When a car's heating system fails, a common cause of problems is a faulty heater core. Therefore, there is an urgent need to replace this element on your car. The procedure for changing the stove element itself may differ depending on the design features of the car. But the key issue here is the right choice. The main dispute is over aluminum and copper products. It is not always possible to give a definite answer to which radiator is better - aluminum or copper. To do this, you need to study their features, strengths and weaknesses. This will allow you to give an objective assessment of the devices and understand whether there is an obvious leader among them.

Recommendations for choosing a radiator.

How it works

First you need to understand how the heater cores in your car function. The heat inside the cabin comes from the running engine. This is a kind of side effect of the operation of the power unit. It generates heat, which engineers have learned to use for the benefit of humans, that is, to heat the interior of the car with it. The heat itself is created as a result of the combustion of the air-fuel mixture and friction between the surfaces of engine elements. To remove this heat from the heated components of the motor, its design includes a cooling system. One of its functions is to heat the car interior.

A logical conclusion follows from this. The hotter the engine is, the warmer it can be inside the cabin. The coolant becomes hot, removing heat from the engine, and passes into the heater core. Here the fan comes into operation, blowing air through the heated radiator and distributing it throughout the car. To be more precise, around the cabin. The driver and passengers can regulate the temperature of the supplied hot air using deflectors and a tap, which are located on the line between the power unit of the car and the stove itself. This is the simplest shut-off type valve, which has a mechanical or electrical drive type. With its help, the amount of cooling liquid passing through the heating system is regulated.

If you raise the temperature on the control unit, the tap will open more. When the temperature decreases, the opposite effect occurs. Its functionality directly affects the operation of the machine's stove. If the system cannot provide full passage for the coolant heated by the engine, then the driver and passengers will feel cold. The temperature outside plays a big role. In the case of a serviceable and well-functioning heater, even it will not be able to warm up the interior as much as possible if the outside temperature is at a very low level. The colder it is outside, the more difficult it is for the stove to warm up the interior.

Maximum coolant temperature and its fluctuations

And the temperature of the coolant in our heating systems is not stable. Sometimes the pipes are barely warm, sometimes they are hot, like fire. It is important for us how the radiators will behave in the latter case, whether they can withstand too hot water. The indicators for this parameter are as follows. For a cast iron radiator, the coolant can heat up to 110 degrees. Hot water flowing through the pipes of a bimetallic radiator core can have a temperature of up to 130 degrees. But in general, both types of radiators tolerate temperature changes well. The only thing is that due to the difference in expansion of steel and aluminum, with a sharp change in temperature, you can hear small crackling sounds from the bimetallic radiator.

Maximum coolant temperature: Cast iron + | Bimetal +

Radiator design

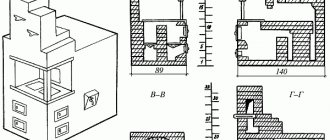

It is important to consider that the car has two radiators at once. One of them is included in the heating system and is in many ways similar to its older brother installed in the cooling system. Their functions are also similar. Only the cooling radiator mainly transfers the selected heat to the atmosphere, and the small one (heating radiator) is intended for the interior. Both devices provide for the presence of 2 tanks connected by tubes to each other. The plates necessary to increase the cooled area are mounted to them. The more plates the device has, the higher its heat transfer rate will be.

Therefore, when choosing a new heating radiator, you should definitely pay attention to the number of plates present. If their density is high, then the heat transfer will be at a high level. The main difference between them is the material of manufacture. The choice in favor of a copper or aluminum option is not so clear-cut. You should study in detail the characteristics and features of the two options in order to understand which one would be better to choose in each specific case.

Effect of carbon concentration

The carbon concentration in steel affects the amount of heat transfer:

- Low carbon steels have a high conductivity index. That is why they are used in the manufacture of pipes, which are then used to create the heating system pipeline. The coefficient value varies from 54 to 47 W/(m* K).

- The average coefficient for common carbon steels is a value from 50 to 90 W/(m* K). That is why such material is used in the manufacture of parts for various mechanisms.

- For metals that do not contain various impurities, the coefficient is 64 W/(m* K). This value does not change significantly under thermal influence.

Thus, the considered indicator for alloyed alloys may vary depending on the operating temperature.

