The lightweight and easy-to-use metal stove “potbelly stove”, with all its advantages, has one significant drawback: low efficiency.

To heat a room, an ordinary metal potbelly stove usually spends 50-70% of its efficiency, the rest of the heat simply flies out into the chimney.

It is clear that it is very difficult to reconcile with such a situation, but unfortunately, few stove owners take radical measures to increase the efficiency of the furnace. Although, as experience shows, with a little skill and spending a little time you can get a fairly effective stove from this gluttonous design.

Improving the stove to increase efficiency

Suitable for heating a garage

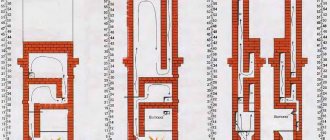

To increase the performance of a potbelly stove, the chimney pipe can be built not at the back, as is traditionally done, but at the front directly above the combustion chamber. In this case, the walls of the stove will first heat up, increasing the heat output. And if the stove itself and the pipe are lined with bricks, the cooling time will increase significantly, which will lead to fuel savings. In addition, if the dimensions of the structure allow, you can make the internal walls in the combustion chamber itself from fireclay bricks, that is, line the furnace.

Another method of increasing the heat capacity of a stove-stove is to install additional fins. To do this, strips of thick metal located perpendicular to the walls are welded to the outside of the side walls of the furnace. At the same time, the heated area increases, which warms up the surrounding air faster. If you place a container of water on the stove, this will also help retain heat for a long time after the fire stops.

A furnace with welded fins can be protected with a special casing made of metal or heat-resistant materials. This will reduce the risk of getting burned when firing the stove.

Another way to increase the efficiency of a potbelly stove is to weld large-diameter hollow metal pipes to it. Their ends at the top of the stove will be directed in opposite directions according to the principle of Buleryan stoves.

Increasing heat capacity

The heat capacity of a potbelly stove can be increased both by increasing its weight and dimensions and by using additional heated materials. In any case, it is necessary to make design changes to the heating system. One option may be to use smoke circulation inside the oven. This can be done by installing sheets of heat-resistant metal in the firebox, thereby providing additional paths for the movement of gases. At the same time, they are burned, heating the furnace to a higher temperature. But at the same time, the temperature of the exiting smoke also increases. With a short chimney, the heat is simply released into the atmosphere.

To use this heat, a heat-storing container is installed on the exhaust pipe of the potbelly stove, which can be made either from an old gas cylinder or from a large-diameter pipe. The container is filled with large stones that retain heat well. At the same time, it is loaded to approximately 2/3 of the volume. The stones are placed on the grate. Hot gases flowing through the battery heat them up and, giving off heat, go outside.

The stones are heated to a temperature of about 400 °C. After the fuel burns out in the stove, the damper on the chimney is closed and the room is heated using the heat accumulated by the stones. In this case, the stove is in a cold state. Using such a battery allows you not only to save fuel, but also to receive heat after the stove stops working.

The battery, which increases the efficiency of the furnace, can be made of brick and installed on metal supports above its surface. But such a design cannot be used with a round stove.

The calorie content of fuel depends on its type and quality. Replacing fuel with a higher-calorie fuel is expensive and requires additional storage space. As a rule, garages are heated with waste material that is easy to find. Now, knowing how to increase the efficiency of a potbelly stove, you can begin work. It should be noted that the best results are obtained with the integrated use of methods that increase the heating efficiency of the furnace.

Ways to increase efficiency

Potbelly stoves are made in various shapes and sizes. But they have one drawback in common - low efficiency. More than half of the thermal energy, in the literal sense of the word, flies out into the chimney. The irrational use of heat has led to the fact that the owners of these heating devices began to think about possible changes in the design of the furnace to increase its efficiency. The solution to this problem could be a partial modernization of the potbelly stove. There was no single concept for solving this issue, and each stove owner began to solve the problem independently, by trial and error.

Increasing the efficiency of a potbelly stove means receiving additional heat from the heating device while maintaining a constant amount of burned fuel. This can be achieved in several ways:

- changing the heat transfer surface,

- increase in heat removal;

- using more high-calorie fuel;

- increasing the heat capacity of the furnace.

The potbelly stove gives off heat to the surrounding space not only with its body, but also with its metal chimney. You can increase the heat transfer surface of the device by revising its dimensions upward. This option is possible when creating a stove with your own hands. Having already made a potbelly stove, you can do it in another way. Usually a corner is welded to a chimney made of a metal pipe. Position it with its apex facing the element along its entire length. The angle is installed around the pipe. Thus, the area of the heat transfer surface can be increased by 3-4 times, depending on the size of the corner.

Another option for increasing the heat transfer surface is to make a chimney running inside a large area. For this purpose, a chimney with turns is made. They are performed in the form of smooth transitions. It is undesirable to create turns at right angles, as the potbelly stove may start to smoke. The last section of the chimney is installed vertically. A pocket is made on it with a hatch for cleaning soot.

If it is impossible to lengthen the pipe, its design is changed. Cylinders made of pipes with a diameter of 300-400 mm are welded onto the pipe coming out of the furnace body. They are connected to each other by pipe sections with a diameter no less than that of the smoke pipe. They are welded out of alignment to increase the smoke path.

Traditional methods of furnace modification

Solution #1

The first thing you need to do to modify a homemade or purchased stove is to install side screens. To do this, sheets of metal (not painted) are applied to the furnace body and secured with self-tapping screws or bolts. The thickness of the sheets can be any (standard roofing iron will do). The screens should be located at a distance of 5-6 cm from the stove itself.

This DIY design changes the principle of heat transfer. Thermal energy is now transferred to the room not through radiation, but through convection. Air circulates in the space formed between the surface of the oven and the screens. This technique allows you to increase the rate of warming up the room and save on fuel consumption.

Solution #2

The next step is to modify the stove's chimney - one of the necessary structural elements. Most heating problems occur here. The chimney is usually the cause of large heat losses. In a standard potbelly stove, the chimney pipe is straight and smoke immediately enters it when leaving the room. In order to somehow “retain” hot air in the pipe and thereby increase heat transfer, it is necessary to add several elbows to the straight path of the pipe. For example, two bends at 90 degrees are purchased and connected to each other in the English letter S. Thus, rising hot air and smoke will be trapped in the bends, the pipe will heat up more, thereby increasing heat transfer. And if you add a fan and a blowing chimney at the knee points to such a design, the heat transfer will increase even more.

Solution #3

Now we are modifying the stove in order to save fuel. Partially, the lack of “gluttony” of the potbelly stove has already been eliminated due to the convector, the addition of elbows and a fan. In stoves with a high level of efficiency, heating of the room occurs not due to the combustion of fuel, but, for the most part, due to its smoldering. There is no provision for adjusting the combustion intensity in a classic potbelly stove. But this is easily solved. As is known, oxygen promotes combustion, that is, the intensity of combustion can be regulated by increasing the supply of oxygen.

https://youtube.com/watch?v=GeMINGFp_lo

Solution #4

The last interesting engineering solution is useful for those cases when the fuel source is exclusively firewood. The design features of the potbelly stove allow the wood to burn out quickly. To save fuel, it is more profitable to burn it with short wood, thus reducing the volume of the firebox. But even in this case, the firewood burns out quite quickly and it becomes necessary to constantly refill it. If you add a number of design additions to the design of the potbelly stove, made on your own and with your own hands, you can extend the burning time of the fuel and increase the heat retention time.

