Smoked products are distinguished by a bright and rich aroma, pronounced taste and a fairly long shelf life, especially when it comes to cold smoky processing.

For lovers of smoked delicacies, it is expensive to regularly buy them in stores. Plus, the quality does not always meet expectations and cost. Therefore, in many respects the most correct decision is made. You are building your own smokehouse, and it is not necessary to build huge brick structures. If somewhere in the country or in a country house there is an old gas stove, it can be turned into a full-fledged smokehouse.

Mini smokehouse oven

In such a product, a dish can be prepared in just one hour - this becomes possible because the products are located much closer to the smoldering wood chips, and the volume of the smokehouse is only 10 liters.

The operating principle is similar to any model - products are hung on vertical rods above the pallet, the top cover is screwed to the central pin. Such compact smokehouses are produced in the city of Kirov, Ulyanovsk region and are simply called “Selmash”. They can be ordered directly from the factory by mail, the product will arrive packaged in compliance with safety regulations. The diameter of the smokehouse is only 26 cm and fits on one burner. Cost - from 2.6 to 3 thousand rubles.

The process of making a smokehouse from an old gas stove

To ensure that the process of making a smokehouse does not take much time, it is worth preparing all the necessary materials and tools in advance. It is also advisable to familiarize yourself with the most common diagram options that will help during the assembly of the structure.

Scheme and drawings

Schemes and drawings of a gas stove smokehouse are freely available on the Internet. You can choose the most suitable option and assemble a structure for smoking products based on it.

Principle of operation

All smokehouses have the same operating principle. Products prepared in advance must be placed on a special grid or hung with hooks. Then they will be treated with smoke, which is released as a result of smoldering wood chips.

A smokehouse made from an old gas stove will allow you to quickly prepare high-quality, tasty and completely safe for human health smoked meats at any time convenient for the owner of the structure.

Preparing the Slab

You first need to prepare the old stove so that it can be used to make an effective smokehouse. It is best to carry out all work outdoors. The stove is thoroughly washed beforehand, and all the necessary tools and materials that may be needed during the assembly of a homemade device are prepared.

Internal refurbishment

To make a smokehouse from a gas stove, it is worth additionally carrying out its internal refurbishment.

- First, remove the oven door from the stove. It is also worth removing its back wall.

- The gas burner, which is located in the oven chamber, is dismantled.

- You need to install an electric stove at the bottom of the oven or make a fireplace under its bottom, where you can later build a fire.

- In the lower part, four holes are drilled on the sides, the diameter of which is 10-20 millimeters. Through them a sufficient amount of air will flow into the smoking cabinet.

- A couple more holes are made in the upper part of the walls, through which excess smoke can escape.

For these works it is worth using the simplest drill. It is worth noting that this type of smoking chamber has some disadvantages that should be remembered in advance.

- It is not possible to smoke food using the cold method.

- It is quite difficult to regulate the distribution of smoke in the smoking chamber.

- The number, as well as the diameter of the holes, is selected at random.

- There is a high rate of heating inertia. The temperature rises quickly and decreases very slowly. Because of this, the fuel may begin to smolder too intensely or even ignite, which will cause damage to the products used.

How to choose a suitable smokehouse model for an electric stove

There are no fewer supporters of electric smokehouses than gas smokehouses. The electric version takes up less space. Half of these models can fit in a kitchen cabinet. Another plus is ease of use. Here you simply set the desired temperature, as written in the instructions for the smokehouse. Cooking takes even less time - from half an hour to forty minutes, depending on the smoked semi-finished product. The set temperature inside the device does not change, remaining the same all the time.

There are also more expensive automatic models. They have the ability to monitor the smoking process. The device also turns off at the right time. The user's task is only to add new fuel. Some devices even have smoking programs “Meat”, “Fish”, “Vegetables”.

What is smoking in an electrostatic field

Smoking products in an electrostatic smokehouse occurs faster, the smoke is distributed evenly. Cooking smoked meats is a rather lengthy process.

Represents the slow penetration of smoke and some combustion products into the product. In this case, a number of specific and biochemical reactions occur that lead to the denaturation of proteins. Fish, meat, and sausage acquire a specific pleasant taste. Smoking in an electrostatic field differs only in the timing. Acceleration is provided by the following:

- the smoke is produced by the generator, not the coals;

- it passes through the grid to which the anode is connected, the current strength is small;

- the smoke is ionized and enters the smoking chamber;

- the products in the chamber are connected to the cathode;

- since ionized gas and fish and meat have opposite charges, the product literally attracts smoke;

- ionized smoke particles are very evenly distributed throughout the meat.

There are two types of smoking:

- hot – the process lasts 2–4 hours at a temperature of +120°C;

- cold – requires from 10 hours to 2 days and is carried out at +215°C.

Cold smoking is preferable; such meat is stored much longer.

How to make a hot smoked smokehouse with your own hands

If you have the skills to work with metalworking tools, you can easily make a smoking apparatus yourself.

Fire extinguishers, barrels and other containers are used as housings. A refrigerator smoker is easy to make, especially for cold smoking.

Simple smokehouse

The easiest way to make a hot smoker is from a conical bucket. This shape makes it easier to install grates with smoked meats at the required height. Instead of a grease tray, use an old bowl, which is placed on a stand made from a tin can. Holes are cut in its walls to allow smoke to escape, and the can itself is turned upside down.

Simple smokehouse diagram

Brick smokehouse

If space allows and you need to regularly cook a large amount of food, then it makes sense to make a stationary hot-smoked smokehouse out of brick.

