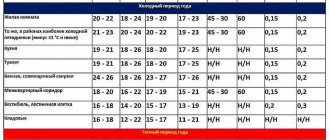

Coolant flow per 1 m.p. cast iron radiators

| Designer's Handbook “Internal sanitary installations” (I.G. Staroverov, 1975), table 12.3, p. 47 |

Let's determine the coolant flow through one section of a cast iron radiator kg/h

35:10 = 3.5 kg/h coolant flow through one section (G), where:

10 pieces. – number of sections in 1 m.p. radiator;

35 kg/h – coolant flow per 1 m.p. radiator

Coolant flow per 1 m.p. heating devices

| Estimated heating surface area of sectional radiators Fp depending on the number of sections in the radiator | |||||

| Number of sectionsNi | Radiator | ||||

| M-140-AO | M-140 (M-140-A) | M-140-AO-300 | M-90 | RD-90s | |

| Heating surface area of one section, ecm | |||||

| 0,35 | 0,31 | 0,217 | 0,26 | 0,275 | |

| 2 | 0,84 | 0,76 | 0,59 | 0,67 | 0,70 |

| 3 | 1,18 | 1,07 | 0,80 | 0,93 | 0,97 |

| 4 | 1,52 | 1,37 | 1,01 | 1,18 | 1,25 |

| 5 | 1,84 | 1,67 | 1,22 | 1,43 | 1,50 |

| 6 | 2,16 | 1,98 | 1,43 | 1,68 | 1,73 |

| 7 | 2,54 | 2,26 | 1,64 | 1,93 | 2,01 |

| 8 | 2,82 | 2,52 | 1,85 | 2,19 | 2,28 |

| 9 | 3,15 | 2,83 | 2,06 | 2,44 | 2,56 |

| 10 | 3,49 | 3,1 | 2,27 | 2,69 | 2,80 |

| 11 | 3,82 | 3,39 | 2,47 | 2,94 | 3,05 |

| 12 | 4,12 | 3,68 | 2,68 | 3,19 | 3,30 |

| 13 | 4,45 | 3,96 | 2,89 | 3,45 | 3,57 |

| 14 | 4,77 | 4,26 | 3,10 | 3,70 | 3,86 |

| 15 | 5,08 | 4,58 | 3,31 | 3,95 | 4,06 |

| 16 | 5,42 | 4,82 | 3,52 | 4,20 | 4,32 |

| 17 | 5,73 | 5,09 | 3,73 | 4,45 | 4,54 |

| 18 | 6,05 | 5,39 | 3,94 | 4,71 | 4,80 |

| 19 | 6,37 | 5,67 | 4,15 | 4,96 | 5,07 |

| 20 | 6,70 | 5,96 | 4,36 | 5,21 | 5,33 |

| 21 | 7,01 | 6,24 | 4,57 | 5,46 | 5,59 |

| 22 | 7,34 | 6,58 | 4,78 | 5,71 | 5,85 |

| 23 | 7,65 | 6,81 | 4,99 | 5,97 | 6,11 |

| 24 | 7,99 | 7,10 | 5,20 | 6,22 | 6,37 |

| 24 | 8,31 | 7,38 | 5,41 | 6,47 | 6,57 |

| Designer's Handbook “Internal sanitary installations” (I.G. Staroverov, 1975), table 12.13, p. 67 |

The data on radiators of the 1st (7 sections) types is highlighted in red, the data on the 2nd (8 sections) is highlighted in green, and the data on the 3rd (9 sections) is highlighted in blue.

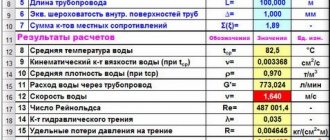

Let us determine the calculation formula for the heat flux density per 1 ecm of the heating surface of heating cast iron radiators Grel / Fp ≤ 7 or

Grel / Fp ≥ 7

Radiators M-140-AO 7 sections (4 radiators)

Grel / Fp = (3.5 x 7) : 17.4 : 2.54 = 0.55

Total: 0.55 < 7

The resulting value is less than 7; further calculation will be performed using the formula from the table below.

Let's calculate the heat transfer of cast iron radiators.

3.5 x 7 = 24.5 kg/h water flow in the radiator

qe = 1.89/φ ·∆tav1.32 = 1.89/1.05 x ((95.0 + 70.0):2 -20)1.32 = 422.5 Kcal/(h ekm)

0.35x7 = 2.45 ecm

422.5x2.45 x4 = 4140.5 Kcal/h

Radiators M-140-AO 8 sections (1 radiator)

Grel / Fp = (3.5 x

Total: 0.57 < 7

The resulting value is less than 7; further calculation will be performed using the formula from the table below.

Let's calculate the heat transfer of cast iron radiators.

3.5 x 8 = 28 kg/h water flow in the radiator

qe = 1.89/φ ∆tav1.32 = 1.89/1.04 x ((95.0 + 70.0):2 -20)1.32 = 426.5 Kcal/(h ekm)

0.35x8 = 2.8 ecm

426.5x2.8 x1 = 1194.2 Kcal/h

Radiators M-140-AO 9 sections (1 radiator)

Grel / Fp = (3.5 x 9) : 17.4 : 3.15 = 0.57

Total: 0.57 < 7

The resulting value is less than 7; further calculation will be performed using the formula from the table below.

Let's calculate the heat transfer of cast iron radiators.

3.5 x 9 = 31.5 kg/h water flow in the radiator

qe = 1.89/φ ∆tav1.32 = 1.89/1.04 x ((95.0 + 70.0):2 -20)1.32 = 426.5 Kcal/(h ekm)

0.35x9 = 3.15 ecm

426.5x3.15 x1= 1343.5 Kcal/h

Total thermal load for M-140-AO radiators

Qr.ot.= 4140.5+1194.2 +1343.5 =6678.2 Kcal/h

Calculation formula for heat flux density per 1 ecm of the heating surface of heating devices:

| Designer's Handbook “Internal sanitary installations” (I.G. Staroverov, 1975), table 12.8, p. 52 |

View: thermal loads for heating admin building

Coefficient φ, taking into account water flow into the system:

| Designer's Handbook “Internal sanitary installations” (I.G. Staroverov, 1975), p. 48 |

2.1. The procedure for determining the calculated electrical load using the ordered diagram method

1. Group utilization rate is calculated

where k ui ,

— individual utilization rate of the i-th electronic device;

k bi is

the individual inclusion coefficient of the i/th ED;

k zi —

individual load factor of the i-th electronic unit;

р i

is the rated power of the i-th electric unit.