To do this, it is necessary to prepare a blind sealed cylinder (approximate height 400 mm) by welding it from a sheet of steel. The cylinder, which serves as a cassette, is filled with long firewood and installed in the burner hole of the top stove of the potbelly stove. Next, it is necessary to provide the cylinder with reliable support, for example, a welded thrust flange.

When filling the cassette with firewood, you should not overdo it. It is necessary to ensure their free movement when tipping over. Before using the cassette, you need to light the stove and wait for a certain supply of coals to appear. Firewood knocked over from the cylinder will begin to flare up. The main thing in this process is that only part of the firewood pushed into the firebox will burn intensely, while the remaining part will dry out due to the movement of smoke, and then, under the weight of its mass and the mass of the upper layers, will fall into the firebox, where the first ones will gradually burn out. layers.

The cylinder will also heat up from the smoke, releasing heat into the room. Due to this, the heat transfer surface of the potbelly stove increases, i.e. its efficiency increases.

Why is there bad draft in the furnace?

Poor or weak traction most often causes reverse traction as a consequence. The reasons may be completely different from each other. As for the main one, these are the mistakes that people made when designing the heating system. In this case, there is a possibility of improper use of building materials. Let us also consider in more detail the possible sources of the problem and what to do in such cases:

The defect may be hidden in the chimney design. The proportions between height and firebox are sometimes calculated incorrectly. And because of a low pipe, for example, the pulling often happens worse. However, if the parameter for this component was greater, then reverse thrust would not have formed.

REFERENCE

That’s why it’s so important to consider the universal size – about five meters

- Don't forget about the diameter ratio. A narrow value makes it difficult to remove combustion products.

- In addition, if the product is square in shape, then most likely the movement of smoke will not be as free as it would be with rounded corners.

- Natural conditions also significantly influence the presence of weak traction. In rainy climates, high humidity or strong winds, the level tends to decrease.

- If there are various damages or scratches or irregularities on the pipe, then there is a high probability of obstacles to attraction with a good coefficient.

- Stove care. There are often cases when the user forgets about cleaning, thereby accumulating dirt - collapsed building materials.

- The reason is very similar to the previous one. Only this time the clog is soot.

- The ventilation process has been disrupted. Because of this, there is a shortage or no supply of air mass at all.

Preparation of the solution

Let's start by preparing the solution. For masonry work we use a special ready-made mixture. Sold in construction stores. It is a yellow-gray powder in 25 kg bags. All that remains is to dilute it with water in the correct ratio and mix. Detailed instructions are always indicated on the packaging; you need to follow them step by step. This solution is the best choice. It has only one drawback - its high price.

You can prepare the mortar for masonry yourself. For this we need clay and sand. First, let's determine the quality of the available clay and the content of impurities in it. We follow the following instructions:

- Roll the clay into a rope. Thickness - 10-15 mm, length - 150-200 cm.

- Take a rolling pin with a diameter of 50 mm and wrap a rope around it.

- The tourniquet should stretch smoothly and break, stretching by about 15-20%.

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

If the rope stretches more, the clay is “fat”; if it breaks earlier, the clay is “skinny.” In the first option, the solution will shrink greatly under the influence of temperature, in the second it will crumble.

The next step is to prepare the sand. First, sift it through a fine sieve. The cell should not exceed 1.5x1.5 mm. Next we follow the instructions:

- using a handle and burlap, we arrange some kind of net;

- pour sand into it and begin to rinse it under running water;

- Rinse until the draining water runs clear.

Thus, we have rid the sand of impurities.

We do the same with clay. Now it should be soaked. To do this, pour the clay into a previously prepared container. Pour water so that the entire surface of the clay is covered. After 24 hours, mix thoroughly. We repeat the process until the clay has a consistency similar to toothpaste.

There is no universal proportion for a solution. Everything is installed by trial and error, depending on the characteristics of the materials used. The main thing is that the solution is convenient to work with.

To increase strength, experts recommend adding a little cement or salt.

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

Here is a basic recipe for masonry mortar:

Take 2 parts of clay. Add one piece of sand to it. Using a construction mixer, mix until smooth and thick. We will need approximately 40 liters of solution.

Warm brick

A potbelly stove using wood, coal and other types of fuel can significantly increase its efficiency. To do this, it is enough to build a screen of baked clay bricks around it with your own hands. If you look carefully at the drawings of such a mini-building, you will see that the bricks are laid at a short distance from the walls of the stove (about 10-15 cm), and, if desired, around the chimney.

Brick screen for potbelly stove

Bricks require a foundation. Do you want the masonry to last a long time? Then fill the base one at a time to form a monolith. It is better to take concrete as the material for the foundation, which should be reinforced with steel reinforcement yourself. It is advisable to place the reinforcement layer at a distance of approximately 5 cm from the surface of the concrete pad.

Ventilation holes are made at the bottom and top of the brickwork, which will ensure air movement (heated masses will go up, cold air flows will come from below). Ventilation also prolongs the life of the metal walls of the potbelly stove, delaying the moment of their burning due to cooling by circulating air.

Bricks laid around the stove accumulate heat and then release it for a long time, warming the air in the room even after the stove goes out. In addition, brickwork additionally protects objects surrounding the stove from fire.

If desired, you can completely lay out the stove from brick. Such a structure is advantageous in that it will last for many years without additional effort on the part of the owner. However, there are also certain disadvantages. The disadvantages of this option include the following:

- the process of laying out such a stove is quite labor-intensive and is suitable only for those people who have experience in masonry with their own hands;

- a brick stove is quite expensive, as it requires the use of fireproof materials, including fireclay bricks and special clay for mortar.

In order to get a small potbelly stove with wood, it is enough to lay out a cone measuring 2 by 2.5 bricks, 9 bricks high. In the combustion chamber, rows 2-4 are laid out of fireclay bricks. An ordinary fired clay brick is suitable for a chimney, into which you must remember to insert a stainless steel sleeve.

Whatever the method of making a miniature stove or potbelly fireplace with your own hands, whether you make them according to a drawing or by eye, the main thing is that at the end you get an effective heating device, and in an expanded configuration also a hob for cooking. Look around for suitable materials (barrels, sheet iron, etc.) and go ahead to your own homemade stove or even a potbelly stove!

Grid with stones

Modernizing a potbelly stove with a mesh with stones is quite one of the most common improvements. Almost everyone had a bath and steamed in the steam room. There you saw a set of stones that warm the air in the steam room.

