Few people know that the choice of a chimney system directly depends on the temperature of the exhaust gases during fuel combustion in the boiler. Ignoring this important point leads to the fact that soon after assembling the chimney, the metal pipe or brick structure crumbles, so repairs and financial costs cannot be avoided. To understand why this happens, you need to understand the operating features of gas boilers.

Important nuances

In solid fuel boilers, fuel burns at a high temperature, so the exiting gases have a high temperature (usually about 300 degrees, although the values may vary up or down). The situation is completely different with gas boilers.

Modern gas equipment used for space heating has an important feature - the temperature of the combustion products leaving does not exceed 120 degrees, and sometimes is significantly lower than this mark. This is due to the desire of manufacturers to increase the efficiency of gas boilers. This desire also has its negative sides. The lower the temperature of the exhaust gases, the more condensate forms inside the system. Condensate contains aggressive substances and therefore has a destructive effect even on stainless steel pipes. In general, unpleasant consequences can be prevented if you take into account several important nuances.

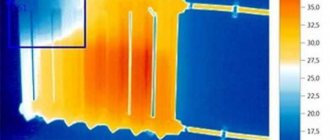

The temperature of the exhaust gases directly depends on the radiator settings. If heating radiators heat up to a temperature of 65 degrees, the combustion products will have a low temperature. When using a heated floor system, in which the water is heated to only 35 degrees, the temperature of the gases will be even lower and there will be more condensation.

SEARCH

Heat losses to the atmosphere by the furnace masonry and returbents depend on the surface of the furnace, the thickness and material of the masonry and roof.

They make up 6-10%. Heat loss from the walls of the combustion chamber is estimated at 2-6%, and in the convection chamber within 3-4%. Heat losses from flue gases depend on the excess air coefficient and the temperature of the gases leaving the chimney. They can be identified from Fig. 177 (a and b), taking into account that the temperature of the flue gases during natural draft should not be lower than 250 ° C and 100-150 ° C higher than the temperature of the raw materials entering the furnace. By using the heat of exhaust flue gases to heat the air using artificial draft, it is possible to significantly reduce heat loss and have a tubular furnace with an efficiency of 0.83-0.88. [p.284] Temperature of the flue gases at the pass, i.e., the temperature of the flue gases entering the convection chamber. Usually this temperature is in the range of 700-900 ° C, although it can be lower. It is not recommended to increase the temperature of gases at the pass excessively, as this can cause coking and burnout of the radiant pipes. [p.104] And only by shielding the combustion chamber and increasing its volume were normal conditions created for the operation of the coil. Radiant-type tubular furnaces were created. In early designs of such furnaces, the ceiling screen pipes were protected from severe flame exposure by cuffs made of fire-resistant material. Corrugated cast iron cuffs on convection pipes increased the heating surface in the convection chamber of the furnace. As a result of shielding the furnace ceiling, heat transfer by radiation increased, the temperature of the flue gases above the pass decreased, and the need for protective cuffs and flue gas recirculation was eliminated. For maximum heat utilization [p.273]

Flue gas temperature after boiler - 210 210 — [p.219]

Technological design standards provide for a reduction in the temperature of flue gases before entering the chimney at natural draft to 250 °C. If you have special smoke exhausters, the temperature can be reduced to 180-200 °C. The heat of flue gases having a temperature of 200-450 ° C (average figure) can be used to heat air, water, oil in the installation and to produce water steam. Below are data on the thermal resources of flue gases at an ELOU-AVT installation with secondary distillation of gasoline with a capacity of 3 million tons/year of sulfur oil [p.211]

Average flue gas temperature of 293 305 310 - [p.219]

The temperature regime of raw material heat exchangers is also limited. The maximum permissible temperature at a regeneration pressure of 3.0-4.0 MPa should not exceed 425 ° C, and therefore the temperature of the flue gases leaving the reactors before entering the raw heat exchanger should be reduced by mixing with a cold coolant. [p.129]

Thermal intensity of pipes, kcal/(m2-h) radiant convection Flue gas temperature, [p.121]

Surface of heaters, Air heating temperature in heaters, °С Temperature of flue gases, °С [p.186]

Typically, the temperature of the flue gases at the pass is automatically regulated with correction based on the temperature of the product at the outlet of the furnace. To monitor and regulate tube furnaces, the following elements are provided in their piping. [p.48]

Liquid fuel consumption, kg/h Flue gas temperature at the furnace outlet, °C. . . . Flue gas volume at gas outlet temperature from 4000 3130 2200 [p.211]

