A single-circuit or double-circuit gas boiler is equipment that makes our life in a house or apartment more comfortable. Manufacturers now produce a huge range of gas appliances, differing in power, functionality, and installation method. However, even the most expensive and reliable models can fail. Agree, it’s not very pleasant to be left on a winter evening without heat and hot water.

Having analyzed the possible causes of breakdowns of gas equipment, we came to the conclusion that most often malfunctions occur due to the fact that the pressure in the expansion tank of a gas boiler or water heater is incorrectly adjusted. In this article we will figure out why an expansion tank is needed, how to pump air into it yourself and set the optimal pressure.

Why do you need pressure in a closed heating system?

Standard pressure values contribute to the efficient and smooth operation of the entire heating system.

It guarantees a high production coefficient and uniform distribution of the coolant through the pipes in all rooms.

The pressure level sets the water pressure speed parameter. The heat exchange process in the system, its intensity and its final efficiency directly depend on this.

Pressure stabilization reduces the rate of heat loss, and the liquid entering all elements of the heating system retains the same temperature as it received as a result of heating.

Membrane tank maintenance - recommendations and tips

Maintenance of the hydraulic tank must be carried out in the warm season with the heating turned off:

- Measure the pressure and, if necessary, pump up the air cushion or bleed off excess fluid. If the tank does not hold, most likely it has a damaged membrane that needs to be replaced. For some models this cannot be done - in this case the entire damper will have to be replaced.

- Inspect the connections of the hydraulic tank with other elements of the system - pay attention to tightness and absence of leaks.

The hydraulic tank does not create problems when used correctly. The main thing is to monitor its condition and regularly measure the pressure of the gas cushion. It is ideal to combine this procedure with preventive maintenance of radiators and other elements.

Changes and their reasons

Pressure surges indicate improper operation of the system. The calculation of pressure losses in a heating system is determined by summing up the losses at individual intervals that make up the entire cycle. Identifying the cause and correcting it early can prevent more serious problems that lead to costly repairs.

If the pressure in the heating system drops, this may be caused by the following reasons:

- the appearance of a leak;

- expansion tank settings failure;

- failure of pumps;

- the appearance of microcracks in the boiler heat exchanger;

- power outage.

How to increase the pressure in the heating system?

The expansion tank regulates pressure drops

If a leak occurs, all connections must be checked. If the cause is not visually identified, each area must be examined separately. To do this, the valves of the taps are closed one by one. The pressure gauges will show the change in pressure after cutting off a particular section. Having discovered a problematic connection, it needs to be tightened, after further sealing it. If necessary, the assembly or part of the pipe is replaced.

The expansion tank regulates differences due to heating and cooling of the liquid. A sign of a tank malfunction or insufficient volume is an increase in pressure and a further decrease.

A gap of 1.25% should be added to the result obtained. The heated liquid, expanding, displaces air from the tank through the valve in the air compartment. After the water cools, it will decrease in volume and the pressure in the system will be less than necessary. If the expansion tank is smaller than required, it should be replaced.

An increase in pressure may be caused by damage to the membrane or incorrect setting of the heating system pressure regulator. If the membrane is damaged, the nipple must be replaced. It's quick and easy. To configure the tank, it must be disconnected from the system. Then use a pump to pump the required number of atmospheres into the air chamber and install it back.

You can determine if the pump is faulty by turning it off. If nothing happens after switching off, it means the pump is not working. The reason may be a malfunction of its mechanisms or lack of power. You need to make sure that it is connected to the network.

If there are problems with the heat exchanger, it needs to be replaced. During operation, microcracks may appear in the metal structure. This cannot be eliminated, only replacement.

Why does the pressure in the heating system increase?

The reasons for this phenomenon may be improper fluid circulation or its complete stop due to:

- formation of an air lock;

- clogging of the pipeline or filters;

- operation of the heating pressure regulator;

- continuous replenishment;

- overlapping shut-off valves.

How to eliminate differences?

An air lock in the system does not allow liquid to pass through. The air can only be vented. To do this, during installation it is necessary to provide for the installation of a pressure regulator for the heating system - a spring air vent. It works automatically. The new model radiators are equipped with similar elements. They are located at the top of the battery and operate in manual mode.

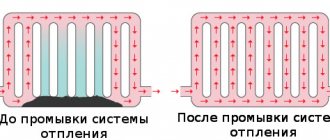

Why does the pressure in the heating system increase when dirt and scale accumulate in the filters and on the walls of the pipes? Because the flow of fluid is hampered. The water filter can be cleaned by removing the filter element. Getting rid of scale and blockages in pipes is more difficult. In some cases, washing with special means helps. Sometimes the problem can only be fixed by replacing a section of pipe.

When the temperature rises, the heating pressure regulator closes the valves through which liquid enters the system. If this is unreasonable from a technical point of view, then the problem can be corrected by adjustment. If this procedure is not possible, the unit should be replaced. If the electronic make-up control system fails, it should be adjusted or replaced.

The notorious human factor has not yet been canceled. Therefore, in practice, shut-off valves overlap, which leads to increased pressure in the heating system. To normalize this indicator, you just need to open the valves.

How to adjust optimal pressure

If the expansion tank is inflated correctly, the pressure gauge needle will display a smooth rise; when jumps or jerks appear, I have suspicions, which lead to additional adjustment. Without the most careful attention to manipulations, it will not be possible to achieve productive operation of the heating system.