The principle of this modernization method is similar. It is necessary to line the potbelly stove with stones, which continue to retain heat for a long time. It is worth remembering that you should not use galvanized material for manufacturing, since when heated, toxic fumes are released into the air.

Materials and tools

For this event we will need:

- a set of good stones (you can use high-quality clay bricks), preferably of medium size, similar to those you came across in the steam room.

- dense metal net, you can use a chain-link net.

- if you plan to do it like an adult, then you will need fittings and a welding machine.

Instructions

Making this improvement is simple:

- It is necessary to make a frame of metal mesh (or reinforcement) near the stove, which will not block access to the technological openings of the potbelly stove.

Design example

- After creating this frame, it is necessary to fill the cavities between the stove and the frame as tightly as possible with prepared stones.

You can also fill the cavities between the stones with clean clay, which will also help retain heat.

Precautionary measures

It is strictly forbidden to use flammable materials and metals with low melting points to create this improvement. Also, this structure should ensure free maintenance of the potbelly stove, not block access to the firebox, to the ash pan, and not interfere with the removal and replacement of outlet pipes.

What is a potbelly stove

For those who have never seen such stoves, we need to tell you what a potbelly stove is. This is a metal firebox with a straight chimney and a hole into which firewood is placed. These fireboxes are often made from any metal object of suitable volume or welded from scrap metal. A potbelly stove can be round, for example, made from an old metal barrel, or square or rectangular from iron boxes. The stove is placed on metal legs or simply on bricks. The pipe is routed through the roof. The good thing about a potbelly stove is that it is cheap, and you can heat it with any waste.

The operation of such a stove is based on constant combustion. Thin metal heats up quickly and transfers heat to the room. Everything would be fine, but you have to constantly maintain the fire in the firebox, because when the flame becomes smaller, the stove begins to cool down. It cools down quickly, and the room becomes cold again. But craftsmen learned to get out of the situation by modernizing the stove with their own hands. Having such a stove and slightly modernizing it, you can get a very cheap heating device that will retain heat even after the fire goes out. And when burning, the converted potbelly stove will produce much more heat than before.

Why do you need furnace modifications?

Every model, and not just stoves, is imperfect, and you always want more and better. So it is in this case with heating partings. Any modifications are carried out in order to obtain maximum effect without reducing the service life of the heating device.

For example, with the help of improvements, you can achieve maximum proper combustion, with a good level of heat transfer, without heating the potbelly stove to the limit so that the metal turns red.

Watch the air damper. It must be at a level so that the flame does not enter the chimney. The fire should not exceed the level of the top of the stove. The heat must be distributed evenly throughout the device in order to properly warm the room.

There are many options for modification; you should choose the optimal one for yourself in order to ensure a comfortable temperature for being in the room.

How to make a homemade potbelly stove?

- The first type of potbelly stove

- The second type of stove-stove

- The third type of stove-stove

- Step-by-step construction of a potbelly stove

The stove, popularly known as a “potbelly stove,” is a barrel- or box-shaped metal structure equipped with a pipe and a door. As a rule, the chimney was led directly into the window of the room. The “potbelly stove” literally saved people in the cold season, if the house did not have a large Russian stove or there was simply not enough wood for heating.

Sawdust stove diagram.

This stove got its name because of its high efficiency; she could heat a room in a short time by burning several birch branches.

Until now, homemade potbelly stoves with a similar design are successfully used for heating garages, temporary buildings and small country houses.

In addition, urban apartment dwellers should also resort to such simple equipment if the heating is turned off in winter.

Potbelly stoves impress with the simplicity of their design and high efficiency. Today there are several different types of baby stoves, let's look at some of them.

Content

The garage is a favorite place for many car enthusiasts. Car owners are trying to improve the room, make it more practical and cozy. In the winter, it is problematic to spend a lot of time in an unheated garage, so many people make homemade potbelly stoves for heating. Of course, you can buy a ready-made heating device, but making a stove yourself will be cheaper and more economical.

A potbelly stove is suitable for heating a garage in the cold season. It is much more economical than electric heating devices, and its installation and installation do not require serious construction skills.

Chimney for potbelly stove

Material for making a chimney

Before you start making a chimney pipe that will be installed on a potbelly stove, you need to decide on the material that will be used.

Taking into account the fact that a potbelly stove is a portable stove, we immediately refuse brick chimneys. In this case, we have few options: either asbestos-cement or metal pipes. Most heating experts still recommend using metal chimneys: they are lighter and easier to manufacture

We'll talk about them in more detail.

Most heating experts still recommend using metal chimneys: they are both lighter and easier to manufacture. We will talk about them in more detail.

Cast iron stove with steel chimney

Making a metal chimney for a potbelly stove

So, we have decided on the material - we will make a chimney from a metal (stainless steel) pipe. However, it is not enough to simply insert the chimney pipe into the corresponding hole in the potbelly stove - the chimney must be correctly mounted and optimally located.

Potbelly stove on the street

As a rule, a simple chimney for a potbelly stove installed indoors consists of two parts - internal and external. These parts are connected in the attic or at the level of the under-roof space.

This “double-knee” design makes it relatively easy to replace the lower burnt-out segment of the chimney without dismantling the entire system.

By the way, you can not buy steel pipes, but bend them from a steel sheet, but this will require certain skills from you. On the other hand, then you can make a pipe for a stove-stove of exactly the diameter that you need.

Pipe installation

To install a chimney of standard dimensions, we will need the following materials:

- Elbow 100x1200mm (1 pc.)

- Elbow 160x1200 mm (2 pcs.)

- Butt elbow 160x100 mm (3 pcs.)

- Tee 160 mm with plug

- Mushroom 200 mm

Also, depending on the characteristics of the room in which the potbelly stove with our chimney will be installed, you may need a passage glass, a rain canopy, thermal insulation, etc.

Also, to seal the joints between pipes, we may need an asbestos cord or a special sealant.

After all the materials are ready, we begin assembling the pipe for the potbelly stove:

- We fix the first section of the pipe on the chimney opening or the furnace pipe.

- We extend the pipe bends until they overlap.

Chimney hole

- We make a hole in the floor slab with a diameter of at least 160 mm for the chimney outlet. We remove the thermal insulation along the edges of the hole to prevent it from igniting.

- We insert a passage glass into the hole, and then pass the potbelly stove pipe through it.

- We connect the pipe to the external chimney.

- To ensure optimal operation of the chimney, we provide thermal insulation to the outer part of the chimney by wrapping it with thermal insulation and coating it with bitumen.

Chimney outlet through a window

We strengthen the fungus on top of the chimney, which protects the pipe from precipitation and small debris getting inside.

Pipe care

In order for the chimney (and with it the potbelly stove itself) to work properly, it must be looked after:

- At least once a year we check the outer surface of the pipe for defects - burnouts, rust, cracks.

- Likewise, the pipe needs to be cleaned annually. To do this, you can either use special chemical compounds that are burned in the firebox along with firewood, or simply burn several aspen logs in a potbelly stove. Aspen gives a very high temperature, which perfectly burns soot.

