ever encountered a problem when the boiler began to poorly heat the water circulating through the heat exchanger? How did you solve the problem?

01.07.2021

The boiler does not heat water for heating

So, let's look at the main reasons why a gas boiler does not heat water for the heating system and what to do about it:

- airlock. It is necessary to inspect the heating system for the presence of air in the radiators. To eliminate this problem, you need to install an air vent. Its operating principle is similar to that of an expansion tank, but it is capable of maintaining pressure in the system. Using an air vent, you need to bleed air from the system. It is important to inspect the valve itself for mechanical blockages - scale may be present there;

- corrosion in radiators. Clogging of heating devices can be determined by draining water from the system. If the water flows dirty, then you need to flush the system until visually clean water appears;

- connection errors. Hot water may not flow if the diameter of the pipes is not as specified in the project or instructions. It is necessary to check the compliance of the pipeline, the correct connection and the quality of installation of shut-off valves;

- insufficient pressure in the network. You should try adding water to the heating system, as there may not be enough pressure to trigger the automatic ignition of the burner;

- presence of scale in the heat exchanger. The first sign is prolonged heating of the coolant and heating of the batteries. It is necessary to get rid of sediments and carry out boiler water treatment. To do this, you need to disassemble the boiler and remove the heat exchanger assembly.

Before doing this, you need to shut off the flow of gas and water to the device. Then flexible connectors from the pump are connected to the heat exchanger and it is washed with a composition containing a special cleaning agent, which can be purchased over the counter. After which the parts are washed with water.

Some manufacturers allow the use of antifreeze instead of water in the heating system. This substance can be used in the following boilers: “Baxi”, “Vaillant”, “Proterm”, “Beretta”, “Korea Star”. However, it should be understood that each manufacturer recommends using its own antifreeze;

- filter clogging. If the filter screens are clogged with mechanical debris, the radiators may also have poor heating. Therefore, the filter should be checked and cleaned regularly by rinsing with water. If clogging occurs too often, then such a part must be replaced;

- incorrect setting. First of all, if there is weak or no heating, you need to check the settings of the control unit. The temperature may be set insufficiently and the gas does not heat the water;

- malfunctions of pumping equipment. If the pump power is not enough to ensure good circulation, it may turn off if it overheats. This can happen when the DHW circuit is turned on;

- incorrectly selected heating devices. If the system has radiators with unsuitable heat transfer and design parameters, this can also lead to low heating;

- incorrect slope of pipelines. Most often this problem occurs in systems with natural circulation. Regulatory documentation specifies that the slope of pipes should be 10 mm per meter of pipe. If these requirements are not met, circulation may be disrupted and, as a result, there may be no heating due to low coolant flow.

The insertion was carried out poorly: the diameter does not match or there are narrowings in the gas pipeline

A common reason for a complaint that a gas boiler in a house does not heat well is poor-quality connection of heating equipment to the general gas supply system (gas pipeline).

Often, gas service workers weld an additional thread, screw a tap onto it and drill a small hole where the thread joins the gas pipe. The diameter of such a hole is much smaller than the diameter of the pipe, which leads to a drop in pressure. As a result, the gas boiler does not heat hot water well.

Correct connection requires compliance with certain rules and takes more time. Therefore, negligence occurs frequently.

You can determine this reason in the following way:

- there is a sharp decrease in the flame after ignition of the boiler;

- stops gaining temperature, or the flame goes out on its own.

Special calculators are used to calculate the required diameter of pipes in a particular room. The power of the boiler requires a larger volume of gas supply, therefore it is necessary to use pipes with a larger diameter. Before connecting the boiler to the gas pipeline, you must call a qualified specialist who will calculate the required diameter for the pipes, taking into account the characteristics of the room and the power of the boiler.

The following factors influence the choice of a larger cross-section in the connected pipes:

- low pressure requires connection to pipes with a large diameter;

- boiler power and room area affect the diameter;

- the longer the system, the larger the cross-section must be used;

- a reserve in diameter is necessary when there are many turns in the system (gas flow slows down at turns);

- number of consumed points;

- the required room heating temperature with the water heating temperature for domestic use;

- what pump is installed in the boiler.

The boiler does not heat water for hot water supply

In addition to the lack of heating of the heating system, it happens that the gas boiler does not heat the hot water supply circuit.

After all, scale has a structure that limits the passage of coolant and also takes away its heat. This is due to the thermal conductivity of salt deposits - it is much lower than the thermal conductivity of the metal from which the heat exchanger is made. Therefore, the boiler does not heat hot water well.

It is also possible that a piece has come away from the salt deposit, blocking the flow completely, which leads to a complete stop in the supply of hot water.