If the exhibitor is over-pumped, the compensating functions simply will not work, and the integrity of all components will be at risk.

Excess air pushes liquid out of the reservoir, thereby creating high pressure in pipes and radiators.

Low performance will also not be beneficial, the equipment will not work at all, the membrane will be pushed out by water and the entire container will be filled with coolant.

When the liquid expands, the safety valve will operate, and the hot water system will stop working, and the device will be of no use. That is why I advise you to pay special attention to correct adjustments so as not to encounter surprises and problems.

The optimal value can be simply calculated and brought to an ideal state by bleeding off excess air. All manipulations are carried out with a cold system; 0.2 atm must be added to the initial value.

The statistical pressure can be calculated using the example of dividing by 10, let’s say my house is 8 meters high, then the formula looks like this: 8/10+0.2 atm. To equalize this indicator, air is gradually added or bleed into the tank through a special spool.

DIY open tank

Open tank

Another thing is an expansion tank for heating an open-type house. Previously, when in private homes they only assembled the opening of the system, there could not even be any talk about buying a tank. As a rule, the expansion tank in the heating system, the design of which consists of five main elements, was made directly at the installation site. It is not known whether it was even possible to buy it at that time. Today it’s easier because you can do it in a specialized store. Nowadays, the vast majority of homes are heated by sealed systems, although there are still many houses where there are open circuits. And as you know, tanks tend to rot and there may be a need to replace it.

The heating system expansion tank sold in the store may not meet the requirements of your circuit. There is a possibility that it will not fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank has rotted, it means we need to make sure that this doesn’t happen to the second one. Therefore, it is better to use stainless steel. You don’t need to take a thick one, but you don’t need to take one that’s too thin either. This metal is more expensive than regular metal. In principle, you can make it from what you have.

Now let's look at how to make a tank with your own hands step by step:

action one.

Marking a sheet of metal. Already at this stage you should know the dimensions, since the volume of the tank depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or calculate it yourself, the main thing is that there is enough space in it for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another part and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable part;

act three.

Welding workpieces into one structure. Make a hole in the bottom and weld a pipe there through which coolant from the system will flow inside. The pipe must be connected to the entire circuit;

act four.

Insulation of the expansion tank. Not always, but often enough, the tank is located in the attic, since that is where the peak point is located. The attic is an unheated room, which means it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool or some other insulation material that is resistant to high temperatures.

As you can see, there is nothing difficult about making a tank with your own hands. The simplest design is described above. Moreover, in addition to the pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the expansion tank circuit for heating:

- through which the system is fed;

- through which excess coolant is drained into the sewer.

Diagram of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The discharge of water through the drain is called an emergency release and the main task of this pipe is to prevent the coolant from overflowing from the top. The recharge can be inserted anywhere:

- so that the water is above the level of the pipe;

- so that the water is below the level of the pipe.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is located above the water level, will gurgle. This is more good than bad. Since replenishment is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water is flowing into the expansion tank from the water supply, then you already understand the possibility of some problems occurring in the circuit.

As a result, to the question: “is an expansion tank needed in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

Gas boiler baxi eco four 24

Despite the fact that the pressure in the tank should be constant, it often drops during operation of the heating system.

There are a number of reasons why blood pressure drops:

- Coolant leak. Such problems usually appear in heating systems operating on antifreeze, which can penetrate even small cracks. As a result, leaks occur. They must be eliminated before pumping the expansion tank in the heating system with air.

- Reduced pressure in the boiler. If it falls significantly, you should contact the experts. If the pressure has not dropped critically and has leveled off after starting the system, then it can be used, since such failures cannot harm it.

A very popular series among all others in the BAXI line. The 4th generation boiler with a capacity of 24 kilowatts is available in various versions: with an open and closed combustion chamber. Boilers with a closed combustion chamber and forced smoke removal are designated by the letter “F” in the name. Baxi turbocharged boilers are the most popular and are often used when organizing apartment heating, so we will consider the use of an expansion tank in the heating system using this boiler model as an example.

The volume of the built-in expansion tank of the baxi boiler is indicated in the characteristics and for the ECOFOUR series it is 6 liters. To answer the question of its necessity in a separate heating system, you need to know the total volume of this system.

Calculating it is not so difficult: the filling volume of the boiler and radiators is in their characteristics, and the filling volume of pipelines can be calculated by knowing their diameter and total length. Water, after heating by 80 degrees Celsius, will increase in volume by approximately 4-5%, therefore, the recommended volume of the expansion tank is 8% of the total volume of the heating system if filled with water and 12% if antifreeze is used as a coolant (thermal coefficient antifreeze expansion is greater).

These figures are conditional (with a margin) and when selecting the capacity of the expansion tank, you must be guided by the design calculations of a specific heating system, or the manufacturer’s recommendations.

In most cases, the built-in boiler tank is quite sufficient and the decision to use a separate additional tank is made by specialists at the design stage.

Pumping up the expansion tank should only be done when the boiler is empty!

Therefore you need to do the following:

- Turn off the heating system taps

- Drain the water from the boiler through the drain valve

- Inflate the tank to the required pressure

- Close the drain valve

- Feed the heating system through the make-up tap

- Open the heating circuit taps

The air cavity of the expansion tank is equipped with a valve for carrying out technical

service. The valve design is a regular car nipple, so the easiest way to pump the expansion tank of a baxi boiler is to use a tire pump - manual or electric car. The latter is convenient because it has a pressure gauge to control the pressure, but often the boiler is located in cabinets or niches and it is not always convenient to get to it, so it is preferable to pump it up with a hand bicycle pump, and then check the pressure with a car pressure gauge and, if necessary, bleed off excess.