2. The effective (rms) number of the group's EPs is determined by active power

The literature provides many methods for a simplified determination of the effective number of EPs, which makes it possible to quickly and easily calculate PSC with large variations in nominal powers, however, with modern computer capabilities, calculation using an exact formula should not cause difficulties.

3. Using the curves Km = f(nCKp) for a given Ki and pSKr, the value is found

group maximum coefficient Km (Fig. 2.1).

Km, p.u.

Rice. 2.1. Dependence of the maximum load coefficient on the effective number of EDs at various K and

(according to the “Guidelines for determining electrical loads in industrial installations”)

The group maximum coefficient can also be calculated using the algorithm given in.

4. The design load of the group is determined

Рр = Ki.Km.Rn,kW. (2.8)

The reactive load can be calculated in two ways. The first of them requires knowledge of cos φsv - the weighted average power factor and cos φm - the power factor during the period of maximum loads. Then for a group of EPs with inductive cos φ

Qc = Рс tan φсф kvar, (2.9)

QM = Qc. tan φм, kvar, (2.10)

where tan φsv and tan φM are found according to the given cosines.

The second calculation method does not require knowledge of two power factors, however, the indicators of the reactive load schedule must be specified.

- Group utilization rate is calculated

where lui is the individual utilization factor of the i-th electric power plant in terms of reactive power;

lBi=kBi—individual switching factor of the i-th electronic device;

lzi is the individual load factor of the ith electric power plant in terms of reactive power;

q,

— rated reactive power of the i-th electric unit.

2. The effective (rms) number of the group's EPs by reactive power is determined

With sufficient accuracy it is usually accepted nCKp=nCKq, pcs.

3. According to the curves L M = f(n C K at the calculated

L

u

is the value of the group maximum coefficient LM (Fig. 2.5).

The group maximum reactive power factor can also be calculated using the algorithm given in.

4. The estimated reactive power load is

Q M =L U .L M .Q U ,

kvar. (2.14)

If the group contains electric motors with leading current (synchronous motors, capacitors, etc.), their reactive power is assumed to be equal to a constant value determined from the calculation of the required reactive power; if there is no other data, then it can be assumed to be equal to the rated reactive power, it is subtracted from the reactive power of the remaining electric units, as from Q c ,

and from

Q„.

An example of calculating electrical loads using the ordered diagram method. Let a group of EP (oil production installations) be given, consisting of five centrifugal electric pumps with indicators N

= 5,

p i =

45 kW;

ku = 0.6; η u

= 0.85;

lu = 0.65; cos φ n

= 0.8 (

tan φ n =

0.75);

seven pumping machines with an asynchronous drive with indicators N

= 7;

p i =

20 kW;

k u

= 0.7;

η n

= 0.875;

lu=0.75; cos φ u

= 0.8;

three pumping machines with synchronous drive: N

= 3;

p i

= 30 kW;

k u

= 0.65;

ηн= 0.9; cos φ H

= 0.9 (capacitive), that is,

tanφ„ = -

0.44 Determine the rated load for active and reactive power, as well as the rated current in a line with voltage

U, =

6000 V.

The calculation begins with determining the load based on active power.

The utilization factor is found using formula (2.6)

and the effective number of EDs in terms of active power is found according to formula (2.7):

Using the curve in Fig. 2.5, find the maximum coefficient at K and -

0.64 and

n CKp

= 13. Maximum coefficient

K M

= 1.25. Average active power load

R s

= 0.64. (5.45 + 7.20 + 3.30) = 291.2, kW.

Estimated active power load

R m

= 0.64. 1.25. (5.45 + 7.20 + 3.30) = 364, kW.

We define reactive power loads in the same way. However, before carrying out the calculation, we will find the rated reactive powers of individual electric units for the first group (centrifugal electric pumps) using formula (2.12):

Total reactive load

Research has established that the use of the ordered diagram method is limited to a voltage of 1000 V, and the EP groups must be fairly homogeneous in composition. As a rule, this method is used to calculate the loads of individual transformer substations and lines supplying a specific technological process.

Heat consumption for heating and ventilation of industrial enterprises

Calculation of heat consumption for heating. The indicator depends on the time of day, the purpose of the room and the type of building, the outside temperature, the duration of the heating period, the presence of heated surfaces in the room, etc.

Heat consumption during working hours (MJ/h) is calculated according to specific thermal characteristics:

Depending on the time of day, heat consumption for heating (MJ/h) of industrial enterprises is determined by the formula

The air temperature in the room during working hours must comply with the recommendations for the operation of ventilation units.

Hourly heat consumption during non-working hours is determined by the formula used when calculating heat consumption during working hours, taking into account the decrease in air temperature in the room during non-working hours to 5 °C.

The specific thermal performance depends on the purpose of the room and the type of building. For example, for industrial premises located in a one-story building, q is 0.75–2.1 MJ/(m3 • h • K); for industrial premises located in a multi-storey building - 0.20 - 1.05 kJDm3 • h • K); for household and auxiliary premises - 1.4 -2.5 kJDm3-h-K); for warehouses - 2.50 - 3.35 kJDm3-h • K); for administrative buildings - 1.7 - 2.6 kJDm3 • h • K).

The correction factor a depends on the outside temperature. So, for public buildings at tH = -10° C a = = 1.45; at tH = -20 °C a = 1.17, etc.

after hours

Depending on the presence of heated surfaces in the room, heat input (MJ) is calculated using the following formulas:

from heated surfaces of equipment

from heated material

from electric drive

Depending on the heating period, heat consumption (MJ) is calculated using the following formulas: during working hours

The heating system of industrial enterprises must ensure a thermal balance between the amount of heat purchased from the heated surfaces of technological equipment, heated material, people, etc., and the amount of heat loss through the external enclosures of buildings.

from working people

Heat losses through the building enclosures of premises consist of heat losses through the walls of the building, covering, door and window openings.

