There are several ways to figure out how suitable foam materials are for an attic space. For example, use reviews about attic insulation with polystyrene foam. It’s even better if you manage to take part at least once in the process of laying insulation in a residential attic or any other room similar in structure and size to an attic. Once done with your own hands, insulating an attic with penoplex is worth ten reviews, although, from a practical point of view, you can find a lot of rational ideas in them.

Is it possible to insulate an attic from the inside with penoplex?

The problem of using foamed polystyrene or its more rigid and durable form - extruded penoplex has always been associated with the safety of the material. The main obstacle preventing insulation with expanded polystyrene from the inside of the attic, according to reviews from developers, is considered to be:

- The presence in the foamed structure of polystyrene foam of residues of the primary solvent styrene and foam-forming freons, inhalation of which can lead to serious illnesses;

- Flammability of the material. Unlike mineral wool or even polyurethane foam, attic insulation made from polystyrene foam burns very quickly, releasing a huge amount of toxic thermal decomposition products.

It cannot be said that fears regarding the use of polystyrene foam insulation are too exaggerated. According to reviews, few developers really understand the dangers of old polystyrene foam, and that both factors are more relevant to foam plastics and EPS produced using old technology.

Important! The vast majority of modern polystyrene foam manufacturers have long abandoned freon; the residual toluene content in the mass is controlled by technology, and special additives of non-ferrous metal salts are used to reduce flammability.

Moreover, polystyrene foam, intended for insulating the walls of attics, verandas, and rooms of residential buildings, has appropriate markings that are different from technical foam plastic and EPS for communications and road construction. It is with this type of penoplex that you can insulate an attic, without any particular risk to the health of the residents.

Content:

The construction of the roof of a house, by its truss structure in any variant (except for a flat roof), implies the creation of a void above the living quarters. Previously, when building a house, attic spaces were intended for storing things that were not needed or were not in demand at the moment.

Today, many people, when planning the construction of a house and creating a project, take into account the creation of not an empty attic, but a residential mezzanine called an attic.

Since the roof is most susceptible to natural atmospheric influences, when creating a living space under it (attic floor), insulation and sound insulation are necessary.

There are a huge number of options for insulating walls from the inside with penoplex videos and articles, and in order to choose the right one you need to know at least the characteristics and usefulness of the insulating material. For insulation and soundproofing of the attic, penoplex (extruded polystyrene) is most suitable.

Pros and cons of attic insulation with polystyrene foam

It cannot be said that penoplex has completely and completely replaced all competing methods of insulation. According to reviews, along with EPS, craftsmen actively use mineral wool and fiberglass materials, polyurethane foam and granule-based backfills to insulate attics and residential buildings.

Insulating the attic with extruded polystyrene foam makes sense in two cases:

- The house with an attic was built in an area with a fairly humid climate; polystyrene foam insulation, unlike expanded clay and mineral wool, is not afraid of fog and “wet” air, so it can be used even without external cladding;

- A country house or country house with an attic is visited in winter no more than 1-2 times a week. The use of insulation based on polystyrene foam guarantees the safety of thermal insulation under conditions of fluctuating temperatures and humidity.

It is clear that penoplex and lighter foam plastic have disadvantages, which in some cases can outweigh even the positive qualities of the material. In addition to the fact that polystyrene foam insulation can burn in direct contact with the fire front, the material is also quite sensitive to solar ultraviolet radiation. Therefore, when insulating the gables of a dacha with an attic, the heat-insulating layer must be laid only from the inside of the room, or use siding. According to reviews, penoplex on the facade is clearly better than mineral wool.

The main inconvenience in using foamed polystyrene is its almost zero vapor permeability. While polystyrene foam can still somehow transmit water vapor, foam boards are absolutely impermeable to moisture. This dramatically worsens the level of comfort in the room and requires the use of additional supply and exhaust ventilation. According to reviews, it is errors in the insulation device that become the reason for replacing polystyrene foam with mineral wool.

In addition, polymer foam material is easily damaged by rodents, so if there is a threat, the attic insulation must be covered with metal mesh and finishing based on sand-cement plasters.

For your information! Polystyrene foam is easy to cut even with an ordinary knife or thermal cutter, but the dust generated during mechanical processing and cutting of insulation boards is easily electrified and sticks to any surface.

