To heat premises, be it residential buildings, manufacturing, industrial, warehouse, public premises, today special devices are increasingly used - registers made of several connected pipes. This is because they heat more efficiently than conventional radiators, especially when the room is large. Thus, a heating register is a device that is designed to increase the efficiency of heat exchange between the external environment and the coolant.

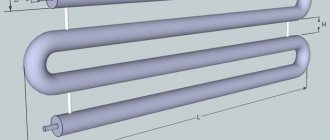

Heating registers consist of either one or several smooth-walled steel pipes, which are connected by pipes of slightly smaller diameter; the registers can also be connected by pipes in the form of a coil.

Features of register heat exchangers

To supply heat in residential and public buildings, heating registers made of smooth pipes are installed. These are devices that are designed to increase the efficiency of heat exchange between the external environment and the coolant.

Structure of a sectional heater

The registers consist of several smooth-walled steel pipes connected by special pipes of smaller diameter. In their shape they resemble a zigzag or a “fence”. In this regard, there are sectional, coil, registers made of smooth pipes with columns, and registers with heating elements.

Registers made of steel with ribs

Before installing registers made of steel pipes with fins, it is recommended to pay main attention to the volume of the pipe.

For a private home, craftsmen recommend installations with a volume of 3 or 4 centimeters. How to choose heating radiators Which heating batteries are better

You can use larger diameter pipes for work, but it should not exceed 8 centimeters. The main reason lies in the heating boiler. A device of the type that is installed in everyday life cannot generate a large amount of thermal energy sufficient to warm large areas.

When performing calculations, you need to take into account the length of one register rib and its heat transfer per meter of area. To give an example, a meter-long pipe with an internal cross-section of 60 mm can heat approximately one square meter.

Having calculated the required number of registers, rounding is carried out upward. But, there are certain conditions under which the obtained indicators increase by 20 or even 50 percent. This includes:

- The presence of a large number of openings for windows and doors in the room.

- Small wall thickness.

- Low-quality insulation of the room, or its complete absence.

A simple heating register has less heat transfer than devices with fins. They not only increase heat transfer, but also turn the register into a design - a radiator, which can play an important role in the aesthetic design of the interior.

Advantages of steel heating registers and their disadvantages

Steel heating has a number of advantages:

- When working, you can realize any individual drawing.

- Not only water, but also heated steam can serve as a heat carrier.

- Easy to connect to the system.

- Its high heat output makes it an excellent option for installation in a large building.

- Low cost.

Video

There are also disadvantages. These include:

- Low heat transfer rates.

- Fear of corrosion.

- Unpresentable appearance.

- Such products require regular painting.

Simple ways to increase heat transfer from radiators

We improve air circulation. The batteries transfer heat to the air, which, when heated, rises, and then, when cooled, falls down. This is how air circulates, and the room becomes as warm as the heat transfer of the battery and the air flow speed allow. Therefore, in order to increase the temperature inside the room, first of all, you need to ensure good air circulation. To do this, you should free up the space around the battery as much as possible: remove the protective screen, raise the curtains, move the furniture, and so on.

We accelerate air circulation using a fan. The faster the air moves, the more thermal energy it can take from the battery. On the coldest days, you can turn on the fan, directing it to the center of the radiator to cover as much area as possible. To ensure the autonomy of such a system and ensure its quiet operation, computer fans can be placed. They are quiet, low-power, and when placed directly under the battery, they do not disrupt the natural direction of air movement in the room. The fans will allow you to raise the temperature in the room by 3-10 degrees, and their low consumption makes it possible to blow on the battery all winter long without significantly damaging your wallet. Calculate for yourself: the power of ordinary fans is about 40 Watts, computer fans – no more than 5. Total consumption: 40 * 24 (hours) * 30 (days) = 29 Kilowatts = about 95 rubles per month. In the case of computers, it’s even less – about 23 rubles/month. when connecting 2 at once.

We install a heat-reflecting screen. Heat from the radiator emanates in all directions, and in order not to heat the walls, but to direct thermal energy into the room, you need to install a heat-reflecting screen behind the radiator. For these purposes, you can use foil-isolon (foam base with foil on one side), gluing it to the cleaned wall behind the battery with any suitable means (tile adhesive, universal glue 88, silicone, etc.). Ideally, the area of the heat-reflecting screen should be larger than the area of the battery.

