Many people try to expand the usable space in their apartment by adding a balcony. In warm regions, they even remove the door, combining the loggia with the living space.

However, simple insulation is not enough to ensure a comfortable temperature, so it is recommended to install a warm floor on the loggia. It will allow you to maintain an optimal microclimate and use additional space to create a recreation area, dining room or office.

In the article, we will look at the types of heating systems that can be laid on the balcony, their pros and cons, as well as how to install them yourself. Methods for preserving heat in a loggia by insulating walls, ceilings or floors are described.

Which heated floor is best to use on the balcony?

What type of warm floor heating is best to use for a balcony or loggia? This question is asked by many owners of these premises. There are different types of underfloor heating - water, cable, infrared film:

- Water is the most expensive device, consisting of pipes; it is often mounted in a screed.

- Electric cable - in it the cable acts as a heating element. The “pie” is also filled with concrete mortar.

- Infrared film - heating is produced by carbon plates; they emit ultraviolet waves.

A balcony is a protruding slab that cannot withstand heavy loads, so a heavy water structure is not suitable here. It is also not recommended to install an electric heated floor on the balcony under the screed. Infrared film is considered the most suitable; it weighs little and is easy to install.

In loggias, a water or electric model for screeding can be considered if the given loads on the slab are acceptable in a particular case. To do this, it is necessary to calculate the load level in advance.

Electric TP on the wall? It is possible or not, which type to choose and install.

To determine which heated floor is best to choose, we will consider each model in detail.

Choosing material

Before choosing linoleum for a balcony, you need to consider what types of material exist. It is divided according to the types of material from which it is made. And this:

- colloxylin;

- glyphthalic;

- polyvinyl chloride;

- glassine;

- rubber.

The polyvinyl chloride type of material has earned the greatest popularity among consumers. When purchasing, you should pay attention to the availability of additional coverage. The small pores of which will absorb dust. It is also better to take material with a rough surface. To avoid slipping later if the floors are wet.

Polyvinyl chloride linoleum

Water floor - its characteristics

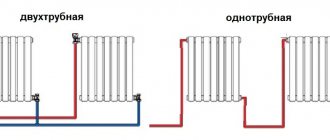

A water floor is one of the types of heating systems. It is a structure made of pipes with a circulating coolant inside. It could be antifreeze or water. Heating elements are laid in a “snake” or “snail” pattern.

The floor “pie” consists of a base, a layer of hydro and thermal insulation, pipes, concrete screed, and a finishing coating.

Advantages and disadvantages

Despite the significant installation costs during operation, such a floor is the most economical, perfectly warms the room and does not take up useful space.

It is connected to the central heating (but this requires permission, which is time and money), or connected to an independent source.

But since during construction the hydrofloor is often filled with screed, it is not recommended to install it on the balcony due to its heavy weight. Also, it is difficult to adjust the entire system in such a room.

And due to pressure surges in the pipeline, installation of a pump is required - this is quite difficult. Another disadvantage of water structures is the risk of leakage, since it is difficult to find the cause and also eliminate it in such conditions.

The disadvantage of the system, if it is connected to a common riser, is the inability to turn it on when it gets cold. You will have to wait until the general heating of the house starts working or use a cold room.

Installation

Despite the fact that it is not recommended to install a water floor on the balcony, its installation on the loggia is possible. Indeed, unlike a balcony, a loggia is equipped with two supports at the bottom, so the structure can withstand a large load.

Watch the video on how to connect to central heating

Balcony features water heated floor from central heating

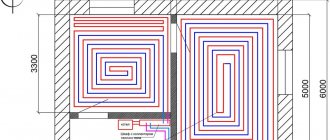

Before work, you need to stock up on materials, tools, and also develop a layout diagram for the heating elements.

The reinforced concrete slab must be flat, without holes or protrusions. If there are irregularities, the installation process should begin with it.

Step by step, do-it-yourself water heating installation looks like this:

- A thin leveling screed is poured.

- A layer of waterproofing (technical polyethylene) is laid; it must be laid extending onto the walls.