Structurally, the sensor is a paddle device through which water flows, which is the condition for its operation, because it sends a signal about the presence of a flow to the electronics, which, in turn, starts heating the water again. It happens that the sensor gets clogged, but it can be cleared of the blockage without removing it.

The device has the shape of a cylinder and is located near the circulation pump. To start cleaning, open and close the tap near the sensor. If this does not help, then it should be unfastened and removed, cleaned by hand and reinstalled. If this does not help, then the sensor is most likely faulty and needs to be replaced.

It is designed to shut off the heating system when the hot water tap on the mixer is opened. If the valve does not work, the boiler does not switch to heating water for DHW from heating water for heating. The first reason for its failure may be clogging with corrosion products, which needs to be removed.

If this does not help, the valve should be replaced. The hose system and filter may also become dirty. This problem is barely noticeable on the heating circuit, but on the hot water supply circuit it will be more noticeable. These elements need to be cleaned.

Heat exchanger clogged

Despite the fact that in every gas heating system, water purification filters are installed at the coolant inlet, the heat exchangers tend to become dirty. The cause of pollution is due to various natural impurities found in water. Salt and calcium deposits form on the walls, which are not so easy to clean. And if this is not done on time, then over time the heat exchanger will fail.

The shelf life also depends on the material. For example, the most durable ones are cast iron, although they are the most expensive. The most unreliable are steel ones. Their service life is only about 3 – 5 years.

You can read more about heat exchangers here: Which heat exchanger design and material to choose

You can find many cleaning methods on the Internet. Let's look at the two most popular ones.

Chemical cleaning of biothermal heat exchanger

Modern technologies use special chemical reagents to clean the bithermal heat exchanger. Before performing any manipulations, the boiler completely stops and cools down. Then the heat exchanger is removed. There may be water left in it, so it must be carefully drained.

In a container of sufficient size to completely immerse the heat exchanger, liquid with chemical reagents is diluted, then the bithermic heat exchanger is immersed. Cleaning time, solution concentration, and the need to use additional protective equipment (gloves) are indicated in the instructions for use for each individual reagent and depend on its chemical properties.

After this procedure, the hot water (heating) heat exchanger is washed under cold running water, dried, and installed in place. You can run it.

Chemical cleaning of the secondary heat exchanger

To chemically clean the secondary heat exchanger, you can use citric acid, active thermal agent, STEELTEXT Cooper, Detex liquid concentrate or hydrochloric acid. The choice of one or another component depends on the degree of contamination and the material from which the heat exchanger is made. It is necessary to pump 10 liters of solution to clean it thoroughly.

The process of removal and installation with cleaning is best left to professionals. Gas equipment is complex, despite its apparent simplicity, and dangerous for unqualified maintenance.

Why doesn't the boiler heat water?

Most often, such problems occur before the heating season, when the boiler is turned on after a long period of inactivity. There are two possible scenarios:

- the boiler passes an automatic test, lights up, but does not heat the water well or does not heat it at all;

- the boiler simply does not work, the radiators remain cold.

We remind you that modern heating boilers have built-in advanced automation, which diagnoses all components of the device before starting. If a malfunction is found, the security system will stop the boiler from operating and the error number will be displayed. You can decipher error codes using the instructions for the device or using our classifier.

The boiler power is incorrectly selected

It is very important that the boiler is individually selected to suit your needs. Otherwise, the following problems may occur.

- Situation one. The low power of the boiler does not allow heating the entire volume of water. In this case, the device will work constantly, but the water will still not warm up to the desired temperature.

- Situation two. The model chosen is too powerful for the small volume of coolant. In this case, the water will not cool down; hot water will still flow into the boiler. As a result, this will lead to constant overheating of the boiler, due to which it will “clock” - constantly turn on and off.

The first thing you can do is adjust the boiler for optimal operation, for example, reduce the gas pressure at the inlet or the power of the device itself. If this does not help, you will have to either replace the boiler or redesign the heating system, for example, add or remove radiators.

The boiler is boiling and the radiators are cold

So, the boiler operates at full power, but the batteries remain cold. In this case, experts recommend immediately checking the operation of the circulation pump. After sitting for a long time, it may become clogged or stick. Then the heated coolant will accumulate in the boiler and not move through the pipes. The problem is easily solved by simply flushing the pump or replacing it.

The heat exchanger is clogged

As the temperature rises, salts dissolve in the water, which then settle on the heat exchanger. The resulting scale reduces the heating of the coolant (heat is simply not transferred to the water due to the layer of solid deposits), so although the boiler is working, the water in the heating circuit still remains cold.

The second option is possible: as a result of constant combustion of fuel, soot accumulates on the surface of the heat exchanger. Due to such a thick layer, the fire ceases to contact the surface of the heat exchanger and simply does not heat it. As a result, the water remains cold.