The transfer of heat Q through the walls of a building and window openings occurs in three stages: from the air in the room to the inner surface of the walls of buildings Qh through the walls of the building Q2 and from the outer surface of the walls to the environment Q3.

The amount of heat lost through the walls of a building is calculated using the formula

Approximately heat losses (kJ/h) of premises are determined by the formula

If the production building has many windows, then it is advisable to take into account the additional heat consumption for heating based on the heat losses of window openings during the heating period.

The calculation is carried out according to the formula

If the wall does not accumulate heat, we can assume that

where K is the heat transfer coefficient, depending on the type of glazing; FK—window area, m2; n is the number of days of the heating period; t — operating time, h; /vn p — temperature inside the building during working hours, °C; *n.av - average temperature of the heating period, °C.

Depending on the type of glazing of buildings, the heat transfer coefficient can have the following values, kJ/(m2 - K): single-layer glazing - 4.5; double-layer glazing with wooden paired window sashes - 2.9; double-layer glazing with metal paired sashes - 3.25; double-layer glazing with wooden separate sashes - 2.67; double-layer glazing with metal separate sashes - 3.02.

The total annual heat consumption for heating (MJ) is

Part of the heat in production premises comes from solar radiation through the glass surfaces of buildings.

In table 20, 21 provide data on heat input from solar radiation and from working people.

Determination of heat loss through external fences

To begin with, let’s present the formula from SNiP, which is used to calculate the thermal energy lost through building structures separating the interior of the house from the street:

Q = 1/R x (tв – tн) x S, where:

- Q – heat consumption passing through the structure, W;

- R – resistance to heat transfer through the fencing material, m2ºС / W;

- S – area of this structure, m2;

- tв – temperature that should be inside the house, ºС;

- tн – average street temperature for the 5 coldest days, ºС.

The area for each type of external fencing is calculated separately, for which windows, doors, walls and floors with roofing are measured. This is done because they are made of different materials of varying thickness. So the calculation will have to be done separately for all types of structures, and the results will then be summed up. You probably know the coldest street temperature in your area of residence from practice. But the parameter R will have to be calculated separately using the formula:

R = δ / λ, where:

- λ – thermal conductivity coefficient of the fencing material, W/(mºС);

- δ – material thickness in meters.

As an example, let’s calculate how much heat a 10 m2 brick wall with a thickness of 250 mm (2 bricks) will lose if the temperature difference outside and inside the house is 45 ºС:

R = 0.25 m / 0.44 W/(m ºС) = 0.57 m2 ºС / W.

Q = 1/0.57 m2 ºС / W x 45 ºС x 10 m2 = 789 W or 0.79 kW.

If the wall consists of different materials (structural material plus insulation), then they must also be calculated separately using the above formulas, and the results must be summed up. Windows and roofing are calculated in the same way, but with floors the situation is different. The first step is to draw a plan of the building and divide it into zones 2 m wide, as shown in the figure:

Now you should calculate the area of each zone and substitute it into the main formula one by one. Instead of parameter R, you need to take the standard values for zones I, II, III and IV, indicated in the table below. At the end of the calculations, we add up the results and get the total heat loss through the floors.

Average heat load

It is as simple as possible to independently calculate the heat load by area of a building or individual room. In this case, the indicators of the heated area are multiplied by the level of thermal power (100 W). For example, for a building with a total area of 180 m2 the level of heat load will be:

180 × 100 W = 18000 W

Thus, to heat a building with an area of 180 m2 as efficiently as possible, 18 kW of power will be required. The result obtained must be divided by the amount of heat generated within one hour by a separate section of installed heating radiators.

18000 W / 180 W = 100

As a result, it can be understood that at least 100 sections must be installed in rooms of the building of different purposes and areas. For this purpose, you can purchase 10 radiators each having 10 sections, or opt for other configuration options. It should be noted that the average heat load is most often calculated in buildings equipped with a centralized heating system at coolant temperature values within the range of 70-75°C.

Selecting a calculation method

Sanitary and epidemiological requirements for residential buildings

Before calculating the heating load using aggregated indicators or with higher accuracy, it is necessary to find out the recommended temperature conditions for a residential building.

When calculating heating characteristics, you must be guided by SanPiN 2.1.2.2645-10. Based on the data in the table, it is necessary to ensure the optimal heating operating temperature in each room of the house.

The methods used to calculate the hourly heating load may have varying degrees of accuracy. In some cases, it is recommended to use fairly complex calculations, as a result of which the error will be minimal. If optimizing energy costs is not a priority when designing heating, less accurate schemes can be used.

When calculating the hourly heating load, you need to take into account the daily change in outside temperature. To improve the accuracy of the calculation, you need to know the technical characteristics of the building.

accurate calculation and redundancy

It is worth first mentioning one subtlety of the calculations: it is virtually impossible to calculate completely correct values of heat loss through the floor, ceiling and walls, which the heating system has to compensate for. It is possible to speak only about one or another degree of reliability of the estimates.

The fact is that heat loss is affected by too many factors:

- Thermal resistance of main walls and all layers of finishing materials.

- The presence or absence of cold bridges.

- Rose location and winds of the house on the terrain.

- The operation of ventilation (which, for its part, again depends on the direction and strength of the wind).

- walls insolation and degree of windows.

There is also good news. Virtually all modern systems and distributed heating boilers (insulated floors, electric and gas convectors, etc.) are equipped with thermostats that dose heat consumption depending on the room temperature.

From a practical point of view, this indicates that excess thermal power will only affect the heating operating mode: say, 5 kWh of heat will be provided not in one hour of constant operation with a power of 5 kW, but in 50 minutes. work with a power of 6 kW. Next 10 min. the boiler or other heating device will operate in standby mode without consuming electricity or energy.

Therefore: when calculating the thermal load, our task is to find out its minimum acceptable value.

The only exception to the general rule is associated with the operation of classic solid fuel boilers and is due to the fact that a decrease in their thermal power is associated with an important drop in efficiency due to incomplete combustion of the fuel. The problem is solved by installing a heat accumulator in the circuit and throttling the heating devices with thermal heads.

At the end of the kindling, the boiler operates at full power and with high efficiency until the coal or firewood is completely burned, after which the heat accumulated by the heat accumulator is dosed out to maintain the optimal temperature in the room.