- It is unlikely that it will be possible to use mechanical cleaning means (brush, weight, etc.), because the chimney of a potbelly stove is not very durable.

Manufacturing and arranging both the stove itself and the pipe for the potbelly stove is a difficult task only at first glance. Of course, you will have to work hard and carefully study the proposed instructions - but it is still quite possible to do this without resorting to the help of specialists. So go for it!

Making an ash pit

An ash pan is a grate near a potbelly stove, on which fuel will subsequently be placed to heat the room.

A good ash pan provides the combustion chamber with a sufficient amount of air (that is, oxygen), and also provides good draft, thereby ensuring better combustion. In most cases, ash pans in potbelly stoves leave “much to be desired,” so upgrading the ash pan will help improve the performance of the potbelly stove.

An effective ash pit should be made of heat-resistant material and have a door, thanks to which you can avoid smoke in the room. Improving the ash pan will help turn an ordinary potbelly stove into something like a fireplace.

Instructions

Making an ash pan yourself will require certain skills from you, and the production must be in accordance with the instructions:

- First you need to weld the box to the size of the potbelly stove, without the top wall and leave a rectangular cutout in the end wall. Steel is most often used in production. The dimensions must correspond to the width and length of the potbelly stove itself.

- Make holes in the bottom of the stove.

The diameter of the holes should be about 20 mm. Drilling holes for the ash pan - Weld the box to the stove.

- Install the door into the ash pan.

This design will give better and more uniform operation of the potbelly stove.

Design and principle of operation

What is the difference between the Loginov Potbelly stove and other metal stoves? The point is the L-shaped blower. The ash pan door is replaced with pipes welded perpendicularly. The edge of the horizontal pipe is tightly welded, and the edge of the vertical pipe has a thread for a plug. There are holes made on the thread - by screwing the plug you can reduce the air flow, thereby regulating the combustion process.

Loginov's original potbelly stove

It is important to make a plug with a slight play, so that expansion of the metal when heated will not cause problems. A screen is welded to the sides and back on the stiffeners to increase efficiency

Without such screens, it is extremely uncomfortable to be near the stove - the temperature is too high and can cause burns. The firebox door is also threaded. A 200mm pipe serves as the firebox opening, and a plug with a handle 220mm in diameter is screwed onto this pipe.

You can see more details about Loginov’s potbelly stove in this video:

Modification

N. Pyankov’s model is distinguished by the presence of an additional combustion chamber. Unlike more complex designs of slow combustion stoves, the Pyankov potbelly stove is manufactured even faster, the model proposed by Loginov. It is enough to weld steel sheets 140-160 mm long to the back and front walls of the furnace at different distances from the top. The distance between the sheets should be 80mm. The grate is installed 80mm from the bottom. Pyankov moved Loginov’s firebox door to the top of the stove and began using it as a hob.

It will not be difficult for a good master to evaluate all the advantages and disadvantages of the two drawings. If desired, you can make a new model of a potbelly stove using only these two developments, changing the rectangular shape to a round one.

An example of a homemade design (in this photo there is a modernized Pyankov stove), but there is practically no difference in the manufacturing process.

Potbelly stoves - proven and simple designs

Potbelly stoves were a hit of the 20s of the last century. At that time, these stoves competed with brick stoves and were installed everywhere, even in apartments. Later, with the advent of centralized heating, they lost their relevance, but are used in garages, dachas, and for heating utility or outbuildings.

Sheet metal

Potbelly stoves from a cylinder, barrel or pipe

The most suitable material for making a potbelly stove for a garage is propane cylinders or a pipe with a thick wall. Barrels are also suitable, but you need to look for ones that are not very large in volume and have a thick wall. In any option, the minimum wall thickness is 2-3 mm, the optimal is 5 mm. Such a stove will serve for many years.

By design they are vertical and horizontal. It is more convenient to burn horizontally with firewood - longer logs will fit. It’s easier to make one extended upward, but the firebox is small in size, so you’ll have to cut the wood finely.

A potbelly stove for a garage can be made from a cylinder or pipe with a thick wall

Vertical

First, how to make a vertical stove for a garage from a cylinder or pipe. Divide the selected segment into two unequal parts. Below is a smaller one for collecting ash, above is the main one for storing firewood. The following is the order of work:

- Cut out the doors. Small at the bottom, solid at the top. We use the cut pieces as doors, so we don’t throw them away.

- We weld the grates in the chosen place. Usually this is steel reinforcement cut into pieces of the required length with a thickness of 12-16 mm. The reinforcement installation step is about 2 cm.

- Weld the bottom if there is none.

- We cut out a hole in the lid for the chimney, weld a strip of metal about 7-10 cm high. It is better to make the outer diameter of the resulting pipe fit standard chimneys. Then there will be no problems with the installation of the chimney.

- We weld the lid with the welded pipe into place.

- Using welding, we attach the locks and hinges to the cut-out door pieces and install it all in place. As a rule, potbelly stoves are not airtight, so there is no need to make seals. But if desired, you can weld a strip of metal 1.5-2 cm wide around the perimeter of the doors. Its protruding part will cover a small gap around the perimeter.

Overall, that's it. All that remains is to assemble the chimney and you can test a new stove for the garage.

Horizontal

If the housing is located horizontally, the ash box is usually welded from below. It can be welded to the required dimensions from sheet steel or a piece of channel of a suitable size can be used. Holes are made in the part of the body that will be directed downwards. It’s better to cut something like grate bars.

How to make a potbelly stove for a garage from a gas cylinder

Then in the upper part of the body we make a pipe for the chimney. To do this, you can weld a cut piece from a pipe of a suitable diameter. After the piece of pipe is installed and the seam is checked, the metal inside the ring is cut out.

Next you can make the legs. The best fit is pieces of a corner, to which small pieces of metal are attached from below so that they stand stable.

The next step is installing the doors. You can cut a piece of metal onto the ash pan, attach hinges and a lock. There are no special problems here. The gaps around the edges do not interfere - combustion air will flow through them.

There will be no difficulties if you are making a door from metal - welding the hinges is not a problem. Only here, in order to be able to at least slightly regulate the combustion, the door needs to be made a little larger - so that the perimeter of the opening is closed.

How to install stove casting on a metal stove

It is problematic to install furnace casting. Suddenly someone wants to have not a steel door, but a cast iron one. Then you need to weld a frame from a steel corner, attach the casting to it with bolts, and weld this entire structure to the body.

From two barrels

Anyone who has used a potbelly stove knows that very hard radiation comes from its body. Often the walls become heated to a red glow. Then it is impossible to be near her. The problem is solved with an interesting design: two barrels of different diameters, inserted one into the other. The gaps between the walls are filled with pebbles, clay mixed with sand (calcined over a fire, then filled in only after it has cooled). The inner barrel acts as a firebox, and the outer one is just the body.