- Thermal insulation is installed - extruded polystyrene foam boards 30 - 50 mm.

- Damper tape is glued around the perimeter of the loggia - it will compensate for the thermal expansion of the screed.

- The pipes are placed according to the planned pattern, but for loggias a “snake” is more suitable; the standard pipe diameter is 20 mm. The pipeline is attached to the grooves of the plates, or with special fasteners. Seamless metal-plastic pipes are a must. They should be placed at a distance of 50 mm from the walls, in increments of 100 - 150 mm.

- Connection is made to the heating system or an independent source.

- A concrete screed is poured.

- The finishing coating is installed (only after the concrete has completely hardened) - a material with high heat transfer; you can cover the floor with linoleum, laminate, or tiles.

Before pouring concrete into the structure, you need to test the system.

You can lay water-heated floors on logs, which will be much faster and easier.

The logs are placed at a distance of 30 - 40 cm from each other. Waterproofing is laid under them, and thermal insulation material is placed between them. The pipes are placed in the grooves made, and sheets of plywood are laid on top of the logs. The finishing coating is laid on it.

What to look for when choosing

The first thing to take into account is whether the balcony or loggia will be heated. With the first option, we must not forget about the limitation by building codes of the load per 1 m2 of reinforced concrete slab protruding beyond the perimeter of the load-bearing walls - up to 200 kg. That is, you should calculate the weight of the concrete screed in which the heating element will be located, as well as massive finishing products - porcelain stoneware, marble, ceramic tiles.

With a loggia you don’t have to think about it. It has a common slab with the adjacent room; it rests securely on the load-bearing elements of the house structure. The second serious point is that it is prohibited to use the heat carrier (hot water) from the central system for purposes other than heating the main rooms. And the system itself is prohibited from being taken beyond the boundaries of the apartment.

Consequently, water heated floors are not used in apartment buildings. It is successfully integrated into the radiator heating system of individual housing construction with a single circuit for coolant circulation and a common boiler.

Other nuances that influence the choice of the optimal floor heating system include: the type of finishing floor covering and its material, the possibility of screeding, and the financial capabilities of the homeowners. You also need to know where massive furnishings will be located so that heating elements are not laid under them.

Heating mats and their types

A heating mat is essentially the same as an electric cable floor, but the wire is already fixed to a fiberglass mesh. The length of the mat is from 50 cm to 3 meters, the width is usually 50 cm. These heated floors operate on 220 W electricity. The device uses a cable with a diameter of 2.5 and 4.5 mm.

Electric mats use two types of wire:

- Single-core - both ends are connected to the thermostat, so it is more difficult to install heating with such a cable. The downside of the wire is that it emits an electromagnetic field; it is not recommended for installation in rooms where people spend a lot of time. Plus - the cost is not high.

- Twin-core - a more advanced look, suitable for a balcony. When placing it, it is not necessary to bring both ends to the regulator. Such a cable emits a minimum of electromagnetic waves, so it is not dangerous for people.

Electrical mats with any of these types of wires can last for more than one year.

A single-core cable is thinner than a two-core cable, has more power, and therefore warms up faster.

Advantages and disadvantages

The main advantages of electric heating mats:

- do not take away the height of the room, since the thickness of the “pie” is only about 2 cm;

- economical - electricity consumption is not significant;

- easy to install.

But the cost of mats is higher than the price of a regular cable floor.

The mats are recommended for heating for a short period of time; they are not intended for continuous operation. The product cannot be shortened. Therefore, having chosen a warm floor in the form of mats, you first need to measure the area of the balcony.

Installation

Apartment renovation in a new building. Do-it-yourself floor insulation on a loggia

Electrical mats must be installed carefully so as not to damage the cable.

The process consists of:

- drawing up a project - it reflects the wire laying diagram, the location of the temperature sensor and regulator;

- preparing the rough base - leveling and sealing uneven areas, clearing debris.