In this structure, the food chamber is located above the fireplace and is separated by a sheet of thick metal.

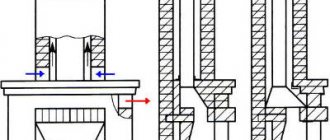

There are two options for this design:

- Holes for smoke are drilled in the separating sheet, and a chimney is located at the top of the chamber. This design is simpler, but the smoke is hotter, and the firewood should only be hardwood.

- There are no holes in the separating sheet and sawdust and wood chips are poured onto it. The fireplace has its own chimney and can be heated with any flammable substances.

Components of a brick smokehouse

Electric smoker

An electric smokehouse differs from a conventional one in the way it is heated. Instead of a fire, the bottom is heated by electric heaters. This makes it possible in medium-sized devices to install an electric stove inside the housing, and place a container with sawdust, for example, an old frying pan, on it.

Electric smoker diagram

Household smokehouse

You can prepare homemade smoked meats not only in the country, but also in the kitchen of a city apartment. To do this, you need a small-sized smokehouse with a smoke exhaust hose. This smokehouse is made from stainless steel.

This device heats up on gas. The dimensions in the drawing of a hot smoked smokehouse are determined by the dimensions of the gas stove and are 450x300x250 or 500x300x300 mm. Structurally, it is a metal box made of carbon, or preferably stainless steel, 2 mm thick, with a lid and handles on the sides of the body and on top of the lid. Inside, a grease tray and one or two grates assembled into one structure are installed on a stand.

The lid has a 1/2″ smoke outlet pipe, onto which a regular garden hose is placed. This hose protrudes through the window or is inserted into the ventilation duct.

During operation, sawdust is poured onto the bottom, a tray and grates are installed, the device is closed and placed on the gas stove. The heated smoke goes through the hose into the window, and air from the kitchen is sucked into the gap between the lid and the body. Therefore, there is practically no smell in the room. To completely eliminate the smell, you need a smokehouse with a water seal.

Components of a household smokehouse

Hot smoked smokehouse for an apartment

Most smoking devices produce smoke when in use, so they are only used outdoors. But there is a design that can be installed even in the kitchen of a multi-story building. This is a smokehouse with a water seal.

This device is similar to a small-sized household smokehouse with some differences:

- the lid is 10 mm larger and has curved edges;

- a 15x15mm corner is welded to the upper part of the body;

- Water is poured into the formed gutter and the edges of the lid are lowered.

The resulting water seal prevents smoke from escaping into the kitchen. To better protect the room from odors, the lid contains a connection for the smoke exhaust hose.

Hot smoked smokehouse

Semi-hot smoked smokehouse

In addition to cold and hot, there is semi-hot smoking. It is produced at a temperature of 50-70 degrees. Cooking time is about 12 hours.

Structurally, this is an ordinary smokehouse with a smoke generator. The difference is in the length of the supply chimney. It is made in such a way that the smoke does not have time to cool and enters the smoking chamber heated to the required temperature.

If you lengthen the chimney, you can easily turn a semi-hot smoked smokehouse into a cold smoked smokehouse with your own hands.

Smokehouse for semi-hot smoking

Smokehouse Assembly Instructions

Understanding the process of smoking products, it is absolutely not difficult to assemble a smokehouse yourself, come up with its diagram and even develop instructions. Since there are a huge number of items from which you can make a smokehouse with your own hands, there are ready-made instructions for transforming them into home smokehouses.

The simplest design of a smokehouse made of polyethylene film

The smokehouse made of polyethylene film is intended for cold smoking.

To create it you will need:

- about 2 meters of thick polyethylene film, the kind that is used for greenhouses or covering plants;

- two-meter wooden stakes;

- wooden or wire rods;

- for work you need a hammer, an awl or a gypsy needle, thick threads, fishing line or thin wire;

- and the main thing is to allocate a space of about 1 square meter for installing the structure.

The stakes, which serve as the frame of the smokehouse, are driven into the ground, and for stability they are fixed together with crossbars made of rods or wire. Additionally, the structure should be secured diagonally in several rows.

The products that will be smoked are hung on the partition rods at a distance from each other so that they do not touch.

The polyethylene film must be sewn according to the principle of a bag, which is pulled over the frame with hung products. In this case, the bag should not touch the ground, since there should be space between it and the ground.

This space is left for pouring hot coals. A layer of grass is laid on top of the coals, the smoldering of which will create smoke for smoking. Afterwards, the bag is pulled to the ground. To ensure better tightness, the edges of the bag should be secured around the perimeter with stones or any heavy objects at hand.

If the choice of products for smoking is fish, chicken or sausages, then cooking will take about 3 hours. If you plan to smoke denser types of meat, then the smoking procedure must be repeated.

Bucket smokehouse

For such a smokehouse, any old, unnecessary bucket with a lid and a couple of stainless steel grates of different sizes will do.

The bottom of the bucket is filled with sawdust or shavings. Then, a smaller grid is fixed at a height of 10 cm from the bottom, and a second one is placed above it (you can get by with one grid if there is not a lot of food).

The products are placed on the grates, and the smokehouse is placed on the fire, covered with a lid, so that the smoke remains inside the smokehouse bucket.

Smokehouse from a barrel

The homemade barrel smoker is the most popular. It can be made from either wooden or metal barrels. The structure of a barrel smokehouse is similar to a bucket smokehouse. However, the size of the barrel allows you to also use hooks for smoking.

