One of the main conditions for the operation of electric boilers is their reliability and safety during operation. But even the most reliable equipment breaks down over time. The validity period of any components and assemblies is limited - this is natural. However, premature failure of the device causes the owner a feeling of great distress.

Malfunctions that occur during the warranty period can be repaired free of charge at a service workshop. In all other cases, there will be a paid repair of electric heating boilers. Sometimes it is possible to restore the unit yourself.

What is an electric boiler

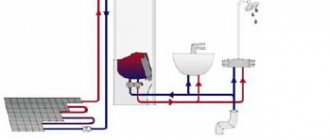

An electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules of its operation and perform timely technological maintenance.

Watch the video about the operating principle and design of the Protherm Skat electric boiler.

Device

Despite the wide variety of boilers with different operating principles, the design of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler unit. If they malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have different configurations.

List of elements:

- Electronic control unit. Regulates temperature conditions by turning equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system and maintains a stable speed of coolant movement in the circuit. It produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most effective heat exchange and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if you purchase equipment without a tank, you will need to purchase this part separately and install it by cutting it into the pipe heating circuit.

- Filters. They purify and remove various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Performs emergency water release when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids and gases inside the boiler and pipes of heating systems; it is necessary for monitoring.

- Thermal switch . Shuts down equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency release of air from the tank in case of excess pressure.

Types of electric boilers

Depending on the operating principle of the heater, all electric boilers are divided into three types.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element – heating element. Water or other approved liquids are used as a coolant, in accordance with the operating instructions.

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant heats up.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when alternating current passes through it.

A feature of the use of this type of boiler is the mandatory monitoring of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomenon of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in equipment failure.

The liquid used cannot be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced technician.

Noise in the middle of the tank

If the boiler is making noise, then you need to listen to the sounds.

- The noise is uniform and monotonous.

- The noise is uneven. Cods are heard.

If the boiler makes noise evenly and monotonously, then there are no problems with its operation. The source of noise is the heating of water. This noise can be weak, or it can be loud. It all depends on whether the heating system is open or closed. If it is open, the boiler makes louder noise. The reason is the presence of air in the coolant.

You can get rid of noise by converting an open system to a closed one.

When the boiler makes uneven noise and crackles are heard, this is a breakdown. The cause may be scale on the heating element. The high temperature of the heating element causes the scale to heat up, which is accompanied by increased noise. Uneven sound and crackling occurs due to the fact that the thickness of the scale in individual areas of the heating element is different. The noise is generated like this:

- First, thin deposits of limestone are heated. They don't make too much noise.

- Thicker deposits are then heated. They take longer to heat up. That's why they hum louder than fine deposits.

- The cracking sounds are very thick. This sound can also be created by plaque, which has begun to lag behind the heating element.

You can get rid of noise by regularly cleaning the heating element from scale.

Causes of breakdowns

The causes of breakdowns can be established even before the boiler starts operating. These are: errors in the design and calculations for the selection of additional devices (not included in the boiler configuration), switching elements, determination of the type and cross-section of the required installation wires.

The causes of breakdowns in the future may be:

- Poor quality, incorrect installation and connection of the device with deviations from installation requirements.

- Violation of the basic rules for using the equipment specified in the instructions.

- Failure to comply with the requirements for carrying out routine, preventive and periodic work and inspections.

- The presence of a manufacturing defect, which is discovered both during the warranty period and after its completion.

- All components and assemblies have a certain service life, and the reason for their failure is natural wear and tear.

- In heating element boilers, the heating elements themselves may fail due to low water quality and the formation of salts and scale on their surface.

- Failure of most components and assemblies due to large voltage surges exceeding all permissible standards. These tolerances are specified in the operational documentation.

For ion boilers, water compliance with the required standards is of great importance.

If the boiler does not turn off

The boiler does not turn off on its own due to the fact that the automation does not work. This can be caused by a breakdown of the temperature sensor or the device that is supposed to disconnect the contacts.

You need to check the suitability of the automation by changing the settings in the control panel. At the same time, a mode is set in which the heating boiler should definitely turn off. If the automation does not respond, then it is broken.