- laying thermal insulation - this is necessary to eliminate heat loss;

- pouring the screed - the concrete layer will serve as the base;

- placement of mats according to the pattern;

- installation of a thermostat and connection of the system;

- applying tile adhesive 2 - 3 mm and fixing the tiles - the adhesive must be applied evenly so that air voids do not form.

If you plan to lay a wooden covering on a balcony or loggia, then polystyrene foam is laid on top of the mats, on which the boards are laid.

Principle of calculation of floor systems

Before choosing any floor system, it is important to calculate the power of the heater and determine its required length.

To do this, you need to calculate the heat loss of the loggia. A lot of thermal energy comes out through window openings, so ensuring a temperature of +20-+23°C is quite problematic, especially in the winter season. Therefore, it is recommended to install heating equipment in heating mode.

You can calculate the heat loss of a balcony using an online calculator.

Before installing a heated floor system on a loggia, it is important to first insulate the room

The recommended temperature of heating mats, cable or IR film is +26°C. This mode is suitable for heat-insulating parquet floors. If tile, marble or other heat-conducting coating is used as a coating, then the recommended cable temperature is +28-+31°C.

Typically, loggias require 160-180 W per m2 for heating and 200-220 W per m2 for heating mode. Taking these recommendations into account, you can calculate the required cable length, laying pitch, and system power.

For example, a loggia has an area of 2 m2. The flooring is tiles, no screed is planned. Let's take the heating mode, which requires 200 W per m2. Next, we determine the heating area.

It is calculated using the formula:

Sgr=Stot-Spr, where

- Spr - the area occupied by cabinets and other furniture;

- Stotal - total area of the room.

Let's say the area occupied by furniture is 0.5 m2. Then Sgr=2-0.5=1.5. The heating mode is selected for the loggia, so the required cable power is 200 W per m2.

Then the recommended system power is 1.5 * 200 = 300 W per m2.

If a screed is not planned, choose a thin cable system that can be completely embedded in a layer of tile adhesive.

You can select a system with the required characteristics using tables describing the characteristics of the equipment.

Using the technical characteristics of the mats, you can determine the optimal model based on individual requirements (+)

Based on the table, we determine the thickness of the mat, its dimensions and length based on its area. In our example, the power of the mat is 0.25 kW, and the length is 17 m.

Next we look for the installation step. We calculate it using the formula:

h=(Sgr*100)/Lcab , where

- h —laying step;

- Lcable - cable length in meters.

We substitute the values into the formula and get: h=1.5*100\17=8.8 cm.

When laying mats or cables, remember that the distance from the walls should be 10 cm.

Heating electric cable

The heating element in the electric cable floor is a two-core 5 mm shielded cable, and the system is controlled via a regulator. The device operates at a voltage of 220 W, it heats the surface from +25 to +32 degrees.

The wire is placed in a concrete solution or tile adhesive mixture, although dry installation is possible.

Advantages of a heating cable:

- the size of the electromagnetic field emanating from the system is small and not dangerous to humans;

- since the design uses low-power cores, the service life is significantly increased;

- The presence of a screened film ensures electrical and fire safety and protects against damage.

A good choice for placement on a loggia or balcony would be electric heated floors with a tile finish.

The disadvantage of a cable device filled with a concrete mortar screed is the heaviness of the structure and the duration of installation.

Installation

Warm floor on the balcony

The principle of arranging an electric cable floor on a balcony is similar to the process of laying cable mats:

- you need to start with preparing the rough surface - cleaning and leveling;

- then you need to make thermal insulation - lay extruded foil polystyrene foam 20 - 30 mm thick;

- pour a concrete screed on top of the thermal insulation with a thickness of 10 - 15 mm - there will be no contact of the material with the insulation, and the risk of overheating will be minimized;

- lay down the mounting tape and spread the cable according to the planned layout - the wire is fixed with tape;

- install a thermostat and a temperature sensor - grooves must be made for the wires running from the floor to the control unit;

- Lay down the finishing coat only after the screed has dried.

The cable should be installed on a well-insulated loggia, otherwise you will simply heat the street. Before pouring the concrete mixture, you should check the system for functionality.

