Izospan is an insulating film coating. The main purpose of the film is to ensure that the original thermal insulation characteristics are maintained throughout its entire service life. It is difficult to imagine a modern construction project without the use of various types of thermal insulation. Mineral wool, Penoplex, Izolon, Izover, various polystyrene foams and simply polystyrene foam - all these materials require their own protection.

Thermal insulation materials practically envelop our house, retain heat on frosty and rainy days, create comfort in the hot summer, preventing the penetration of heat flows. But how to protect the thermal insulation belt from negative atmospheric phenomena? Reliable protection from moisture, rain, damaging winds is designed to be provided by 100% polypropylene, with the proud name - Izospan .

To create a barrier at the stages of the construction process, to perform the function of protective insulation for thermal insulation, this is the true purpose that isospan vapor barrier successfully fulfills. Despite its apparent simplicity, the material differs by type.

We bring to your attention – Izospan instructions for use. Figure it out: which side to lay the isospan on. Consider the isospan technical characteristics, and the installation method.

Worthy competitors of isospan:

- Tyvek vapor barrier;

- Vapor barrier TechnoNIKOL;

- Vapor barrier Nanoizol;

- Vapor barrier Ondutis;

- Vapor barrier Yutafol.

Before moving on to a detailed review, it should be clarified that the films are presented by the manufacturer in a wide variety and have different purposes. Vapor barrier films and membranes are divided into absolutely vapor- and water-tight and partially permeable to moisture only in one direction. Some of the materials successfully complement thermal insulation, enhancing its characteristics.

Application of Izospan

Izospan is a non-woven membrane or film that is used as part of insulating structures to protect the heat insulator from moisture, as well as wood and metal elements from rot and corrosion.

In construction, Izospan roof waterproofing is used, which is attached directly to the rafters under the sheathing, and a vapor barrier for installation from the attic side, in order to protect the fibrous insulation from moisture accumulation. Also, vapor barrier film is used for insulation of attic floors, floors and ceilings, and thermal insulation of walls on the room side.

For the walls of a wooden building that is insulated from the outside, a vapor-permeable membrane is used, which protects the fibrous heat insulator from weathering and does not prevent the escape of steam.

Example of use in an insulated roof

Quality and range: everything to protect your home

In total, the Izospan line of insulating products has an assortment that is conventionally divided into 4 groups:

- windproof waterproofing vapor-permeable membranes;

- waterproof vapor barrier films;

- universal materials that work in several directions at once;

- heat-steam-waterproofing materials with additional energy-saving effects.

Here is an explanatory illustration of how exactly all these materials differ:

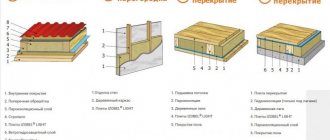

A roofing pie with films from Izospan looks like this:

Series A are windproof materials, and series B, C and D are hydro-vapor barrier membranes. If you are afraid of getting confused in abbreviations, remember a simple rule: the first letter means the insulation class, and the second means the modification.

If there is no second letter, then the material is classic, without additional frills:

Plus Izospan produces a special tape designed specifically for this product:

This manufacturer also produces special waterproofing materials for flat inversion roofs. The company itself always boasts that it creates all its products in automated production facilities.

And this is evidence that technical control is constantly being exercised over the quality of products. This cannot be achieved with any kind of handicraft production.

Types and purpose of material

Before buying material, you need to understand what types of Izospan the manufacturer offers, their features and purpose. The range includes rolled materials made of non-woven fabric and film, including those with additional coating. Installation of Izospan is carried out depending on the purpose of a particular type of product.

The characteristics of Izospan vapor barrier of different types have significant differences. According to the classification, three types of materials can be distinguished

:

- hydro- and windproofing membranes;

- hydro- and vapor barrier films with different properties;

- vapor-tight roll materials that promote heat conservation.

Groups of materials of the Izospan trademark

Each type of Izospan has several versions. All have letter markings, which simplifies the choice at the point of purchase and helps to understand how this or that material should be used. You can read more detailed instructions in the user manuals.

A little about the manufacturer: why does everyone know about it?

Gexa company is one of the largest manufacturers of nonwoven materials for building insulation. The company itself is relatively young, operating since 1998 and began as a small family company. Today, Gex already employs more than 2,000 employees, and even has its own representative offices in neighboring countries.