You can disassemble it, check and clean the contacts, and determine whether any of the wires in it have burned out. If all the wires are intact and the contacts are clean, check the operation of the automation. When it works well, but the boiler does not turn off, it means that the temperature sensor is broken. It will have to be replaced.

Types of faults

When operating electric boilers, various types of malfunctions arise - from coolant leaks in pipelines and structural elements to automatic malfunctions. If electronics fail, it is recommended to entrust repairs to specialists in this field.

Typical faults include:

- violation of the tightness of the system, the presence of leaks and smudges in fuel lines, elements and assemblies;

- heating of electrical wires and odor due to electrical insulation failure;

- various types of noise in highways and system elements;

- there is no or slight heating of the coolant;

- when turned on, the boiler does not start;

- After heating the coolant, the electric boiler does not turn off.

Design features

Regardless of the type, the design of electric boilers requires the following mandatory elements:

- circulation pump;

- copper heating unit;

- fuse in the form of a thermal switch;

- safety valves;

- air valve;

- pressure gauge;

- control panels;

- power control systems.

DIY repair

To carry out work on repairing an electric heating boiler with your own hands, you must have a minimum amount of knowledge on the design and installation of electrical equipment, as well as the heating system as a whole.

It is recommended to study the information on operation, installation and comply with all the requirements specified in the instructions. To troubleshoot the operation of the electric boiler, it is necessary to use diagrams.

In case of all types of malfunctions, it is necessary to first turn off the power to the equipment and then conduct a thorough visual inspection of it. You should pay attention to burning, integrity of various types of connections, damage to insulation and other deviations.

Doesn't start

To determine the reasons for the impossibility of starting the boiler unit, it is advisable to use the electrical diagram of the equipment. Check the integrity of the cable and all fuses, and also ensure that the circuit breakers are working properly using a multimeter and other relevant elements on the control panel. All work should be carried out with the equipment de-energized.

To fully turn on the boiler, the starting circuit must be in good working order, which includes, depending on the type of boiler, its own set of elements.

Components:

- emergency thermal switch;

- pressure meter;

- flow switch;

- thermostat sensor.

It is necessary to check their serviceability, and if a breakdown is detected, repair or replace them. Otherwise, starting the boiler will be problematic.

The emergency thermal switch is a bimetallic contact that opens when overheated. It is designed to turn off the boiler in case of temperature overload and failure of the main thermostat circuit. When a critical value is reached, the thermal switch opens its contacts and removes voltage from the electrical appliance.

When cooling, the contacts close again and prepare the circuit for the next start. It is worth noting that the reason for the inoperability of an electrical appliance may be the thermal switch itself, the contacts of which remain open. Then starting the boiler will be impossible.

Simple thermal switches are checked using the “diagnosis” method using a tester. In the normal “cold” state the contacts are closed. To check the operation of this element, it is necessary to heat it above the shutdown temperature using the usual action of an open flame or a soldering iron, and then measure the resistance of the contacts.

The heating elements are turned off and on to maintain the required coolant temperature when the thermostat and temperature sensor in the boiler are working properly. If they break down, starting the boiler is impossible.

A level sensor (coolant presence) is installed in the upper part of the unit body; it ensures that the power to the electric boiler is turned off if there is no liquid in the tank. In this case, the “dry” type electrode must be in water. In this case, the corresponding relay is activated, and the circuit is prepared to start the boiler. The flow switch is designed to turn off equipment in the absence of coolant circulation in the system, which helps prevent overheating of the liquid.

Doesn't turn off

If the boiler does not turn off when it overheats, it means that the emergency thermal switch is not working, if there is no water in the boiler, the level sensor is faulty, and so on.

To turn off the boiler, it is necessary to break the starting circuit, which includes the corresponding automation elements. It is necessary to check the serviceability of all components that are present in this type of boiler and determine why this or that device does not turn off. The same search methods using a multimeter are used. Do not forget about de-energizing and completely shutting down the boiler if necessary.