Pouring rough screed

We mark points on the walls using a laser or hydraulic level along the entire perimeter of the room, finding the highest point of the balcony slab, we determine the level of the rough screed.

The rough screed should be located 5-7 cm below the finished floor level. This depends on the diameter of the pipes used. The rough screed is usually made from cement mortar with the addition of expanded clay. For small balconies there is no need to install beacons; level the mixture using a board or any long object. It is quite difficult to mix expanded clay with cement mortar, and besides, expanded clay dust worsens the quality of the mortar, so let’s take a different route.

Let's install the beacons using a level; this can be done in two ways. The first method: we make piles of mortar, let them harden, then throw the mortar between them and rub the paths with the rule. The second, simpler method: we install painting beacons or guide profiles, which are used for fastening drywall, into piles of mortar.

To prepare concrete, you can use a stationary concrete mixer.

If the distance between the balcony slab and the floor is large enough, then the screed is made on top of the laid filler. After installing the beacons, expanded clay is filled in and leveled. To strengthen the balcony slab, it is necessary to lay a welded mesh on top of the expanded clay. This will protect the fragile cement screed from destruction.

Infrared heated floor

Infrared electric floor is a popular model, especially for installation on a balcony. The design is two layers of polyester film with carbon plates inside.

The work of IR flooring is the generation of long-wave infrared rays. The film comes in different types, differing in power, heating temperature, thickness and area of application.

When choosing the power of a strip floor for a loggia, you should take into account the characteristics of the finishing material. At high power, it is recommended to lay ceramics.

Advantages and disadvantages

The main advantages of the film:

- environmental friendliness and safety for humans;

- the device does not worsen air quality, as it heats objects, not air;

- does not emit electromagnetic waves;

- does not affect the height of the room - the film thickness is only 0.3 mm;

- if one area is damaged, the entire film continues to function;

- durability, practicality, no repair required.

Due to the flexibility of the canvas, it is easy to install in a room of any shape and is easy to dismantle. The installation process is simple and not lengthy, since there is no need for a screed. Suitable for heating open spaces such as balconies, even in winter.

The main disadvantage of infrared floors is energy costs, but since most often balconies have a small area, they are not significant. The inability to place heavy furniture on the film is also one of the disadvantages of the model.

Installation

Insulation of the loggia Warm floor and electrics (PART 2) WE BUILD FOR OURSELVES

The film floor is installed on the loggia in several stages:

- the base is being prepared - it is important that it is level;

- insulation with a reflective layer (foil insulation) is laid, the joints between the sheets are glued with tape;

- openings are cut into the insulation for the contacts and sensor so that there are no protrusions;

- the infrared film is mounted, if necessary, it is cut strictly along special lines;

- contacts are connected and insulated with bitumen tape;

- a regulator and temperature sensor are installed;

- spread polyethylene over the film with a slight overlap;

- flooring is being laid.

This heating can be used immediately after installation.

Step-by-step instructions for installing heated floors

For example, let’s take floor heating using infrared films; the balcony is pre-prepared: plastic windows are installed, the ceiling and walls are insulated. The cheapest floor covering was chosen - linoleum. But specific materials have little impact on the technology and the order of work. If you understand the algorithm of actions, the order and consequences of each operation, you will be able to install any heating systems on the balcony for various finishing coatings.

To work you will need:

- heated floor system kit;

- polyethylene film and infrared reflective insulation;

- electrical equipment and special sensors;

- fiberboard sheets for laying linoleum.

Heated floor kit

To improve the appearance, it is recommended to cover the plastic thermostat box with self-adhesive film in the color of the balcony walls.

Thermostat

The function of controlling an electric “warm floor” is assigned to a special device - a thermostat. Read detailed instructions on connecting a heated floor to a thermostat on our website. Step-by-step guide + diagrams with explanations!

Step 1. Prepare the floor surface, it should be clean and as smooth as possible. In our case, the concrete slab of the balcony is covered with a 2 cm thick chipboard slab. Using this method, we simultaneously perform thermal insulation and level the base.