If the battery is cold you need to bleed the air. To do this, you need to unscrew the regular or “Mayevsky” tap at the battery.

It will not be superfluous to keep a container or towel under the valve, because as soon as the air comes out, water will flow in a thin stream. Once this happens, the valve can be closed. The procedure should be repeated for each battery in the house.

Types and technical characteristics

There are many modern varieties of registers: from traditional utilitarian designs for heating made of steel pipes 108 mm in diameter to exclusive design developments.

In terms of technical characteristics, tubular batteries are inferior to radiator models:

- A system with tubular heating devices requires a larger amount of coolant, greater boiler and pump power.

- They have greater inertia - the system warms up much more slowly (but also cools down more slowly). This quality sometimes comes in handy when connecting to centralized heating systems, but in a private home, long-term heating of the system is not very convenient.

- Heat transfer by convection is less for pipes than for radiators; Most heat transfer occurs by radiation.

- Traditional registers made of large pipes are bulky.

- Tubular batteries have considerable weight and require reliable fastenings.

According to execution form

The shape of the registers is serpentine (S-shaped) and sectional (columnar):

- The coil is a curved structure made from small diameter pipes. Horizontal pipes are connected by arched bridges made of pipes of the same diameter. Plastic contours made of copper and stainless steel are simply bent.

- Sectional ones are made from separate horizontal pipes, welded at the ends and connected to each other by jumper tubes. According to the method of arrangement of jumpers, there are two design varieties: thread and column.

Complex combined heating designs can be distinguished - usually these are ready-made commercial registers made of stainless steel, brass and copper. One pipe stretched through the room is also a register.

There are designer decorative structures with vertical pipes. Sometimes ready-made finned pipes (made of one metal and bimetallic) are used.

By installation method

Registers are stationary and mobile:

- Stationary heating devices are mounted on walls and can be installed on supports separately from building structures.

- Occasionally there is a type of mobile registers heated by electric heating elements and filled with oil or antifreeze (such designs are often used in garages, poultry houses, and country houses; the design must have an expansion tank).

By connection method

According to the connection method, tubular heating devices are available: with lateral upper and lower connections. An ineffective method in terms of heating the room;

- With bottom connection. Not the most effective method for heat transfer, but for the sake of beauty it is sometimes used (it is easier to disguise a pipe at floor level than at height).

- With diagonal connection (input on top, coolant outlet on bottom). The optimal connection method is that heat transfer is maximum and the entire volume of the heating device is used.

- With top connection. This method is the least efficient in terms of heat transfer. They are used very, very rarely - only if, due to production needs, laying pipes at floor level is impossible. It should not be used in private homes, even if it means placing the register in a different location.

The registers are connected to the system using threaded connections, flanges and welding. Flanges and welding are for production, but for heating systems in a private house, the ability to assemble and disassemble the system for repair, cleaning and modernization is relevant, so installation is carried out using threaded connections.

By material

Traditional registers are made of black (carbon steel). Sometimes they use cast finned cast iron pipes or homemade conversions from used cast iron pipes.

The modern range of materials for registers is much wider:

- Steel. Conventional electric-welded pipes are most often used. Along with round ones, there are profiled rectangular or square pipes: they are more decorative and have a larger surface area emitting heat. Finished steel structures are coated with nickel or temperature- and wear-resistant paints.

- Stainless steel. A popular, practical and inexpensive material for heating and heated towel rails in bathrooms and toilets. Plastic, durable, stainless, but quite expensive. In residential premises, stainless steel is used if the entire system is made from it. Very often, stainless steel (especially polished) is used for original designer heating devices. Unfortunately, the cost of such products is exorbitant.

- Cast iron. Durable, reliable, but rough and heavy material. Cast iron registers are still produced, despite the heavy weight and inertia of heat transfer. Mainly used for decorative purposes. Old pipes are rarely used due to the complexity of their installation (you cannot weld a threaded pipe to cast iron, it is difficult to cut a thread - cast iron is brittle), and the need for internal cleaning from salts and silt. Sometimes cast iron finned pipes are used.