Advantages and disadvantages of copper devices

Let's start with copper. Many people call them the preferred choice because they have better technical characteristics. But there are also disadvantages here. Let's start with the advantages. These include:

- Thermal conductivity. This is one of the main arguments that speaks in favor of copper and against aluminum. Copper devices are characterized by greater thermal conductivity compared to competitors. As you already understood from the above, the higher the radiator’s thermal conductivity, the higher the quality of its work in heating the interior.

- Suitability for repair. Copper is a rather unique material. It is both lightweight and yet resists damage from minor impacts and dents. Therefore, it is much easier to repair in case of emergency situations. The experience of car owners clearly shows that in case of cracks or damage to the tubes, you can easily solder them with your own hands or seek help from specialists. With such a repair, the thermal conductivity does not change, and therefore partial failure does not force you to throw away the radiator and buy a new one in its place.

- Copper tank. Copper radiators are equipped with tanks made of similar material. This is considered a significant advantage, since such design features help improve the performance characteristics of the product.

But such efficiency and repairability come at the price of one objective drawback. It lies in the high price. If we compare both design options, the copper one will significantly exceed the cost of its aluminum competitor. Therefore, when choosing a car, this issue is very acute for car owners. Not everyone is ready to give that kind of money, even despite the obvious advantages and most important characteristics of the element.

What is thermal conductivity

This term means the ability of various materials to exchange energy , which in this case is represented by heat. In this case, energy transfer passes from the hotter part to the colder part and occurs due to:

- Molecules

- Atoms.

- Electrons and other particles of the metal structure.

The thermal conductivity of stainless steel will differ significantly from that of another metal - for example, the thermal conductivity of copper will be different than that of steel.

To indicate this indicator, a special value is used, called the thermal conductivity coefficient. It is characterized by the amount of heat that can pass through a material in a certain unit of time.

Indicators for steel

Thermal conductivity can vary significantly depending on the chemical composition of the metal. The coefficient of this value will be different for steel and copper. In addition, with an increase or decrease in carbon concentration, the indicator under consideration also changes.

There are other features of thermal conductivity:

- For steel that does not have impurities, the value is 70 W/(m* K).

- Carbon and high-alloy steels have much lower conductivity. Due to an increase in the concentration of impurities, it is significantly reduced.

- The thermal effect itself can also affect the structure of the metal. As a rule, after heating, the structure changes its conductivity value, which is associated with a change in the crystal lattice.

The thermal conductivity coefficient of aluminum is much higher, which is due to the lower density of this material. The thermal conductivity of brass also differs from that of steel.

Pros and cons of aluminum radiators

By comparing the strengths and weaknesses of devices, you can understand their main differences. After all, the difference between copper and aluminum radiators lies in their main characteristics. What is considered an objective advantage for one person turns out to be a serious disadvantage for another. Just look at the pros and cons of aluminum products and you will understand the difference between them.

Let's start with the positive aspects of aluminum as a material for the manufacture of car heater radiators.

- Price. While cost was considered a disadvantage of copper radiators, here it is a serious advantage. If we compare the price tags for both products, aluminum ones will win by about 2 times. Much depends on the manufacturer, but still the difference in cost remains significant. The buyer can save a lot. Because of this, aluminum units have such a large audience.

- Heat dissipation. Provided that the number of plates is increased, that is, the cooling area becomes larger, aluminum will not be much inferior to copper in terms of heat transfer. Therefore, in this component they are practically the same. But remember that aluminum ones are cheaper.

- Range. A huge proportion of modern cars that have been produced over the past few years are equipped with aluminum units from the factory. Because of this, the number of their analogues and original spare parts offered by different manufacturers is growing. The copper versions have a more modest choice.

We're done with the benefits. Let's move on to the other side of the coin. Aluminum is not doing so well. The stated advantages are beyond doubt. But still, motorists make a choice in favor of copper after they have studied the main disadvantages of the design option under consideration.

Therefore, the disadvantages should definitely be pointed out. This clearly shows the differences between the elements. The main disadvantages include:

- Thermal conductivity indicators. This is a very important drawback that literally negates all the objective positive qualities of the devices. If the driver needs to get the most efficient radiator so that the heating system works efficiently and fully warms up the interior, he will not look in the direction of aluminum.