Flue gas temperature in front of the boilers, °C 375 400 410 — [p.219]

In drying installations, the material being processed is not in close proximity to the furnace, as is the case in furnaces for various types of cooking, distillation and similar boilers. Therefore, the temperature in the combustion chamber of the drying installation can be significantly higher than the temperature in the furnaces, in in which the devices that consume heat are located. However, in this case, the temperature is determined by the properties of the material being dried and the requirements dictated by the quality of the product. Some types of raw materials do not tolerate high temperatures, so it is necessary to reduce the temperature of the flue gases to the temperature [p.252]

Based on the amount of heat given off by a given amount of flue gases in the radiation system, the temperature of the flue gases entering the convective system is determined. [p.269]

During operation of the regenerator, the flue gas temperature may exceed normal due to the combustion of carbon monoxide. If this phenomenon is detected in a timely manner, it is necessary to redistribute the air across sections, reducing the supply to those sections where there is excess oxygen in the flue gases leaving the section, and increasing its supply to sections where there is not enough oxygen. In the event of a sharp increase in the temperature of the exhaust gases, the air supply to individual or all sections is temporarily stopped. [p.153]

Primary reforming of natural gas with steam is carried out in vertically located pipes heated by flue gases, the lower ends of which are introduced directly into the secondary methane reforming reactor. A portion of the flue gases is fed through a perforated plate into the secondary reforming catalyst bed, which produces nitrogen-enriched gas. Flue gas temperature - 815° C [p.97]

Fire-type stoves have been replaced by convection stoves, in which the pipe coil is separated from the combustion chamber by a pass wall. During the operation of such furnaces, significant disadvantages were identified: high temperature of the flue gases above the pass wall, melting and deformation of the brickwork, burnout of the pipes of the upper rows of the coil. To reduce the temperature in the combustion chamber, flue gas recirculation was used and fuel was burned with an increased excess air ratio. However, increased air flow reduced the efficiency of the furnaces and did not reduce pipe burnout. [p.273]

Temperature at the superheater. In some cases, a coil is installed in the convection section of the furnace to superheat water vapor supplied to distillation columns for stripping low-boiling fractions. The superheater is placed where the temperature of the flue gases is 450-550 ° C, i.e. in the middle or lower section of the convection chamber. The temperature of superheated steam is 350-400° C. [p.282]

The temperature of the flue gases above the pass wall is especially important. The high temperature of gases at the pass corresponds to high thermal stress on the surface of the radiant tubes, the temperature of their walls and a high probability of coke formation. Being deposited on the inner surface of the pipes, coke impedes heat transfer, which leads to a further increase in the temperature of the walls and to their burnout. [p.283]

Increasing the speed of movement of the heated raw material in the furnace pipes increases the efficiency of heat removal, reduces the temperature of the pipe walls and, thus, makes it possible to work with higher thermal intensity of the radiant pipes and the temperature of the flue gases at the pass. [p.283]

A typical ELOU-AVT (A-12/9) installation with a capacity of 3 million tons/year with secondary distillation of gasoline has five furnaces with a total thermal capacity of 81 Gkcal/h. In all furnaces, 11,130 kg of fuel are burned in 1 hour. The temperature of the flue gases at the exit from the convection chambers of the furnaces is 375–410 °C. To use the thermal energy of flue gases before entering them into the chimney, remote waste heat boilers of the KU-40 type are installed in the furnaces. [p.219]

The lower the temperature of the flue gases leaving the convection chamber, the more heat is absorbed by the heated oil product. Typically, the temperature of the flue gases at the exit from the convection chamber is taken to be 100-150 ° C higher than the temperature of the raw materials entering the furnace. But since the temperature of the raw materials entering the furnace can be quite high, approximately 160-200 ° C, and for some processes reaches 250-300 ° C, then to utilize the heat of the flue gases, an air heater (recuperator) is installed, in which the air going into the furnace is heated ovens. If there is an air heater and a smoke exhauster, it is possible to cool the flue gases before releasing them into the chimney to a temperature of 150° C. With natural draft, this temperature is at least 250° C. [p.90]

Convection pipes receive heat through convection of flue gases, radiation from masonry walls and radiation of triatomic gases. As noted at the beginning of the chapter, heat transfer in a convection chamber depends on the velocity and temperature of the flue gases, as well as the temperature of the feedstock, the diameter of the pipes and their arrangement. The speed of flue gases in a convection shaft usually varies between 3-4 m/sec, and in a chimney 4-6 m/sec. [p.107]