Most of the other parameters that need to be calculated also allow for some redundancy. But more on this in the relevant sections of the article.

Which heating system for a private home is better and why?

An autonomous heating system for a private house is structurally composed of a boiler, radiators and a closed circular pipeline through which the coolant (except air) moves. Based on the type of coolant, the following types of heating are distinguished:

| Coolant | Advantages | Flaws |

| 1. Water (water or antifreeze is used) | Cost-effectiveness, availability of coolant, its low cost and safety of the system. | The rooms take quite a long time to warm up. In winter, neither planned nor emergency shutdown of the water system should be allowed, because at sub-zero temperatures the pipes will burst. |

| 2. Steam | Low inertia (rooms warm up immediately after switching on), energy efficiency. | Noisy, difficulties with regulating room temperature, the need to close pipes and radiators, high demands on the quality of pipes and radiators. |

| 3. Air | High efficiency, no costs for pipes and radiators, low inertia. This is an ideal option for a summer residence. | The air dries out, there are difficulties with the air supply (warm air rises, but the temperature below remains cold). |

Boilers differ in the type of fuel. You can talk for a long time about which heating to choose for a private home, go through the options and find their own advantages and disadvantages in each. To present the information more clearly and summarize the results, we suggest considering a comparative table.

| Coolant | Advantages | Flaws |

| 1. Gas | Comfortable operation (fully automatic system), large selection of boilers (single-circuit and double-circuit, wall-mounted and floor-mounted, convection and condensation), low operating costs, high efficiency, durability. | Limited accessibility (gas supply is not available everywhere), complexity of installing the system, the need for design and paperwork, high level of danger (leakage cannot be ruled out), maintenance costs. |

| 2. Electric | Availability of a heat source, low cost of equipment and installation, absence of a chimney and environmental friendliness, efficiency, comfort during operation, safety, high efficiency. | There is always a possibility of interruptions in power supply (it is advisable to have an alternative source of heating), it is necessary to comply with the requirements for the electrical network, the cost of electricity in some regions of Russia is quite high. |

| 3. Solid fuel | Low cost of energy, large selection of fuel types (coal, firewood, pellets, briquettes), availability of fuel in any region of Russia. | The need to load fuel manually, low efficiency, costs for cleaning and maintenance of the boiler and chimney, there must be a room for storing fuel. |

| 4. Liquid fuel | Low cost of fuel, can run on diesel fuel, fuel oil, waste oil, system autonomy, good efficiency. | A separate boiler room with a fuel storage tank is needed; combustion products may enter the room (depending on the boiler and the project), and requires regular maintenance and cleaning. |

| 5. Combined | Versatility. Cost-effectiveness and the ability to use the most profitable and practical energy carrier, quick payback. You can choose a single-circuit, double-circuit boiler, connect a boiler or a heated floor system. | A bulky boiler, a technically complex unit with a large amount of additional equipment. High cost of the system and installation. |

When you need to dot all the i’s

But a completely reasonable question arises: “How to count something that is invisible and can disappear instantly, literally out the window.” There is no need to despair of this struggle with the air; it turns out that there are quite clear mathematical calculations of the calories received for heating.

Moreover, all these calculations are hidden in official documents of state utility organizations. As usual in these institutions, there are several such documents, but the main one is the so-called “Rules for accounting of thermal energy and coolant”. It is he who will help solve the question - how to calculate Gcal for heating.

The actual problem can be solved quite simply and no calculations will be needed if you have a meter not just for water, but for hot water. The readings of such a meter are already “filled” with data on the heat received. When taking readings, you multiply it by the cost tariff and get the result.

Find out also how to hide heating pipes - three main ways.

Basic formula

The situation becomes more complicated if you do not have such a counter. Then you will have to be guided by the following formula:

Q = V * ( T1 – T2 ) / 1000

- Q is the amount of thermal energy;

- V – volume of hot water consumption in cubic meters or tons;

- T1 - hot water temperature in degrees Celsius. More precisely, use temperature in the formula, but reduced to the corresponding pressure, the so-called “enthalgy”. But in the absence of a better, appropriate sensor, we simply use the temperature, which is close to enthalgy. Professional heat metering units are capable of calculating enthalgy. Often this temperature is not available for measurement, so they are guided by the constant “from the Housing Office”, which can be different, but is usually 60-65 degrees;

- T2 is the cold water temperature in degrees Celsius. This temperature is taken from the cold water pipe of the heating system. Consumers, as a rule, do not have access to this pipeline, so it is customary to take constant recommended values depending on the heating season: during the season - 5 degrees; off-season – 15;

- The “1000” coefficient allows you to get rid of 10-digit numbers and get data in gigacalories (not just calories).

As follows from the formula, it is more convenient to use a closed heating system, into which the required volume of water is once poured and in the future there is no further supply. But in this case, you are prohibited from using hot water from the system.

The latest developments in the field of radiators, to some extent, may allow you to keep warm, but the desire to count everything will still not disappear.

The use of a closed system forces us to slightly improve the given formula, which already takes the form:

Q = ( (V1 * ( T1 – T ) ) – ( V2 * ( T2 – T ) ) ) / 1000

- V1 is the coolant flow rate in the supply pipeline, regardless of whether the coolant is water or steam;

- V2 - coolant flow in the return pipeline;

- T1 is the temperature of the coolant at the inlet, in the supply pipeline;

- T2 is the temperature of the coolant at the outlet, in the return pipeline;

- T - cold water temperature.

Thus, the formula consists of the difference of two factors - the first gives the value of the heat received in calories, the second - the value of the heat output.

Meet the collector heating system. Read here.

Source

Thermal imaging inspection

Increasingly, in order to increase the efficiency of the heating system, they are resorting to thermal imaging inspections of the structure.

This work is carried out in the dark. For a more accurate result, you need to observe the temperature difference between indoors and outdoors: it should be at least 15 o. Fluorescent and incandescent lamps turn off. It is advisable to remove carpets and furniture as much as possible; they knock down the device, causing some error.

The survey is carried out slowly and data is recorded carefully. The scheme is simple.

The first stage of work takes place indoors

The device is moved gradually from doors to windows, paying special attention to corners and other joints

The second stage is an inspection of the external walls of the building with a thermal imager. The joints are still carefully examined, especially the connection with the roof.