Makes noises

When any electric boiler unit operates, there is always a certain background and noise. This is a typical and natural phenomenon. But the nature of the noise can be different, and some sounds can be used to judge the technical condition of the boiler. During operation, the types and nature of noise change somewhat over time. It all depends on the quality of equipment installation, installation, configuration, physical wear and tear of components and assemblies, as well as operating conditions.

A low noise level in the system indicates the high quality of the electric boiler used. A uniform, monophonic sound of operation indicates normal functioning, and the source of noise is, like in a kettle, heated water. The volume of sounds depends on the degree of oxygen saturation of the liquid. This process does not have any negative impact on the condition of the boiler and system.

If an uneven noise is heard, accompanied by a crackling sound, this is due to the formation of lime deposits on the walls of the heat exchanger. Over time, their number increases, and gradually they begin to flake off and enter the system.

Depending on the amount of deposits, sounds of different volume and timbre are heard; with a significant increase, a crackling sound is heard. To eliminate this phenomenon, it is recommended to flush the heat exchanger elements. In addition, the temperature of the internal walls of this device also increases, and this affects the wear resistance and durability of the equipment.

Doesn't heat water

The lack of heating of water, provided that the rest of the equipment circuit is in good working order and operable, can be due to two reasons: insufficient voltage at the terminals of the heating elements or problems in the elements themselves and their connections.

The integrity of heating elements can be determined by checking the resistance using a tester or similar device. Each component of the device must be tested separately. To do this, you need to disconnect them to gain access. If a malfunction is detected, the heating elements should be replaced.

Replacing the heating element

Depending on the type of boiler, appropriate heating elements are installed in them. These can be heating elements or electrodes. If they cannot be repaired, they must be replaced.

Procedure:

- Shut off the water supply to the unit.

- Drain the fluid from the system.

- Disconnect the equipment from the power supply.

- Make sure there is no voltage.

- To access the heating elements, dismantle the necessary equipment and its elements.

- Disconnect the wires from the heating elements. To facilitate installation work, it is advisable to first sketch or photograph the connection diagram.

- After unscrewing the fasteners and removing them, remove the faulty element.

- Install a new heating element corresponding to this boiler.

- Install a new waterproofing gasket and secure the heating component.

- Connect the appropriate wires to the contacts of the element and check the result obtained with the previously sketched diagram.

- Check the correct installation.

- Fill the system with water and start the boiler in accordance with the operating instructions.

Prices for heating elements for boilers

Heating element boiler spare part

Restoring the performance of electrode and induction boilers

Unlike heating element boilers, in electrode-type heaters, faulty electrodes are replaced. The same approach is used here as in the case of repairing heating elements units. The requirements for replacing heaters in electrode boilers are higher.

Typical problems

Among the most common problems that are typical for electric heating boilers are the breakdown of heating elements, equipment for monitoring and controlling the operation of the system.

If the heating elements fail, restoring the boiler's functionality involves replacing the heating elements or electrodes, depending on the type of equipment.

To prepare for the planned activities, you need to visit a specialized spare parts store. Here you can find the required electric heating element without any problems. You can find out the model of the spare part that will help perform repairs from the technical data sheet of a specific heating unit.

If the problem concerns control and monitoring systems, it is necessary to first take measures to identify the faulty units.

In cases where it is impossible to repair heating boilers by repairing a non-working element, it should be replaced.

Causes of failure

Common reasons for insufficient performance of electrical equipment and its complete failure are as follows:

- untimely maintenance of boilers and unfair operation;

- poor-quality installation and connection of the heating unit;

- incorrect design;

- presence of manufacturing defects;

- natural wear and tear of functional elements.

Replacing heating elements

Troubleshooting an electric boiler by replacing heating elements requires compliance with the following sequence of actions.

To begin with, the boiler is disconnected from the power supply, which is a basic safety requirement and allows you to avoid electric shock. All working fluid is drained from the heating system.

If the heating element mount is in a hard-to-reach place, the electric boiler is dismantled. Next, the wires are disconnected from the heating elements. Each wire is pre-labeled with convenient symbols. The initial order of fastening (zero and phase) is recorded.

Then the fastening elements of the electric heating elements are unscrewed. The heating element is directly dismantled. The special waterproofing gasket is being replaced.