- Copper. Finished products of complex shape are used in copper heating systems. Lacquered copper serves as interior decoration. Copper is not subject to corrosion, is strong, durable - the potential service life reaches 100 years, and is relatively easy to install. But a copper heating system is not a cheap pleasure.

- Brass. Quite a rare material for registers, but sometimes used for decorative design products for interior decoration.

- Aluminum. Heating devices are made by pressing, so they are not very cheap, but not as expensive as copper and stainless steel. Sometimes finned aluminum tubes are used. Aluminum conducts heat well, is not subject to corrosion, and is quite durable - you can count on 30 years of service.

It is worth noting registers with pressed plates to increase heat transfer. The industry produces ready-made painted steel systems or products from a steel core and pressed aluminum plates; there are copper options.

What are there

Heating registers are made of different materials and have different shapes. Each has pros and cons.

What are they made from?

If we talk about materials, the most common is steel, or rather electric-welded steel pipes. Steel does not have the best heat transfer, but this is compensated by its low price, ease of processing, availability and a large selection of standard sizes.

It is very rare to find pipes made of stainless steel - for decent power a large number of pipes are required, and you have an idea how much stainless steel products cost. If they did, it was probably a long time ago. They also use galvanized steel, but it is more difficult to work with - you won’t be able to cook it.

Registers made of copper pipes have high heat transfer and an equally high price

Sometimes they make copper registers - they are used in those networks where the wiring is made with copper pipes. Copper has high heat transfer (four times more than steel) and therefore their sizes are much more modest (both in length and in diameter of the pipes used). In addition, the distribution pipes themselves (if they are not hidden in the wall or floor) give off a sufficient amount of heat. At the same time, the plasticity of this metal allows pipes to be bent without any special tricks or effort, and welding can be used only at the junction of different pieces. But all these advantages are offset by two big disadvantages: the first is the high price, the second is the capriciousness of copper to operating conditions. Everything is clear about the price, but there are a few explanations about the operation:

- Requires neutral and clean coolant, free of solid particles

- the presence of other metals and alloys in the system is undesirable, except for compatible ones - bronze, brass, nickel, chromium, therefore all fittings and fittings will need to be made from these materials;

- Careful grounding is mandatory - without it, in the presence of water, electrochemical corrosion processes begin;

- the softness of the material requires protection - we need screens, covers, etc.

There are registers made of cast iron. But they are too bulky. In addition, they have a very large mass; no less massive racks need to be made for them. Plus, cast iron is fragile - one blow and it can crack. It turns out that this type of registers also needs protective covers, and they reduce heat transfer and increase cost. Moreover, installing them is complex and hard work. The advantages include high reliability and chemical neutrality: this alloy does not care what coolant it works with.

Cast iron finned tube registers

In general, copper and cast iron are not easy. So it turns out that the optimal choice is steel registers.

Adviсe

Before you start making registers, you should take care of purchasing the appropriate materials. You will need pipes of one diameter or another and some length. Exact numbers are not given here, since the device of the type in question can be assembled from any pipes without focusing on their diameter and thickness. More important is to ensure optimal heat transfer, which involves carrying out calculations regarding the required surface area of the register.

To do this, you will need to determine the outer area of the entire system. The resulting value is then multiplied by 330 W. The use of this method is based on the statement that 1 m2 gives off 330 W of heat if the temperature of the medium is 60 °C and the air inside the heated room is 18 °C.

Advice! You don’t have to do manual calculations, but use a simple program in EXCEL and then correctly weld the register according to the exact parameters. You can download the program in one click from the link: https://al-vo.ru/wp-content/uploads/2014/02/teplootdacha-registra-otopleniya.xls.