Insufficient pipe diameter or narrowing area

When choosing a pipe diameter, several parameters must be taken into account:

- pressure in the system (with low pressure, larger diameter pipes are needed);

- area of the heated room and boiler power;

- pipe length (a longer system requires pipes with a larger cross-section);

- the number of turns in the system (a large number of turns affects the flow rate of the coolant; in this case, pipes with a reserve diameter are also selected);

- number of consumption points;

- required level of water heating;

- pump parameters.

The diameter of the pipe is determined primarily taking into account special calculations. For this, a special table is used to calculate the pipe capacity. If the boiler is powerful, a large diameter pipe needs to be inserted.

Only a specialist can accurately and accurately determine the cross-sectional diameter of pipes so that the system works properly and as efficiently as possible. However, you can determine the approximate range of the permissible cross-section yourself using simple calculations.

So, based on the average coolant speed of 0.02 km/s, it can be calculated that to ensure a throughput of 30 l/s, a pipe with a diameter of 25 mm will be required, and to provide a throughput of 50 l/s - 32 mm. When calculating depending on the length of the system, for a length of less than 10 meters, pipes with a cross-section of 20 mm are used, for a length of 30 meters - with a cross-section of 25 mm, for a length of 35 or more meters - 32 mm, etc.

Even if the main pipe through which the coolant passes has a suitable diameter, but in some area there is a narrowing, the throughput will decrease throughout the system and this will serve as an obstacle to reaching the desired temperature.

How to avoid the problem?

You can avoid malfunctions if you follow a few simple recommendations:

- Be sure to contact professionals at the boiler room design stage. Incorrectly selected boiler power or insufficient volume of the heating system will negatively affect the operation of all equipment.

- Entrust installation to specialists. High-quality installation and connection of boiler equipment will eliminate most of the malfunctions that may arise during further work. In addition, this is a mandatory item to obtain a warranty period from the manufacturer.

- Perform regular maintenance on your equipment. Once a year, a technician comes to diagnose your boiler, clean all components, check operating pressure, check for leaks, and perform a test run.

- Follow all manufacturer's recommendations when operating boiler equipment. Carefully read the user manual for your equipment. Please comply with the specified requirements.

- Entrust the repair of your equipment only to specialists from specialized companies. Remember that independent repair of gas equipment is strictly prohibited! In addition, if you entrust the work to an unqualified specialist, there is a possibility that the boiler will fail altogether or an emergency situation will be created.

Thus, you will not only extend the uninterrupted and safe operation of the boiler, but also will not lose the warranty. And solving problems in a timely manner will help you avoid costly repairs and save your money.

Connection

If we consider equipment such as electric heating boilers from the point of view of fire safety, then we note that they do not pose any danger to humans. Under no circumstances can an electric boiler cause a fire in a wooden house. However, there are nuances that you should be aware of

When calculating the wiring, it is necessary to take into account the power of the heating installation. If its cross-section is smaller than required for your equipment, then it will heat up

And this is no longer safe for both the house and the people living in it.

When determining the optimal wire cross-section, the following calculation is used: 8A per 1 mm 2 cross-section. If a 6 kW heating boiler is installed in the house, then the minimum cross-section of the wire leading to it should not be less than 3.4 mm 2.

A water heated floor is the optimal heating system for an electric boiler. Among all installations intended for heating premises, an electric boiler for heating private houses is the most expensive class. The cost of a kWh of thermal power when operating this equipment is 3-4 rubles. By placing the unit in the lower part of the room, it is possible to ensure the most efficient use of the supplied heat.

The boiler does not reach temperature - reasons

Electric

Let's try to figure out why your electric boiler does not reach the set temperature; as a result, you have cold batteries.

The reasons may lie in the following:

- If you have several heating elements for heating, perhaps one of them is not connected, the problem may be caused by poor contacts of the wires suitable for the heating element, or it has burned out.

- The wiring in your home does not match the power consumption of the device. Perhaps the reason lies in the wrong cross-section of the wires. If, however, this is due to insufficient voltage in the network or its surges, the solution may be to connect through a voltage stabilizer.

- If only one of the batteries remains cold, while the others remain within the set temperature range, this most likely indicates the formation of an air lock.

To remove air you will need to do the following:

- Open the Majewski tap using a screwdriver or rotary lever.

Mayevsky tap on a heating radiator - Gradually add coolant to the system until it begins to flow out of the tap, this will mean that the air has been removed.

- Stop the coolant supply.

- If uniform heating does not occur, repeat the procedure again.

