²In the modern world, natural gas is one of the cheapest and most accessible types of fuel. However, the cost of gas connection is quite high.

Therefore, many calculate in advance the average and maximum gas consumption for heating a house and only then draw conclusions about how economically profitable such costs are. For the calculations to be correct, you should know the average gas consumption for heating in a private home. Only then sum up the total value for the purpose of comparison with other types of fuel.

We recommend: Gas holder, main gas or pellets, which is cheaper and How to save gas with gas heating in a private home

Such manipulations are carried out at the beginning of the design of the entire heating system. If high gas consumption turns out to be financially difficult, the measures turn out to be unprofitable.

Average flow calculator

The nominal gas consumption for the past heating period is not so difficult to calculate. You just need to take meter readings every month. After the end of the season, summarize the monthly readings. Then calculate the arithmetic mean.

If you need to find out the nominal values at the stage of designing a house, or when choosing efficient, but at the same time economical heating equipment, you will have to use formulas.

When arranging autonomous heating for a country cottage or apartment, average parameters are used to determine heat loss

To obtain approximate calculations, the specific heat consumption is determined in two ways:

- Based on the total volume of heated rooms. Depending on the region, 30-40 W are allocated for heating one cubic meter.

- According to the overall square footage of the building. The basis is that 100 W of heat is spent to heat each square of room area, the height of the walls in which on average reaches 3 meters. When determining the value, they also focus on the region of residence: for southern latitudes - 80 W/m2, for northern latitudes - 200 W/m2.

The main criterion that must be taken into account when making calculations is the required thermal power to ensure conditions for high-quality heating of premises and replenishment of its heat losses.

The basis for technological calculations is the average proportion at which 1 kW of thermal energy is consumed per 10 square meters of area. But it is worth considering that such an average approach, although convenient, is still not sufficiently capable of reflecting the real conditions of your building, taking into account the climatic region of its location.

Using a simplified calculation method, it is taken as a basis that to heat 10 square meters of a private house, 1 kW of thermal power generated by a generator is required

By correctly calculating the estimated fuel consumption, you can clarify for yourself what measures should be taken to reduce its consumption. As a result, the item of regular payments for consumed “blue fuel” will be reduced.

Calculation example

As an example, it is proposed to take an apartment with an area of 80 m² in the central zone of the Russian Federation. To heat it in the coldest period, you will need 80 m² x 100 W = 8000 W or 8 kW. It is planned to install a modern condensing boiler using natural gas with an efficiency of 96%. Then the calculation of gas consumption for heating looks like this:

V = 8 / (9.2 x 96 / 100) = 8 / 9.768 = 0.91 m³/h

It is not difficult to calculate how much fuel is required per day: 0.91 x 24 = 21.84 m³. But to determine the cost of natural gas consumption, you need to know more realistic figures, for example, its average consumption in an apartment for the entire heating season. Since there are significant temperature fluctuations during this season, the average amount of fuel is expected to be half the maximum.

Then the average daily gas consumption for heating the apartment will be 21.84 m³ / 2 = 10.92 m³. All that remains is to multiply this number by the duration of the heating season; in Moscow it lasts 214 days: 10.92 x 214 = 2336.9 m³. Having made a monthly breakdown, it is easy to determine the cost of autonomous heating of an apartment.

To calculate the average gas consumption in an apartment, you can go another way. First, find out the gas consumption to produce 1 kW of thermal energy, and then multiply this value by 8 kW. The calculation formula for calculating the volume of fuel per 1 kW of heat is as follows:

v = 1 / (qx efficiency / 100), where v is the required volume in m³/h.

Accordingly, 1 / (9.2 x 0.96) = 0.113 m³/h, and for the entire apartment it will be 0.113 x 8 = 0.905 m³/h with a small error. Further calculations are carried out in the same way as described above.

Note. The amount of gas consumed by the gas stove and for hot water supply is not taken into account, which will be discussed later.

Mains gas for heating needs

A G20 gas mixture is supplied to private homes from a centralized pipeline. In accordance with the adopted standard DIN EN 437, the minimum specific heat value for the combustion of G 20 fuel is 34.02 MJ/cubic meter.