After installation, the slab must be cleaned of dust and sawdust.

Practical advice. To increase the efficiency of heating, professionals recommend taking more significant insulation measures; depending on the climatic region of residence, the thickness of foam or mineral wool should start from 10 cm.

Our recommendations are not followed for two reasons: the apartment is located in the south and the balcony is not used as a permanent living space.

Step 2: Install the temperature sensor. The performance of the device largely depends on the specific location, but deviations are not critical - during the operation of the floor, over time, you can notice a relationship between the performance of the device and the actual parameters. What influences the sensor performance?

- Proximity to the heating elements of the mats. It is not recommended to install the device directly under or above carbon tracks.

- Distance to cold warping. In our case, there is no foam insulation under the chipboard, and a groove is cut for the sensor. This means that at the place where the device is installed, the thickness of the slab is only a few millimeters; the cold from the concrete slab significantly affects the sensor performance.

Strobe and strip for the sensor

You should know that in practice there are extremely rare situations when the temperature sensor readings and the actual values completely coincide. By and large, it is used not to control the microclimate, but to control the heating system. She doesn’t care at what values it turns on and at what values it turns off. The main thing is that the heating temperature does not exceed permissible limits.

Step 3

. Carefully remove the covering from sawdust and other construction debris, preferably using a vacuum cleaner.

Step 4

. Lay down the insulating underlayment. In our case, the cheapest option for general building thermal insulation was chosen. The base is made of 3 mm thick foam rubber, the heat-reflecting film is made of specially treated polyethylene. It is very important that it is a dielectric and not foil or other conductive materials.

Substrate

Practical advice. Balconies have narrow load-bearing surfaces, often their width is only slightly greater than the width of the roll. If you have the same situation, then the roll must be cut and laid across the floor.

It is impossible to roll out a long layer and then fit a narrow strip from the edge; this method significantly reduces the heat-saving indicators. If you wish, you can glue thermal insulation to the base.

Prices for infrared heated floors

infrared heated floor

Glue

The fact is that small pieces often move out of their places and complicate the installation process. There are no such problems in the rooms; long pieces of thermal insulation lie more or less firmly on the surface.

Applying glue

Bonding the backing

Step 5

. Bring a roll of heated flooring and roll it out on the balcony. Do not try to cut the packaging tape with scissors or a knife; there is a high risk of damaging the conductive strips. The tightening tape can be easily removed with your fingers; grab it by the end and pull it towards you.

Step 6

.

Lay the system over the entire surface of the floor, cutting it only in the indicated places. Cutting thermal film along cutting lines

All manufacturers use standard designations; the cutting line is indicated by the image of scissors. Glue the ends with a special insulating tape, it is sold complete with a heating system.

Laying and cutting the film

General diagram of thermal film connection

Step 7

. Install the power supply terminals.

General view of the CALEO LINE thermal film, location of its main elements.

Pay attention that both halves of it are adjacent to the contacts over the maximum area, do not rush. The film is very thin and reacts extremely negatively to repeated installation/disassembly; all connections must be made the first time. To do this, you should carefully study the purpose of each element, think through your actions, prepare a suitable tool, and only then get to work.

Busbar insulation and terminal connections

Step 8

.

Connect the wires to them. Before this, you need to remove the insulation, and here problems can arise if you have little practical experience. What should you pay attention to? To cut the insulation around the perimeter of the wire, never use a very sharp knife; it cuts off not only the polymer, but also thin wires. One more nuance. Before clamping the wires into the terminal blocks, they must be tightened; only this method guarantees full contact of all wires with the terminal block. Connected wires

Photo of the connection process

Important. When connecting wires, you must comply with the requirements of the PUE. And they say that the directions of the cables should only be horizontal and vertical, turns are made only at right angles.

This is very important in our case, when the wiring is hidden. When fixing external sheets, the risks of damage by wire with self-tapping screws or dowels are minimized. In order not to make a mistake with the length of the wires, it is recommended to first place the heating system in the working position, temporarily fix it with tape and measure the cables in this position.