This stove will take longer to heat up. It will not immediately begin to give off heat, but it will be more comfortable in the garage and after the fuel burns out, it will warm the room for another couple of hours - releasing the heat accumulated in the bookmark.

https://youtube.com/watch?v=PEWZxL2ebXE

The third type of stove-stove

Now let’s figure out how to construct a homemade potbelly stove with a square body with thin walls and an adjustable draft. The main advantage of a square-shaped potbelly stove is its larger surface area of interaction with air, that is, greater efficiency compared to a stove based on a pipe.

The most optimal dimensions for a homemade stove will be a structure height of 800 mm and a base of 450 × 450 mm. A potbelly stove of this size will not take up much space and can easily accept almost any piece of wood.

Chimney installation diagram.

You should also determine what thickness of metal will serve as the material for the stove. Here, as in everything, a golden mean should be observed: very thick walls (about 1 cm) take too long to warm up, thin-walled metal sheets swell after heating, and the stove will become shapeless.

For these purposes, choose an average wall thickness - approximately 0.3-0.5 cm. Then the potbelly stove will retain its original appearance and will perfectly warm the room.

Features of operation

When operating a homemade potbelly stove, it is very important to follow certain rules. This is necessary not only for the safety of its use, but also for a long service life. These rules are:

- it is necessary to maintain a safe distance between the walls of the stove itself and the walls of the room (a distance of 50 cm is considered ideal);

- the chimney must be routed directly to the street; in no case should it be connected to the ventilation system of the garage (very often this desire arises when the stove is installed in the basement of the garage), since this is the only way to guarantee sufficient draft for proper combustion;

- places where the pipe is exposed to the street must be insulated with asbestos or other non-combustible material;

- You can increase the efficiency of a potbelly stove by insulating the room itself;

- It is necessary to install a box of sand and a fire extinguisher next to the potbelly stove, as this is required by fire safety regulations.

What are the advantages of bourgeois?

First of all, such long-burning devices are characterized by low profitability. After all, for their production, as a rule, used containers are used. They can be purchased completely free of charge or for a minimal cost. The same can be said about the price of fuel.

Besides:

- You can make a potbelly stove with your own hands if you find successful and understandable drawings of its design.

- Despite the small size of the stove, it has sufficient efficiency.

- There is no need to build a strong foundation for it.

- You don't need to fill out a bunch of permits.

- Easy maintenance and free installation.

- A potbelly stove, in addition to its heating function, can serve as a cooking stove.

Fire door

But despite all the advantages of such do-it-yourself stoves, they have such disadvantages as rapid burning of fuel, as well as rapid cooling due to the inability to accumulate heat. All these shortcomings can be eliminated if improved types of furnaces are used and heat-storing structures are built.

Device assembly process

https://youtube.com/watch?v=J8iA78F9Df8

- The potbelly stove will be made from a can. The container must be thoroughly cleaned of dirt and corrosion.

- In the body of the future heating apparatus, you need to make holes for the ash pan and loading of firewood or coal. This can be done using a chisel and hammer.

- You need to attach the door hinges to the body, and then install the doors into the holes made.

- At the bottom of the container you need to make a hole for the smoke exhaust. It is recommended to install a chimney with a 10 cm diameter.

- The next step is to install the grate. You can purchase it at a specialty store or make it yourself. To do this you will need steel wire. It needs to be bent several times and placed inside the heating tank. Before this, you need to weld supports on the inner walls so that the grille does not fall through. The supports can be made from steel rod.

- Then you need to attach the chimney to the hole made in the bottom using a welding machine.

- The potbelly stove is installed in the place intended for it. As noted above, it is not necessary to make a foundation. It is enough to install a brick support or lay a metal sheet, the thickness of which is at least one centimeter.

- A special screen should be laid out of brick around the device. This is necessary to increase the heat transfer of the stove. During operation of the potbelly stove, the brick will also heat up and give off additional heat, even after the wood or coal has completely burned.

How to make a potbelly stove from steel

Potbelly stove of convection type.

If you need to heat a house in the country and cook food, you should definitely know how to weld a potbelly stove yourself from sheet steel. This design will not require a lot of fuel. This is achieved through the installation of partitions in the firebox, reliable fastening of the doors and the ability to adjust the air flow. To make such a device with your own hands, you will need to prepare the following elements:

- sheet metal 4 mm thick or more;

- metal 8-12 mm thick, from which the partitions will be made;

- lattice;

- chimney pipe;

- corners from which the legs will be constructed;

- welding device.

Sequence of manufacturing actions

From the steel sheet, the first thing you need to do is cut out elements for the body and several partitions that will be mounted in the upper part of the firebox. They will be able to create a labyrinth for the smoke, which will increase the efficiency of the stove. In the upper part you can make a recess for the chimney structure. The recommended recess diameter is 100 mm. Next, you will need to make a recess for the hob with a diameter of 140 mm.

Potbelly stove made of sheet steel.

Using a welding device, you need to attach the side elements to the bottom of the structure. You will need to attach thick strips of metal to the side walls. As a result, it will be possible to attach the grate. This can be a sheet of metal with recesses with a diameter of about 20 mm. The lattice can be made of reinforcing bars. At the next stage, you need to attach supporting elements from a metal strip to the side walls. After this, the partitions are installed.

Doors for the firebox and ash pan should be cut out of metal. They can be installed on ordinary hinges. However, a more reliable option is to use curtains made of steel pipes and rods. They can be secured to wedge latches. The elements are cut out of a stainless steel sheet and then secured with bolts. In order to be able to adjust the intensity of fuel combustion, a recess must be made on the door that closes the ash pan for mounting the damper.

A sleeve 200 mm high must be attached to the recess for the chimney structure, on which the pipe will be mounted. A damper in the tube will help retain heat. For it you will need to cut a circle from a metal sheet. One extreme part of the steel rod needs to be bent. After this, you will need to make several parallel holes in the tube. Next, the rod is mounted, after which a round damper is welded to it.

Diagram of a brick fence for a potbelly stove.

The chimney pipe should be installed at an angle of 45°. If it passes through a recess in the wall, the part must be wrapped in fiberglass in this place, and then secured with a cement mixture.

To prevent burns from touching a hot stove, you will need to build a steel protection screen on several sides and place it at a distance of 50 mm. If there is a desire to increase the thermal efficiency coefficient, the structure can be covered with brick. After the firebox is finished, the brick will continue to heat the house for some time. The laying should be done at a distance of 12 cm from the metal body.

A pillow of air can act as a heat protector.

To implement it, holes for ventilation must be made in the masonry at the top and bottom.

Rules for safe installation of a metal stove

A potbelly stove heats up much hotter than a brick stove, so all flammable objects should be kept at a sufficient distance from the stove. If the floor in the room is wooden, it is installed only on bricks or metal sheets. The metal, in turn, is laid on an asbestos sheet with its removal 35 cm or more from the edges of the stove. In the front part in front of the firebox it should protrude 5.5 cm. Asbestos can be replaced with felt impregnated with clay. You can also install such a screen to reflect heat on concrete.