As the basis of a smokehouse, a barrel is also convenient because it allows you to make different types of smokehouses from it:

- a smokehouse made from a barrel for hot smoking, assumes that the heat source will be located under the barrel itself;

- a barrel smokehouse for cold smoking will consist of a free-standing barrel and a 2-meter chimney that will connect it to a heat source;

- universal, multifunctional barrel smoker. For this option, you will need two identical barrels with a volume of about 200 liters. The barrels are fastened together in the shape of the letter “T”, and if they are made of metal, then the best option would be to weld them into a single whole. The upper barrel serves as a smoking chamber, into which a grate, hooks and a tray for collecting fat are installed. A firebox is installed in the lower barrel, in which you need to place a tray for sawdust. And the source of heat is the fire under the barrel. On the convenient side of the lower barrel, it is necessary to cut an opening to install the door and valve, to control the fire and regulate the flame. This design can be used not only for smoking, but also as an oven for baking, heating food, barbecuing and even grilling.

Smokehouse from an old refrigerator

A very good option for a home smokehouse is an old refrigerator. This non-working device should not be thrown away or sold for scrap. It is enough to clean it of the electrical filling and the refrigerator chamber can easily be transformed into a chamber for a smokehouse.

To do this, inside the refrigerator, using corners, grates and hooks for smoking, a tray for collecting fat, and at the very bottom a tray for sawdust are installed. A small hole is made in the ceiling of the refrigerator to install a chimney. And since the chamber of an old refrigerator is used, it is worth paying attention to how tightly the door is closed to ensure the tightness of the smoking.

Metal smokehouse

A more convenient and practical smokehouse model can be made from metal. However, this will require certain skills and a specific set of tools: namely a welding machine and a grinder with a metal disc.

The simplest and most functional form of such a smokehouse is a square or rectangle, that is, it is necessary to create a box into which all the elements of the smokehouse are built.

Metal - stainless steel (the best option for operation, but difficult to weld) or cold-rolled steel (a material that is very light and flexible in work, but is susceptible to oxidation and is short-lived).

The dimensions of the smokehouse depend solely on personal wishes.

Having decided on the shape, size and material, the metal sheets are cut with a grinder according to the selected parameters. Using a carpenter's angle, the sheets are welded together at an angle of 90 degrees to form a box. The joints of the structure must be welded both from the outside and from the inside, for better tightness of the smokehouse.

After creating the body, the bottom of the smokehouse is cut out and welded to it, also with double-sided seams.

To make the lid, cut a sheet to the size of the smokehouse box and 4 narrow strips for the sides of the lid. All elements are welded together using double-sided seams.

To make it easier to carry the smokehouse, handles can be welded on the sides.

The inside of the smokehouse is equipped with fasteners for installing grates, hooks and a tray for collecting fat.

This smokehouse can be heated either over an open fire or on an electric stove.

Smokehouse from a gas cylinder or fire extinguisher

An unnecessary gas cylinder can also be used as a home smokehouse. However, in addition to certain skills in working with an angle grinder and a welding machine, you will also have to take into account safety rules.

Before starting work on the manufacture of a smokehouse, you will have to carry out preparatory work and “neutralize” the gas cylinder. To do this, you need to open the valve and give time for the remaining gas from the cylinder to completely come out. After this, the valve is sawed off. Everything that remains in the cylinder is poured into a separate container, the cylinder is thoroughly washed and dried.

A door is cut out of part of the same cylinder (for loading products inside), which is placed on hinges and again attached to the cylinder.

To equip the firebox, the bottom of the cylinder is sawed off, and a firebox is welded from separate sheets of metal, which is welded to the cylinder.

At the end of the work, to ensure the safety of food preparation, the structure must be well calcined.

Next, you can install gratings, hooks and trays inside the cylinder chamber.

Smokehouse made of brick and stone

In this part we will talk about a universal stationary smokehouse for hot and cold smoking, which also serves as a barbecue, grill, barbecue, Russian oven and oven.

A brick smokehouse is not only an ideal device for cooking, but also a very colorful decorative element for a personal plot.

The design of such a smokehouse is quite complex, so to build it you should contact designers or look for ready-made options on the Internet. In both cases, when creating such a structure, you should strictly adhere to the construction plan, drawings and instructions, since failure to comply with them will lead to the complete unsuitability of the smokehouse, and accordingly, loss of time and finances.

First of all, a decision is made on the location of the smokehouse: whether it will be a separate structure, part of a veranda or gazebo.

The basis of any capital structure is its foundation, a brick smokehouse is no exception, and if you start laying on open ground, then under the weight of stones and bricks the ground will sag, which will lead to the destruction of the structure. Therefore, the foundation should be strengthened with reinforced concrete or reinforcing mesh, and some time should be given for the foundation to gain strength.

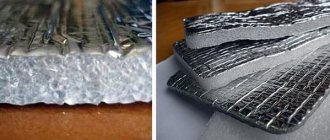

On top of the foundation, brick or stone masonry of the wall of the lower belt is made, taking into account a tunnel chimney with a length of plus or minus 2 linear meters. In order for the smokehouse to be universal (cold and hot smoking), the chimney pipe should be insulated with any mineral insulating material.

Before laying the wall of the second belt, the first one is filled with a thin concrete screed and reinforced. A ready-made concrete slab is also suitable for separating wall belts.

The design of a brick smokehouse involves the presence of two chambers: one of which is the smoking chamber itself, and the second is a stove, which can be used independently for preparing various dishes and is a heat source for the smokehouse. The furnace chamber should be built exclusively from refractory bricks.