The third stage is data processing. First, the device does this, then the readings are transferred to the computer, where the corresponding programs complete the processing and produce the result.

If the survey was carried out by a licensed organization, it will issue a report with mandatory recommendations based on the results of the work. If the work was carried out in person, then you need to rely on your knowledge and, possibly, the help of the Internet.

Our ancestors slept differently than we do. What are we doing wrong? It’s hard to believe, but scientists and many historians are inclined to believe that modern man sleeps completely differently than his ancient ancestors. Initially.

Never do this in church! If you are not sure whether you are behaving correctly in church or not, then you are probably not acting as you should. Here's a list of terrible ones.

20 photos of cats taken at the right moment Cats are amazing creatures, and perhaps everyone knows this. They are also incredibly photogenic and always know how to be in the right place at the right time.

Top 10 Broke Stars It turns out that sometimes even the biggest fame ends in failure, as is the case with these celebrities.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don’t worry about the shape and length of their hair. It seems that youth is created for experiments with appearance and daring curls. However, already last.

Unforgivable Movie Mistakes You Probably Never Noticed There are probably very few people who don't enjoy watching movies. However, even in the best cinema there are mistakes that the viewer can notice.

Accurate heat load calculations

Thermal conductivity value and heat transfer resistance for building materials

But still, this calculation of the optimal heat load for heating does not provide the required calculation accuracy. It does not take into account the most important parameter - the characteristics of the building. The main one is the heat transfer resistance of the material used to manufacture individual elements of the house - walls, windows, ceilings and floors. They determine the degree of conservation of thermal energy received from the coolant of the heating system.

What is heat transfer resistance (R)? This is the reciprocal of thermal conductivity (λ) - the ability of the material structure to transmit thermal energy. Those. the higher the thermal conductivity value, the higher the heat losses. This value cannot be used to calculate the annual heating load, since it does not take into account the thickness of the material (d). Therefore, experts use the heat transfer resistance parameter, which is calculated using the following formula:

Calculation of walls and windows

Heat transfer resistance of walls of residential buildings

There are standardized values for the heat transfer resistance of walls, which directly depend on the region where the house is located.

In contrast to the enlarged calculation of the heating load, you first need to calculate the heat transfer resistance for the external walls, windows, ground floor floor and attic. Let's take the following characteristics of the house as a basis:

- Wall area – 280 m². It includes windows - 40 m²;

- The material used for making the walls is solid brick (λ=0.56). The thickness of the external walls is 0.36 m. Based on this, we calculate the TV transmission resistance - R = 0.36/0.56 = 0.64 m²*C/W;

- To improve the thermal insulation properties, external insulation was installed - polystyrene foam 100 mm thick. For him λ=0.036. Accordingly, R=0.1/0.036= 2.72 m²*C/W;

- The overall R value for external walls is 0.64 + 2.72 = 3.36 which is a very good indicator of the thermal insulation of a house;

- The heat transfer resistance of windows is 0.75 m²*C/W (double glazing filled with argon).

In fact, heat losses through the walls will be:

(1/3.36)*240+(1/0.75)*40= 124 W at a temperature difference of 1°C

We will take the same temperature indicators as for the aggregate calculation of the heating load +22°C indoors and -15°C outdoors. Further calculations must be made using the following formula:

Ventilation calculation

Then it is necessary to calculate the losses through ventilation. The total air volume in the building is 480 m³. Moreover, its density is approximately 1.24 kg/m³. Those. its mass is 595 kg. On average, air is renewed five times per day (24 hours). In this case, to calculate the maximum hourly heating load, you need to calculate the heat losses for ventilation:

(480*40*5)/24= 4000 kJ or 1.11 kW/hour

By summing up all the obtained indicators, you can find the total heat loss of the house:

This way the exact maximum heating load is determined. The resulting value directly depends on the outside temperature. Therefore, to calculate the annual load on the heating system, changing weather conditions must be taken into account. If the average temperature during the heating season is -7°C, then the total heating load will be equal to:

(124*(22+7)+((480*(22+7)*5)/24))/3600)*24*150(heating season days)=15843 kW

By changing the temperature values, you can make an accurate calculation of the heat load for any heating system.

To the results obtained, you need to add the value of heat losses through the roof and floor. This can be done by a correction factor of 1.2 - 6.07 * 1.2 = 7.3 kW/h.

The resulting value indicates the actual energy costs during system operation. There are several ways to regulate the heating load. The most effective of them is reducing the temperature in rooms where there is no constant presence of residents. This can be done using thermostats and installed temperature sensors. But at the same time, a two-pipe heating system must be installed in the building.

To calculate the exact value of heat losses, you can use the specialized Valtec program. The video shows an example of working with it.

Anatoly Konevetsky, Crimea, Yalta

Anatoly Konevetsky, Crimea, Yalta

Dear Olga! Sorry to contact you again. According to your formulas, I get an unimaginable heat load: Kir=0.01*(2*9.8*21.6*(1-0.83)+12.25)=0.84 Qot=1.626* 25600*0.37*((22-(-6))*1.84*0.000001=0.793 Gcal/hour According to the aggregated formula given above, it turns out to be only 0.149 Gcal/hour. I can’t understand what’s the matter? Please explain! Sorry for disturbing you. Anatoly.

Anatoly Konevetsky, Crimea, Yalta

Why do you need to know this parameter?

Distribution of heat losses in the house

What is the calculation of the heat load for heating? It determines the optimal amount of thermal energy for each room and the building as a whole. Variable quantities are the power of heating equipment - boiler, radiators and pipelines. The heat loss of the house is also taken into account.

Ideally, the thermal output of the heating system should compensate for all heat losses and at the same time maintain a comfortable temperature level. Therefore, before calculating the annual heating load, you need to determine the main factors influencing it:

- Characteristics of the structural elements of the house. External walls, windows, doors, ventilation systems affect the level of heat loss;

- Dimensions of the house. It is logical to assume that the larger the room, the more intense the heating system should work. An important factor in this case is not only the total volume of each room, but also the area of the external walls and window structures;

- Climate in the region. With relatively small drops in outside temperature, a small amount of energy is needed to compensate for heat losses. Those. The maximum hourly heating load directly depends on the degree of temperature decrease in a certain period of time and the average annual value for the heating season.