Solution. Let us determine the efficiency of the furnace if the temperature of the flue gases at the exit from the convection chamber [p.113]

The temperature of the flue gases at the outlet of the furnace is 500 C. The heat of the flue gases is utilized in a tubular three-pass (via air) air heater with a heating surface of 875 m2. After the air heater, flue gases at 250 C are removed into the atmosphere through a chimney without the use of forced drafts. [p.107]

Let us set the temperature of the flue gases after the heating section of the radiation chamber to g, c = 850° C, and after the reaction section ip. c = 750° C. Heat content of flue gases but fig. 6. 1 at a = 1.1 [p.120]

A distinctive feature of waste heat boilers, as equipment for generating steam, is the need to ensure the passage of a large amount of heating flue gases per unit of generated water steam (E1/d.g/C). This ratio is a direct function of the initial temperature of the flue gases at the entrance to the apparatus and their flow rate. Due to the relatively low temperature of the flue gases for generating steam, their specific consumption in waste heat boilers is much higher (8-10 times) than in conventional combustion boilers. The increased specific consumption of heating gases per unit of generated steam predetermines the design features of waste heat boilers. They have large dimensions and high metal consumption. To overcome additional gas-dynamic resistance and create the required vacuum in the furnace firebox (draft), 10-15% of the equivalent electrical power of the waste heat boiler is spent. [p.76]

Having filled the hopper with dried catalyst, open the valve under the hopper and pour the catalyst into the calcination column. The volume of the hopper corresponds to the useful volume of the calcination column, i.e. one load. Having filled the column with a catalyst, the furnace is ignited under pressure (using liquid fuel), directing the flue gases into the atmosphere. Then, having adjusted the combustion in the furnace, the flue gases are introduced into the casing of the calcination column. After heating the casing and making sure that the fuel is burning normally, the flue gases are directed to the bottom of the calcination column in the minimum amount necessary only to overcome the resistance of the catalyst layer. Then they begin to slowly raise the temperature of the flue gases at the exit from the furnace and warm up the catalyst. Warming up of the system continues for approximately 10-12 hours, during which time such an amount of flue gases is introduced so that there is no carryover of the catalyst from above. Reaching a temperature at the bottom of the column of 600-650° C is considered the beginning of catalyst calcination. The duration of calcination at this temperature is 10 hours. [p.68]

Then they gradually lower the temperature of the flue gases at the exit from the furnace and at 250-300 ° C they stop supplying fuel, but [p.68]

The temperature of the gases at the pass, the thermal tension of the heating surface of the radiant tubes and the direct efficiency coefficient of the furnace are mutually related. The higher the direct return coefficient, the lower, other things being equal, the temperature of the flue gases at the point of maturity and the lower the thermal tension of the heating surface of the radiant pipes and vice versa. [p.105]

Tubular coil reactors. A tubular coil reactor with a vertical arrangement of pipes was developed for the production of bitumen in a continuous manner at domestic refineries [2, 55, 190]. Temperature conditions of reactors. (Kremenchug and Novogorkovsky refineries) is maintained by the heat of flue gases coming from the prechamber furnace. However, this solution does not take into account the specifics of the exothermic oxidation process. Indeed, to accelerate the heating of the reaction mixture in the first reactor pipes along the flow, it is necessary to increase the temperature of the flue gases, but as a result, the oxidized material in subsequent pipes is overheated, where the oxidation reaction and heat release occur at high rates. Thus, it is necessary to maintain some intermediate temperature of the flue gases, neo[tpmal y, both to heat the reaction mixture to the reaction temperature, and to subsequently maintain the temperature at the desired level. For the installations of the Angarsk, Kirishi, Polotsk, Novoyaroslavl and Syzran refineries, a more successful solution has been found: the raw materials are preheated in a tube furnace, and excess reaction heat, if necessary, is removed by blowing air through the reactor pipes placed in a common casing (according to the design of the Omsk branch of VNIPIneft, each reactor pipe placed in a separate casing). [p.130]

If the temperature of the flue gases at the exit from the common collecting manifolds of the regenerator exceeds 650°, this indicates the beginning of carbon monoxide afterburning. To stop it, it is necessary to sharply reduce the air supply to the upper part of the regenerator. [p.145]