Important! A working oven requires supervision. You should not leave the room where the potbelly stove is heated for a long time.

Installing a potbelly stove on a brick base

How to increase draft in a potbelly stove using a chimney

The design of a high-efficiency potbelly stove chimney should have the following features:

- The chimney should be made high enough. So, the optimal distance from the furnace itself to the top of the pipe is about 5-6 m.

- There should be no horizontal or inclined sections of less than 45 degrees in the pipe shape, or their number should be kept to a minimum.

An increase in the efficiency of a potbelly stove will also be facilitated by the creation of thermal insulation on the pipe, which will significantly reduce the damage from the formation of condensation.

- When establishing the cross-section of the chimney, you need to choose the optimal size. If at the time of establishing the efficiency of the potbelly stove there is already a too narrow chimney, you can put a deflector on top, which will protect the structure from precipitation and increase draft.

- The height of the pipe should also be affected by the level of the ridge. If the chimney is lower than it, you need to extend the pipe.

↓ Be sure to study the recommended material on the topic ↓

How to make an economical stove-stove with your own hands with increased heat transfer

Tip: The draft force in the stove is determined by the color of the flame: if there is not enough air, it is red with dark stripes, if there is too much air, it is bright white, and the chimney often makes a hum. If the color of the flame is golden-orange, then the potbelly stove’s draft is normal.

Preparatory work before assembling the furnace: choosing a location

Using a potbelly stove in a garage, like any other heating device, requires compliance with safety rules. First of all, this concerns the installation location of the device. The corner of the garage, which is located near the walls opposite the door of the room, is ideal for this.

Remember that you cannot place the stove in close proximity to the car. The distance between them should be at least 1.5 m. A similar distance should be from objects that are easily flammable, for example, from barrels of gasoline.

The walls near the stove must be protected with fireproof material

The distance from the stove to the wall depends on what material the garage is built from. If it is wood, then there should be at least 1 m from the stove to the wall. Additionally, it is recommended to protect them with asbestos boards.

The main stages of making a potbelly stove

1. All the details are marked on a sheet of metal: 6 steel rectangles for the walls of the oven, 1 rectangle for creating a smoke reflector, plates for the grate and latch for the door. 2. Cut

sheet metal can be found at any metal depot. The guillotine, unlike the grinder, allows you to cut (chop) it more accurately. In this case, there will be no need to do straightening (alignment of sheets).3. The furnace body is made in the form of a rectangle. Their sides are joined together at an angle of 90° and welded together.

4. To avoid mistakes, the furnace box is first only tacked by welding in several places, and only then, after checking its horizontal and vertical positions, its seams are welded.

Important! All connections in the body are thoroughly welded; To check the seams for leaks, you can coat the joints with chalk or kerosene. 5

Welding seams are cleaned with a wire brush.6. The internal space of the potbelly stove is divided into three parts: the firebox, the smoke circulation chamber and the ash pan. To separate the firebox from the ash pan, a grate is laid between them, on which the fuel will be placed. To do this, at a height of 10-15 cm from the bottom of the stove, 5x5 cm corners are welded on the sides and on the back of the box. On which the grill will be located

5. Welding seams are cleaned with a wire brush.6. The internal space of the potbelly stove is divided into three parts: the firebox, the smoke circulation chamber and the ash pan. To separate the firebox from the ash pan, a grate is laid between them, on which the fuel will be placed. To do this, at a height of 10-15 cm from the bottom of the stove, 5x5 cm corners

. on which the grille will be located.

Advice.

It is better to make the grate from 2-3 detachable parts. Otherwise, when replacing a burnt grate, it will be difficult to remove it from the firebox.

7. The grate is welded from thick steel rods or strips 30 mm wide. They are attached to 2 stiffeners - rods with a diameter of 20 mm. Since the grates burn out over time, it is better to make such a grate removable.

Manufacturing of grate

8. At a distance of 15 cm from the top of the box, two strong rods are welded, on which one or two removable reflectors

– thick-walled sheets of metal that will delay the flow of hot gases and send them for afterburning. However, they should not completely block the oven. To allow hot smoke to enter the chimney, an indent of about 8 cm is made from the front (for the first sheet) and back of the stove.

Diagram of the passage of gases in a simple potbelly stove and stove with an installed reflector

9. Next, the upper part of the box is welded, and then a hole for the pipe

.

Pipe hole

10. The front part of the stove with holes cut in it for the firebox doors and ash pan is welded last. 11. The size of the firebox door must be sufficient to allow fuel to be added and grates to be changed without effort. The hole for the ash pan is made a little smaller. 12. The hinges are welded first to the door, and then to the body of the potbelly stove. They can be bought ready-made or welded from two tubes of different diameters. Door handles can be made from a strip of metal or rod.

Important! When attaching the doors, you should fit them to the body as tightly as possible; To do this, they are straightened (leveled) and cleaned with an emery wheel. Wedge latches closing the doors are adjusted to the body as tightly as possible

13. You can cook food or heat water on such a stove. To do this, a hole of the required diameter is cut in the upper part of the box. Stove burner

.

which will be inserted into this hole can be purchased at any hardware store.14. For ease of use, the structure is installed on legs

or a welded stand made of pipes.15.

The chimney pipe is connected to the stove using a sleeve

.

16. For inserting a gate valve

. to regulate the smoke output, two holes are drilled in the pipe. A metal rod is inserted into the holes and bent at 90°. A metal “penny” is attached to it in the center of the pipe - a gate, the diameter of which should be slightly less than the diameter of the pipe itself by 3-4 mm.

Gate valve for adjusting smoke output

Making an ash pit

An ash pan is a grate near a potbelly stove, on which fuel will subsequently be placed to heat the room.

A good ash pan provides the combustion chamber with a sufficient amount of air (that is, oxygen), and also provides good draft, thereby ensuring better combustion. In most cases, ash pans in potbelly stoves leave “much to be desired,” so upgrading the ash pan will help improve the performance of the potbelly stove.

An effective ash pit should be made of heat-resistant material and have a door, thanks to which you can avoid smoke in the room. Improving the ash pan will help turn an ordinary potbelly stove into something like a fireplace.

Instructions

Making an ash pan yourself will require certain skills from you, and the production must be in accordance with the instructions:

- First you need to weld the box to the size of the potbelly stove, without the top wall and leave a rectangular cutout in the end wall. Steel is most often used in production. The dimensions must correspond to the width and length of the potbelly stove itself.

- Make holes in the bottom of the stove. The diameter of the holes should be about 20 mm.

Drilling holes for the ash pan

- Weld the box to the stove.

- Install the door into the ash pan.

This design will give better and more uniform operation of the potbelly stove.

Requirements for the construction of potbelly stoves

An economical, long-burning wood-burning stove must meet certain requirements and design rules:

- It is mandatory that such a structure is equipped with a smoke exhaust pipe, and the room is equipped with a supply and exhaust ventilation system.