Therefore, when planning work with polystyrene foam or penoplex inside the attic, it is imperative to provide for the removal of dust and scraps, preferably using a vacuum cleaner and exhaust ventilation. According to reviews, you will need a vacuum cleaner and gloves.

What is this material

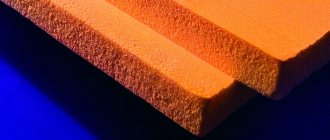

Polystyrene foam is foamed polystyrene, which consists almost 100% of glued air bubbles enclosed in a polystyrene shell - this makes the material very light.

The main advantages of polystyrene foam include:

- extremely low weight;

- low thermal conductivity;

- is not afraid of moisture and temperature changes;

- does not cause allergies and does not harm the environment;

- fungus does not develop on it, and rodents do not damage it;

- ease of processing and installation;

- does not deform over time;

- long service life - up to 25-80 years;

- minimum price.

The disadvantage of polystyrene foam is its sensitivity to external factors, as well as the fact that its transportation must be carried out with extreme caution. The material should be laid in such a way that the material is protected from mechanical damage and is not exposed to direct sunlight.

Before insulating a roof with polystyrene foam, you need to decide on the right choice; all technical characteristics of the material must be taken into account and different brands must be studied.

It is recommended to pay attention to foam plastics of the following densities:

- PSB-15 (15 kg/m3). It comes in a thickness of 50-100 mm, and is used for thermal insulation of pitched and attic roofs, as well as ceilings.

- PSB-25 (25 kg/m3). Used for wall insulation. The thickness is the same.

- PSB-35 (35 kg/m3). Designed for installation in places where it is necessary to withstand large mechanical loads; Suitable for thermal insulation of flat roofs, floors, and attic floors.

How to choose penoplex for insulating an attic roof

Several types of extruded polystyrene foam are used for construction work. The most famous and affordable is brand “C” penoplex. It is used for exterior finishing of walls without cladding or for insulation of vertical surfaces in non-residential premises. It can be used to insulate the gable walls of the attic. For the interior space of the attic floor “C”, penoplex is usually not used due to the high content of chromium salts. According to reviews, “C” - expanded polystyrene is excellent for floor insulation and sometimes attic ventilation.

In addition to expanded polystyrene “C”, material of grades “A” and “K” is produced. In the first case, “A” - penoplex is used in road construction and foundation insulation. The second - penoplex "K" is used to insulate walls and interior space. Material density 33 kg/m2, heat resistance up to 75°C. The main thing is that pressed polystyrene foam does not have unsafe additives and additives, and the mechanical and heat-insulating qualities, according to reviews, are not inferior to other brands.

It is believed that the insulation layer made of "K" grade polystyrene foam provides reliable protection against water vapor and can be used without a vapor barrier, primarily due to the special edge profile that forms a lock. In practice, craftsmen still prefer to play it safe and lay additional vapor barrier on top of the insulation.

additional information

Manufacturers have created improved insulation based on the use of foam plastic. Penoplex seems to be a strong and durable raw material, the fastening of which takes place using mushroom-shaped self-tapping screws. This insulation does not change its external characteristics under the influence of dampness.

Penoplex is convenient and profitable for finishing an attic space. This building material is inexpensive, it is convenient, practical and wear-resistant. You can always carry out installation work using penoplex, regardless of the season.

Penoplex thickness for attic insulation

The most popular sheet size is 600x1200 mm. The material fits easily into the gaps between the rafters or frame slats. The thickness of the penoplex in the attic is chosen depending on the profile of the room and the location of the walls relative to the roof slopes.

For habitable attics, in which the walls are formed by rafters and frame sheathing, the insulation thickness is assumed to be maximum - 100 mm for middle latitudes and 150 mm for southern and northern regions.

If the attic is built as a classic room with vertical walls, then for their insulation you can use polystyrene foam with a thickness of 75-100 mm, provided that an uninsulated roof is laid. For a warm attic, the attic walls can be insulated with slabs 50-75 mm thick.

In any case, the insulation of the room must consist of at least two layers to ensure the overlap of seams and possible cold bridges. According to reviews, it is best to glue with polyurethane foam or paint.