If a highly efficient condenser boiler is installed, the minimum specific heat value for “blue fuel” category G 20 is 37.78 MJ/cu. meter.

You can order a calculation of the heat losses of a residential building in order to create an “accounting” of seasonal costs and clarify for yourself whether there is a need to do insulation from a design organization

Formula for calculating fuel consumption

To determine gas consumption, taking into account the energy potential inherent in it, a simple formula is used:

V=Q / (Hi x efficiency)

Where:

- V is the desired value that determines the gas consumption for generating thermal energy, measured in cubic meters/hour;

- Q – the value of the calculated thermal power expended to heat the building and provide comfortable conditions, measured in W/h;

- Hi is the minimum value of specific heat during fuel combustion;

- Efficiency is the efficiency of the boiler.

The efficiency of a boiler generator shows the efficiency of using the thermal energy generated during combustion of the gas mixture, which is directly spent on heating the coolant. It is a passport value.

In the passports of modern boiler units, the coefficient is indicated by two parameters: by higher and lower calorific value. Both values are written through the fractional line “Hs/Hi”, for example: 95/87%. To obtain the most reliable calculation, take as a basis the value specified in the “Hi” mode.

The lowest value of the specific heat of combustion of gas is a tabular value, the parameters of which correspond to the accepted standards DIN EN 437

The “Hs” value indicated in the table determines the highest heat value of gas combustion. It is indicated in the table for the reason that the water vapor released during gas combustion is also capable of converting latent thermal energy. If you use this thermal energy wisely, you can increase the total return on the consumed fuel.

The operation of new generation boilers – condenser units – is based on this principle. In them, due to the conversion of steam into an aggregate liquid state, an additional 10% of heat is generated.

In addition to G20 gas, an analogue of the second group, G 25, can also be used for domestic purposes. G 20 gas is extracted from Siberian deposits, and G25 is supplied from Turkmenistan and the Volga region. The difference between them is that G25 emits 15% less heat when burned.

Gas grade G25 is characterized by an increased percentage of nitrogen, due to which its energy potential is 15% lower than its natural analogue G20

You can find out what type of gas “flows” in the pipeline from the gas supply company in your region.

An example of calculating network gas consumption

We propose to consider an example of calculating gas consumption for heating a country cottage, the initial data of which has the following parameters:

- The area of the premises reaches 100 square meters. meters;

- recommended heat unit power – 10 kW;

- The boiler efficiency reaches 95%.

To simplify the calculation, joules are converted to another unit of measurement - kilowatts. So, provided that 1 kW = 3.6 MJ, the calorific value of G 20 gas will be 34.02/3.6 = 9.45 kW.

It is also worth considering that the recommended power of the heat generator, indicated as 10 kW, will only be required to heat rooms under the most unfavorable conditions. In fact, throughout the entire heating season, the number of such unfavorable days will be counted in single units.

With a well-thought-out and equipped heating system, the installed boiler unit will definitely not work around the clock

On the remaining days of the cold season, significantly less power is used to heat the building. Therefore, to obtain correct calculations, as well as to determine the average, and not the peak, consumption of “blue fuel”, the boiler power readings are not 10 kW, but “half” 5 kW.

Substituting the obtained data into the formula, perform the calculations: V = 5/(9.45 x 0.95). It turns out that to heat a cottage with an area of 100 square meters, the gas consumption is 0.557 cubic meters per hour.

Having clarified the tariffs for paying for one cubic meter of “blue fuel”, it will not be difficult to calculate material costs for the entire heating period

Based on the data obtained through simple calculations, it is not difficult to calculate gas consumption for the entire heating season, which in mid-latitude regions lasts about 7 months:

- For a day it is 0.557 x 24 = 13.37 m3.

- For a month 13.37 x 30 = 401.1 m3.

- For a heating season lasting 7 months 401.1 x 7 = 2807.4 m3.

Knowing the price of one cubic meter of “blue fuel”, it will not be difficult to plan both monthly expenses and “accounting” for the entire functioning of the heating system.

How to measure flow

Unfortunately, in most articles posted on the Internet, calculation examples do not provide a clear answer to this question, and further confuse the average consumer.