- Considering that the design of a potbelly stove will heat up to very high temperatures when heated, it is necessary to comply with fire safety requirements when installing it indoors.

The stove should be located away from flammable structures of walls, ceilings and floors, and also have a fence to prevent fire and the risk of burns during its operation. A potbelly stove surrounded by a wall made of heat-resistant brick not only becomes safe during operation, but also creates additional heating areas.

Why increase efficiency?

The compact dimensions of the stove mean that the surface that heats up during operation is small. Not much heat flows outside and the room quickly cools down. Sometimes it seems that the return from the potbelly stove is weak.

To help it increase efficiency, several tasks are solved:

- the duration of combustion and smoldering increases;

- a sufficiently high combustion temperature is ensured;

- a high level of traction is achieved.

Standard potbelly stove efficiency

Ensuring heat removal

It is possible to increase heat removal by creating devices that promote natural and forced convection. To ensure natural air circulation, screens are made with a guide device that allows you to create a powerful convection flow and distribute it throughout the room. The guide apparatus is made in the form of curved strips of metal, welded to the screen and directing warm air not only upwards, but also to the sides. The prepared device is attached to the oven.

The heat removal device can also be made from scraps of water supply and profile pipes. The distance from the floor to the bottom edge of the elements must be at least 15-20 cm. The pipes are welded to the stove body and covered with a screen on the sides to protect against accidental contact. A traditional potbelly stove heats the air around it by 0.5-1.0 m, and the use of such a design allows you to increase not only the radius, but also the rate of temperature rise in the room. When the body of the heating device is heated above 60 °C, a stable convection draft appears in the device, the power of which increases as the temperature of the furnace increases.

Heat removal can be increased by using fans to blow over the heat transfer surface. Both household and old car fans are used. Devices with variable rotation speeds have proven themselves especially well. They allow you to regulate the temperature and heating time of the room in various oven operating modes.

For more efficient blowing of the furnace elements, special casings are installed that allow cold air to be directed to the hottest areas of the heating device, while it can be taken from various places in the room. A potbelly stove with pipes welded into the firebox for heating air has proven itself well. A multi-speed car fan installed on a common discharge manifold allows you to effectively heat the room.

Types of stoves for home

Classification by intended use

- Heating. Such stoves are used only for heating a room as a sole or additional heater. Heating stoves circulate and heat the air.

- Heating and cooking. Such stoves can be used to warm up the room and for cooking instead of a stove.

Classification depending on design

Straight-through.

The operating principle of such furnaces is as follows: air moves into the ash pan, goes up and, bypassing the grate, exits through the pipe.

Disadvantages of once-through furnaces:

Low efficiency, due to the fact that along with cold air, warm air also leaves the furnace, which could still be used to heat the room.

Pros:

Due to the fact that such stoves are made of brick, which retains heat well, the room warms up evenly and retains heat.

Duct.

This type of furnace is an improved direct-flow furnace. That is, due to the many channels, warm air does not immediately go into the pipe, but, following them, warms the room. When installing channel furnaces, the linear dependence of the efficiency on the length and number of channels should be taken into account.

Bell bells.

Such stoves serve to retain heat in a room. Warm air, in accordance with the laws of physics, tends upward, where the cap holds it. As the air currents cool down, they become heavier and fall down. And, since the cold air is no longer needed, it comes out through the undercoat.

Advantages of bell furnaces:

- They ensure uniform heating of the room due to their design.

- Soot can be easily removed, as it accumulates in one place - under the hood.

Classification depending on material

Brick

Pros:

- Autonomy. That is, having “refueled” the stove once, you don’t have to worry about it for a long time.

- Heat retention. Brick structures conduct heat poorly, so it remains in them for a long time.

Minuses:

They take a long time to warm up.

Cast iron

Pros:

- Easy to install and does not require a foundation.

- Not fire hazardous.

- Compact.

- Heats up quickly.

- Huge selection of stoves according to external data.

- No additional lining required.

- There are automatic cast iron stoves that independently regulate the temperature.

- High efficiency.

- Performance is relatively less dependent on the amount of fuel.

- Low price.

Minuses:

They cool quite quickly and require additional heating.

Asbestos chimney size

When selecting asbestos chimney pipes, you need to be guided by the following considerations:

- The use of this material is only possible for gas boilers and pyrolysis heating units, which are characterized by a low flue gas temperature. It should be taken into account that the smoke of pyrolysis furnaces is oversaturated with products that contribute to the formation of condensation, and therefore soot.

- The diameter of the asbestos chimney pipe should not be less than the outlet pipe of the heating unit.

- The total length of the chimney must be at least 5 meters, while the excess above the roof ridge must be at least 0.5 meters.

- Significantly exceeding this indicator will also lead to undesirable consequences due to a decrease in the speed of gas movement in the pipe.

This will increase the amount of condensate formed. The effectiveness of a chimney made of any material depends on its correct installation on the roof of the house

Option two, allowing you to use the heat of the chimney

In the chimney, the air heats up to a very high temperature, since the brick warms up quite well during the firing process. The longer the stove is heated, the less heat the brick takes and the more the gases escaping through the pipe heat up.

At the same time, this also reduces the efficiency. To increase it, you need to use high temperature, heating the gases that flow through the chimney.

To increase efficiency, it is enough to integrate a steel pipe into the chimney.

For this you can use both round and square pipes. Their diameter can vary from two hundred to three hundred millimeters. When placing the pipe, care must be taken to tilt it towards the stove.

Several pipes can be built into the chimney. This depends on the size of the oven. Having arranged the chimney in this way, you will notice that the room heats up much faster, since the metal has high thermal conductivity and allows the heat of the chimney, which previously went outside, to be transferred into the room.

A well-heated pipe heats the air that circulates in the room, and does not create a vacuum, but rather enhances the movement of warm air. As a result, the room heats up faster, fuel is saved, and the efficiency of the stove increases significantly. However, such reconstruction must be carried out at the masonry stage.

These two methods have already been tested in practice and proven to be effective. Experts recommend not limiting yourself to one of them, but boldly implementing both in order to feel the difference both in fuel economy and in heating the house before using and after improving the stove.

Step-by-step instructions for assembling a potbelly stove with your own hands

The first stage is the preparation of the drawing and necessary materials. As for the drawing, it should reveal the design features and subtleties of all elements in as much detail as possible.

For experienced craftsmen, this stage can be skipped, but for those who are just starting the journey of constructing potbelly stoves, it is recommended to assemble a model from cardboard. Modeling, in this case, will cost much less than miscalculations immediately embodied in metal.

The next step is the selection of tools and materials. Here it is recommended to use ready-made components and housings produced industrially as much as possible. This way you can not only reduce the cost of work, but also find new, more effective technical solutions. Another piece of advice regarding this stage is proper organization of the workplace. When working with sheet metal, it is recommended to assemble a jig from wood so that the structures to be welded can be easily installed in the desired position.