Closer to the chimney, a chamber for the smokehouse is laid out. There is no open fire or too high temperatures, so any type of brick will do and no interior finishing is required. To ensure tightness, a tightly closing door must be installed on this chamber. For a brick stationary smokehouse, most often they make not a metal door, but a wooden door from fruit trees (apricot, cherry, apple tree). Such a door will give a rich aroma to the products when smoked.

A chimney pipe is installed on the smoking chamber. With its help, you can regulate the smoke draft for the intensity of sawdust smoldering and, accordingly, select the type of smoking:

- for hot smoking, sawdust combustion increases and smoke draft decreases;

- for cold smoking, the fire decreases and the draft increases, due to which the smoke is cooled to a temperature of 35 degrees.

The brick smokehouse chamber is also equipped with grates, hooks and trays. Another advantage of this smokehouse is that it can be used as a storage chamber for kitchen and yard supplies.

Features of work

In fact, mini-smokers running on gas are not new for a long time and are already available in different variations. Each model has its own operating characteristics, so before purchasing it is worth getting acquainted with the basic designs. First of all, they are divided according to the method of preparing dishes:

For hot smoking. Such smokehouses are compact in size, since there is no need to place food away from smoldering wood chips. Here, meat and fish dishes are cooked faster, as they are exposed not only to smoke, but also to high temperatures (within +60..+140 °C). However, the shelf life of hot smoked products does not exceed 3-5 days, so you should not buy a model that is too large for a small family. For cold smoking

Here it is very important to monitor the temperature in the internal compartment with food so that it does not rise above +40 °C. And if in electric smokehouses this mode is set simply from the control panel, then in models for gas stoves the desired effect can be achieved only by significantly increasing the size of the chamber

True, such processing of products will require a lot of time (two or three days), but the finished delicacies will be stored longer, so feel free to add large portions.

Smokehouses with a water seal

The easiest to use models are available in different volumes from 30 to 60 liters, so it will not be difficult to choose a home mini-smokehouse for small and large portions.

To put the smokehouse into operation, you need to perform a few simple steps:

- Pour sawdust and chips from any trees (not birch or coniferous) into the lowest container.

- Place the salted food on the grate that comes with it and place it all on top of the tray.

- Then all that remains is to close the unit with a lid, pour water into the water seal and place the smokehouse on the gas stove.

- You need to put a smoke exhaust pipe on a special fitting and bring its end out into an open window - one hood may not be enough.

Smokehouses with a water seal are produced by our own factories, and they offer to use them not only in apartments on the stove, but also during forays into nature. Therefore, the kit often also includes a durable carrying bag, as in the “Astrakhanka” models. These are large three-tier smokehouses with a barbecue grill on which food should be laid out. The price of fully assembled steel boxes depends on the size of the body and the thickness of the steel. Sufficiently sized models can be purchased for 10-15 thousand rubles.

Smokehouse-oven

Dishes are prepared in it quite quickly - in just an hour, but the design and method of fastening the products are much closer in execution to a conventional garden smokehouse. Above the same tray for wood chips there are long vertical rods on which pieces of meat or fish carcasses are hung. After this, the body is put on top, and the lid is screwed to the central pin and securely held in this position.

A striking example of such an express oven is the compact model for hot smoking “Selmash”, which is produced in Kirov. It is only 26 cm in diameter (like a medium-sized frying pan), so it can easily fit on one gas burner. The internal volume of the chamber is 10 liters. Such a miracle costs 2600-3000 rubles.

How to use it correctly

Before placing certain foods in the smoker, they must be carefully prepared. For example, fish is cleaned and soaked in brine. For 4 kg of fish you need to take about a glass of salt. Some types of fish need to be generously rubbed with salt, wrapped in cling film and, pressed with a lid, left for two days. Then the fish is dried for a couple of hours and completely cooled. Only after this can you begin the smoking process.

What can you cook in an electric smoker?

With an electric smoker you can cook a wide variety of smoked meats.

Most often, meat and fish, cheese, homemade sausages, vegetables and even some fruits are prepared.

The finished product is not only very tasty and aromatic. It does not contain any harmful components or additives that can adversely affect human health.

Useful tips

In order for the use of an electric smoker to be completely safe, and the prepared products to be truly tasty, you should adhere to some simple rules.

- It is necessary to ensure that the food does not touch the walls or heating element during smoking.

- Absolutely all elements that can become electrified must be carefully isolated from the device body.

- During cooking, do not touch food with your hands.

- Humidity indoors or outdoors should not be more than 80%.

Cooking in an electric smokehouse is very simple, regardless of whether the model is factory-made or self-assembled.

Components of the structure

For hot smoking

The design is in the form of a container with a tight-fitting lid. It is made from almost any metal barrel tanks.

The hot smoked smokehouse consists of:

Fireboxes. It is placed under the chamber and plays the role of a heating element; Hermetic compartment (smokehouse). This element ensures good heating of products and maintaining the specified temperature; Water seal. It is recommended to install it, since the shutter helps reduce the level of carcinogenic components in smoke and regulates air flow; Grilles. For displaying products; Removable tray; collector for melted fat released during cooking.

For cold smoking

These modifications are constructed according to the basic law - the smoke must cool down before reaching the products. These models have any standard sizes and consist of the following parts:

Firebox

It can be made from galvanized sheets or ordinary bricks (when installing a firebox, it is additionally equipped with an ash pan and a door to regulate the smoke flow;

Smokehouse compartment

Considering the low temperature of cold cooking, it can also be built from wood;

Chimney

Combining the chamber and the firebox, metal will be a suitable raw material for its manufacture, but it is advisable not to use brick with its porous texture.