In order to reduce the temperature of the flue gases above the pass wall, in old-style radipant-convection furnaces, especially thermal cracking furnaces, flue gas recirculation is used. Cooler flue gases from the furnace hog are returned to the combustion chamber, which leads to heat redistribution between the chambers. In the convection chamber, the thermal tension of the upper pipes is reduced, but due to the increase in the volume of flue gases, their speed increases, and heat transfer throughout the convection chamber improves. The recirculation coefficient in tube furnaces ranges from 1 to 3. [p.90]

The imperfect design of the burners of furnaces and boilers for burning fuel and the insufficient sealing of the furnaces do not yet allow operation with small excess air. Therefore, it is believed that the temperature of the air heater tubes should be higher than the dew point temperature of aggressive flue gases, i.e. not lower than 130 °C. For this purpose, preliminary or intermediate heating of cold air or special heating surface layout schemes are used. There are devices that are structurally designed in such a way that the heat exchange surface on the flue gas side is much larger than on the atmospheric air side, so air heater sections are assembled from pipes with different finning coefficients, increasing towards the cold end (to the point of entry of cold air), and thus the temperature the pipe walls approach the temperature of the flue gases. Bashorgener-Goneft air heaters are constructed using this principle from cast-iron finned and ribbed-toothed pipes with good performance indicators. [p.80]

The catalyst is heated and calcined by direct contact with flue gases coming from the furnace in which gaseous or liquid fuel is burned. The temperature of the flue gases is automatically maintained at the level of 630-650 ° C, while the temperature in the calcination zone is 600-630 ° C. The calcined catalyst enters the cooling chon through the iridescent tubes of the lower grille-gate, where it moves between rows of air-cooled pipes and It cools itself to the desired temperature. A movable metal cup is placed at the end of the refining tube, the position of which regulates the height of the catalyst layer on the conveyor located below and, consequently, the speed of product unloading. A conveyor belt feeds the unloaded catalyst into a screen for screening out fines. Next, it is poured into metal barrels and delivered to the finished product warehouse. [p.70]

The higher the temperature of the heated raw material in the radiant tubes and the greater its tendency to coke formation, the lower the thermal intensity should be, and therefore, the lower the temperature of the flue gases above the pass. For this furnace, an increase in the surface of the radiant tubes leads to a decrease in the temperature of the flue gases above the pass and the heat intensity of the radiant tubes. Contamination of the inner surface of the pipes with coke or other deposits can lead to an increase in the temperature of the flue gases above the pass and to burnout of the first rows of pipes in the convection chamber of the furnace. The temperature over the pass is carefully controlled and usually does not exceed 850-900° C. [p.283]

The temperature of the flue gases above the pass wall is usually maintained at 700-850 ° C, i.e., high enough to transfer part of the heat by radiation to the upper rows of pipes of the convection chamber. But the main amount of heat in the convection chamber is transferred due to forced convection of flue gases (created by a chimney or smoke exhauster). [p.89]

The fraction of distillate at the furnace outlet is e = 0.4, the density of distillate vapor = 0.86. residue density = 0.910. The diameter of the pipes in the radiation chamber is 152 X 6 mm, in the convection chamber 127 X 6 mm, the useful length of the pipes is 11.5 m, the number of pipes is 90 and 120 pieces, respectively. The fuel composition and theoretical air flow are the same as in examples 6. 1 and 6. 2, the heat content of flue gases with excess air a = 1.4 can be found from Fig. 6. 1. Flue gas temperature at the pass [p.109]

The total duration of hydrothermal treatment including heating is approximately one day. After the pressure in the apparatus begins to drop, the temperature of the flue gases at the outlet of the furnace is gradually reduced and, finally, the nozzle is extinguished. The apparatus is cooled with cold air from the firebox through the casing. The dried balls are unloaded and sent to the hopper of the calcination column. [p.127]

Suction pyrometers. In the practice of measuring high flue gas temperatures, suction pyrometers are used. The main elements of suction pyrometers are a thermocouple placed in a cooled housing, a screen system and a device for suctioning gases. Thermal electrodes are insulated from one another and from the protective cover by rigid elements (straw tubes, single- and double-channel beads) made of quartz (up to 1100°C), porcelain (up to 1200°C), and porcelain with a high alumina content (up to 1350°C ) ceramic materials and glass enamels applied by broaching methods. [p.139]