Taking these factors into account, the optimal thermal operating conditions of the heating system are compiled. Summarizing all of the above, we can say that determining the thermal load for heating is necessary to reduce energy consumption and maintain the optimal heating level in the premises of the house.

To calculate the optimal heating load using aggregate indicators, you need to know the exact volume of the building. It is important to remember that this technique was developed for large structures, so the calculation error will be large.

Thermal engineering calculation of an individual residential building

The above methods of aggregated calculations are most focused on sellers or buyers of radiators for heating systems installed in typical multi-story residential buildings. But when it comes to selecting expensive boiler equipment, or planning a heating system for a country house, in which, in addition to radiators, underfloor heating, hot water supply and ventilation systems will be installed, using these methods is highly not recommended.

Each owner of an individual residential building or cottage, even at the construction stage, is quite scrupulous in developing construction documentation, which takes into account all modern trends in the use of building materials and house structures. They must not be standard or obsolete, but made using modern energy-efficient technologies. Consequently, the thermal power of the heating system should be proportionally lower, and the total costs of installing a home heating system are much cheaper. These measures make it possible to reduce energy consumption costs in the future when using heating equipment.

Heat loss calculations are performed in specialized programs or using basic formulas and thermal conductivity coefficients of structures; the influence of air infiltration and the presence or absence of ventilation systems in the building are taken into account. Calculation of recessed basement rooms, as well as outer floors, is carried out using a method different from the main calculations, which takes into account the uneven cooling of horizontal structures, that is, heat loss through the roof and floor. The above methods do not take this indicator into account.

Thermal engineering calculations are carried out, as a rule, by qualified specialists as part of a heating system project, as a result of which further calculations are made of the number and power of heating devices, the power of individual equipment, the selection of pumps and other related equipment.

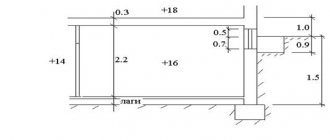

Initial data:

- A room with external dimensions of 3000x3000;

- Window dimensions 1200x1000.

The purpose of the calculation is to determine the specific power of the heating system required to heat 1 m².

Result:

- Qsp at 100 mm insulation is 103 W/m?

- Qsp at 150 mm insulation is 81 W/m?

- Qsp at 200 mm insulation is 70 W/m?

As can be seen from the calculation, the greatest heat losses are for a residential building with the smallest insulation thickness, therefore, the power of boiler equipment and radiators will be 47% higher than when building a house with 200 mm thermal insulation.

Main Factors

An ideally calculated and designed heating system should maintain the set temperature in the room and compensate for the resulting heat losses. When calculating the heat load on the heating system in a building, you need to take into account:

— Purpose of the building: residential or industrial.

— Characteristics of the structural elements of the building. These are windows, walls, doors, roof and ventilation system.

- Dimensions of the home. The larger it is, the more powerful the heating system should be. It is imperative to take into account the area of window openings, doors, external walls and the volume of each internal room.

— Availability of rooms for special purposes (bathhouse, sauna, etc.).

— Degree of equipment with technical devices. That is, the availability of hot water supply, ventilation system, air conditioning and type of heating system.

— Temperature conditions for a single room. For example, in rooms intended for storage, it is not necessary to maintain a temperature that is comfortable for humans.

— Number of hot water supply points. The more there are, the more the system is loaded.

— Area of glazed surfaces. Rooms with French windows lose a significant amount of heat.

— Additional conditions. In residential buildings this may be the number of rooms, balconies and loggias and bathrooms. In industrial - the number of working days in a calendar year, shifts, technological chain of the production process, etc.

— Climatic conditions of the region. When calculating heat loss, street temperatures are taken into account. If the differences are insignificant, then a small amount of energy will be spent on compensation. While at -40 o C outside the window it will require significant expenses.

Who needs a review (calculation or recalculation) of the heat load and heat energy consumption:

– organizations that have received notification of the need to clarify (calculate or recalculate) the heat loads of non-residential premises of the building from OJSC “MOEK”, in the form of instructions, acts of readiness for winter protection (organizations disconnected from the heat supply networks of a residential apartment building);

– organizations paying for services using the calculation method (not having the opportunity to install a meter), including in case of an unreasonable increase in consumption values on the part of the energy supply/management company;

– organizations that have installed additional heat consuming equipment (heater of the supply ventilation system, thermal curtain, etc.) to prove compliance of the new heat load and new heat consumption with the calculated (limit) established by the Energy Supply Organization.

Introduction

Requirements for determining the heat loads of consumers when developing heat supply schemes are reflected in the following regulatory and legislative acts: - Federal Law of the Russian Federation of July 27, 2010 No. 190-FZ;

- Order of the Ministry of Regional Development of the Russian Federation dated February 28, 2009 No. 610;

Contract loads are usually calculated based on design data. Design heating loads mainly depend on the calculated parameters of the microclimate of the premises, the calculated temperature of the outside air during the heating period (assumed to be equal to the temperature of the coldest five-day period with a probability of 0.92 according to 8. SP 131.13330.2012) and the thermal insulation characteristics of enclosing structures. Design loads on hot water supply depend on the volume of hot water consumption and its design temperature.

Over the past 20-30 years, many of the parameters and characteristics listed above have changed several times. Methods for calculating thermal loads and requirements for thermal protection of enclosing structures have changed. In particular, the energy efficiency class of apartment buildings (ABCs) is determined based on a comparison (determining the deviation value) of actual or calculated (for newly built, reconstructed and overhauled ABMs) values of the indicator of specific annual consumption of energy resources, reflecting the specific consumption of energy resources for heating, ventilation, hot water supply and basic values of the specific consumption of energy resources in apartment buildings. In this case, the actual (calculated) values must be brought to the design conditions for comparability with the basic values. The actual values of the specific annual consumption of energy resources are determined based on the readings of common house meters.

The climate itself has also changed, as a result of which, for example, for St. Petersburg, the standard design temperature of the outside air has increased over thirty years, from –26 °C to –24 °C, the design duration of the heating period has decreased by 6 days, and the average The temperature of the heating period increased by 0.5 °C (from –1.8 to –1.3 °C).