Using an old gasket can quickly lead to leaks when the new heating element is operating.

A working heating element is installed and secured. In reverse order, perform the steps indicated above in the description of the disassembly process. The electric boiler is connected to the network. The operability of the boiler and the reliability of the entire heating system are checked.

Restoring the performance of electrode and induction boilers

Repair of electrode-type boilers occurs by replacing electrodes. The same approach is used here as in the case of repairing heating elements units. However, electrode boilers are more demanding in terms of assembly accuracy.

As for restoring the operation of induction boilers, such heating devices do not have heating elements. Therefore, in case of malfunctions, independent repairs are not possible here.

It is worth noting that the most likely breakdowns of electric heating boilers, as well as the causes and methods for eliminating them, are given in the operating instructions for specific models.

Prevention and recommendations for use

Compliance with operating rules, together with the implementation of timely preventive measures, extends the period of trouble-free operation of the unit. It is preferable to carry out preventive maintenance during the lowest load of the boiler, in the summer.

During the current heating season, it is advisable to pay attention to problems and deviations that arise during operation. In the warm season, it is recommended to replace all unstable elements and troubleshoot problems. Then carry out a preliminary launch and check the functionality of the boiler equipment and systems.

Preventive measures include: cosmetic repairs, cleaning of various systems and equipment elements. Particular attention must be paid to fastening and connecting elements, which can significantly affect the functionality of the equipment.

Timely, regular implementation of preventive measures along with high-quality installation and proper operation will allow heating equipment to operate trouble-free for decades.

To extend the service life of the heating unit, it is necessary to clean the heating elements from scale. However, you can prevent the problem by pouring distilled or soft water into the heating system. If ordinary water was used before, then the heating elements are cleaned using special powders that are sold in hardware or auto stores.

The powder is diluted in water, the resulting mixture is poured into the heating system, which is turned on at full power. After 30-40 minutes, the entire solution (it will be rusty in color) is drained into the sewer system. Now you can be sure that the entire system will again receive its normal 100% power. A less effective option is to install devices for filtering the working fluid.

The reliability of the electrical system in the home is of particular importance. Outdated wiring is one of the most common causes of electrical equipment failure. It is advisable to replace the aluminum wire with a copper wire with a larger cross-section.

A feature of the use of this type of equipment is the mandatory monitoring of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomenon of electrolysis and breakdown should not be allowed. You can find out how to cook in a Pompeii oven by following the link.

Prevention

In order to eliminate the occurrence of malfunctions in the heat supply system, before the heating season, preventive and routine repairs of the boiler are carried out within the time limits established by the manufacturer.

This requires:

- Check the quality of the internal heating surfaces of heat exchangers and promptly descale them.

- Monitor the condition of electrical components.

- Monitor the operation of heating elements and clean them of deposits.

- Monitor the technical condition of pipes and promptly treat them with anti-corrosion materials.

- Check the tightness of threaded connections and the absence of leaks.

In order to reduce scale formation processes, it is recommended to take care of installing filters to purify the source water from hardness salts.

If the boiler does not turn on

The cause of this problem may be the burnout of any electronic part: control panel, power control board, or failure of the heating element. Failure can be determined by assessing the operation of the indicator lights. For this:

- Turn on the boiler and set the desired coolant temperature. The water in the tank should be cold. Current should flow to the heating element, and the electric boiler operation indicator should light up. It is often connected to the same cable that leads to the heating element. This cable comes from the power control unit.

- Check to see if the indicator lights up. If it burns, then there is a problem with the heating element. If not, then there is a breakdown in the electronic part.

To determine the damaged node, you can use a multimeter. One end of it is applied to one output of the boiler plug, and the other - in turn to all elements connected to the cable with the plug. The second end of the multimeter is applied to each of the two contacts. If the device does not produce a signal, then there is a problem in the area between its two terminals.

Check with a multimeter:

- Plug with electrical input cable.

- Control Panel.

- Power control unit.

- Thermal switch.

- Thermal sensor for overheating.

If any of these elements breaks, it must be replaced.