Sources

- https://gidpopechkam.ru/pechki/koptilnya-chertezhi-razmery.html

- https://pro-kopchenie.ru/koptilni/koptilnya-goryachego-kopcheniya.html

- https://tytpodelki.ru/kak-sdelat-koptilnyu-goryachego-kopcheniya/

- https://o-remonte.com/koptilnya-svoimi-rukami-kholodnaya-gor/

- https://DimDom.ru/koptilnya-goryachego-kopcheniya-svoimi-rukami.html

- https://jamaster.ru/kak-sdelat-koptilnyu-goryachego-kopcheniya-svoimi-rukami/

- https://homius.ru/koptilnyu-goryachego-kopcheniya-svoimi-rukami.html

- https://HouseChief.ru/koptilnja-gorjachego-kopchenija-svoimi-rukami.html

- https://moekopchenie.ru/koptilni/svoimi-rukami/goryachego-kopcheniya

- https://landshaftdizajn.ru/koptilnya-svoimi-rukami/

- https://stroy-podskazka.ru/koptilnya/svoimi-rukami/

- https://grillrest.com/koptilni/svoimi-rukami-instrukciya/

Material selection

It is extremely important to choose the right material from which our smokehouse will be made. Usually there are two ways to go here

Using brickwork, a grill, a barbecue and, accordingly, a smokehouse are combined, or the latter is welded from a metal sheet. So, brickwork has several significant disadvantages. Firstly, it takes up a lot of space, and secondly, over time it develops an extremely unpleasant smell, which is why you definitely don’t want to cook anything there. Yes, and it's expensive.

A normal homemade hot-smoked smokehouse can be obtained if you use a 4-mm metal sheet. This thickness is considered optimal. If you take less, the metal will burn out quickly enough, therefore, our smokehouse will turn out to be short-lived. If you take more, you will not be able to achieve a high heating rate. Although smoking fish in a home smokehouse can be done on a metal sheet of less thickness, since the fish cooks very quickly.

Where is the best place to place a smokehouse?

This article examined options for stationary and mobile home smokehouses. However, choosing a place to install any smokehouse is extremely important, since the smoking process takes time and is associated with the release of a large volume of smoke. Therefore, using the smokehouse indoors is not possible.

Harmful substances from combustion products can also harm vegetation and outdoor pets.

Thus, when choosing a place for a smokehouse, it is worth considering many factors and choosing it taking into account the safety of people and nature, as well as the characteristics of a personal plot or recreation area.

As for the storage of portable (mobile) smokehouses, after use they can be hidden in a garden house, garage or basement; and finished smoked products are stored for a long time in any cold and dry place.

Advantages and disadvantages

Advantages of smokehouses for a gas stove:

- the ability to use both at home and in the field;

- cheap equipment;

- you can do it yourself;

- food is prepared quickly and very tasty;

- simplicity in use.

Flaws:

- as standard, the internal temperature cannot be controlled;

- if there is no water seal, it is necessary to install a chimney;

- bulky dimensions in horizontal models;

- cold smoking will be very expensive and uncomfortable.

Due to the small number of disadvantages, people are increasingly choosing smokers for a gas stove. This is a universal and convenient unit that can be placed on any heat source and in a few hours you will get a wonderful finished dish with an incredible aroma.

Working on the principle of an oven, the smokehouse retains all odors, fats and embedded components inside itself. Food is processed evenly on all sides.

Sawdust container

The sawdust container is the place where the fuel for smoking is placed. It is in it that the wood burns, the heat from which rises to the top and heats the meat. Therefore, the device must be made of non-toxic and durable material.

A cast iron pan or bowl is ideal as a container for sawdust. These are in every summer resident’s home set.

Why a gas stove?

Cooking surfaces made of ceramics, glass or metal are not recommended. They are technically able to reach a temperature at which the sawdust inside the smokehouse begins to smolder. But the bottom of the smokehouse is flat and adheres tightly to the surface over the entire area. Air is not removed, and the heating elements of the stove can simply overheat and fail.

A gas stove is the optimal heat source for smoking in an apartment or house

In addition to uniform heating, it provides the ability to quickly regulate temperature, which is important for high-quality preparation of smoked meats. But such a smokehouse can also be used outside the home

For example, on a picnic, fishing or hunting. It fits freely into the trunk of a car. By building a base of several boulders or bricks and lighting a fire under the smokehouse, you can quickly set up the production of smoked meats in the open air, creating the necessary conditions inside for hot smoking of products.

When it comes to smoking, many believe that it must be done in the backyard of a country house or where there is a large stove made of stone or an ordinary metal barrel. But here it must be said that you can smoke meat or fish right in your apartment in the kitchen. A gas stove will be used for this. In this case, you will need a small smokehouse, and making one yourself will not be difficult.

Today in the city in special stores you can buy a hot smoked smokehouse, which was manufactured in a factory.

It is important to note that such a device will be expensive. However, the quality of smoked products will be high

Mobile smokehouses have not become so widespread yet, but you can cook very tasty foods in them.

In order to make your own smokehouse for a gas stove, you will need:

- stainless steel - sheet, up to 2 millimeters thick;

- stainless steel wire;

- Bulgarian;

- drill;

- welding machine;

- roulette.

This material and tools will be enough to make a medium-sized smokehouse. The body is quite simple. It will resemble a metal box with handles on the sides. A groove is made from a U-shaped profile along the entire perimeter in the upper part into which water will be poured.