Sometimes, users encounter a problem when the pressure drops when turning on hot water in the baxi boiler. This problem may just be due to insufficient pressure in the expansion tank. The fact is that when the boiler switches to the hot water preparation mode, the circulation pump pumps the liquid in a small circle, i.e.

READ MORE: How to get rid of condensation in ventilation in a private house

only inside the boiler itself - through a secondary plate heat exchanger. In this case, the heating circuit actually does not heat up and the coolant begins to cool, the volume decreases and in the absence of compensating pressure in the expansion tank, the pressure of the heating system may drop and the boiler will display error E10.

In such a situation, you can also consider the possibility of a breakdown of the heat exchanger itself (a gap between the plates) and water from the heating circuit entering the hot water system, but this is easy to check. To check, you need to shut off the cold water supply to the boiler and open any drain valve. If water comes out of the tap under such conditions, it is obvious that this is coolant from the heating circuit and the heat exchanger needs to be replaced.

Remember, timely maintenance of a gas boiler will help avoid such situations and increase the service life of the unit.

In addition to the pressure gauge readings, frequent discharge of water through the safety valve and blocking the operation of the device help to detect an increase in pressure in a gas boiler. Having determined high pressure, first of all, excess air is released through the Mayevsky taps and the boiler is turned off. There may be several reasons for malfunctions.

The normal upper pressure value is ensured by the system by discharging excess coolant through a safety valve into the drain

An increase in pressure in a gas boiler can be caused by damage to the partition of the secondary heat exchanger, which simultaneously serves to insulate and increase the contact area of two circuits - heating and hot water supply.

The secondary heat exchanger takes water from the heating circuit for preparing and supplying hot water in a double-circuit boiler. Damage to the partition leads to the forcing of water from the hot water circuit into the heating system, increasing the pressure in it.

The secondary heat exchanger serves to service the hot water supply system. Water for domestic hot water is heated as a result of contact with the coolant of the heating circuit. The system is protected from mixing the two circuits by a metal partition, damage to which leads to the exchange of liquids and disruption of normal pressure

Replacing the heat exchanger will solve the problem. You can carry out repairs yourself, but it is not advisable to do this, since interfering with the operation of gas equipment requires knowledge and experience in this area. In addition, repairing the boiler yourself will deprive you of the right to warranty service.

A malfunction of the automatic gas boiler or a loose pump impeller, which sucks in air, also increases the pressure in the gas boiler. Equipment malfunctions that lead to disturbances in normal pressure may be the result of a manufacturing defect, a breakdown of the control board, or an incorrectly configured system. Only a qualified technician can fix this kind of problem.

Common reasons why the pressure in a gas heating boiler drops are:

- Coolant leak. Damage to the heating line leads to a loss of tightness, loss of heating water and a decrease in pressure.

- Cracks in the heat exchanger. Leaks in the boiler itself will not only lead to a decrease in pressure, but can also provoke more serious equipment breakdowns and damage electronics.

- Rupture of the membrane in the expansion tank. Through damage to the rubber partition, liquid enters the air compartment and the pressure in the circuit decreases.

To determine the location of the leak in the system, it is fed to normal pressure and the circulation pump is stopped. Step by step, it is necessary to inspect the highway, identify the problem area and troubleshoot.

SETTING THE EXPANSION TANK

The second thing you should pay attention to when the pressure in the heating system drops is the correct operation of the expansion tank. As you know, liquids increase their volume when heated. Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%

Therefore, to prevent excess pressure from being created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume should enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during boiler operation is maintained within acceptable limits. In double-circuit boilers, expansion tanks are already installed in the boiler itself

Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%. Therefore, to prevent excess pressure from being created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume should enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during boiler operation is maintained within acceptable limits. In double-circuit boilers, expansion tanks are already installed in the boiler itself

As you know, liquids increase their volume when heated. Water, for example, at a temperature of 90 degrees has an expansion coefficient of 3.59%. Therefore, to prevent excess pressure from being created in the heating system, expansion tanks are used. When the liquid is heated, the excess volume should enter the expansion tank, thereby stabilizing the pressure, and when the water cools, it leaves the tank, filling the system. Thus, the pressure in the heating system during boiler operation is maintained within acceptable limits. In double-circuit boilers, expansion tanks are already installed in the boiler itself.

An indication of improper operation of the expansion tank may be that when heated, the pressure increases sharply, even an emergency release of water through the safety valve is possible, and when it cools down, the pressure gauge needle drops down to such an extent that the system has to be recharged. In this case, you need to adjust the operation of the expansion tank.

The instructions for the boiler indicate what air pressure should be in the expansion tank. Therefore, for the tank to operate properly, this pressure must be set. For this:

1. Shut off the water supply and return taps.

2. Find the drain fitting on the boiler,

Let's open it and add water.

3. Find a nipple on the expansion tank, like on a bicycle wheel, and bleed off all the air.

4. Connect the car pump to the expansion tank and pump it up to 1.5 bar, while water may come out of the drain fitting.

5. Let's deflate again.

6. If a hose from the boiler is connected to the tank, disconnect it; you need to pour all the water out of the tank.

7. Attach the hose back.

8. Pump up the expansion tank with pressure according to the instructions for the boiler

(in our case this is 1 bar).