For people skilled in welding, assembling the structure will not be difficult. It will be necessary to prepare pipes and cut them into sections, and also take care of the plugs, for the manufacture of which a steel sheet will be required. Register assembly does not imply the presence of a strictly defined order of actions. Upon completion of welding work, it is necessary to ensure the tightness of the created structure. Otherwise, the following advice can be given:

- you should select pipes with an optimal wall thickness, since too thin ones cool quickly enough, and thick ones take a long time to warm up;

- the upper section must be supplemented with a Mayevsky valve, with the help of which air is released;

- assembly of the register in the form of a coil involves the use of a pipe bender; if this is not possible, the rotary sections can be assembled from ready-made elbows;

- the coolant inlet must be equipped with a tap, and the outlet with a valve;

- The installation of the register should be carried out with a slight slope in the direction where the supply pipe is located, which ensures that the Mayevsky crane occupies the highest position.

Video

DIY heating register

Today we will tell you how to make a heating register with your own hands, as they say, from what is on the farm, because this is what usually happens. We will talk about how to make a drawing of the future design and how to connect the registers to the heating. You can calculate the length of the sections and their number based on an existing pipe of a certain cross-section, or make a calculation for purchasing a new rental. If the production of heating registers is supported by the desire to save money, hiring an experienced welder is out of the question. Yes, and there is nothing complicated there. You will soon see this for yourself.

How to improve heat dissipation of registers

The efficiency of registers depends on the heat-transfer surface area, which is relatively small for these devices. In this connection, to improve heat transfer, it is desirable to increase the mentioned area, which can be achieved by welding metal plates. Such elements are installed vertically, providing a kind of ribbing of the pipes.

It is also possible to create something similar to convection heating. This is possible if you weld not metal plates, but profile pipes that are mounted on the front of the device in a vertical position. As a result, cold air will enter these pipes from below, heat up and exit through their upper part.

How to install

There are two installation options: hang it on the wall or put it on a stand. The choice depends on the dimensions and weight of the resulting structure, as well as on the type of walls.

Quite often they do a combined installation: they weld racks, which are then attached to the wall. Even very massive registers can be installed in this way. This installation option also provides a high level of security.

Each such heating device must have an air vent at the top point. It is needed to bleed air from the system.

Design of heating registers

Heating devices in the form of registers are a structure of several vertical or horizontal pipelines connected to each other using jumpers. In this case, the connecting elements can have different shapes and sizes. Depending on their location, classification is performed.

Register structure

For the manufacture of heating registers, smooth carbon steel pipes with a round cross-section, as well as square and rectangular ones, are used. Their combined use is possible. Stainless and galvanized steel, aluminum, copper, and brass can also be good materials for registers, but they are much more expensive and more difficult to process with your own hands.

Heating registers made of steel profile pipes are considered the simplest to make. They can be made in two main configurations: sectional type and coil type (S-shaped).

In a sectional type register, several sections of profiled metal with capped ends are arranged in parallel and connected to each other by round tubes of smaller cross-section. The jumpers ensure that the rows of the device are filled with coolant from both sides simultaneously. Moreover, the closer to the edge the transition pipes are installed, the higher the heat transfer of the device.

In a coil register, the liquid passes in an S-shape through rows of profile pipes, gradually cooling. To add rigidity to the structure, additional blind jumpers are used. Horizontal rows are connected in pairs by a snake using tubes of a smaller cross-section, like in sectional models, or sections of the main profile. The latter option is preferable due to lower hydraulic resistance and greater heat transfer.

Connecting pipes are made with threads or welding. The most effective option for connecting a heating device is a top-down diagram. For low models and in the case of forced circulation of coolant, entry and exit from below may be justified.

The design of the register must include a Mayevsky valve or an automatic air vent. It is located at the end of the top row on a threaded fitting to allow replacement. A prerequisite for installation is to maintain a slope of 0.05% in the direction of coolant movement.

Registers can be either stationary or portable. The former work as elements of a general heating system, the latter perform the task of local heating. The heat source for a separate mobile register is a heating element with a power of 1.5-6 W, mounted in the housing.

Important! The distance between register rows significantly affects heat transfer. The closer the pipes are to each other, the greater their mutual influence, which reduces the efficiency of the device. It is recommended to place the rows at a distance of at least the height of the profile pipe, increased by 50 mm.

In addition to large horizontal registers, small vertical models are also in demand. If you carry out the work carefully, you can get homemade cheap heating radiators from profile pipes that are almost as aesthetically pleasing as modern sectional radiators.