Thanks to the availability and thoughtfulness of its products, Hexa quickly captured a large part of the market for similar products, while also developing geosynthetics for road construction and a stable production of disposable clothing for medical workers. Today there are about 15 of its representative offices in Russia.

By the way, Izospan is one of the very first brands of insulation produced domestically. Among builders, all these films and membranes are so well known that they have already received a household name. True, today the company has to actively fight against mass counterfeiting of its films, which differ in quality for the worse and spoil the entire impression of the brand.

Also, Izospan films are well known among the population due to the fact that they are always available. This is a credit to Hex's logistics system. But sometimes you have to look for other brands all over the city; you’re probably familiar with this situation.

In addition, Izospan is constantly working to improve its product; for example, it recently released a three-layer moisture-windproofing membrane with an anti-condensation coating. Another interesting new product is heat-saving insulation based on kraft paper with lamination with metallized lavsan, which we will talk about later.

Vapor-permeable membranes for waterproofing and wind protection

A membrane made of non-woven fabric for creating waterproofing, vapor-permeable barriers is developed for external work on thermal insulation of roofs and wall structures. The material does not allow moisture to pass through and is able to protect the insulation from the effects of precipitation and wind.

In addition to waterproofing the insulation, the diffusion membrane performs another function - it prevents condensation of moisture entering the fibrous heat insulator through the walls of the building along with steam. The steam is quickly released outside, so that wooden structures are not threatened by fungus, and the insulation does not lose its thermal insulation properties.

Example of ceiling vapor barrier

Diffusion membranes are made of polypropylene. Their use is safe for human health and prevents the appearance of fungus. Scope of use

:

- insulation of pitched roofs with an angle of inclination over 35°;

- construction of frame houses;

- external wall cladding with siding or clapboard;

- hydro- and wind protection of heat insulation under ventilated facades.

Izospan A, AM, AS, AQ proff, A with OZD

The line of hydro-windproof, vapor-permeable membranes includes non-woven materials of various densities

:

- Izospan A (density indicator 110 g/m2) is the most permeable membrane of the entire line, it allows moisture to escape out, but does not let it in. When installing, it is necessary to leave a gap for ventilation.

- Izospan AM (90 g/m2) is a three-layer membrane. The technical characteristics of Izospan AM allow the installation of a protective hydro- and wind barrier without a ventilation gap, since air circulates between the layers of material and removes moisture.

- Izospan AS (115 g/m2) is also a three-layer diffusion non-woven material, but more dense than AM.

- Izospan AQ proff (120 g/m2) is a professional material. Izospan AQ proff has a three-layer structure with reinforced reinforcement. It is recommended to use Izospan AQ proff if externally insulated walls or roofing systems will have to be left for some time without an external protective and decorative coating. Features of Izospan AQ proff - increased resistance to moisture, ultraviolet radiation, and mechanical damage.

- Izospan A with OZD - the material differs from Izospan A in the presence of fire retardant additives. A non-flammable membrane is used if welding work is expected to be carried out in close proximity to an insulated structure, for example, when installing ventilation facades.

Be sure to read: Which insulation is not chewed by mice and rats

Table of vapor-permeable membranes

Microporous membranes are made of two or three layers. Their characteristic feature is the different quality of the material on the front and back sides. One side is smooth, the other is rough. Hydro-windproof Izospan is laid to the insulation with the white side, if we are talking about Izospan AQ proff, AM and AS membranes

.

In this case, the diffusion barrier Izospan A and A with OZD, according to the instructions, is mounted with the smooth side out

. The accumulated condensate should flow along it into the drainage drain.

Vapor barrier isospan technical characteristics

- The material is waterproof;

- Elasticity is beyond praise; it is not difficult to get around the most difficult areas and bends;

- Resistance to ultraviolet radiation;

- Resistance to negative atmospheric phenomena;

- Does not emit harmful substances. Safe for human health. Does not harm the environment.

- Withstands temperature changes in the range from – 60 °C to + 80 °C

- Fireproof elements added in production determine the fire hazard group G4, which is confirmed by relevant certificates.