During assembly, you need to remember that all connections must be as precise and strong as possible, especially for the body and supports of the potbelly stove. And of course, after assembly, it is necessary to make a test firebox to check the functionality of the assembled structure.

Washing machine tubs

Many have noticed that when the stove is burning, sheaves of sparks often fly out of the chimney. This means that the fuel did not burn out completely and left the working chamber, taking with it most of the thermal energy. So, one of the first ways to improve a potbelly stove is to create a working chamber where small coals will burn out and heat will be retained.

A common method of such an improvement is to install two washing machine tanks welded together, which will act as a kind of car muffler.

Materials and tools

To make this structure we will need:

- First of all, two whole tubs from old washing machines,

Tubs from washing machines - welding machine,

- tool for working with metal.

Instructions

To properly attach 2 tanks from a washing machine welded together, you must follow a simple guide:

- First, you need to weld two washing machine tanks together so that after welding they form a single container resembling a large cylinder.

- After welding, clean the weld seams and bring the single tank to a marketable condition.

- The next step is to make one hole at opposite ends of the tank, the size matching the diameter of the furnace outlet pipes. Carefully clean out the holes made.

- Insert the outlet pipe elbow into these holes, but so that the pipes inside the tank are at different levels, as if overlapping each other.

- Seal one connection between the pipe and the tank and clean it. Make the second hole in such a way that it fits tightly around the pipe, which will be directly inserted into the potbelly stove. There is no need to weld the second hole, as it will later be useful for removing carbon deposits inside the tank.

Upgrade with washing machine tanks

This simple improvement will allow you to retain a large amount of heat, which previously simply flew away into the chimney.

Step-by-step instructions for making a stove

A stove for a garage is made from various materials. We will analyze the option of producing a rectangular long-burning stove with our own hands. Our design provides:

- an ash pan for collecting ash in the form of a drawer in the lower part;

- main fuel combustion compartment;

- a chimney made of galvanized pipe;

- convection systems and an upper compartment with a cooking zone.

The principle of operation is based on retaining heat with bricks and gradually heating the box. The walls of the potbelly stove are provided with installation of vertical convection tubes. Cold air enters them from below, heats up, leaves their tubes and distributes the heated air throughout the room. At the same time, the box heats up quickly and the efficiency level increases. To make such a potbelly stove for a garage, you will need to perform several operations:

- Before starting work, make a drawing of the heater. You can find a ready-made sketch on the Internet and make adjustments to your dimensions. To produce the case, you will need to prepare:

- bottom;

- 2 side panels;

- rear part, made according to the dimensions of the oven;

- We make the front part smaller in height, taking into account the drawer of the ash pan.

- We cut out blanks from sheet metal, 3-4 mm thick, using a grinder or electric metal scissors. Additionally, you will need to prepare pieces of corners for attaching the grate and guides for the ash pan. You should end up with a structure with a large wood burning chamber, a small lower cavity for collecting ash, and a quarter of the height is left for laying bricks and a hob. Here, according to the markings, sections of the corner are welded to lay the sheet of metal.

- We make a grate from thick sheet steel or steel rods. If a sheet is used, its thickness should be at least 5-6 mm. To produce a grate from rods, rolled 8 mm wire or fittings are suitable. Having made the dimensions of the grate from the long pieces, secure them by welding. After cutting off several longitudinal jumpers, weld them to the frame. For greater rigidity and to prevent large coals from entering the ash pan, the distance between the jumpers should not exceed 5-7 mm.

- Having marked the installation location of the grate, weld corners to the sides for its installation. Now, using electric welding, assemble the structure box, be sure to check the diagonal and correct connection of all parts. Boil the boxes in 1 pass, beat off the slag, make sure there are no pores or holes.

- Place the grate on the corners. It should not be welded, so you can easily clean or replace the damaged part. We make the ash pan according to the size; do not forget to make a handle on the front of the box.

- On the front part, cut a hatch for storing firewood. You can buy a ready-made cast iron door or make it from thick steel. Make simple hinges from pieces of thin tube and rods and secure the door by making a small handle on it. The door should fit tightly to the body, so you can attach an asbestos cord on the inside, and install a simple latch or latch on the outside.

- On the back side, use electric welding or a drill to make a hole for the chimney outlet and weld a small section of pipe. Its diameter should be slightly smaller than the ventilation pipes. We clean all the seams with a grinder. The stove in the garage can be painted with fireproof paint.

- We place a sheet of steel on the upper corners and lay fireclay or refractory bricks in an even layer. We place the hob on top.

- All that remains is to weld pieces of steel pipes on the side of the stove, which act as a convector. Depending on your desire, you can weld the legs from the corner.

What to heat with?

A potbelly stove is efficient and small-sized, does not require special knowledge for its operation, installation is not complicated, and even a person who has never done this can handle the kindling. Unfortunately, not everyone can accurately answer the question: “What to heat with?” In principle, a potbelly stove is not much different from an ordinary stove and therefore can use the same types of fuel, namely:

- the most popular are firewood;

- in the second place you can place coal;

- sawdust;

- peat;

- and even oil.

What to use besides firewood?

Yes, firewood undoubtedly occupies a leading position in use, but other types of fuel can also be used:

Coal

- Coal, like firewood, is popular, but due to the fact that it is more expensive and not everyone can afford it, it is used less often. Although in terms of indicators it is higher than firewood. For example, coal burns longer and produces a high temperature, which means it has a high efficiency index. But it is precisely because of the increased heat that the chimney needs to be reworked.

Peat in briquettes

- Peat, as well as sawdust, have one significant drawback - they require special storage conditions. Under no circumstances should briquettes be allowed to get wet, otherwise they will lose some of their properties and, in some cases, will not be able to burn. After the briquettes burn out, quite a bit of waste from their use remains in the ash pit, and during the combustion process an unpleasant odor is released.

Pellets

- Pellets – or in other words pressed sawdust. It would seem that the benefit is obvious, you can heat a stove from production waste, but unfortunately the price is not much less than firewood.

What can't you heat?

It is strictly prohibited to use liquid fuel in residential premises. This type is fire and explosive. In addition, after using it, it is necessary to clean the chimney more often, since due to the mixing of condensate and soot, a black tarry mass is formed, which is difficult to clean off. Even if you use liquid fuel in industrial premises or cabins, you must have good exhaust and good air circulation. Otherwise, burning mass may be released into the room.

Furnace efficiency. What it is

The efficiency factor in relation to a stove is the ratio of the heat entering the room to the level of thermal energy that the fuel is capable of releasing.

However, this indicator cannot be measured today for several reasons.

Firstly

, at different stages of combustion, the efficiency of the furnace will change.

Secondly

,The efficiency varies depending on the fuel used, wet or dry logs.

Third

, this indicator is affected by heat losses: these can be exhaust gases, mechanical and chemical losses, which are caused by incomplete combustion of fuel. All this depends on how the oven is designed, what the atmospheric pressure, temperature and humidity are.

We will not be able to change many indicators, but there is still an opportunity to improve the operation of the furnace. Let's consider two ways.