Prices for CALEO LINE

thermal pad CALEO LINE

Connecting terminals and wires

The cross-section should be selected taking into account the total power of the heating system and the type of conductors. We will not consider numerous options; when installing heating, mainly stranded copper wires are used. There are only two parameters to remember: for a power of 4 kW you need a cable of 1.5 mm2, for a power of 6 kW you need a cross-section of 2.5 mm2.

Step 9

. Find the special bitumen insulation included in the system kit and reliably insulate all open contacts. Do not try to replace it with ordinary tape; in all physical and operational characteristics it is much inferior to bitumen tape.

Bonding bitumen insulation

Cut out recesses in the soft bedding to hide the connection points in them. If you use foamed polyethylene as a lining, then you don’t have to make indentations; this material has almost zero strength and compresses under contact without any problems. The hole is considered a must for durable extruded polystyrene foam pads.

Step 10

.

Check the quality of the connection; if everything is normal, then you can stick the mats to the surface with tape. Remember that infrared heating systems really have a very long service life; all premature failures after analyzing the causes were explained by gross violations of the recommended technology during installation. Fixing the mats with tape

Step 11

.

Install the temperature sensor into the prepared channel. Temperature sensor

You need to find it by touch and cut through the thermal insulation in the right place with a sharp knife. It is strongly recommended to check the ease of movement of the sensor in the channel. During operation, sometimes it becomes necessary to replace it; this is very difficult to do if it is not possible to remove the device from the channel. The finishing flooring has to be removed.

The sensor must be placed in the channel

Step 12. Cover the heating system with plastic wrap. This is additional protection of all elements from water penetration. The film is bought in a sleeve; after cutting it, the resulting width is quite enough to protect the surface of the balcony floor in a continuous piece. Secure it with tape.

Polyethylene film laid

Step 13

. Check the operation of the system, turn on the power for a short period of time. If the floor heats up evenly over the entire surface, then turn off the power and cover the system with fiberboard. This is the cheapest and best option for a base for linoleum. There is no need to buy thick slabs, they will reduce the efficiency of the heating system.

Fix the slab with self-tapping screws, do it in stages. Due to this technology, the possibility of damage to the system is eliminated - you always see its actual location and, taking this into account, select the locations for fixing the screws.

Fixing fiberboard boards

The base is ready, all that remains is to lay the linoleum, level it and fix the plinth around the perimeter.

Laying linoleum on the balcony

How to lay linoleum correctly? Read on our website!

And one last thing. Analyze carefully how exactly the comfort of using a balcony with heated floors will improve, how often you will turn them on, for how long and for what purpose. The results of the reflections will provide practical assistance when making decisions about installing heated floors in non-residential premises.

Temperature sensor installation

To regulate the temperature in a room heated by electric floors, you cannot do without a temperature regulator and sensor. The method of connecting devices is simple, it is the same for all systems, the main thing is to follow the instructions.

To install this device, you must:

- make a recess in the wall for the box;

- cut grooves for the wire in the wall from the floor to the location where the regulator is installed;

- install the device in the prepared opening;

- insert the sensor into the corrugated pipe and place it between the heating elements;

- connect the sensor and cable from the floor to the regulator.

The regulator should be placed close to the wiring - this will save on wires.

Pipe laying and trial run

To insulate the joints of the insulation, you need to use aluminum tape.

Before laying the pipes, we put foil-coated thermal insulation material. It plays the role of a heat shield. The joints of the insulation must be taped with aluminum tape. The edges of the thermal insulation should extend onto the walls by about 3-4 cm. Excess insulation must be cut off. Then we lay the pipes according to the diagram. You can bend the pipe using a pipe bender, which prevents it from bending.

Insulation of balcony floors

When a heated floor operates, a lot of heat is lost through the base slab. And if the neighbors below have an unheated balcony, then these losses will increase significantly. Therefore, the insulation of balcony floor slabs must be approached responsibly.