The reason for this is the fact that such calculations are based on the power of the gas boiler that it produces over a certain period of time.

Power is measured in kilowatts (kW/h).

However, not all authors of articles clarify that in this case they mean thermal power, not electrical power, so for many users the value in kW/hour causes an association with electricity consumption.

It is much clearer and more common to measure the consumption and cost of natural gas in cubic meters (cubic m/h), and liquefied gas in kilograms (kg/hour). Knowing the gas consumption for a certain period of time and the current gas tariffs, you can easily calculate the approximate cost of heating your home.

Consumption of liquefied propane-butane mixture

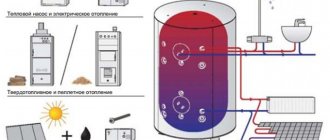

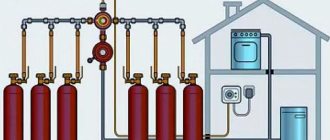

Not all owners of country houses have the opportunity to connect to a centralized gas pipeline. Then they get out of the situation using liquefied gas. It is stored in gas holders installed in pits, and replenished using the services of certified companies that supply fuel.

Liquefied gas used for domestic purposes is stored in sealed containers and reservoirs - propane-butane cylinders with a volume of 50 liters, or gas holders

If liquefied gas is used to heat a country house, the calculation formula is taken as the basis. The only thing you need to take into account is that the bottled gas is a G30 mixture. In addition, the fuel is in an aggregate state. Therefore, its consumption is calculated in liters or kilograms.

Formula for calculating fuel mixture consumption

A simple calculation will help you estimate the cost of a liquefied propane-butane mixture. The initial construction data is the same: a cottage with an area of 100 square meters, and the efficiency of the installed boiler is 95%.

When calculating, it should be taken into account that fifty-liter propane-butane cylinders, for safety reasons, are filled to no more than 85%, which is about 42.5 liters

When performing calculations, we focus on two significant physical characteristics of the liquefied mixture:

- The density of bottled gas is 0.524 kg/l;

- The heat released during the combustion of one kilogram of such a mixture is equal to 45.2 MJ/kg.

To facilitate calculations, the values of heat released, measured in kilograms, are converted into another unit of measurement - liters: 45.2 x 0.524 = 23.68 MJ/l.

After which joules are converted to kilowatts: 23.68/3.6 = 6.58 kW/l. To obtain correct calculations, the same 50% of the recommended power of the unit is taken as a basis, which is 5 kW.

The obtained values are substituted into the formula: V = 5/(6.58 x 0.95). It turns out that the consumption of the G 30 fuel mixture is 0.8 l/h.

An example of calculating liquefied gas consumption

Knowing that on average 0.8 liters of fuel are consumed per one hour of operation of a boiler generator, it will not be difficult to calculate that one standard cylinder with a 42-liter refill will be enough for approximately 52 hours. This is a little more than two days.

For the entire heating period, the consumption of the combustible mixture will be:

- For a day 0.8 x 24 = 19.2 liters;

- For a month 19.2 x 30 = 576 liters;

- For a heating season lasting 7 months, 576 x 7 = 4032 liters.

To heat a cottage with an area of 100 square meters you will need: 576/42.5 = 13 or 14 cylinders. For the entire seven-month heating season, you will need 4032/42.5 = from 95 to 100 cylinders.

To accurately calculate the number of propane-butane cylinders needed to heat a cottage for a month, you need to divide the consumed monthly volume of 576 liters by the capacity of one such cylinder

A large volume of fuel, taking into account transportation costs and the creation of conditions for its storage, will not be cheap. But still, in comparison with the same electric heating, such a solution to the issue will still be more economical, and therefore preferable.

The boiler is powered from a gas tank or cylinder

The formula Gas volume = Qmax / (Qр * ŋ) is suitable for determining the need for various fuels, incl. and liquefied gas. Let’s take from the previous example the resulting boiler power indicator - 7 kW. If such a boiler requires 0.82 m3/h of natural gas, how much propane-butane will be required?