9. Close the drain fitting.

10. Open all taps.

11. Fill the heating system with water under pressure of 1-2 bar.

12. Turn on the boiler and check. If, when the water is heated, the pressure gauge needle is within the green zone, then we have done everything correctly.

Purpose of an additional tank of a double-circuit boiler

As a rule, built-in compensation tanks in gas boilers have a volume of about 6-8 liters. They are designed to compensate for the expansion of 120 liters of coolant circulating in the heating system. Under normal operating conditions, such an expansion tank is enough for a small apartment or house.

When installing radiators of non-standard shape and size, the heating system must be equipped with an additional expansion tank. Because these batteries hold more water

If the heating area is large, heated floors are installed or there are many radiators in the rooms, the volume of the standard built-in tank will be small, since more water is used.

When heated, excess coolant completely fills the tank. And since there is no free space left in the tank, the water pressure increases in the heating system itself and an emergency release occurs by the safety valve. After this, it is unlikely that the gas boiler will be able to start working automatically.

To avoid such negative consequences, an additional expansion tank with a membrane is installed in the heating system in a design for a double-circuit gas boiler. When the standard tank is completely filled, the water goes into the reserve hydraulic tank. After cooling, the liquid returns to the radiators.

What pressure value is considered normal?

A stable amount of atmospheres in the main helps to reduce the level of heat loss and ensure that the circulating coolant has almost the same temperature to which it was heated by the boiler.

It is necessary to talk about what the pressure should be, taking into account what kind of heating system we are talking about. Options:

Pressure in the heating system of a private house. With the open heating method, the expansion tank is the communicating link between the system and the atmosphere. Even with the participation of a circulation pump, the number of atmospheres in the tank will be equal to atmospheric pressure, and the pressure gauge will show 0 Bar.

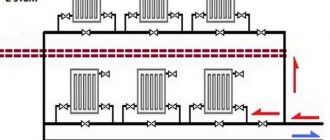

Pressure in the system of a multi-storey building. A characteristic feature of heating systems in multi-storey buildings is high static pressure. The higher the height of the house, the greater the number of atmospheres: in a 9-story building - 5-7 Atm, in 12-story buildings and higher - 7-10 Atm, while the pressure in the supply line is 12 Atm. Therefore, it is necessary to have powerful pumps with a dry rotor.

Pressure in a closed heating system. The situation with a closed highway is somewhat more complicated. In this case, the static component is artificially increased to increase the efficiency of the equipment, as well as to prevent air penetration. The required pressure in the heating system of a private house is calculated by multiplying by 0.1 the difference between the highest and lowest points in meters. This is an indicator of static pressure. By adding 1.5 Bar to it, we get the required value.

Thus, the pressure in the heating system in a private house when installing a closed circuit should be within 1.5-2 atmospheres. An indicator outside the range is considered critical, and when mark 3 is reached, there is a high probability of an accident (depressurization of the main line, failure of units).

Yes, high pressure can improve the operation of the equipment, but the technical characteristics of the installed boiler should be taken into account. Some models can withstand 3 Bar, but most are designed for 2, and in some cases 1.6 Bar

It is important, when setting up the equipment, to achieve a reading in a cold system that is 0.5 Bar lower than the value stated in the passport. This will prevent the pressure relief valve from constantly tripping. It is important to remember that measuring the water pressure in the heating system or trying to regulate it in a single apartment is pointless

The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline

It is important to remember that measuring the water pressure in the heating system or trying to regulate it in a single apartment is pointless. The only thing that depends on the owners of the living space is the choice of batteries and the diameter of the pipes in the pipeline. For example, cast iron is not recommended, as they can only withstand 6 bar

And the use of pipes of larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving into an apartment with old heating, it is better to immediately replace all possible elements

For example, cast iron is not recommended, as they can only withstand 6 bar. And the use of pipes of larger diameter will lead to a decrease in pressure in the entire heating system of the house. When moving into an apartment with old heating, it is better to immediately replace all possible elements.

Another parameter that affects the amount of pressure in any heating line is the coolant temperature. A certain amount of cold water is pumped into the mounted and closed circuit, which ensures minimum pressure. After heating, the substance will expand and the number of atmospheres will increase. Therefore, by adjusting the water heating temperature, you can control the pressure in the circuit. Today, companies involved in heating equipment offer the use of equipment with hydraulic accumulators (expansion tank). They prevent the pressure from increasing, accumulating energy within themselves. As a rule, they come into operation when the level of 2 atmospheres is reached.

It is important to regularly check the accumulator in order to empty it on time. It would also be useful to install a safety valve, which can be activated at a pressure of 3 atm and a full tank to avoid an accident

Principle of operation

The principle of operation of the expansion tank is based on the intake of hot water inside when excess pressure is formed in the system, followed by its return after it has been reduced to the established norm.

As a result, changing this parameter does not have a negative impact on the condition of the pipes and does not reduce the performance of the system.

Additional control and safety are provided by pressure gauges and automatic valves for releasing excess air, but if necessary, expansion tanks function without them.

Calculating pressure in two ways

Before you buy a tank, you need to calculate its volume. In practice, decisions are made in the following order:

- design. At this stage, a decision is made about which rooms will be heated and which will not, diagrams are drawn and the volume of the system in liters is calculated;

- boiler selection. Based on the volume of the system and the area of the heated premises, a heater is selected. For 15 liters of coolant, one kilowatt of heater power is required;

- determining the required volume of the expansion tank.