Izospan has various applications, taking into account the field of construction use. Isospan, a type of insulation unique in its structure, has individual technical characteristics and its own labeling.

Manufacturers classify their products by letter indices A, B, C, D, F, R. The combination of letter indices adds numerous variety, applications and installation of isospan. Each new designation assumes its own isospan application. This fact must be taken into account when building your home.

roof vapor barrier isospan

Waterproof and vapor barrier films

Waterproof and vapor barrier film is intended for indoor installation. It is used to protect insulation and structures from moisture, which increases the thermal conductivity of the thermal insulator and contributes to the destruction of wood and metal. The use of films that do not allow steam and condensation to pass through extends the service life of insulation and building structures if the installation has been carried out correctly.

Scope of application of hydro- and vapor barrier films

:

- arrangement of the floor base;

- installation of an insulated roof (protection of the material insulating a flat or pitched roof);

- insulation of building envelopes, sound insulation of partitions;

- protection of floors - basement, interfloor, attic (serves as a waterproofing barrier);

- laying wood-containing or wooden floor coverings (parquet boards, floor slats, laminate).

Laying vapor barrier on the floor

Izospan B, C, D, DM, RM, RS

The manufacturer offers a wide range of materials that serve as vapor barriers and waterproofing. All types of Izospan differ in density and functional purpose:

- Izospan B (density indicator 72 g/m2). Vapor barrier Izospan B is one of the most popular types of material due to its characteristics and affordable price. With its help, internal walls, ceilings with basement and interfloor ceilings, attics and attics under an insulated roof are vapor-insulated.

- Izospan S (90 g/m2). Concrete floors are waterproofed with film. The material is laid to protect the heat insulation on pitched roofs.

- Izospan D, DM (105 g/m2). Izospan D and DM are varieties of high-strength material. Brand DM has an anti-condensation surface. Izospan D, DM is designed for high loads. Izospan D and DM are primarily used for waterproofing flat or pitched roofs. The material is suitable for use as a temporary roof covering. Izospan D will also help resolve issues with a concrete floor or basement floor if the structures require reliable protection from moisture.

- Izospan RS (84 g/m2), RM (100 g/m2). Like Izospan D, these types of films are characterized by high strength. In particular, it is achieved due to the three-layer structure of Izospan RS and RM - a polypropylene mesh is located in the middle. Application of Izospan RS and RM - arrangement of hydro- and vapor barriers for ceilings, wall structures, floors, ceilings, for any type of roof.

The wide scope of application and technical characteristics of the materials Izospan D, C, B, Izospan RS and RM make them the most popular among all roll materials of the brand

.

Table of steam and waterproofing

Izospan D, like other representatives of the group, has two outer layers with different functions. One of the surfaces is smooth, the second is rough and fibrous. The roughness of the outer side contributes to the properties of the material to retain and disperse settling steam and condensate over the surface, allowing it to quickly evaporate.

High-strength fabrics (Izospan D, Izospan RS, RM) are treated with water-repellent compounds during the manufacturing process. The hydrophobic material is suitable for use as a waterproofing layer during the installation of earthen floors and cement screeds on a concrete base in wet rooms.

When installing a vapor barrier, it is necessary to lay Izospan with a smooth surface to the insulating material

. Depending on the operating conditions of the structure, it may be necessary to provide a ventilation gap of 40–50 mm to ensure moisture evaporation.

Two sides of one film: Izospan S

Izospan S is another type of hydro-vapor barrier. It differs from simple films primarily in that it also has a double structure - smooth on the inside and rough on the outside.

This film is also denser and more durable, and therefore suitable not only as a vapor barrier, but even as additional insulation. And its rough part is attached inside the building.

It is recommended to fix such a vapor barrier to the roof using galvanized nails:

Izospan C is also often used as a waterproofing agent during the installation of cement floor screeds in rooms with high air humidity.

Heat-reflecting vapor-waterproofing materials

Among the Izospan materials, it is worth highlighting films on which an aluminum coating is applied using the spraying method. A feature of foil materials is the ability to reflect thermal radiation.

Be sure to read: Basalt thermal insulation boards - characteristics

Indoors, foil film is used to create a vapor-waterproofing barrier to protect the heat insulator, as well as to increase the energy efficiency of insulation. When installed outside the building, the foil material will protect the insulation from precipitation and weathering.