The technology and material for thermal insulation are selected taking into account the characteristics of the balcony and ceiling height. In private houses, where the ceilings are high and the loggias below are supported by columns, there are many options; any method will do.

In apartments, when choosing a material, you have to take into account the design features, even if this affects the quality of heating.

Insulation with expanded clay

To get the effect of insulating a balcony slab with expanded clay, its layer should be at least 5 cm, and preferably 20 cm.

Expanded clay is a hygroscopic material; when wet, its thermal insulation properties are lost, and it takes a long time to dry. There are several types, depending on the size of the fractions (from 5 to 20 mm) - sand or gravel. It has been used as a material for thermal insulation for a long time, since it is not expensive, and its characteristics are practically not inferior to modern insulation materials.

The larger the fractions, the higher the thermal properties of expanded clay, but the degree of shrinkage is greater.

Styrofoam

Polystyrene foam is an artificial material made from polymers; it is not afraid of moisture and is not destroyed by external factors.

But since it has a lower density, its thermal insulation qualities are lower. Foam plastic is less durable, so it is not recommended for floors, although it is often installed due to its low price.

Extruded polystyrene foam

Extruded polystyrene foam is a solid sheet insulator, standard thickness is 3 - 5 cm. The boards are durable and can withstand the weight of a person. This material makes it easy to install beacons and install a heating element.

Penoplex practically does not reduce the height of ceilings, but it costs significantly more than expanded clay and polystyrene foam. But since the average balcony area is 3 sq.m., the costs will not be significant, so it is better to use it.

The process of insulating a balcony slab with polystyrene foam is not complicated, it is similar to laying any heat insulator, so this work is easy to do yourself:

- the slab is leveled - large bulges are cut off, and depressions larger than 3 mm are filled with cement mortar;

- polyethylene is spread as waterproofing;

- damper tape is glued around the perimeter of the balcony, its width is 10 cm - it compensates for temperature expansion;

- sheets of expanded polystyrene are laid;

- a reinforcing concrete screed is poured in a layer of 5 cm, and a plastic mesh is used for reinforcement.

After the screed has dried, you can proceed directly to installing the heated floor.

Selection of pipes for installation

Types of materials:

- Copper. Long service life. They are considered the most reliable, which explains the cost above other pipes.

- Metal-plastic. Durability and good flexibility. High temperature tolerance. High price.

- Polyethylene. Favorable price-quality ratio. Extremely elastic. Resistance against high humidity.

- Polypropylene. Reliable and practical. Resistance to acid-base substances. The cost is lower than that of metal products.

Insulation of walls and ceilings

To maintain comfortable conditions in the loggia, without wasting heat, it is imperative to insulate the walls and ceiling.

To do this, you can use various thermal insulation materials: mineral or polymer, sheet or roll, hard or soft.

Mineral wool

Mineral wool is made from basalt rocks. Pros: low thermal conductivity, fire resistance and affordable price.

However, it is hygroscopic and requires additional protection, so it is not recommended for insulating walls and ceilings on the balcony.

Styrofoam

Polystyrene foam is produced by foaming synthetic masses, resulting in a light and porous product.

It has a low level of thermal conductivity, does not rot and is easy to install.

Expanded polystyrene

Expanded polystyrene is a type of polystyrene foam, but a more modern and improved model. It is an excellent heat insulator, easy to install, lightweight and inexpensive.

Today, polystyrene is one of the most commonly used thermal materials, so let’s consider the process of insulating walls and ceilings on a balcony or loggia from it.

The method of attaching the insulation to the walls depends on their finish:

- on PVA glue or other composition that contains an aggressive solvent;

- using special wedging fungi;

- on wooden slats or metal profiles.

The following finishing is possible on top of the insulating material:

- installation of reinforcing mesh, with puttying, painting or wallpaper;

- cladding with plastic panels or siding.

Other styling options

Not every balcony structure can withstand the weight of a cement screed. In this case, there are as many as 3 analogues to the standard installation procedure.