When the niroscoils become coked, there is a gradual increase in the temperature of the pipe wall, the pressure drop increases, and white spots may be observed in places where the pipes are overheated. The formation of coke deposits in the pyro-coils is also judged by the increase in the temperature of the flue gases at the furnace pass. Coking of the IIA is characterized by an increase in the hydraulic resistance of the system with an increase in the temperature of the pyrolysis products after the IIA. An increase in hydraulic resistance in pyro-coils and ZIA is accompanied by an increase in pressure in the furnace unit and, as a result, the contact time increases and the yield of lower olefins decreases. [p.198]

chem21.info

When choosing a chimney, consider the boiler power

When choosing a chimney system, it is necessary to take into account the power of the gas boiler. The higher the power, the higher the combustion temperature of the fuel will be. This is sure to be reflected in the escaping gases. The power value helps to choose the correct pipe diameter and length. For example, a 300 kW boiler requires a pipe with a diameter of 150 mm.

Typically, the instructions for use indicate not only the technical characteristics of the heating equipment, but also provide recommendations for the selection and installation of a chimney system. If necessary, seek help from a specialist if you yourself cannot correctly calculate the optimal parameters of the chimney pipe.

Parameters affecting boiler operation

- One of the important factors influencing the operation of the chimney of a solid fuel boiler is the height of the pipe, that is chimney length. This is explained simply: in straight sections, the flow of flue gases picks up speed. The cross-section and smoothness of the chimney walls are also important. Below are the parameters that are crucial for the efficient operation of the chimney:

- To – absolute external temperature;

- g – free fall acceleration;

- Ti – average internal temperature (K);

- A – pipe cross-sectional area (m²);

- h – pipe height (m);

- Q – air flow, (m³/s);

- C is the coefficient introduced due to friction (0.65–0.70).

- The design of the chimney for a solid fuel boiler is also important The fewer horizontal and narrowed sections and turns there are, the better the traction. This is explained by the fact that the flow of flue gases rises through the pipe along a spiral path. Encountering obstacles on its way in the form of roughness, seams, etc., the flow changes direction and mixing of gases occurs.

Which material should you prefer?

Nowadays, stainless steel chimneys are very popular on the market. They are used for boilers of various types, although this approach is fundamentally wrong. If you plan to install a gas boiler, you need to decide what material the chimney should be made of. Don't rush to buy metal pipes. They are excellent for solid fuel boilers, as they can easily withstand high temperatures.

For gas boilers, which are characterized by low temperatures and large amounts of condensate, it is preferable to choose plastic or polymer pipes. Their main advantage is good resistance to moisture. Because of this, they usually last longer than metal chimneys. FuranFlex pipes are excellent for gas boilers, which are characterized by excellent resistance to aggressive substances, strength and durability.

If you use a gas-wood combination boiler, you will have to abandon the use of FuranFlex. The fact is that polymer pipes are produced in two versions - for high and low temperatures (solid fuel and gas boilers, respectively). Polymer stockings cannot be used effectively at high and low temperatures at the same time.

Device and installation

When installing a metal chimney, work starts from the bottom, gradually moving upward. Pipes can be connected in several ways:

- By the movement of smoke.

- For condensate

When the boiler is connected to the chimney according to the first option, installation occurs from the boiler. The second option, on the contrary, goes to the boiler. The metal structure consists of several parts:

- Cup.

- Pipe sandwich.

- Condensate collector.

- Spark arrestor.

- Header.

- Cleaner.

To create a reliable connection, establish:

- Adapters.

- Tees.

The joints are fastened with clamps from the outside.

Features of repair work to restore the chimney

If repair of a gas boiler, or more precisely its chimney system, is required, the most effective solution would be to use FuranFlex technology. When installing a polymer stocking, there is no need to perform dismantling work. The FuranFlex pipe is inserted into the chimney from the inside, and after hardening it serves as support and protection. It prevents further destruction, while the material itself has excellent performance characteristics. The main thing is to choose the right type of material, but our employees are always ready to help in resolving this issue. They will advise you on all your questions.

Pipe height

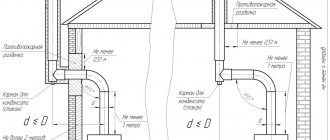

This size is determined by SNiP, which sets certain parameters:

- If the roof is flat, the chimney should rise 1.2 meters above it.

- If the chimney is located near the ridge, and the distance is less than 1.5 meters, it should rise above the ridge by 0.5 meters or more.

- When the pipe is located in the range of 1.5 - 3 meters to the ridge, it should not be below the ridge line.

- If the location of the chimney from the ridge exceeds 3 meters, its height should be on a line extending from the ridge, maintaining an angle of 10 degrees relative to the horizon line.