Now let's look at several different methods for calculating the pressure in the expansion tank of a sealed heating system.

Option #1.

For this we need the following quantities:

- system volume (OS);

- tank volume (VT);

- the maximum permissible value of the pressure gauge scale for a given system (DM);

- water expansion – 5%.

By the time you have to make calculations, you already know how many liters the system holds. The required volume of the tank is calculated by dividing the capacity of the circuit in liters by ten. Although this is an approximate calculation, it is very working.

There is another way to calculate the air pressure in the expansion tank of the heating system:

Air vent

Option #2.

It's good that we live in a world of fierce competition. To ensure that the client is satisfied with the purchase and does not have any problems with operation, boiler manufacturers indicate the required pressure of the heating expansion tank in the product data sheet. If for some reason this cannot be found out, then you can calculate this value, knowing what the pressure gauge readings should be in the operating mode of the system.

The latter can be found with one hundred percent probability in the technical documentation or on the boiler. Then 0.2-0.3 atmospheres should be subtracted from the working pressure. What is it for? If the pressure in the tank is greater than the working pressure in the system, the coolant will not be squeezed into the tank. He simply cannot do this, as an even greater force acts on him from the side of the tank. And if there is not enough air in the tank, then there will be difficulties with returning the coolant to the system.

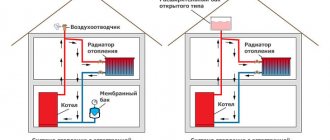

Types of heating systems

There are two schemes for building heating networks - open and closed. An open (gravity) heating system is used in centralized heating networks and allows water to be directly withdrawn for hot water supply needs, which is impossible in private housing construction. Such a device is located at the top point of the heating system circuit. In addition to leveling pressure drops, the heating expansion tank performs the function of natural separation of air from the system, since it has the ability to communicate with the outside atmosphere.

Thus, structurally, such a device is a compensation tank of the heating system, not under pressure. Sometimes a system with gravitational (natural) circulation of a heat-carrying fluid may be mistakenly called open, which is fundamentally incorrect.

With a more modern closed circuit, an expansion tank of a closed-type heating system with a built-in internal membrane is used.

Sometimes such a device can be called a vacuum expansion tank for heating, which is also true. Such a system provides for forced circulation of the coolant; air is removed from the circuit through special taps (valves) installed on the heating devices and at the top of the system pipelines.

Benefits of a circulation pump

The inclusion of such a device in the heating system has the following advantages:

- Both water and antifreeze can be used as a coolant. In this case, it is guaranteed that the entire system will not freeze.

- Due to the fact that the circulating liquid moves at increased speed, it does not have time to cool down. In this case, the water heating boiler will operate in an average gentle mode.

- Such a heating system does not stop functioning even in the off-season period, when the temperature of the coolant decreases.

Photo 1. Circulation pump model UPS 25-60, material - cast iron, Denmark. - The length of the heating circuit is determined solely by the power parameter of the circulation pump and the technical characteristics of additional system devices.

- The radiators are connected using either a single-pipe or a two-pipe scheme.

How to control the system and work with it?

Expansion tanks are tightly closed vessels, which are divided into two fragments using rubber membranes. This is not simple rubber, since it must withstand significant heat while remaining elastic and without losing strength.

That is, by the time it is put into operation, the tank will be completely empty, and its entire volume can be used to correct the thermal expansion of water or antifreeze. If the gas boiler sensor detects that the pressure in the heating system has dropped to 0.7 bar or less, it gives a command to turn off the heater. And the average value that ensures normal operation is 1.2 bar. Since moving from a non-equilibrium position to an equilibrium one, the membrane can increase the pressure further, its initial level for an empty tank is taken to be 0.3 bar (on average) higher than the standard for a heating system.

Conclusion: with a closed heating circuit with a gas boiler, the pressure should be from 0.8 to 1 bar; the parameters of any system deviating from the standards are calculated individually, taking into account:

- expected volume of water or antifreeze;

- Tank efficiency;

- its required value;

- initial pressure at start-up.

Tanks on Baxi double-circuit boilers, as follows from the instructions, must operate at a pressure of 0.5 bar. However, in reality this figure is minimal, and the same pressure of 0.8 - 1 bar allows you to guarantee the normal functioning of the device. The built-in expander with a capacity of 6 liters works stably with heating systems with a capacity of 75 liters (on water). Or 50 l (with antifreeze).

Whether it is necessary to use an additional expansion tank, or whether standard equipment is enough, is decided only by specialists at the time of preparation of the project.

It is very important to check the actual pressure in the expansion tanks. Hand-held pressure gauges are almost always used for this purpose, since most air chambers are equipped with standard nipples, like car or bicycle tires. A problem may arise if the boiler is wall-mounted. Compensating devices are most often located on its rear wall, and it can be difficult to use them. The solution is to use a compact mobile pressure gauge.

As soon as a downward deviation is detected, the air should be inflated correctly. Leaving everything as it is, you may encounter emergency shutdowns of the boiler. It is difficult to even say whether this outcome or the release of excess fluid is worse. Each manufacturer of gas boilers advises consumers to measure the pressure in the tank annually. There will be no harm, of course, if you do this twice as often.

It must be remembered that pumping is carried out only when the tank is completely empty; to do this, drain the water from the boiler. The easiest way is to use a bicycle pump while monitoring the result through a hand-held pressure gauge.