About once a week you will have to go to a gas station with gas cylinders, which means transportation costs and loss of personal time. A drop in temperature below zero can also bring an unpleasant surprise if gas cylinders are placed outside. In a frozen cylinder, the gas does not freeze, but it does not evaporate, turning into liquid. And the boiler stops working

To calculate, you need to know what its calorific value is. Ud. the calorific value (this is the calorific value) of liquefied hydrocarbons in megajoules is 46.8 MJ/kg or 25.3 MJ/l. In kilowatt hours - 13.0 kW*h/kg and 7.0 kW*h/l, respectively.

Let's leave the efficiency of the gas heating boiler equal to 92% and calculate the hourly gas demand:

Gas volume = 7 / (13 * 0.92) = 0.59 kg/h

One liter of liquefied gas weighs 0.54 kg; in an hour the boiler will burn 0.59 / 0.54 = 1.1 liters of propane-butane. Now we calculate how much liquefied gas a gas boiler consumes per day and per month.

If the boiler operates for 16 hours, then per day - 17.6 liters, per month (30 days) - 528 liters. A typical 50-liter cylinder contains about 42 liters of gas. It turns out that our house with an area of 100 m2 will require 528 / 42 = 13 cylinders per month.

A gas holder with a reserve volume allows you to save on gas. The cost of refueling rises in the fall, while spring is a period of falling prices. Try to fill the tank as much as possible in the spring

Installing a gas tank is much more convenient than replacing empty cylinders with full ones. It is enough to refill the gas tank 2-3 times during the entire heating season.

Ways to reduce consumption

The main reason for significant heat losses, which lead to ineffective consumption of the thermal energy released by the boiler unit, is insufficient insulation of the structural elements of the house. Up to 40% of heat is wasted through “cold bridges.”

Up to 35% of the heat generated by the boiler leaks through windows with poor-quality frames, up to 25% through the walls of the house, and up to 15% through the roof and entrance doors.

In order not to waste money every time heating the street, it is better to spend money once on high-quality insulation of the building. Believe me, the costs for it will be fully recouped in 3-4 years.

Thermal insulation of a house includes:

- Insulation of walls. The easiest to implement and affordable option is the installation of polystyrene foam panels. The thickness of the panels is chosen based on the climatic conditions of the construction region, the thickness of the walls of the building and the type of material used in their construction.

- Insulation of the roof or attic floor. For these purposes, sawdust, mineral wool or polystyrene foam tiles are used. The heat-insulating material, produced in the form of slabs, is mounted on the internal walls of the attic space or placed between the floor beams.

- Insulation of floors. Not only concrete, but also wooden structures need good thermal insulation. To form a thermal insulating layer, bulk and slab materials such as expanded clay and expanded polystyrene are used.

- Replacement of windows. The most reliable shield that prevents the penetration of cold into heated rooms will be PVC windows with high-quality double-glazed windows. They are made for a specific window. Thanks to this, they hermetically close the window opening, reliably protecting household members not only from the “leakage” of heat, but also from the penetration of street noise.

Proper thermal insulation allows you to reduce heat loss to a minimum.

In addition to high-quality insulation, to increase the efficiency of heat transfer, experts recommend using other equally effective measures

Experts include additional measures to increase the efficiency of heat transfer:

- Equipment of radiators with thermostatic devices. Thermal heads will maintain the required comfortable temperature in the rooms.

- In addition to radiators, install convectors with directed circulation function. They will create thermal curtains from heated air in the area of the openings.

- Connecting equipment that allows you to program optimal heating modes. Installing chronometric thermostats is effective if there are rooms in the house that are empty for several days, which there is no point in intensively heating.

The costs of purchasing and installing automation will more than pay off within the first heating season.

And finally, it’s worth reconsidering whether the system is too loaded. It is possible that it produces excess heat. And it is likely that without compromising the comfort of household members, the indoor temperature can be reduced by a couple of degrees.

At first glance - a trifle. But, considering the situation on the scale of at least one month, and even more so the heating season, such a decision can have a beneficial effect on the wallet.

How to reduce gas consumption

So how can you reduce gas consumption in a private home during the heating season? This question is asked by many who live in private houses. There are several different methods that together will significantly reduce your fuel consumption without reducing the temperature in your home. Small expenses will help you save a significant amount of money, since all the activities will ultimately be useful for not just one year, but for many years to come.