Using foil material in the attic

Izospan FB, FD, FS, FX

The group includes foil materials, the structure of which can significantly reduce heat loss in heated rooms. The specific purpose of materials marked Izospan FB, Izospan FS, Izospan FD, Izospan FX is selected in accordance with the characteristics of the base and coating.

- Izospan FB (density indicator 132 g/m2). The basis is thin, high-density construction cardboard. Izospan FB is equipped with a lavsan coating with aluminum coating on the outside. Area of use: covering ceilings and walls in saunas and baths. Izospan FB is capable of blocking up to 90% of heat rays.

- Izospan FD (132 g/m2). This is a woven base made of polypropylene with a layer of aluminum applied on one side. Izospan FD allows you to create a protective barrier along the ceiling and floor of the attic; it is used when installing a heated floor system, water or electric.

- Izospan FS (92 g/m2). The base of Izospan FS is made of non-woven fabric, on top of which foil is applied. Izospan FS is a rolled material that is not afraid of moisture, durable and easy to install. It is used as a roofing heat and vapor barrier for sloping roofs, as well as for frame walls.

- Izospan FX (145-175 g/m2). Izospan FX is distinguished by a foamed polymer base 2–5 mm thick with an aluminum coating. Izospan FX can be used as an independent heat insulator or mounted in combination with other types of insulation. Area of use: heat-reflecting, hydro- and vapor-tight cladding of walls, ceilings, and attics. Also installed as a heat-reflecting underlay under laminate.

In accordance with the instructions, materials such as Izospan FB, Izospan FS, Izospan FD, Izospan FX are laid so that the foil heat-reflecting side faces the room

.

What tasks do insulating films perform?

Izospan is a film or non-woven membrane used in thermal insulation structures to protect insulation from moisture, wooden and metal elements from rotting and corrosion.

Vapor barrier membranes are necessary when arranging multilayer building structures, mainly external ones. These are external insulation systems, pitched roofs, frame housing construction, and the installation of wooden interfloor ceilings.

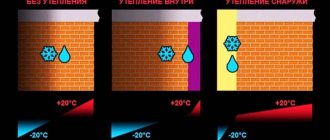

The main task of the Izospan vapor barrier is to prevent the appearance of a “dew point” in the structure. Warm air tends to leave the room, and cold air tends to get inside. Without a well-equipped barrier, flows of different temperatures will meet in the density of the wall and condense into droplets of moisture. The result is that wet insulation freezes, thermal efficiency decreases, and mold appears inside.

Vapor barrier solves this problem - the membrane allows moist air to escape without being trapped in the thermal insulation layer. The dew point moves - condensation does not fall.

Installation of hydro-wind protection and vapor barrier on insulated pitched roofs

Taking into account the technical parameters of the material, Izospan grade A is used as waterproofing and wind protection for the insulated roofing pie of a pitched roof. To find out the required amount of material, you need to calculate the area of all slopes and calculate the number of rolls.

Laying Izospan for roof waterproofing (choice between grade A and similar types of material - AM, AQ proff) is carried out using the instructions

:

- At the preliminary stage, fiber insulation slabs are inserted between the rafters.

- Waterproofing roll material should be placed on the outside of the wooden roof frame in horizontal stripes, starting from the bottom.

- It is important not to confuse which side to lay Izospan to the insulation - place the waterproofing on the insulation with the white side without inscriptions.

- Laying is carried out with an overlap of the upper strip on the lower one by 15–20 cm, without tensioning the web, but also without allowing sagging - otherwise the material will make noise in a strong wind.

- During the laying process, the material is fixed to the rafters with staples using a construction stapler.

- The upper strip in the ridge part is mounted with a bend on the second slope; the instructions for use of Izospan indicate that it is advisable to avoid joining the strips in the ridge part of the pitched roof.

- Slats are stuffed along the rafters to create a ventilation gap (the thickness of the slats is 40–50 mm) so that air flows help remove moisture from the insulating layer. A self-adhesive sealing tape is first attached under the slats, and then the sheathing for the roofing is mounted on them.

- All joints and abutments of the waterproofing material to the structures are glued with mounting tape for sealing.