The sequence of actions is as follows:

- the heating system taps are turned on;

- water drains from the boiler;

- the tank is inflated to the required pressure;

- the drain valve is closed;

- the heating circuit is saturated to the required level through the provided tap;

- The taps connecting the tank to the heating open.

Problems with the expansion tank that affect the pressure in the heating circuit are very common. Incorrectly calculated volume of the expansion tank is one of the most characteristic prerequisites.

Malfunctions can result from improper installation, low or high pressure in the air chamber of the tank, a damaged membrane - each of the reasons can lead to disruption of coolant circulation in the system.

If a small volume tank is installed in the heating system, it cannot compensate for the expansion of heating water when heated. At a temperature of 85-95 °C, water expands by approximately 4% and its excess volume exits through the safety relief valve.

In order for the expanzomat to fully perform its compensatory function, its capacity for systems with a gas boiler must be at least 10 percent of the total volume of water in the circuit.

If you install a tank with a larger volume than normal, the pressure fluctuations will be even smaller. Reducing pressure differences has a positive effect on the operation of the system and the service life of heating equipment

Damage to the tank membrane leads to water completely filling its volume and the pressure in the circuit drops. If you fill the volume of the circuit by opening the make-up valve, this will create a new problem - when the coolant heats up, there will be no room for it to expand and the pressure in the system will increase more than normal. The situation can only be corrected by replacing the rubber partition.

The tank should only be installed on the return pipe, in front of the heating boiler. This way the tank will have minimal impact on the operation of the circulation pump, which is installed after the gas boiler. In addition, here the water temperature is lower and the negative impact on the pressure in the system and on the tank membrane will be less.

The pressure formed in the air chamber of the expansion chamber can also lead to an increase or decrease in pressure inside the heating system. You can check and pump up the air in the tank only if there is no coolant in the tank.

To do this, you need to shut off access to the common circuit using shut-off valves and drain the water through the drain. Then the pressure in the air chamber is measured and inflated/lowered to the required values.

You can check the pressure in the expansion tank using a car pressure gauge, and pump it up using a car pump.

To set the pressure of the expansion tank in the air chamber, it must be 0.5 bar higher than the expected maximum pressure in the system. After the pressure in the equalizing part of the tank is adjusted, fill the circuit with cold water to the expected pressure value.

Then the air is released from the air chamber until the pressure in the heating circuit and the tank begins to decrease simultaneously - here it is necessary to simultaneously monitor the pressure in the system and in the expansion tank.

In this phase, changes in indicators are little noticeable, so you must be prepared to immediately stop bleeding air from the expansion tank as soon as a simultaneous decrease is detected.

All tanks are similar in design. They have a metal body, divided from the inside into two rolled compartments. The tank has a nipple on one side, and on the other there is a neck designed for connection to pipes.

There is a diaphragm inside the body. When the container is empty, it fills most of it, and the remaining space is occupied by air. During the operation of the network, the coolant heats up, its volume increases, and the excess penetrates into the cavity between the diaphragm and the housing.

After the temperature drops, the working medium decreases in volume, and the previously pumped air squeezes it back into the system.

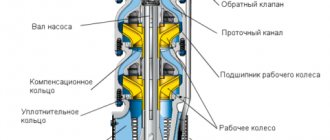

Circulation pump

The circulation pump ensures the operation of the closed heating system. Its power depends on many factors: the material and diameter of the pipes, the number and type of radiators, the presence of shut-off and thermostatic valves, the length of the pipes, the operating mode of the equipment, etc. In order not to go into the intricacies of calculating power, the circulation pump can be selected according to the table. Select the nearest larger value for the heated area or the planned thermal power of the system, and find the required characteristics in the corresponding line in the first columns.

You can select the parameters of the circulation pump from the table

In the second column we find the power (how much coolant it can pump in an hour), in the third - the pressure (system resistance) that it is able to overcome.

When choosing a circulation pump in a store, it is advisable not to save money. The entire system depends on its performance. Therefore, it is better not to save money and choose a trusted manufacturer. If you decide to buy unknown equipment, you need to somehow check it for noise levels. This indicator is especially critical if the heating unit is installed in a residential area.

Strapping scheme

As mentioned earlier, circulation pumps are installed mainly on the return pipeline. Previously, this requirement was mandatory, today it is only a wish. The materials used in production can withstand heating up to 90°C, but it’s still better not to take risks.

In systems that can also operate with natural circulation, during installation it is necessary to provide for the ability to remove or replace the pump without the need to drain the coolant, as well as for the possibility of operation without a pump. To do this, a bypass is installed - a workaround through which coolant can flow if necessary. The installation diagram of the circulation pump in this case is shown in the photo below.

Installation of a circulation pump with bypass

In closed systems with forced circulation, a bypass is not needed - without a pump it is inoperative. But two ball valves on both sides and a filter at the inlet are needed. Ball valves make it possible, if necessary, to remove the device for maintenance, repair or replacement. The dirt filter prevents clogging. Sometimes, as an additional element of reliability, a check valve is also installed between the filter and the ball valve, which will prevent the coolant from moving in the opposite direction.

Connection diagram (piping) of a circulation pump to a closed-type heating system

Advantages and disadvantages

Closed expansion tanks have a number of advantages over open ones:

- Closed analogues do not necessarily need to be installed in the attic; they can be installed near the boiler itself. And open ones must be installed at the highest point of the system.