In addition to the above factors, consumers of thermal energy themselves contribute to energy-saving measures, for example, by replacing wooden windows in apartments with more airtight plastic ones.

All these changes, taken together, contribute to the fact that the actual heat consumption and contractual heat loads of thermal energy consumers differ.

Examples of developed Heat Supply Schemes for a number of large settlements (for example, Nizhny Novgorod) have shown that if the contractual load (the load established in heat supply contracts) is taken as the actual load, this creates an excess capacity reserve of heat supply organizations. A significant portion of the load in this case turns out to be unclaimed, but at the same time constant operating costs remain, which negatively affects the efficiency of heat supply organizations (TSO) and the consumer of thermal energy.

The Strategy notes that the currently used technology for planning heat supply systems leads to unnecessary investments, the creation of excess thermal power in all elements of energy systems and the preservation of a low level of efficiency of the entire Russian energy sector.

The relevance of the topic raised in the article is due to the lack of methods in the current regulatory and legislative acts for determining actual heat loads in the design elements of the territorial division at design outdoor temperatures, the problems of reconciling the actual heat loads used for investment planning in heat supply schemes with TCO, as well as the consequences of incorrect analysis heat loads of consumers established in heat supply contracts.

What is ventilation load?

In small rooms - apartments or offices - there is practically no heat load. The ventilation conditions of such rooms do not require a forced supply of fresh air flow, so there is no preparation of fresh flow. However, in buildings with large halls and a large number of people, there is a need to heat the supply air.

To increase the temperature, electric or (most often) water (steam) type heaters are used. The heating process is a simple passage of air flow through a frame filled with ribbed hot tubes. They give off thermal energy to the air flow, and the circulating coolant prevents them from cooling. Such designs are the most economical, although they require rather labor-intensive installation of piping and coolant supply.

If necessary, the amount of heat load can be changed. For example, this is done when the seasons change, when heating the supply air is no longer needed. In addition, the flow heating mode has to be changed when reconstructing the ventilation system and connecting additional lines.

How to reduce current heating costs

Central heating scheme for an apartment building

Considering the constantly increasing tariffs for housing and communal services payments for heat supply, the question of reducing these costs becomes only more relevant every year. The problem of reducing costs lies in the specifics of the centralized system.

How to reduce heating bills and at the same time ensure the proper level of heating of the premises? First of all, you need to understand that the usual effective methods for reducing heat losses do not work for central heating. Those. if the facade of the house was insulated, window structures were replaced with new ones, the payment amount will remain the same.

The only way to reduce heating costs is to install individual heat meters. However, you may encounter the following problems:

- A large number of thermal risers in the apartment. Currently, the average cost of installing a heating meter ranges from 18 to 25 thousand rubles. In order to carry out heating cost calculations based on an individual device, it is necessary to install them on each riser;

- Difficulty in obtaining permission to install a meter. To do this, it is necessary to obtain technical specifications and, based on them, select the optimal model of the device;

- In order to make timely payments for heat supply using an individual meter, it is necessary to periodically send them for verification. To do this, dismantling and subsequent installation of the device that has passed verification is carried out. This also entails additional costs.

The principle of operation of a common house meter

But despite these factors, installing a heat meter will ultimately lead to a significant reduction in payments for heating services. If the house has a circuit with several thermal risers passing through each apartment, you can install a common house meter. In this case, the cost reduction will not be so significant.

When calculating payment for heating using a common house meter, it is not the amount of thermal energy received that is taken into account, but the difference between it and the return pipe of the system. This is the most acceptable and open way to formulate the final cost of the service. In addition, by choosing the optimal model of the device, you can further improve the heating system of your home according to the following indicators:

- The ability to regulate the amount of thermal energy consumed into the building depending on external factors - outside temperature;

- A transparent way to calculate heating payments. However, in this case, the total amount is distributed among all apartments in the house depending on their area, and not on the volume of thermal energy that came to each room.

In addition, only representatives of the management company can maintain and set up a common house meter. However, residents have the right to demand all the necessary reporting to reconcile completed and accrued housing and communal services payments for heat supply.

In addition to installing a heat meter, it is necessary to install a modern mixing unit to regulate the degree of heating of the coolant entering the heating system of the house.

How to calculate the load?

The heat load indicator is determined by several of the most important factors, therefore, when performing design measures, it is imperative to take into account:

- total glazing area and number of doors;

- difference in temperature conditions outside and inside the building;

- performance level, operating mode of the ventilation system;

- thickness of structures and materials involved in the construction of the structure;

- properties of roofing material and main design features of the roof;

- the amount of insolation and the degree of absorption of solar heat by external surfaces.

It is practiced to use several methods for calculating the thermal load, which differ markedly not only in the degree of complexity, but also in the accuracy of the calculated results obtained

It is important to first collect the information necessary for design and calculation activities regarding the installation diagram of radiators and the location of the hot water supply, as well as the floor plan and explication of the structure

Feasibility of calculations

Indeed, why know the heat loss coefficients of a residential building?

The term “residential” means a room in which people will live during the heating season. Country houses, which usually have heating during the cold season on weekends, do not belong to this category. In order to achieve optimal thermal conditions in them, it will take more time, which depends on the design of the building and the greater power of the heating system.

The heat loss of a building needs to be known in order to organize an effective heating system by correctly selecting the power of the heating unit.

This indicator is taken into account when choosing and designing a heating system, air conditioning, “warm floor” technology and the power of heating devices.

When thermally insulating buildings, it is also necessary to calculate the power of heat loss, because the type of insulator used, the method and thickness of its installation depend on this.

This indicator depends on many factors. First of all, this is the floor material - panel, brick, aerated concrete, timber, etc. Each building has its own indicators for calculating heat loss at home, taking into account the region of residence, average temperature, number of windows and doors, the presence of an attic or basement and other factors.

Regardless of its design, any building allows heat to pass through its enclosures. Heat loss into the environment is restored using the heating system. The required power of a house heating source is the sum of heat losses with a standardized margin.

In order to ensure the most comfortable conditions in the room, factors such as orientation to the cardinal points, physical qualities of building materials and thermal insulation, building structure, layout of premises, wind direction and average mildness of the climate in the cold season are taken into account.