It will serve as a water seal

so that smoke does not escape into the room. The fact is that during smoking, smoke will be released from smoldering wood chips inside the smokehouse. To prevent the room from becoming smoked along with the meat, you need to worry about protection from smoke.

Video: Review of a kitchen smokehouse for a gas stove

A lid for the smokehouse is required. It must be performed very accurately so that the hydraulic functions are performed one hundred percent. In the upper part of the lid you need to make a hole into which the tube is soldered. Through it, the smoke will be discharged through the window to the street.

It would be ideal if the smokehouse had a hole for a thermometer built into it. This way you can control the smoking temperature of your food.

Hot smoking will always release fat. It is necessary to make a tray into which the fat will drain. We take a regular baking sheet. So that the tray can be conveniently pulled out of the smokehouse without spilling fat, it is necessary to provide special handles.

A wire grid on which we will lay out the smoked products. Fastenings for the grate are welded inside the smokehouse. You don’t have to use a grille, but in this case you will need hangers.

Stainless steel smokers for home

A gas stove is used to heat the smokehouse

It is important that the size of the stove is compared to the size of the smokehouse being made. Wood shavings and chips from fruit trees are placed at the bottom of the smokehouse.

The thickness of the fuel layer is approximately two centimeters. For hot smoking on a gas stove, you can use all types of shavings, except birch and pine. The resin contained in these trees will ruin the smell of the food as well as its taste.

Smoking begins as soon as smoke begins to come out of the pipe. It is not recommended to use ceramic induction cookers for smokers. The fact is that the flat surface of the smokehouse and stove will cause the latter to begin to overheat and fail. And the heating will not be as desirable as on a gas stove.

It is always more convenient to smoke on a gas stove. The main advantage is temperature control by adding or decreasing gas.

Gas smokehouse

Smoked products are always popular. This is a decoration for the festive table and the appearance of mouth-watering aromas in the air. If you want to smoke fish, poultry or pork, you need a device called a smoker. You can purchase it or create it yourself. It is important to be able to handle welding equipment and metals. An area for such a creative process is also required.

Very often they create home-type smokehouses. They operate on gas stoves.

Work principles

Factory and store smokehouses are presented in sales in various modifications. They can work with one or two burners. The shape comes in square, rectangular and cylindrical versions. But they are all similar in operating principles.

Two models are designed for residential use. One has a hose through which smoke is eliminated, the second has a water seal. This shutter prevents smoke from entering the external environment. You can put finely chopped wood chips on the bottom side. When they smolder, they emit smoke. It envelops meat or fish, which are hung on a special device.

Craftsmen in the matter of smoking use small shavings obtained from fruit wood. Cherry breeds are held in special esteem

The operation of a home smokehouse can also work well on alder, aspen, ash or beech shavings, as well as the classic version - oak shavings.

You should not use coniferous wood for smoking. The resin released from it gives food an unpleasant taste. And the walls of the smokehouse itself become covered with soot, which is then very difficult to remove.

The smokehouse needs to be filled with everything necessary and placed on the stove. The throttle position is minimal. Smoking does not need to be rushed.

If the smokehouse has a smoke outlet, then a hose is threaded onto a special fitting (usually included in the kit). Its second end is directed to ventilation. The bottom of the smokehouse is gradually heating up. The branches are smoldering. And the container is filled with aromatic smoke and hot air. From it the food is brought to the required state.

The temperature inside such a unit can be controlled. They are shown on the device thermometer. It's important to take your time here. Smoking is quite a long process. And each type of product has its own intervals.

Fish smokes the fastest. Poultry meat is a little slower. What matters here is the meat of the bird itself. If chickens, the process is quick. Duck meat is smoked more slowly. Goose meat needs more time for this. Turkey takes a very long time to cook.

The longest smoking process is associated with animal meat, especially pork.

Specifics and types of smoking

All home smokehouses are divided into two main categories:

- Hot smoked. The dimensions of these devices are small. Within these modifications, the rate of smoking of products is higher. Reason: they are affected by smoke and temperatures of 60 – 140 °C. You can store smoked meats created in such devices for a maximum of five days. If your family is small, then you should buy a small smokehouse

- Cold smoked. In these versions, the temperature parameters are much lower. And experts do not recommend developing them above 40°C. To achieve the desired goals, it may take a lot of time - up to three days (by analogy with hot smoked versions). But the resulting products can be stored much longer. The parameters of these models are much larger. Reason: Products should be concentrated at positions further away from smoldering chips. True, products can be placed on the entire mass of the unit, that is, in very decent volumes.

Subtleties of smoking

Before smoking fish meat, it is important to consider that it has a rather delicate structure. And before this culinary process, each carcass is tied with rigid twine. This way the meat won’t disintegrate inside the apparatus. Experts advise using a special mesh. It will perfectly protect this meat from falling apart into small pieces.

It is better to cover the tray of the device with foil before work. This way you will protect it from fat deposits. Foil perfectly transmits heat and does not interfere with smoking. After this process, it can be removed and thrown away. The cleanliness of the pallet will remain unshakable.

Mini version of the smokehouse

In this version, it takes 1 hour to prepare the dish. Causes:

- The food items placed are very close to the smoldering wood chips.

- Unit volume – 10 l.

How to make it simple? The model operates on the same principle as other modifications: products hang above the pallet. They are strung on vertical rods. The top cover is attached to a pin located in the middle.

These compact models are produced in large quantities in Russia. They are easy to order online. The main thing is to place an order in a reliable online store. Then you will quickly receive a high-quality device in proper packaging. The gas smokehouse is made in accordance with safety criteria. The diameter of the device is 26 cm. It can easily be placed on one burner. Its price range: 2600 – 3000 rubles.