Polystyrene system

The system is used in all types of houses, as it is light in weight (a square meter is approximately 25 kg). It has good thermal insulation and sound insulation properties. Place on a base cleared of debris.

Step-by-step instruction:

- Cutting grooves in a sheet of foam plastic using a thermal knife.

- Inserting metal plates into grooves.

- Laying heating pipes in the grooves of the plates.

- We finish by covering the structure with polyethylene film and gypsum fiber board sheets.

Wooden modular

Chipboard modules are used in wooden houses with logs. When laying, it is recommended to cover the joists with a layer of waterproofing, and lay insulation between them.

Step-by-step instruction:

- Fastening modules to the floor.

- Inserting metal plates into module grooves.

- Laying heating pipes in the grooves of metal plates.

Wooden on slats

The rack system differs from the modular system only in that boards are used instead of chipboard sheets.

Step-by-step instruction:

- Laying wooden planks on a waterproofing film.

- Laying metal plates between the slats.

- Fastening the plates to the strips with self-tapping screws.

- Laying pipes in the grooves of the plates.

- Covering plates with pipes with waterproofing film.

- Covering the structure with gypsum fiber sheets.

Features of operation

There are several points that need to be taken into account when installing heated floors on the balcony in order to extend the life of the system and its efficiency:

- do not install heated floors on an uninsulated balcony, insulate the floor tiles, walls and ceiling - this will allow you to avoid wasting heat;

- use lightweight thermal insulation material, install from inside the room;

- use a moisture-resistant topcoat.

To summarize, it can be noted that the most suitable models for electric balconies are infrared film or cable mats. Although under certain conditions other types have the right to exist.

Currently, in order to increase the usable area and increase the functionality of the balcony, it is not only glazed, but also insulated, and heating is installed - warm floors. With a well-chosen heating system, you can use the balcony room at any time of the year.

Calculation

A system layout diagram is drawn up so that it is clearly clear what should fit where and what should be connected to. This stage is serious, since the functioning of the heating will depend on the correctness of the calculations. If you make inaccurate calculations, it is possible that you will have to correct shortcomings almost in the first year of operation.

It is best to carry out the calculations in a design organization. But you can calculate everything on a calculator yourself.

Advice

Having measured all the parameters of the balcony room (length, width, floor area, curved corners, height of the base to the window and door), you can enter the indicators into special calculation systems provided free of charge on the websites of organizations and construction companies.

You can find a calculator widely available on the Internet to determine the required pipe pitch and installation parameters. This will give you the value of the heat transfer power, which will need to be taken into account during installation.

A distance of at least 10 cm must always be maintained between the pipes. When calculating their quantity for a water floor, it is important to take into account the length of one circuit, which should not exceed 60 cm. If all these conditions are met, it will be possible to effectively purchase the required amount of material, and then correctly install the water heating .

What kind of pipes are used?

Pipe options differ in material.

Copper

They are considered the most durable, and therefore the most reliable. At the same time, their price is also high. Most of them are made of pure copper, which guarantees a service life of at least 50 years, and a maximum of 200.

Metal-plastic

The inner layer is made of aluminum, which makes them super strong and durable. The high price is covered by flexibility, strength, and the ability not to constantly change shape. Their shape and temperature are unchanged.

Polyethylene

Cheaper than metal-plastic and copper ones, but they have excessive flexibility and low strength.

Polypropylene

Reliable, resistant to water, do not allow corrosion. At the same time, their exposure to blockages is minimal.

Important

Installation of polypropylene pipes is the most labor-intensive. This is due to their least flexibility and the impossibility of installation in limited spaces.

They cannot be used on small loggias and balconies, as their durability is low if they are poorly installed.

Made from cross-linked polyethylene

Strong, wear-resistant, laid at the molecular level, which ensures a long service life.

It is very beneficial to install a water floor on the balcony. A loggia with such heating will ideally warm up and serve as an additional room in which you can even spend the night. Proper installation and correct calculation of water supply guarantee a reliable heating system, which will allow the equipment to operate for a long time.