If Izospan DM is selected as a waterproofing barrier for an insulated pitched roof, the instruction manual requires that a ventilation gap be provided between it and the insulation. This can be done by placing counter battens along the rafters. In addition, ventilation holes must be provided at the roof ridge.

Roofing pie of an insulated pitched roof

A pitched roof, insulated with a fiber heat insulator, needs a high-quality vapor barrier on the side of the attic or attic so that moisture does not damage the insulation

. For these purposes, you can use a vapor barrier film of grade B or RS, or select a suitable foil material.

Be sure to read: Mineral plate for home insulation - technical characteristics

Let's look at how to properly install vapor barriers, following the instructions

:

- Izospan film grade B, RS has a smooth and rough side. It should be laid with a smooth surface towards the heat insulator, and a rough surface towards the room. When laying, the canvases are placed horizontally, overlapping, gluing the seams with a special tape. The material is attached to the rafters using brackets.

- Foil-coated Izospan is simple to use - usually there are no questions about which side to put the material on, since it is clear that the metallized side should reflect thermal radiation from the heat source in the room. The canvases are laid overlapping (FX-butt) and secured to the frame with staples. The installation instructions require the use of aluminum tape to seal the seams.

Insulated roof scheme

Review of existing varieties of isospan

Most isospan is produced in the form of a membrane or film. Both modifications have a vapor barrier function. There are types that are 100% waterproof and unilaterally permeable to moisture. If we consider the types of this material separately, then each is intended for separate tasks.

The term isospan hides four broad groups - A, B, C, D. They are distinguished by individual design features.

Isospan is used when installing attic insulation systems, installing cold roofs, arranging floors, building baths, and improving the thermal performance of walls as an insulator for enclosing structures. The material is especially effective in protecting insulation systems and wooden elements from putrefactive processes, and metal elements from corrosion.

There is isospan, which is used inside buildings, and other varieties are intended for outdoor use. There is also isospan for universal use. In any case, its use makes it possible to significantly prolong the operating time of the insulation, which, under the influence of moisture, quickly loses its properties.

Three main groups of isospan can be distinguished: moisture- and windproof, steam- and moisture-proof, and vapor-proof. Materials included in the second group are used for interior finishing work.

Vapor-tight isospan is used when performing both internal and external work. Based on the functionality of the material, it is divided into classes.

Insulation material group A

The material marked with the letter “A” belongs to the first group. It is characterized by high density, therefore it is indispensable for insulating attics, walls, and roofs. Fungi and mold do not develop on it.

This diffusion membrane retains water, but steam passes through it unimpeded. Polypropylene is used for production. It strengthens and protects thermal insulation from the influence of outdoor atmospheric moisture or cold air from a room that is not heated.

Izospan A is an excellent wind barrier when making ventilated facades. It neutralizes the consequences caused by the onslaught of side winds, which favor the evaporation of heated air from the heat-insulating layer

In order for isospan A to fully reveal its capabilities, it is necessary to strictly follow the technology during installation. Since air streams pass through it only one-sidedly, the sides should not be confused under any circumstances. Otherwise, the insulating layer will get wet due to the accumulation of moisture in it.

Isopan A is produced in rolls 1.6 m wide. The area of the material in the reel is 35.7 m². The optimal temperature limits for operation are -60 - 80⁰. The membrane can be exposed to ultraviolet radiation for three or even four months without loss of characteristics. In the future, these aggressive rays will gradually reduce the UV stability of the material.

Izospan marked with the letter A may contain fire retardant additives. Then another one is added to all its characteristics - fire protection. This brand belongs to the G1 flammability group, and in terms of flame propagation speed - to the RP1 group.

The material can withstand fairly high tensile forces - from 125 longitudinal and from 95 N/5 cm transverse. This is facilitated by special additives that strengthen the structure of the material.

The vapor permeability of the material is at least 3500 g/m² day. Water resistance parameter - 330 - mm. water Art. Based on these characteristics, it is advisable to use isospan A when installing ventilated facades, frame enclosing structures, roofs with double lathing and slopes at an angle of 35⁰.

The 3-layer AS membrane well insulates both wall and roof structures from street moisture and steam. The presence of such a barrier guarantees the safety of the insulation

Unlike the group A membrane, the AM film has a two-layer structure. It has also found application for protecting insulation and roofing elements from condensation and weathering.