In some cases, steel registers can be a good addition to the heating units already installed in the room. Despite the lower heat transfer than radiators of a similar size, their use may be more appropriate due to their lower cost.

Calculation of parameters and drawing

The first stage of making a heating register with your own hands is design. It is clear that it will not be possible to make a heating register normally by eye. Therefore, it is necessary to carry out a number of additional calculations, based on which it will be possible to select the optimal heat exchanger. When making heating registers, many factors need to be taken into account:

Before you make heating registers with your own hands, you need to understand that this is a heating device, which means it must warm up a certain room. Its heat transfer must correspond to the situation; do not install a heat exchanger covering the entire wall in a small room. One meter should account for from 100 to 200 kilowatts, depending on the region. There is a formula for calculating the heat transfer of heating registers. It includes the following values:

- heat exchanger length in meters;

- internal section in meters;

- metal thermal conductivity coefficient;

- delta of supply and return temperatures;

- number "P".

To determine heat transfer, you need to multiply all the components of the calculation. Of course, from this formula you can separately determine each of the above values. So, knowing the square footage of the room, you can determine what dimensions the structure should have. Often, homemade heating registers are made from scrap materials, so it is not possible to select some parameters. It is necessary to adjust the entire structure to the existing characteristics, while not forgetting about the functionality of the heat exchanger.

When calculating the length of the heat exchanger, you need to remember that the resulting value indicates the total length of the pipes.

For example, according to the formula we got a value of five meters. This means that both one five-meter pipe around the perimeter and several sections, the sum of the lengths of which will be the same five meters, are suitable for heating. The point is to maintain the heat exchange area.

There are two methods for placing main (thick) pipes:

In principle, there is no difference in manufacturing. If you take a horizontal structure and rotate it 90 degrees clockwise, you get a vertical heat exchanger. This will make a difference when installing on a circuit.

That's the whole difference between vertical and horizontal register

In addition, the heating registers are secured with special jumpers. There may be one or two such jumpers. Also, the connection of horizontal sections can be carried out using couplings of the same diameter, which are welded into the end. These are the so-called serpentine registers. You can choose any method of assembling a heating register from pipes with your own hands, the main thing is that you have enough skills to perform it.

Do you want to learn more about heating elements for heating radiators, features of selection and operation?

Reviews about infrared heating can be read here.

In order not to complicate the register manufacturing process, we will use a scheme for connecting horizontal sections with two pipes. Heating register, drawing:

Heating register drawing

For work we will need:

- three identical pieces of pipe;

- four connecting pipes;

- six plugs.

The distance between the heating register pipes may be larger, but not smaller. Moreover, if pipes of large diameter are used, the distance between them is determined by the formula: diameter x 1.5. This distance is optimal. The next stage is welding.

Making registers yourself

Steel registers have a fairly simple design and do not require much skill to create. Almost any person who has experience working with a welding machine can make homemade heating radiators from a profile pipe. Unlike round ones, they are conveniently fixed in place, which makes welding easier.

Required materials and tools

Before starting work, you need to stock up on everything you need. Let us consider in detail what is required for the simplest three-row register.

Materials:

- Profile pipe in accordance with the design parameters. Dimensions can be from 30x30x3 to 80x80x3 mm.

- A round pipe with the same wall thickness with a diameter of 25 or 32 mm depending on the cross-section of the profile pipe.

- Steel sheet 3 mm thick.

- Branch pipes with external or internal threads in accordance with the diameter and type of connection – 2 pcs.

- Steel coupling with internal thread with a diameter of 15 mm and Mayevsky tap.

Tools:

- Welding machine.

- Drill.

- Bulgarian.

- Hammer.

- Marker or metal rod.

- Roulette.

Preparation of materials:

- The profile pipe is cut into pieces of the required length in accordance with the drawing.

- The round pipe is cut into 4 pieces of 10 cm each.

- 6 plugs are cut from sheet metal in accordance with the size and shape of the profile pipe. They should be 3-5 mm smaller than the cross-section of the pipe. This will allow you to neatly hide the weld in the gap.

- The pipes are laid on a flat horizontal surface strictly parallel at a distance of 10 cm. You can use two wooden beams for support. The ends are aligned in one line. Marks are made for the holes at a distance of about 5-10 cm from the edge.