Why Penoplex?

Due to the design features of the attic floor under a pitched roof, used as a living space, the creation of a thermal insulation system requires insulation of the roof, gable and floor. Universal thermal characteristics make it possible to insulate the attic floor with penoplex using different brands of thermal insulation boards. Among the advantages of this material that ensure its demand, consumers note:

- the ability to create a comfortable microclimate;

- reliability, efficiency, long operational period;

- resistance to the development of fungal and mold bacteria;

- simplicity and efficiency of work;

- availability of information from the manufacturer on how to properly insulate an attic with penoplex.

A low level of thermal conductivity and almost zero water absorption create all the prerequisites for insulating the attic with penoplex. In addition to the above characteristics, this material:

- has the necessary compressive strength (at least 25 tons per square meter), which allows it to be used for insulating loaded surfaces (in our case, floors and roofs);

- allows you to eliminate vapor permeability of structural elements of the room;

- the high wear resistance of the insulation boards makes it possible to count on a long service life;

- has appropriate sanitary, epidemiological and environmental conclusions confirming its safety for humans;

- is not flammable, due to which the use of penoplex for attic insulation is as safe as wood, chipboard, MDF;

- allows you to carry out work without the involvement of a large team of workers or the use of complex tools, since the insulation boards have a strict geometric shape and an L-shaped edge, which greatly facilitates installation;

- designed to work at any time of the year, which makes it possible to insulate the attic floor with penoplex, even if the cold weather sets in.

Preparing the attic roof for insulation with penoplex

Attic floors with different layouts also have different insulation laying patterns. For example, an inhabited attic is insulated according to the same scheme as the roof. The material is placed in the space between the rafters and attached to the sheathing. In the classic version of the attic, which has both vertical and inclined sections of walls, the process becomes somewhat more complicated.

Putting up the frame

First of all, you will need to assemble the frame of a vertical section of the wall, on which, in fact, the insulation and cladding of the room will be attached. It can be made from a steel profile, but a regular wooden beam is best suited. Initially, a horizontal cross member is attached at the level of the future upper edge. It is stuffed from pediment to pediment along the entire length of the slope. Vertical posts are attached to the crossbar in 0.6 m increments.

Advice! The transverse size of the beam is chosen equal to the thickness of the first layer of future insulation.

According to reviews, it happens that craftsmen tend to simplify the process and lay sheets of polystyrene foam directly on the rafters, directly on the roof lining. You can't do this. According to the execution technology, in order to insulate the attic with penoplex, it is necessary to sew additional sheathing on the inside of the slope. Thus, an air channel will appear between the roof structure and the attic insulation. This will remove water vapor from the space between the attic insulation and the roof frame.

Vapor barrier for future attic

The next step is to stretch a vapor barrier film over the rafters and the assembled frame. If penoplex is laid directly between the rafters of a cold roof, then the sheathing is sewn end-to-end with a board, or moisture-resistant plywood is used, and the film is sewn directly to the sheathing.

The fabric is stretched overlapping and glued with tape. The film is needed primarily to protect the wooden frame parts from moisture.

Where does the heat go?

Before insulating the attic, it is important to determine where the heated air goes, and why is it so difficult to maintain the optimal temperature?

Walls, ceilings, floors, windows and doors – through all these elements of the room’s structure there is a fairly active exchange of air with the outside space. And if the first floor of the house is fully insulated, leisure time in the attic will be more comfortable. But to make the atmosphere as pleasant as possible, you need to pay attention to the entire room.

Heat escapes through cracks in doors and windows, walls and roofs. Cladding with insulation, steam and wind insulation materials will allow you to maintain a comfortable temperature for relaxation and active pastime, and save on heating system resources. Next, we will talk about the nuances of insulating the attic roof, walls, floors and ceilings, recommend materials and demonstrate some expert advice, which will allow you to make the room warmer on your own.

Roofing pie composition

One of the options for multilayer thermal insulation with polystyrene foam is shown in the diagram below.

The use of thin sheets significantly complicates the process; this option turns out to be much more effective. Using three to four layers of expanded polystyrene, laid without using glue, has its advantages:

- Significantly more effective sound insulation;

- There is no risk of destruction of the attic insulation even with severe watering of the material;

- Complete absence of cold bridges.