- In closed tanks, water does not have access to contact with air, which means that oxygen will not dissolve in the water and interfere with the movement of the coolant.

- Most people have converted the attics of their homes into living spaces, so using closed tanks saves space as they can be installed anywhere.

The disadvantages of closed tanks are as follows:

- High price.

- It is necessary to pump air into the device from time to time.

Features of adjusting the hydraulic accumulator

Expansion tanks for water supply are sold with standard manufacturer settings - often the pressure in the air compartment is already set at 1.5 bar. The permissible pressure is always indicated on the label and the manufacturer does not recommend deviating from the specified parameters, especially in the direction of increasing it.

Before proceeding with the adjustment, the system is disconnected from the power supply and the shut-off valves are closed. The membrane tank is completely emptied by draining the water - an accurate pressure indicator can only be measured when the water compartment is empty.

Next, pressure readings are taken using an accurate pressure gauge. To do this, remove the decorative cap from the spool and bring the device. If the pressure differs from the required one, it is brought into compliance by pumping or bleeding excess air.

When adjusting the pressure in the gas compartment of the tank, the manufacturer fills it with an inert gas, for example, dry nitrogen. This prevents corrosion of the inner surface. Therefore, users are also recommended to use technical nitrogen to increase pressure.

Setting the tank pressure in the water supply system

The pressure in a closed tank is always set slightly lower (by 10%) than the pressure level when starting the pump. By adjusting the pressure in the device, you can adjust the water pressure. The lower the gas pressure in the hydraulic tank (but not less than 1 bar), the more water it will hold.

In this case, the pressure will become uneven - strong when the tank is full and increasingly weak when it is empty. To ensure a strong and even flow of water, set the pressure in the chamber with air or gas to within 1.5 bar.

Adjusting the hydraulic tank in the water heater trim

The expansion tank, which is used for hot water supply, should initially not contain water. The pressure in the device is set at a value that is 0.2 greater than the upper pump shutdown threshold. For example, if the relay is configured to turn off the equipment at a pressure of 4 bar, then the pressure in the gas compartment of the expansion tank should be set to 4.2 bar.

Installed in the water heater piping, the tank does not serve to maintain pressure. It is designed to compensate for expansion when water is heated. If you set the pressure in it to a lower value, then there will always be water in the tank.

Malfunctions of expansion tanks

Checking the pressure of the expansion tank is included in the list of annual maintenance procedures and if it is followed there will be no problems, but if neglected it can give the owner unpleasant surprises:

- the pressure in the air chamber gradually decreases and with each refill of the boiler the tank fills more and more with water and gradually ceases to perform its function. In this case, the membrane is so pressed against the wall of the air part of the tank that it can be damaged by the valve spool and the tank will have to be replaced.

- The heating circuit pressure is at the permissible limit, the expansion tank has not been serviced - there is no pressure in it. When the heating system cools down, the volume of liquid decreases, the pressure drop is not compensated for by anything - the boiler stops due to an emergency. This situation can arise, for example, when the boiler operates for a long time in DHW mode or when there is a power outage.

- the owner of the boiler often has to top up the boiler for no apparent reason, for example, while hot water is being used - the pressure on the pressure gauge drops and the boiler stops by mistake - the owner tops up. Since thermal expansion is not compensated by anything, with further heating of the coolant, excess pressure is released through the safety valve. Some users set the reset and simply do not notice this situation. Frequently refilling the boiler with untreated water is detrimental to the heat exchanger!

Which radiators to choose for a wooden house

Heating a wooden house (we are talking primarily about log houses) indeed has its own characteristics, since the thermal conductivity of wood is low and depends on its species. In addition, it is necessary to ensure maximum fire safety. But in general, the issue of providing heat, as well as safety, rests primarily on the correct installation of the heating system, the choice of boiler and the number of radiators. There are no restrictions on the type of radiators here: steel, cast iron, bimetallic, aluminum - all of them can be used in a wooden frame.

Causes of pressure drop

If you find that there is low pressure in your gas boiler, there may be two reasons:

- The heat exchanger has failed.

- There are leaks in the heating circuit.

Any problems with the heating boiler must be identified and corrected as quickly as possible. A drop in pressure can be caused by a manufacturing defect, defects in the expansion tank, clogged heat exchanger, cracks or excessive wear. In any case, all problems should be corrected.

No less often, the pressure in the system drops due to leaks. In particular, they can occur in places of poor-quality soldering of plastic or steel pipes, at joints with radiators, in sections with great wear of the pipe, as well as in the presence of cracks in the rubber gasket in the expansion tank, which leads to coolant entering the air chamber.

You can establish a leak in the rubber membrane by pressing on the spool through which air enters the chamber. If water drips from it, the cause of the pressure drop has been found.

It is somewhat more difficult to detect leaks in pipelines if they run through a wall or under the floor. First of all, they diagnose visible sections of the contour and inspect the condition of the floor to detect stains from dried water. Salt deposits and signs of rust at the joints may also indicate depressurization of the system.

Some systems have the ability to turn off individual sections of the circuit one by one to make it easier to identify leaks.

If visual diagnostics of the condition of a closed pipeline does not produce results, perform pressure testing. This is done by professionals with experience and equipment. First, the coolant must be drained from the circuit, after which the batteries and the boiler are isolated.

Then air is pumped into the circuit, bringing the pressure in the system to a value 20% higher than the working one. After a few hours, the pressure level is rechecked. If it falls, they begin to search for a leak.