To determine the height of the chimney, a large number of indicators are taken into account. The parameters presented above apply only to gas equipment. To make an accurate calculation, you need to use the services of a specialized company.

Gas boiler clocking: causes and ways to eliminate them

The term “clocking” refers to the frequent switching on and instant shutdown of a boiler, which in fact does not fulfill the main task of gas equipment to heat the coolant. Such a “symptom,” if not eliminated, will provoke serious breakdowns, followed by expensive repairs.

Why is this happening

So, you approached the boiler and noticed that it starts working as expected (the torch fires), literally a few seconds pass and it immediately turns off. A few seconds later the situation repeats itself.

The first and most harmless problem from a maintenance point of view is incorrectly installed power when the heating system is short. Let's look at an example: your boiler is set at 55℃, and the pump is set to maximum values.

In a closed system there are only 2 radiators, and outside the window the temperature is above zero. What we have: the return flow pumped from the system returns to the heat exchanger, where, due to the temperature difference, the torch must automatically fire and the boiler ignite in order to eliminate this difference by heating.

Also, the problem of frequent turning on and instantaneous shutdown can be caused by the following reasons:

- Insufficient gas pressure in the system - the boiler automatically goes out because the required volume of gas is not released at the set power.

- Pump malfunction - the unit either does not pump water at all, or pumps it so quickly that it does not have time to go through all the stages from heating to transferring heat to the batteries.

- Overheating of the boiler itself - the manufacturer has established recommended limits for the safe operation of the boiler. If the temperature is higher than normal, an emergency shutdown may occur. This will happen exactly until the boiler cools down.

- Malfunctions of the thermostat - this device can fail due to sudden changes in the voltage in the network, which leads to distortion of the received data and the sending of a false signal to the central board about the need for a quick shutdown.

A pulse shutdown, which alternates with the switching on of gas equipment, significantly depletes the combustion chamber and the working elements in it. Sooner or later, problems will begin with the burner, which tends to fail suddenly when there are no signs of trouble.

What to do

The first thing to do is to correctly set the power of the boiler and pump. If these are the minimum values, then it is enough to set the pump to medium speed. When the water heating is more than 45℃, you can increase the speed.

It is important to set the power correctly

The sequence of actions is as follows:

- Turn off the boiler completely and give it 10-20 minutes to cool down.

- Light it using the lowest temperatures.

- Adjust the pump operation.

- Evaluate the result.

If the problem recurs, but not as often, the thermostat will save you. This device monitors the return temperature and forcibly starts the boiler only if its temperature is lower than the manually set one. The thermostat is good in all respects: it saves gas, protects the boiler, and the pump does not overheat.

Removing air from the heating system

It happens that all attempts to adjust the boiler temperature do not give the desired result. This happens mainly in the fall, after a long summer period of inactivity of the heating system.

When cold weather sets in, the consumer starts the boiler, it starts to work, and the heating radiators heat up unevenly - the sections closest to the boiler at least somehow heat up, and the subsequent ones become slightly warm, or even completely cold.

This can happen if the water level in the heating system was not checked before the first start-up of the boiler in the new heating season. On warm summer days, heated by the sun, the water from the system begins to evaporate little by little, the process lasts all summer, and by autumn the coolant level in the system may drop below the minimum level.

After turning on for the first time, the circulation pump, starting to “drive” water through the system, forces some of the air into the heating system. Pushed by water, it accumulates at the highest and most distant points of the system from the boiler.

The system is “aired” - a plug of accumulated air does not allow the coolant to completely fill the heating radiator.

To solve the problem, a Mayevsky tap is screwed into the upper part of the radiator, on the side farthest from the boiler. The device is designed to remove air from a heating radiator.

When you turn the valve head by hand or with a screwdriver, an indirect through passage opens to remove air - a hissing sound of escaping air appears. As soon as the first splashes of water begin to flow through the tap, it is closed.

In the first 2-3 days of heating operation, it is recommended to carry out several such operations with an increasing break between them.

Before opening the Mayevsky tap, you must place an empty bucket or other suitable container under it. It is advisable to place any protective screen made of cardboard, paper, fiberboard or other materials between the tap and the wall to protect the wall covering from splashing water.

As a “disease” of the heating system, airing is typical for large heating circuits due to the possible unauthorized withdrawal of hot water from the heating system. Therefore, in apartment buildings, the procedure for bleeding air from the heating system may be necessary several times throughout the heating season.