In the diagram shown, the vapor barrier is laid on a wooden sheathing with a wind barrier and a ventilation gap.

Next come three layers of insulation, a vapor barrier and a final layer covering the ends of the rafters.

How to properly insulate an attic with penoplex

The insulation process begins with marking and adjusting the sheets. Since there must be an air gap of at least 50 mm between the first layer of expanded polystyrene and the sheathing, the insulation material must be adjusted in size so that after installation the sheet does not bend towards the gap.

Start of installation

The first layer should be the warmest so that the dew point is located as close to the roofing as possible. In this case, you can use regular polystyrene foam; it is much warmer than polystyrene foam.

The material is placed in the rafter box in a checkerboard pattern. Joints, especially between polystyrene foam and rafters, as well as seams, are covered with foam. In this case, the sheets are temporarily pressed with strips so that the expanding polyurethane foam does not squeeze the insulation layer back into the attic room.

Completion of work on laying polystyrene foam

Before laying the last layer, the ends of the rafters must be cleaned of foam. Often, additional film is stretched over the frame, but if the insulation is done with penoplex, this need not be done.

The last sheets of EPS are laid in horizontal lines, while the locks at the joints are glued with polyurethane foam, and after setting, the foam is attached to the rafters using standard mounting “fungi”.

Advantages

If you place a thermal insulation layer inside the house, the dew point will shift. This indicator determines the temperature value below which condensation occurs. In this case, the dew point moves indoors. This means that the humidity will increase, the walls will begin to “sweat” and mold will form. Internal insulation reduces the space of the room.

Even a small thickness of insulation can significantly reduce the square footage, because to thermally insulate a wooden building you will need to install sheathing. Another factor is the deterioration of the internal microclimate. The use of even modern thermal insulation materials will not allow wood to “breathe”. Insulation from the outside eliminates all of the above factors.

Tips and tricks

The walls of the attic can be plastered, but most often customers prefer cladding with plywood or plasterboard. The walls and ceiling of the attic are in rigid connection with the rafter frame of the roof, so any attempt to plaster or cover with liquid wallpaper eventually results in cracks and peeling of the finish. With drywall, as a rule, such problems do not occur.

According to reviews, the most common mistake in insulating attics with polystyrene foam is failure to follow the rules for spacing the seams. The inter-plate joints of the previous layer should be at least 30 cm away from the seams of the next row. In this case, it is advisable to glue both the locks and the surface of the insulation.

Alternative to foam

The main competitor of polystyrene foam is basalt wool. Some of its varieties have a thermal conductivity coefficient as low as foam plastic - from 0.032 W/m*C.

We have already talked about the disadvantages of basalt wool, it’s time to mention the advantages: this material does not burn and does not emit harmful gases when heated. But there is one thing. Phenol-formaldehyde resin is used to glue the fibers in basalt wool.

But if stone wool was made in some artisanal workshop, it will most likely become a source of toxic fumes.

In addition, the “left” cotton wool produces more dangerous dust.

Today, ecowool is becoming more and more popular. This extremely cheap heat insulator consists of finely chopped paper impregnated with fire retardants and antiseptics.

When dry, Ecowool is a bulk material - it can be laid in wall cavities and under floor coverings.

But if this material is slightly moistened (special equipment is used for application), it becomes sticky and can stick to vertical surfaces, and even to the ceiling. Such materials are called sprayed. They are able to penetrate hard-to-reach areas and form a seamless coating. Ecowool's thermal conductivity is extremely low - about 0.032 W/m*C.

Like polystyrene foam, it is a flammable material, although fire retardant additives give it some resistance to fire. But its smoke is not so poisonous. Antiseptic and fire retardant additives used in the production of Ecowool are considered moderately toxic.

Ecowool insulation

Among foam plastics there are also sprayed materials. This is, for example, polyurethane foam, better known as polyurethane foam. Its characteristics are similar to expanded polystyrene, but it is much more expensive, so it is mainly used to fill small cracks and cavities.

When applying polyurethane foam over a large area, you need to wear a protective suit with a hood, since it is almost impossible to remove it from clothing or hair (hair has to be shaved off).