- Using a cutter or drill, the intended holes are cut in accordance with the diameter of the jumpers.

Work order

- The jumpers are fixed in place and secured by welding at 2-3 points.

- Having positioned the structure vertically, the jumpers are finally welded. It is recommended to first make a thin seam at low current, which will allow the gaps to be filled well. Next, a thick main seam is performed at increased current.

- The internal space of the register is cleared of metal debris and slag.

- The plugs are applied, tacked and welded to the ends of the profile pipes.

- Welding seams are processed. The protruding parts are knocked down with a hammer, then each seam is cleaned with a grinder.

- Holes in the register are drilled depending on the selected connection diagram. In this case, it is better to place them not in the center of the ends, but slightly higher or lower.

- Connecting pipes are welded to the holes.

- The seams are cleaned and all holes except one are plugged. The register is filled with water under pressure and the welding quality is checked. The seams must withstand pressure up to 13 atm.

- The outer surface is cleaned, degreased and painted with heat-resistant paint.

- A fitting is welded to the top row and a Mayevsky valve is installed.

Sometimes supports are welded to the register, but devices without them are more versatile. If necessary, you can always use a stand, but the weight is less and you can still mount it on the wall.

Advantages

- The large length of the devices (up to 6 m) allows you to heat the entire area of the room evenly and in the shortest possible time.

- High hydraulic characteristics.

- Relatively low price. The cost of a mobile 3-pipe device (designed for heating a room with an area of up to 200 m²) with steel pipes with a diameter of 108 mm, a wall thickness of 3.8 mm and a length of 3 m, with a built-in heating element with a power of 2.5 kW is about 13,000 rubles.

- Easy to use. The devices can be easily and quickly cleaned from accumulated dust and other contaminants.

S-shaped or serpentine

Coil or S-shaped heating registers resemble, in appearance, a single pipe bent in a special way. This type of heating device is famous for its high heat transfer, this became possible due to the presence of a large working surface. Most often this type is installed in the bathroom. It is used for drying linen and towels, and is popularly called a heated towel rail.

Previously presented versions of devices used for space heating are based on operation dependent on a constant supply of water. However, it’s no secret that there are rooms in which there is no communication or laying one is simply not possible. And in this case, the engineers found a solution; they proposed shadow heating registers.

A distinctive feature of this type of device is the presence of a heating element in the internal cavity of the main components of the structure. Practice shows that the use of shadow registers allows the owner of the premises to minimize energy costs and such a device cools down longer, therefore, it is an effective heat exchanger.

Therefore, when choosing a device for heating a room of any complexity, it is necessary to take into account the features of different types of registers.

0Did you like the article? Share with friends:You may also be interestedHeating pipes 0

<header class=”entry-header”> Types of boilers for heating a private house In most cases, a country house is not connected to a central heating system. Provide it Heating pipes 0 <header class=”entry-header”> Modern heating systems: what are their design features and advantages? It is difficult to imagine modern residential construction without heating systems. Despite the fact that they are plumbing 0 <header class=”entry-header”> Modern heating systems: what are their design features and advantages? It is difficult to imagine modern residential construction without heating systems. Despite the fact that they are plumbing 0 <header class=”entry-header”> Warm floors under laminate: advantages and options Today, owners of apartments and private houses are increasingly deciding to install heated floors, and this is not without reason: stable Heating pipes 0 <header class=”entry-header”> Weld heating registers from smooth pipes with your own hands Few people know that not only heating radiators are used as a heating device, for this Heating pipes 0 <header class=”entry-header”> Do-it-yourself horizontal or vertical stove made from a pipe for a bathhouse: drawings For a person living in Russia, the bathhouse plays a big role. In this building there is a person. Heating pipes 0 <header class=”entry-header”> How to eliminate a leak in a heating pipe: cold welding, salt Currently, the formation of leaks in the heating system can occur most often in that Heating pipes 0 < header class=”entry-header”> What are bimetallic heating pipes? Bimetallic pipes are pipes consisting of two parts. Externally made of high-strength steel and Heating pipes 0 <header class=”entry-header”> Do-it-yourself heat exchanger for a bathhouse on a chimney pipe Trips to the bathhouse are probably familiar to everyone since childhood. Russian bath, this is a wonderful remedy Search: Categories

- Pipe fittings Review of pipe and fitting models

- Review of construction tools and price comparison

- Fitting

- Ventilation

- Asbestos

- Profile pipes

- Factories

- Question answer

Reduced heat transfer.