It happens that the heating elements are clogged with scale, and the temperature does not rise to the set value. For example, on the Mora TOR model, this problem occurs very often due to poor water quality. To clean, you need to remove the heating elements; the top layer of scale can be cleaned with a screwdriver, scraping off large scale elements, then soak the heating elements in a special solution.

Gas

The situations under consideration are applicable to the following models: Buderus, Conord, Baxi, Proterm, Navien, Vaillant, AOGV, Danko.

The reasons may be the following:

- If it does not heat more than 40-60 degrees, the main burner flame may not be adjusted. To do this, unscrew the screws that hold the casing, find the gas supply regulator to the main burner and, by rotating it clockwise, increase the flame power.

- When the output is 70 degrees and returns 15 degrees, that is, the system does not maintain the water temperature. The coolant speed is set incorrectly; it needs to be increased.

Also adjust the radiator system so that more heat reaches the last radiators. If you have a circuit with natural circulation, it is possible that the incorrect angle of inclination was set during installation; according to the norm, it is 20 mm per 2 lm.

- Perhaps the automation malfunctions, and when the temperature rises by 60 degrees, the nozzles turn off. It is necessary to adjust the operation of the automation.

- Does not maintain the set temperature. An inappropriate power for the heated area was selected.

- The gas pressure in the system is less than required. Check the gas valve; older generation valves contain grease inside; if there is too much of it, remove excess.

- Mismatch in diameter of the pipe and hose suitable for the device. Their inconsistency can contribute to unsmooth operation.

- If the heating boiler does not reach the set temperature, the heat exchanger may be clogged, clean it.

Scale inside the heat exchanger - The selected power is not enough to heat the area of the room with a solid fuel boiler, or the house is very frozen and the device cannot cope. This often happens with Lemax, Aton, Stropuva devices.

- Check the tightness of the firebox; if depressurization is detected, seal the holes.

- The size of the chimney does not correspond to the diameter of the chimney pipe on the boiler; match the chimney pipe and the pipe.

- Poor draft in the chimney, or it is clogged. The damper may be closed and there is not enough oxygen for combustion.

- Low quality raw materials, or low calorie content. If the boiler is wood-burning, the raw materials may be poorly dried or rotten; if it is coal-fired, in this case there may be an increased content of rock.

- The volume of the combustion chamber is not enough. The maximum filling has been made and there is no room for the flame to burn.

- Unsuitable fuel is used, if the boiler is pyrolysis or pellet, the instructions should indicate what else can be used to fuel it.

Solid fuel (including coal, pellet, wood)

Possible reasons why the temperature does not rise:

If the temperature drops quickly, this indicates insufficient power of the device, or the heating circuit is too long. What to do in such a situation? A possible solution is not to use hot water during heating, but to use a boiler to heat hot water for domestic purposes.

What affects electricity consumption

All boilers convert the energy used into heat in a 1:1 ratio. With 100% efficiency, negligible losses in wires and connections are neglected. The exception is heat pumps, but they are still rarely used.

Thus, there are only 2 ways to reduce electricity consumption:

- Reduce heat loss. To do this, the home is covered with mineral wool or polystyrene foam, and the cracks are sealed.

- Optimize the operation of the boiler in order to eliminate excessive consumption of energy resources.

The second problem is also solved in 2 ways:

- Using weather-sensitive automation. Such a system promptly warns the boiler about the onset of warming, and it manages to reduce power without overheating the room.

- Programming. A model with this function, according to user settings, reduces heating output when residents are at work or sleeping. The rest of the time the device returns to normal mode.

It is possible, without reducing consumption, to reduce financial costs. They are switching to differentiated metering of electricity consumption with a big discount at night (RUB 1.68 instead of RUB 3.89). The heating system is equipped with a heat accumulator - a large capacity in which the boiler raises the temperature of the working environment to +98˚C within a grace period. During the day, boiling water is gradually supplied from it through the mixing unit into the circuit as needed; the heater does not work at this time.

In this case, you will have to pay 17,388 × 1.68 = 29,212 rubles for the season. But there is a nuance: the rated power of the boiler should be twice the design power, because at night it works both for heating and for “charging” the heat accumulator. For the example given, a 20 kW unit will be required.

How to fix the problem yourself

Before buying a boiler, correctly calculate the power suitable for your room volume. If the problem is poor draft, it is necessary to clean the chimney, clean the chamber from which the air flows, and the combustion chamber itself. If these manipulations do not produce results, install the draft regulator.

If performance is poor due to fuel, you should first carefully study the instructions and clearly determine what exactly can be used to heat your model. When purchasing a supply for the heating season, first buy a small batch for a couple of days, and, after making sure of the quality, you can make a purchase for the season. If the reason is the volume of the chamber, make an incomplete bookmark.