Based on the results of the thermal engineering calculation, a heating boiler is selected, the number of heating radiator sections is specified, the power and length of underfloor heating pipes are calculated, and a heat generator is selected to compensate for heat loss.

By and large, determining the loss of thermal energy is necessary for economical heating of the room, without unnecessary reserves of power of the heating system.

There are two ways to calculate heat loss at home - manually, using formulas, or a simpler option, using an online calculator with aggregated data.

Calculation of heat load for hot water supply

P = (qhhr,ux U) / (qh x N x 3600) = (1.7 x 4) / (0.2 x 2 x 3600) = 0.00472,

where:qhhr,u = 1.7 l;

U = 4 people - number of personnel;

qh = 0.2 l/s;

N = 2 - number of sanitary fixtures with hot water.

Phr = (3600 x P x qh) / qh0,hr = (3600 x 0.00472x 0.2) / 200 = 0.016992,

where:qh0,hr = 200;

аhr = 0.207

qt = qhu x U/ 1000 x T = 10.2 x 4/ 1000 x 24 = 0.0017 m3/hour

where: qhu = 10.2 l/hour

qhr = 0.005 x qh0.hr x ahr = 0.005 x 200 x 0.207 = 0.207 m3/hour

a) within an hour

QhT = 1.16 x qhT x (65 – tc) + Qht = 1.16 x 0.0017 x (65 – 5) + 0.017748 = 0.136068 kW x 859.8 = 116.9913 kcal / h ( 0.0001169913 Gcal/h)

b) during the hour of maximum consumption

Qhhr = 1.16 x qhhr x (65 – tc) + Qht = 1.16 x 0.207 x (65 – 5) + 2.16108 = 16.56828 kW x 859.8 = 14245.407 kcal / h (0. 014245407 Gcal/h)

Qhyear = gumh ´ m ´ s ´ r ´ [(65 – tсз)´ Zз]´ (1+ Kt.p) ´ 10-6 = 10.2 ´ 4 ´ 1 ´ 1 ´ ´ (1+ 0.3) ´ 10-6 = 1.16158 Gcal/year

where: gumh = 10.2 l/day

View examples of water savings

How to calculate the fee if the IPU readings are missing?

Let us remind you that, according to clause 36 of the Rules for the provision of public utility services, the management company is obliged to make calculations only in accordance with these rules. In other words, if all premises in an apartment building are equipped with heat insulation control units, the calculation should still be carried out using formulas 3(3) and 3(4), even if not all consumers transmit meter readings. At the same time, by virtue of paragraphs. “z” of clause 31 of the rules, the contractor is obliged to notify consumers at least once a quarter by indicating in payment documents: – about the timing and procedure for taking IPU readings by consumers and transferring the relevant information to the contractor or his authorized person; – on the application in case of failure by consumers to provide information on meter readings of the information specified in clause 59 of the Rules for the provision of utility services. According to this paragraph, the payment for utility services for heating (when, in accordance with paragraph 42(1) of the rules, the IPU readings are used to determine the amount of the payment) is determined based on the average monthly (for the heating period) volume of consumption in the following cases: a) in case of failure or the loss of a previously put into operation IPU or in the event of expiration of its service life from the date when the specified events occurred until the date when the accounting of the utility resource according to the IPU was resumed; b) if the consumer fails to provide IPU readings starting from the billing period for which the meter readings were not submitted, until the billing period (inclusive) for which the consumer provided the IPU readings to the contractor; c) in the event of a consumer’s refusal to gain access to the IPU (see paragraph “d”, clause 85 of the Rules for the Provision of Public Utilities) and the contractor draws up a corresponding act starting from the date when the contractor drew up the act of refusal of admission to the IPU until the date of the checks. In all of the above cases, the calculation is made for such a consumer based on the average monthly volume, but not more than three billing periods in a row. How to determine the fee after the specified three months?

Expansion tank

One of the parameters that needs to be calculated for an autonomous system is the amount of expansion tank.

An accurate calculation is based on a fairly long sequence of parameters:

- type and temperature of the coolant. The expansion coefficient depends not only on the degree of heating of the batteries, but also on what they are filled with: water-glycol mixtures increase more strongly.

- Maximum operating pressure in the system.

- The charging pressure of the tank, which in turn depends on the hydrostatic pressure of the circuit (the height of the top point of the circuit above the expansion tank).

There is, however, one nuance that allows you to greatly simplify the calculation. If underestimating the volume of the tank will, at best, lead to constant operation of the safety valve, and in the worst case, to destruction of the circuit, then its excess amount will not harm anything.

It is on this basis that in most cases a tank with a displacement equal to 1/10 of the total amount of coolant in the system is taken.

If calculation in gigacalories is required

In the absence of a heat energy meter on an open heating circuit, the calculation of the heat load for heating the building is calculated using the formula Q = V * (T1 - T2) / 1000, where:

- V – the amount of water consumed by the heating system, calculated in tons or m3,

- T1 is a number indicating the temperature of hot water, measured in o C and for calculations the temperature corresponding to a certain pressure in the system is taken. This indicator has its own name - enthalpy. If it is not possible to take temperature readings in a practical way, they resort to an averaged reading. It is within 60-65 o C.

- T2 – cold water temperature. It is quite difficult to measure it in the system, so constant indicators have been developed that depend on the temperature outside. For example, in one of the regions, in the cold season this indicator is taken equal to 5, in the summer – 15.

- 1,000 is the coefficient for obtaining the result immediately in gigacalories.

In the case of a closed circuit, the heat load (gcal/hour) is calculated differently:

- α is a coefficient designed to correct climatic conditions. Taken into account if the street temperature differs from -30 o C;

- V – volume of the building according to external measurements;

- qо – specific heating index of the structure at a given tн.р = -30 о С, measured in kcal/m 3 *С;

- tв – calculated internal temperature in the building;

- tн.р – calculated street temperature for drawing up a heating system design;

- Kn.r – infiltration coefficient. It is determined by the ratio of heat losses of the design building with infiltration and heat transfer through external structural elements at the street temperature, which is specified within the framework of the project being drawn up.

The calculation of the heat load turns out to be somewhat enlarged, but this is the formula given in the technical literature.