Models equipped with a water seal

Smoking in them follows the same principle. There are these versions:

- Small ones. Their parameters: 40 x 30 x 25 cm. Volume – 30 l.

- Average. The volume is similar. Dimensions: 500 x 30 x 25 (30) cm.

- Big ones. Volume – 60 l. Data: 60 x 30 x 30 cm.

The first versions are intended for a small company or family. They can hold a modest amount of food. The other two versions are designed for large groups.

When using all these models, you need to take into account that when heated, deformation of their bottom may occur. It can bend inwards or, conversely, bend out. In this situation, contacts with the burners will change.

It is prohibited to place such devices on cooking surfaces covered with glass ceramics. A fire or explosion may occur.

For successful smoking, place the device so that its bottom is heated evenly. To start the unit, perform the following steps:

Smokehouse Recipes

- A composition formed from shavings and small branches of various trees is poured onto the container from below.

- A tray is placed that will collect fats. It is covered with foil.

- Products are placed on the grill. Before this, they need to be rubbed with salt or seasonings.

- A special container is filled with water. It will act as a water seal for smoke.

- The lid closes. The device is located on the smokehouse burner. The gas itself is started (central or from a gas cylinder).

- A hose is threaded onto the fitting located on the top cover of the device.

- This hose is routed into the hood above the stove.

Manufacturing

Stores sell machines for smoking meat, but if you don't want to spend money, we'll give you tips so you know how to make a smoker at home.

Making such a design will be an interesting and exciting activity, because there are many options and methods. The device is made from various materials. We suggest considering the simplest options.

From a barrel or bucket

Make a smokehouse from an iron barrel: this solution is the most affordable. To begin, cut off the bottom of the container and attach a grid (or reinforcing bars) to it at 2 levels.

Place a tray below. At the very top, food is hung on hooks. To make a smokehouse, a metal bucket is suitable. Insert 2 stainless steel grates inside.

One of them is placed at a distance of 10 cm above the bottom, and the other 5 cm above from the other mesh. Place up to 2 cm of wood chips on the bottom of the bucket. Place the bird or fish on the grill. Now cover the mini-smoker with a lid and put it on fire.

You can fumigate food in a bucket: it will be ready in 15 minutes. after the smoke appears. Remove the bucket from the open fire and wait until it cools down.

This design works without electricity, so it is well suited for outdoor trips or evening picnics in the country. At the same time, you can save energy.

The bucket won't take up much space. However, a smoker installed on a fire can be dangerous if not used correctly.

If you use it incorrectly, you may get burned or injured. Do not touch the bucket or barrel while the fire is burning as the metal will become hot quickly.

From an old refrigerator

Often people take old household appliances to their country house. Refrigerators are placed in sheds or utility pantries and various small items are stored in them. However, they make practical smoking units.

Masters give advice on how to make a smokehouse with your own hands from a refrigerator. Take out everything inside and leave the base itself with the door. Make a hole at the top where the smoke will escape.

Attach 9 corners to the walls on the inside of the refrigerator (two on each level).

At 2 levels in the upper part, fasten the grilles, hang hooks and strips. Secure the corners at the bottom to secure the drip pan. Sawdust is placed in another tray.

The hot-smoked smokehouse will be made by yourself and ready to use when you install the electric stove. The stove is installed in the lower part of the refrigerating chamber, and a container with shavings is placed on it. Close the door tightly to prevent air from entering the middle.

Stainless steel

To make a reliable smoking chamber, choose a durable metal - stainless steel. In appearance, this design looks like a box. In the inner part, corners for two metal gratings are welded.

Tourists can take this type of smokehouse on a hike. For fumigation, take small logs of deciduous trees or shavings.

Place pieces of lard or game on the mesh, then close the box and secure it over the fire. The first portion will be ready in 20 minutes.

Made of brick

Such a stationary smokehouse is installed on personal plots. Find a place for a guest area in your garden and prepare a site for its installation.

You determine the camera parameters yourself. As with everything else, choose the wood to fumigate. To burn wood in a stationary structure, a stove-stove is installed; it is installed outside, and not in the chamber itself.

Then install a pipe between the stove and the smokehouse. When you carry out construction work, follow the instructions and ask the master for advice.

Take out your work gloves, check whether the tools are in good working order and the condition of the materials. Be careful when using the smokehouse, follow the recommendations.

How to make a smokehouse with your own hands: from simple to complex

When making smokehouses from metal, make sure that it does not react with food when exposed to fire.

Attention! It is unacceptable to use barrels of fuel, lubricants, paints or chemicals, or galvanized metal.

From the bucket: diagram

If you want something smoked right here and now, then you can make the simplest apparatus literally on your knees, without any special skills or tools. To do this, you will need a steel (by no means galvanized) bucket, a large-diameter metal dumpling maker, thick foil or a steel “bowl” and a lid.

Photo 1. Schematic illustration of the internal structure of a hot smokehouse made from a bucket.

Pour wood chips into the bottom, place a “bowl” or foil on it, which will collect dripping fat, and place food on the grate. Close the top with a lid. Place the entire structure on the fire and wait for it to cook.

Pros: high production speed, minimum required tools and skills. Cons: small volume, unaesthetic appearance, risk of spoiling food if you choose the wrong bucket.

Refrigerator device

It is quite possible to give an old refrigerator a second life. To do this, it is necessary to remove all non-metallic “filling”, leaving only the body. The wood chips can be heated with an electric heating element, stove, or fire - in this case, the former refrigerator will need to be placed on supports.