These types of insulation have a number of differences:

- AS is the most durable, in addition, it has a fairly significant service life, but the steam transmission rate is only 1000 g/m² per day.

- A - the best type in terms of vapor permeability.

- AD is a strong membrane with a vapor permeability of 1500 g/m² per day.

There are also differences in terms of installation. If you choose brand A, an air gap is required, otherwise the steam will be discharged ineffectively. AS and AD membranes are mounted directly on the insulation.

Second group marked B

This vapor barrier has a slightly lower price.

Technical parameters of isospan B are as follows:

- composition - polypropylene;

- minimum breaking load - 130 N/5 cm;

- minimum lateral load - 107N/5 cm;

- application temperatures - -60 - 80⁰;

- water resistance - 1000 mm water. With t. minimum;

- UV resistance - 3 - 4 months;

- minimum vapor permeability - 7 g. per m² per day;

- The structure is two-layer.

It is used as an under-roofing film in frame enclosing structures and in interior partitions. On one side it is smooth, the opposite side is rough, where moisture is retained and evaporates.

With its help, the building is insured against penetration into the insulating layer of the ceiling, walls, and floor insulation systems in a private house.

Lay isospan grade B so that the rough side is on top. It is a high-quality vapor and waterproofing for rooms with traditionally high humidity - bathrooms, toilets, showers, basements

The price of this brand is the most affordable. Unlike brand A, this material is not attached to the top of the insulation, but to its lower side. Do this from bottom to top, then overlap. For better capture of water vapor, a 5-centimeter gap above the rough layer is required.

Features of group C material

Regarding resistance to vapor permeation, water resistance, and UV stability, this type of insulation does not differ from the previous material. Isospan grade C has the same temperature range: (-60) - (80⁰). The difference is in the breaking load, here it is greater - longitudinal minimum 197, transverse - 119 N/5 cm.

The two-layer film is characterized by particular strength. Polymer membranes of group C perform hydro- and vapor barrier to protect the thermal insulation of attics, attics, and roofs with a slope of maximum 35⁰.

It is used as a waterproofing substrate under metal tiles, as it perfectly protects the rafter system from rain and melt water. In addition, it is a good waterproofing for different types of bases. The material is also used in the case of concrete floors in places of high humidity.

Description of brand D products

A distinctive feature of isospan D is its good resistance to UV rays. Tensile strength is also high - longitudinal breaking load is no less than 1068 N/5 cm, 890 - transverse.

This vapor barrier is marketed in rolls measuring 160 x 437.5 cm, which is 70 m². The reel weighs 7.7 kg. Elongation coefficient - within 23%

Due to its great strength, grade D polypropylene fabric can easily withstand considerable mechanical forces during installation and operation, including the weight of snow. For this reason, it is quite suitable as a non-permanent roof, functioning normally for about 4 months.

The material also performed well as under-roof waterproofing in cold roofs. It saves wooden elements from the destructive influence of moisture penetrating from the outside, as well as wind and snow, which may end up there through leaks in the roof. It is also an effective waterproofing layer in floor insulation systems and basement floors.

Installation of waterproofing for non-insulated pitched roofs

To protect the wooden elements of the frame of an uninsulated roof from precipitation, wind and condensation, it is recommended to use Izospan film grade D or DM (featuring an anti-condensation surface), as well as RM or RS as a wind-waterproof barrier.

On roofs of complex configuration, or taking into account further insulation of the roof, it is recommended to use vapor-permeable reinforced material of the AQ proff brand.

Since it is not necessary to insulate the roof before laying waterproofing, the material is immediately rolled out over the rafters and cut to size. The strips are mounted horizontally, from bottom to top, using a construction stapler with staples or nails with wide heads. The overlap at all horizontal and vertical joints is from 15 cm. Joints and junctions should be glued using a special mounting tape. Self-adhesive tape is installed over the flashing along the rafters to seal the attachment points. Counter battens are placed on top under a solid or sparse sheathing for installation of roofing material on the roof.

Roofing pie of an uninsulated pitched roof

Which side to lay the wind-waterproof barrier

:

- for films D, DM, RM, RS, the smooth side should be facing upward, towards the roofing;

- Membranes used as waterproofing, including AQ proff, are laid with the white side down.