- Suitability for repair. In this case it is absent. If the tubes are damaged, it will not be possible to resold them even with the participation of specialists. It is necessary to change the entire assembly at once. There are also products that are initially supplied to the market with cracks in the tanks. These are mostly little-known companies of dubious origin. In theory, you can change the tank, and similar practice occurs. But in fact, such manipulations are very dangerous and can lead to damage to the car’s stove.

- Corrosion. The appearance of rust, that is, the corrosion process, is considered an objective and significant drawback for aluminum. Such phenomena further reduce the quality of heat transfer, contribute to the appearance of leaks and further failure of the heating system.

Approximately the same conclusions can be drawn regarding these devices, which are made from two different materials.

Conclusions from comparative characteristics

When purchasing radiators, you need to take into account the main performance characteristics: the ability to withstand significant pressure drops, resistance to corrosion processes, the strength of section connections and, ultimately, the durability of the product.

Aluminum ones can be installed in private households, where it is possible to control the quality of the coolant and the pressure in the system. They will serve well for many years. Home owners will receive good quality at an affordable price. However, you should not install such radiators in houses where antifreeze is supposed to be used as a coolant.

Where to choose

The question of choice still remains open. But you need to try to answer it as objectively as possible. Despite the shortcomings mentioned, when choosing a radiator several years ago, everyone would definitely have opted for a copper product. Such designs were objectively better and could ensure excellent performance of the entire heating system of the car. But now the situation is different. There are many manufacturers, but there are no truly high-quality copper elements as they used to be. This is due to the desire to reduce the cost of production.

As a result, all sorts of impurities began to be added to copper, which negatively affect strength, quality, thermal conductivity and other aspects that have always been considered the main advantages. Therefore, it is more logical to choose aluminum. This material does not need to be reduced in price due to impurities, therefore it actually completely retains its advantages. And car owners say the disadvantages are not so significant, since the radiator is still a consumable item that can be changed every few years.

Under current conditions, aluminum is objectively better than copper. But if you manage to find the highest quality product without any admixtures of other metals, then you can safely opt for a copper stove radiator. But what you should categorically refuse is painted heating radiators. The presence of a layer of paint significantly reduces heat transfer. In addition, when the paint coating heats up, it begins to emit an unpleasant odor that enters the interior of the car. Try to carefully monitor the heating system to prevent clogging of the channels. If they turn out to be clogged, the fact of what material these elements of the car heating system are made of will no longer play any role.

Manufacturers

If you have been able to determine for yourself which radiator is better, then all that remains is to resolve the issue with the manufacturer. Copper and aluminum are actively used in the production of their products by various companies that create components for automotive heating systems. There are a lot of good manufacturers, but everyone has their own experience in working with certain factories. It is impossible to objectively determine the best company. Some people speak well of them, others were not particularly pleased. The question is quite subjective.

But if you take into account the number of reviews, the level of sales and the opinion of experts, then the list of the most preferred manufacturers of copper and aluminum radiators for car heating systems should include:

- Fenox;

- Bautler;

- luzar;

- Radiator Iran;

- Oberkraft;

- DZA.

Don't try to save a lot on such devices for your car. Let you choose the aluminum option, which initially costs less than its competitor, but if the price is too low, do not expect high efficiency or other positive characteristics. Radiators are not designed to last for the entire period of operation of the vehicle. Therefore, this element will definitely need to be changed at some point. Most experts agree that for imported and domestic cars, despite its shortcomings, the best solution is an aluminum device. Such units are able to serve their life without creating unnecessary problems in the operation of the heating system.

Remember that dirt is generated equally in both design options. And this happens inside and outside.

It is not that difficult to clean the outside of the device. This will require a minimum of time and equipment. But with the internal part things are much more complicated. It is difficult to carry out high-quality cleaning; not everyone can cope with it on their own. Provided that the cooling system on your car’s engine is clean, you have a new car or have recently undergone a major overhaul, the copper heater radiator will be able to perfectly show its best qualities. Of course, if your car is designed to use such elements.

If you don’t know what condition your heating and cooling system is in, you don’t need to create additional problems for yourself and spend extra money. Install a good aluminum radiator and replace it with the same one after a few years of operation. As practice shows, such a way out of the situation is the most effective and correct.