Insulation of attic floors and roofs

Insulating the attic is a primary measure that significantly increases the thermal insulation of a living space. For these events, there are several options for insulating material. By the way, an insulated attic makes it possible to sleep in it even in winter, and this is a significant increase in living space with a low level of expenses.

The insulation work itself is carried out in several stages. The first thing to do is install waterproofing and roof ventilation. It must be installed taking into account the roof overlap. This must be done from the inside of the attic. This technology protects the structure itself from mold and rotting wood (for example, beams and boards).

Waterproofing also protects the roof from possible ingress of snow or rainwater. For proper and high-quality insulation of the attic space, materials such as mineral wool and special vapor barrier foil are used. Plus, the work requires various consumables and fasteners. Those. nails (you can use self-tapping screws), wire, staplers.

Mineral wool is most often used to insulate attics. It comes in several types. The most commonly used options are stone and glass wool. Sometimes special boards made from tree fibers or expanded polystyrene are used.

It is better to use flexible and elastic materials, as they simplify the installation process.

The most important thing to remember when choosing insulation materials is that they must withstand the two most important risk factors - temperature rise and humidity.

Therefore, many professionals recommend using penoplex material. It is a little more expensive than the others, but can withstand high loads, copes well with risk factors, and also has a long service life.

Considering our climate and sudden temperature changes at any time of the year, the minimum layer of penoplex that is installed in the attic to insulate the roof should be 25 millimeters. The most suitable thickness will be around 100 millimeters.

Sometimes foam boards are also used to insulate the roof. This material has the lowest price, but at the same time, it is very fragile and has a shorter service life.

Recently, insulating foam has become popular. It is quite easy to install and does not require special skills. The foam is simply dispensed from a hose and must be applied evenly over the entire area of the attic. The advantage of this material is that it clogs all kinds of cracks.

Insulation of floors

Insulating floors prevents cold from entering from the basement and also improves the thermal insulation of the house. To properly insulate it, you need to select a material. Modern manufacturers are replete with their offerings. The most popular of which are: expanded polystyrene, penoplex, mineral wool (divided into stone and glass wool), flax mats, self-leveling floors, cork insulation, polystyrene foam.

Insulation materials, in turn, are divided into natural and synthetic. The first include cork, flax, sawdust, and cellulose. All the rest are synthetic, or as they are also called artificial.

Depending on the type of materials, they can be tiled, self-leveling, bulk, rolled or sprayed. The installation technology also depends on each specific type.

Each of the materials has its pros and cons. However, they all do an excellent job with their main task. Before work, it is necessary to take into account all factors. The level above the ground, the depth of the basement, etc., in order to maximize the thermal insulation of the floor.

Window replacement

Replacing windows helps to significantly improve the thermal insulation of a living space, and therefore reduce the consumption of heating materials. It is worth using double-glazed windows. By the way, with this type of window, the frames themselves can be either wooden or plastic.

Energy-saving metal-plastic ones also cope well with the task. The number of double-glazed windows must be at least three, i.e. two-chamber. Single-chamber windows (windows with two glasses) cannot be used in a residential area, since the glass will freeze and condensation will form.

If you don’t have the opportunity to urgently replace your windows, you can simply insulate yours. For this purpose, insulation materials are used. For example, cotton wool or foam rubber. Fortunately, today the market is represented by a huge selection of such products.

You can also change the doors, which will also help improve thermal insulation and reduce the amount of heating material.

Wall insulation

Insulating the walls of a house is one of the first measures that needs to be carried out to improve thermal insulation (along with insulating the roof and attic).

The walls need to be insulated on the street side. For this purpose, slabs of mineral wool or polystyrene foam are used. The thickness of materials must be used taking into account temperatures in winter, i.e. depending on the latitude in which you live. The optimal insulation thickness is from 6 to 10 cm. In the case when you are building a house according to a high-quality and well-thought-out plan, it is possible to calculate fuel consumption in advance. However, if the house has already been built, the optimal way would be to turn to professionals for the purpose of calculation. A specialist will not only do the job correctly, but will also advise possible ways to save money.