In order to save energy, it becomes important to reduce the heat transfer of pipes in those sections of communications that are not used for their intended purpose, for example, when moving from one building to another or in an unheated room.

There are many options for using thermal insulation materials for this. Manufacturers offer a fairly wide range to choose from, ranging from cheap fiberglass to more expensive types of polystyrene foam. You can purchase pipes with insulating elements already built into them.

To summarize, we conclude that the use of such calculations helps to significantly save money and avoid many technical obstacles when designing water and heat supply systems.

Actually, you are a desperate person if you decide to undertake such an event. The heat transfer of a pipe, of course, can be calculated and there are a great many works on the theoretical calculation of the heat transfer of various pipes.

Let's start with the fact that if you decided to heat your house with your own hands, then you are a stubborn and purposeful person. Accordingly, a heating project has already been drawn up, pipes have been selected: either metal-plastic heating pipes or steel heating pipes. Heating radiators have also already been looked at in the store.

But, before acquiring all this, that is, at the design stage, it is necessary to make a conditional relative calculation. After all, the heat transfer of heating pipes, calculated in the project, is the key to warm winters for your family. There is no room for error here.

Methods for calculating heat transfer from heating pipes

Why is the emphasis usually placed on calculating the heat transfer of heating pipes? The fact is that for commercially manufactured heating radiators, all these calculations have been made and are given in the instructions for use of the products. Based on them, you can easily calculate the required number of radiators depending on the parameters of your home: volume, coolant temperature, etc.

Tables.

This is the quintessence of all the necessary parameters collected in one place. Today the Internet contains a great many tables and reference books for online calculations of heat transfer from pipes. In them you will learn what is the heat transfer of a steel pipe or cast iron pipe, the heat transfer of a polymer or copper pipe.

All that is needed when using these tables is to know the initial parameters of your pipe: material, wall thickness, internal diameter, etc. And, accordingly, enter into the search the query “Table of heat transfer coefficients of pipes.”

This section on determining the heat transfer of pipes also includes the use of manual reference books on heat transfer of materials. Although they are becoming more and more difficult to find, all information has migrated to the Internet.

Formulas.

The heat transfer of a steel pipe is calculated according to the formula

Qtr=1.163*Str*k*(Twater - Air)*(1-efficiency of pipe insulation), W where Str is the surface area of the pipe, and k is the heat transfer coefficient from water to air.

The heat transfer of a metal-plastic pipe is calculated using a different formula.

Where is the temperature on the inner surface of the pipeline, °C; t

c is the temperature on the outer surface of the pipeline, °C;

Q—

heat flow, W;

l

—pipe length, m;

t

—coolant temperature, °C;

t

inc—air temperature, °C;

a n is the external heat transfer coefficient, W/m 2 K; d

n - outer diameter of the pipe, mm;

l—thermal conductivity coefficient, W/m K; d

in

-

internal diameter of the pipe, mm; a int - internal heat transfer coefficient, W/m 2 K;

You understand perfectly well that calculating the thermal conductivity of heating pipes is a relative value. The formulas include the average parameters of certain indicators, which may, and do, differ from those that actually exist.

For example, as a result of the experiments, it was found that the heat transfer of a polypropylene pipe located horizontally is slightly lower than that of steel pipes of the same internal diameter, by 7-8%. It is internal, since polymer pipes have a slightly thicker wall thickness.

Many factors influence the final figures obtained in tables and formulas, which is why the footnote “approximate heat transfer” is always included. After all, the formulas do not take into account, for example, heat loss through the building envelope made of different materials. There are corresponding tables of amendments for this purpose.

However, by using one of the methods for determining the heat output of heating pipes, you will have a general idea of what kind of heating pipes and radiators you need for your home.

Good luck to you, builders of your warm present and future.