The used waterproofing film D, DM, RM or RS additionally requires the installation of a ventilation slot in the roof ridge.

Installation features

Vapor barrier protection meets the declared characteristics only if installed correctly. This is possible if the coating is continuous. For sealing joints, fixing canvases and restoration, the manufacturer offers a number of additional materials:

- SL tape connects the edges and is vapor-tight;

SL tape Source stblizko.ru

Installation of steam-waterproofing on insulated flat roofs

If a flat roof requires external insulation, use Izospan grade D or RM; it is also possible to use RS and C films. The material is rolled out onto a base of concrete slabs with an overlap of 15–20 cm. The choice of side of installation does not matter. To connect the strips to each other and to attach them to concrete structures, proprietary connecting tapes are used. Insulation and roofing are installed on top.

Pie flat roof

Product Overview

Under the brand “Izospan”, insulating sheets made of polypropylene are distributed on trading platforms. The film membrane is designed to protect the insulation and structural elements of the building from the negative effects of condensation. Technically, non-woven material performs several tasks: preventing the penetration of wind, dust and steam, retaining heat indoors, and removing moisture outside.

The membrane is used in the construction of heated or cold roofs, installation of a ventilated facade, arrangement of internal walls and ceilings. Insulation copes with the protection of metal products from corrosion, and wooden products from rotting. In addition, the advantages include the following qualities:

- strength and elasticity;

- one-way throughput;

- inertness to rust, fungi, mold and bacteria;

- wide range of permissible operating temperatures;

- environmental Safety;

- easy installation;

- durability (more than 50 years).

Wind protection at home Source stroy-podskazka.ru

The variety of fabrics allows for insulation measures to be carried out in buildings for almost any purpose. While there are a lot of positive aspects, there are also negative ones. Among them is the need to follow installation rules so that the declared characteristics correspond to the real ones. And also polypropylene cannot be classified as non-flammable materials.

It is important to note that installation can only be carried out after the roll has been kept in a warm room for 24 hours. And installation is carried out with positive thermometer readings, without fog and rain, on a warm base (not lower than 0℃).

Installation of attic floors

It is important to use the right materials for arranging attic floors, choosing them depending on the operating conditions and purpose of use

:

- If it is necessary to protect the heat insulator in the ceiling between a heated room and an uninsulated attic from weathering and moisture, and to ensure the removal of vapors from it, AQ proff, AM or AS membranes are used. The sheets should be laid with the white side facing the heat insulator, close to each other, without gaps.

- A vapor barrier layer, which simultaneously protects against insulation particles entering the air, is installed on the side of the living room. Film grade B, RS, C or DM should be laid between the sub-ceiling and the finishing. The rough side should be facing down. It is advisable to provide a ventilation gap (40–50 mm) between the sub-ceiling and the vapor barrier.

Attic floor diagram

The vapor barrier on the room side of the rough ceiling can be mounted from foil materials. The reflective layer should face down

. A gap of 40–50 mm should be left between it and the finishing material.

All types of canvases are laid with an overlap of 15–20 cm, the joints and junctions are glued with mounting tapes appropriate to the material.

Description of materials Izospan allows you to understand the types of membranes and films, understand how to choose and how to install vapor and waterproofing.

Features of the Izospan B vapor barrier ↑

This type of vapor barrier films copes with its task very effectively, which confirms its demand in the construction market. But, in addition to the main functions - preventing the penetration of gaseous moisture into the layers of the roofing pie, the material also has other important features.

1Unlike many cheap PVC sheets, in addition to a high degree of protection against steam, Izospan B “breathes”. That is, the living space, despite the insulating layers, is ventilated and natural air circulation is maintained. 2Izospan B cloth is more resistant to mechanical stress. The material is not as easily damaged by sharp objects as, for example, cheap films. 3The rough structure of the surface of the material prevents the drainage of condensed moisture, which in turn simply evaporates from the panel.

Advice

You should know that the smooth side of the Izospan panel is mounted to the insulation, and the uneven side is installed inside the room!

General provisions

- Laying films does not require special skills; it can be done independently, taking into account the individual characteristics of the membrane.