Photo 2. Inside the body of the old refrigerator there are already special grates on which it is convenient to lay out products for smoking.

Pros: large volume of product loading at one time. Cons: it is difficult to achieve the required tightness of the chamber, there is a risk that the metal will begin to emit harmful fumes.

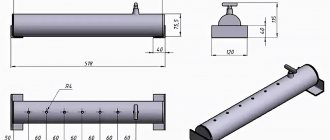

"Suitcase". Drawing with dimensions

This smokehouse is a rectangular box made of stainless steel or ferrous metal, which is why it received its name. If you have a vice, grinders, pliers, welding clamps and welding itself, it’s easy to make the device yourself. You just need to decide on the size of the camera.

And then there are two possible options. The first is that you order cutting and/or bending of metal from a company, and they bring you a ready-made “constructor”, which all you have to do is weld. The second is to buy metal, cut it yourself, then weld it at the seams according to the drawing.

Photo 3. Three-dimensional drawing of a smokehouse in the form of a stainless steel suitcase. Dimensions are indicated in centimeters.

The grating is welded from perforated or wire. It should be approximately 20 cm above the wood chips, take this into account when making internal stops. The pitch of the grate rods is 3 cm. A tray for fat is required. It looks like a top cover. The only difference is that the stand is placed at the bottom of the box, has a handle and curved edges. When making it, carefully weld the corners.

The lid is made of a sheet of metal so that its curved edges extend beyond the limits by 5–7 mm, and a handle is welded on top. A smoke exhaust fitting is required.

If desired, you can make a water seal - cut at 45°C and welded around the perimeter with a continuous seam and a corner flange inside. When smoking, water is poured into it and prevents smoke from escaping.

It is recommended to assemble the “suitcase” smokehouse in the following order:

- weld the lattice supports to the end walls from the inside and the handles from the outside;

- manufacturing (welding) of the “box”;

- pallet production;

- production of internal grating;

- production of a cover with a fitting;

- making a water seal (optional).

Be sure to try on each subsequent part after making the previous one, and make adjustments for deformation.

Pros: mobility, high smoking speed for a relatively large number of products, ease of care, durability. Cons: It is impossible to control the temperature during smoking.

A smokehouse is made from a barrel in the same way, in this case the body is already ready, all that remains is to make a tray, a lid and stops for vertical or horizontal loading of products.

Brick "cabinet"

The choice of advanced smokers or those who need to smoke a lot at once.

As a rule, the firebox is built separately from the brazier, and the stones ensure the most even distribution of heat.

Pros: food tastes better, stationary design is durable. Disadvantages: high labor intensity and price during production.

Made of wood

The wood smokehouse resembles a miniature house. There are walls, a door, a roof, and a pipe. Products cooked in a wooden smokehouse are distinguished by their rich taste and aroma.

Case manufacturing

The smokehouse body is made like this:

- The frame of the device is a rectangular structure, the height of which is 2 meters and the width is 1 meter. It is assembled from beams.

- The frame is finished on three sides with boards that fit tightly to each other.

- On the fourth side, a board is installed, also made from boards. It should close tightly without any holes.

- A roof with a hole for the tube is knocked together. If there is none, then a window is simply made so that it can be opened and closed at any time. After this, the roof is fixed to the structure.

- Grooves for the pallet and grate are arranged inside the structure. For the pallet, the grooves are made at the bottom of the structure, for the grate - in the middle.

Important! If gaps form between the boards, this will negatively affect the quality of the product. The gaps need to be sealed with tow.

How to make a lattice

To make the grating you will need unpainted wire with a diameter of 5-6 mm. A frame is made from it, the size of which corresponds to the internal size of the smokehouse. Pieces of wire with a diameter of 3 mm are fixed to it. The distance between them is 2 cm. All parts of the grille are welded together.

A pallet is made from a metal sheet. Its size corresponds to the size of the grate, as well as the internal size of the smokehouse.

Smoke exhaust

The chimney is carried out as follows:

- A trench is dug, the length of which is 2.5-3 m, width - 0.5 m, depth - 0.3 m.

- The trench is lined with bricks, which are connected to each other with cement mortar.

- A metal sheet is fixed to the brick.

- Earth is poured on top, in a layer of 15 cm, so that the chimney does not freeze in winter.

Assembly

A hole is dug corresponding to the size of the smokehouse. Its depth is 40 cm. Crushed stone is laid at the bottom of the foundation, and concrete blocks are fixed along the walls using reinforcement. Next, all this is filled with concrete mortar. A chamber is installed on the foundation, inside which a tray for collecting fat from food and a grate should already be installed.

Attention! Assembling the smokehouse begins with arranging the foundation for it. The chimney is connected to the foundation

An iron square welded from a metal sheet is fixed at one end. Its size must match the dimensions of the camera. It is installed on the foundation. A firebox is installed at the other end of the chimney. It should be made of refractory brick and equipped with a metal door. This will be the place where the fire is made

A chimney is connected to the foundation. An iron square welded from a metal sheet is fixed at one end. Its size must match the dimensions of the camera. It is installed on the foundation. A firebox is installed at the other end of the chimney. It should be made of refractory brick and equipped with a metal door. This will be the place where the fire is lit.

The final stage is installing the smokehouse. It is fixed directly to the foundation. The two structures are fastened together using metal brackets. The device is ready for use.

Photo 1. Possible drawing of a wooden smokehouse with the indicated dimensions. The arrows indicate the direction of smoke movement.