At the same time, on visible sections of the pipeline, the joints are lubricated with a soap solution. Where the soap begins to bubble and hiss, the seal of the circuit is broken.

Next, the defective seam is either sealed or the pipe section is replaced.

How to check the pressure in the heating expansion tank

Checking the pressure in the heating expansion tank is done with a hand-held pressure gauge, since in most cases the air chamber of the tank is equipped with a regular nipple, the same as on a car or bicycle wheel.

If we are talking about a wall-mounted gas boiler, the compensator is usually located on the back wall and is not so easy to get to, especially if the boiler is hanging in a niche or in a closet.

Therefore, it is most convenient to use a compact tire pressure gauge with the ability to record readings. If the test reveals that the pressure is insufficient, this must be corrected. Lack of proper pressure can cause trouble for the user in the form of emergency shutdowns of the boiler or release of excess pressure through safety devices.

It is not advisable to lead to such situations and according to the recommendations of most boiler equipment manufacturers - the pressure of the expansion tank should be monitored once a year during maintenance.

It is necessary to pump up the tank only when it is completely empty

Since it is structurally located on the boiler, it will be enough to drain the water from the boiler. You can pump up in any available way. Practice shows that the easiest way to do this is with a regular bicycle pump and check it with a hand pressure gauge. If the pressure in the air chamber of the expansion tank cannot compensate for the pressure in the water chamber, there is also a possibility of damage to the membrane or valve.

Prevention

To keep the boiler in good condition and prevent excessive pressure, regularly:

Monitor the health of the equipment security group. It includes: a pressure gauge, an air vent and a safety valve.

- Add coolant (antifreeze) to the coolant. Please read the instructions carefully, as this is not permitted in all boiler models. Thanks to this measure, the filter will become less clogged, the amount of scale on the air vents will be reduced, and the safety valve components will not stick.

- Clean the heat exchanger. This is how its service life develops, and fistulas and scale will not appear on it.

Tests and parameters before the boiler

The hydraulic accumulator is one of the key components of the hydraulic accumulator. To ensure its proper operation, and the operation of the boiler itself and the network, special tests are carried out. They are usually arranged during the production of apparatus and some pipeline units. The process occurs after installation and connection of the entire system. A check is in progress. The pressure is 1.5-3 times higher than the working pressure. It rises very carefully. The acceptable indicator is calculated using a special formula. To control it, two unconnected pressure gauges are used. If the parameter is too high, it is necessary that air does not accumulate in the water volumes. During testing, the measured parameter is constantly monitored. Then it gradually decreases to normal.

Correct setting of this parameter is the key to successful operation of the device. Each model has its own parameter. The following table is provided as an example:

| Model | Min. parameter.(Pa). Type of gas - liquefied | Max. parameter.(Pa). (liquefied gas) | Min. Pa (natural gas) | Max Pa (natural gas) |

| Protherm LYNX Condens | 13 | 13 | ||

| Daewoo DGB _ | 4 | 25 | 28 | 33 |

| Mora W 65 | 2,5 | 20 | 6,2 | 13,2 |

| Buderus | 4 | 22 | 27 | 28 |

| Junkers K 144-8 | 18 | 24 |

The correct gas setting is important here:

- Loosen the bolt to change the pressure.

- Threading a flexible hose.

Setting maximum gas consumption:

- Any faucet with hot water opens.

- Set max. temperature.

Conclusions and useful video on the topic

Pressure surges in a heating system with a double-circuit boiler:

Why does the pressure in the heating system drop:

Reasons for the increase in pressure in the heating circuit:

Instability of pressure in the heating system occurs due to its incorrect connection, non-compliance with operating rules, and the use of faulty devices.

Understanding the reasons for the drop and increase in pressure in a gas boiler helps to properly maintain the system, but this is not a reason to independently interfere with the operation of the equipment. For help, it is better to contact a specialist from a gas service that supplies blue fuel.

Other troubleshooting methods

Checking the parameters in the expander is included in the list of annual boiler maintenance. When air flows through the drain valve during the test, and the pressure gauge needle in the gas sector drops to atmospheric pressure, it means that the membrane in the tank is broken and needs to be replaced.

It is not recommended to glue the membrane together, since it works cyclically in tension/compression, which will cause repeated destruction of the glued joint, and at the most inopportune moment for the boiler.

Acceptable problems with the expansion tank:

- The needle on the pressure gauge in the heating system fluctuates greatly and has a high value even at low coolant temperatures due to the lack of air in the cavity - the expander needs to be pumped with air.

- The membrane is damaged - it needs to be replaced with an original one at a service center.

- The case is damaged, the integrity is restored at the service center.

- The air sector nipple is leaking - you need to blow out and pump the vessel with air.

- Small volume of the expander - you need to perform a new calculation and replace the device with a new modification.

- Coolant leakage from the vent due to damage to the membrane - it must be replaced with an original one at a service center.

- The coolant pressure is low, it does not flow to the upper point of the network, due to the lack of air (nitrogen) in the expander, the installation will need to be filled with air.

Thus, to summarize, it should be noted that the requirements for the operation of heating networks to compensate for the thermal expansion of the coolant in systems, both closed and open, require compensation for the temperature expansion of network water using expansion tanks.

They are pre-calculated for the technical characteristics of the in-house heating system. During operation, such devices must be periodically maintained and filled with a working agent: air or nitrogen.