- The set of films comes with instructions; you must act according to its instructions. It is especially important to pay attention to the correct side of the attachment to the insulation.

- The material should fit snugly to the surface with a small gap in the corners (3-4 cm or more, if it depends on the design features). The canvases are overlapped relative to each other (at least 15 cm).

- Fastening to wood is done using a stapler; you should not forget about sealing seams and possible cracks using Izospan tape.

- For heat-insulating films, the metallized part should look inside the room, and the installation work itself is done end-to-end, without overlap. The seams are also sealed with metallized tape.

What is the canvas? ↑

If we compare Izospan with other cheaper analogues of vapor barriers, it is made not from polyethylene, but from 100% polypropylene. In addition, the material of the panel itself is reinforced and has two layers - smooth (rear) and rough (external).

This structure gives all the advantages: high strength and stability, the ability to remove moisture from the surface, close contact with the insulation.

In the production of Izospan, they adhere to the technology of melting the initial raw materials, followed by rolling and rolling on rollers, forming the residual thickness of the web and its structure.

But, such material has one drawback - its cost is higher in comparison with polyethylene analogues. However, high-quality vapor barrier coatings are well worth their price.

On a note

It is also worth knowing that although the film contains ultraviolet stabilizers, they do not eliminate the destructive effects of sunlight, but only slow it down. Therefore, the direct influence of UV radiation from the sun on the surface of the material should be excluded!

Briefly about the main thing

To work correctly with Izospan, you must carefully study the instructions, as well as the product labeling. How fully the insulation will perform its functions will depend on which side the insulator is adjacent to the insulation. An error in location will cause the heat insulator to quickly fail.

Loss of the positive characteristics of the insulation will lead to the formation of an atmosphere in the room unsuitable for life. Expensive repairs will be required. After all, you will have to open the walls and completely change both insulators.

Vapor barrier for frame walls

On the outside the insulation is protected with hydro-wind protection, and on the inside with vapor barrier. Therefore, for work you will need two types of membranes:

- Izospan A (or AS, AQ Profi, AM);

- Izospan B or RS.

General scheme of a wall pie:

- External cladding.

- Cottrogrid.

- Hydro-wind barrier – Izospan A.

- Thermal insulation layer.

- Vapor barrier – Izospan V.

- Internal finishing.

Izospan A is mounted on the frame on top of the insulation, the side of placement is not important. If the brands AS, AQ Profi, AM are used, then the white side faces the heat insulator. The panels are placed from top to bottom, horizontally with an overlap of 10 cm at the joints. They are fixed to the frame with a construction stapler.

Vertical slats are attached on top of the hydro-windproofing film - the basis for the outer cladding. The lower edge of the membrane is fixed to the drainage drain of the base.

Instructions for use of Izospan B:

- Installation of the canvas from inside the room, on top of the insulation. Fixation to the supporting beams of the frame.

- The order of installation is from below, with an overlap of horizontal panels of 15 cm.

- Izospan B is placed with the smooth side facing the heat-insulating layer, the panels are fastened with connecting tape.

- The interior decoration is mounted on a slatted frame (lining, plywood) or galvanized profiles (plasterboard) - a ventilation gap of 4-5 cm should be obtained.

Manufacturer of membrane film

Products under the Izospan brand are produced by Hexa LLC, which is located in the Tver region. Products of different classes and categories come off the conveyors, intended for wind and vapor barrier of wall, roofing and other structures.

All manufactured products are certified and comply with European quality standards. Gexa LLC warns that cases of counterfeit products have recently become more frequent. Counterfeit material is produced under different brands and may have names that are similar to the original brand.

The fake film is similar in appearance to Izospan, but is inferior in characteristics. Therefore, buyers of such products, attracted by the low price, are subsequently disappointed. To avoid troubles, you should pay attention to the name, appearance and branding, and also ask the seller for documents confirming quality.

Advantages and disadvantages

The Izospan film of this brand has much more positive features than negative ones.

Benefits stated by the manufacturer:

- resistance to pathogenic microflora;

- environmental Safety;

- immunity to aggressive environments;

- high waterproofing ability;

- resistance to mechanical damage and weather conditions;

- ease of installation;

- The warranty period is 50 years.

The material has only 2 significant drawbacks. The first is the high price of some modifications, the second is flammability.