Today, many heating systems have been developed that can create a comfortable microclimate in rooms for various purposes.

However, most of them give the desired effect only when used at home, since the ability to maintain the required temperature is limited by the area of the room.

When using alternative heating sources in large areas of industrial premises, there is an excessively high level of fuel or electricity consumption.

Original heating systems, called water fan heaters, were developed especially for industrial enterprises

How to make a water fan heater with your own hands?

The structure can be assembled from a small car radiator, copper pipes and a duct fan. A galvanized steel sheet 1 mm thick is selected for the body. A metal box is made from it, in which two working components are fixed tightly to each other - a fan and a radiator. On both sides, two pipeline circuits are connected to the system, which can later be connected to the central DHW communications. In the manufacture of a water fan heater you will need a jigsaw, a grinder, a marking tool and a set of metalwork fasteners. You should also ensure that the fan is connected to a 220 V network, otherwise the system will not work. Except that for workshops and large industries, massive ventilators operating at 380 V are used.

No. 4: Device with water instead of electricity

An interesting variant of this type of device is the so-called water fan heater. Here, not a spiral is used as a heater, but a heat exchanger through which water circulates from the heating system of a house or apartment. Thus, a water fan heater can be considered as an addition to the heating system.

This device is not mobile; it is installed in a specific place. The idea is to circulate air between the heat exchanger pipes and thus improve the rate of heating of the room and the efficiency of home heating. The installation location of the fan heater is chosen so that it can be easily connected to the heating pipes, and also so that there are no obstacles in the path of the flow of warm air.

First, the device body is cut out and welded to the size of the fan from sheet metal. To do this, cut a strip of metal, the width of which corresponds to the width of the fan heater, and the length is equal to the perimeter of the fan plus a couple of centimeters for fasteners. A strip of metal is bent and its opposite sides are connected with bolts.

These are the walls of the device. For the front part, a sheet of suitable size is cut, in which many air holes are drilled. This is the equivalent of a safety grille. Now you need to make a heat exchanger. To do this, use a copper tube, which is bent, giving it the shape of a coil.

At this time, it is recommended to fill the tube with sand to prevent the formation of creases. Upon completion of work, the sand is removed. In the side walls of the water fan heater, you need to drill two holes for the heat exchanger pipes. If the connection to the heating circuit will be made using a thread, it must be cut at the edges of the heat exchanger pipe.

It makes sense to install shut-off valves at the inlet and outlet, and a Mayevsky valve at the top point of the heat exchanger to bleed the air that has entered the system. The heat exchanger is installed in the device body and its position is secured with nuts. After this, the fan heater is fixed in the selected location so that there is a space of at least 10 cm between the wall and the housing. All that remains is to connect the heat exchanger pipes to the heating system, and the fan to the power supply.

DIY fan heater made from trash + video

In the video you will clearly see how a fan heater is made from various elements that may remain from components of household appliances that are no longer working.

For the fan heater model in question you will need:

- Cover with cooler from the power supply;

- Broken hair dryer;

- Plastic grille for ventilation;

- Iron cord with plug;

- Textolite;

- Pieces of plywood.

Step by step guide:

- Installation of the heating element. A frame is made from narrow strips of textolite, and a spiral, which was removed from a hair dryer, is wound onto it in a zigzag. Holes are prepared in the textolite structure and wire is inserted into them. A spiral is attached to it so that it does not touch the frame material. As a result, the spiral plays the role of a large variable resistor.

- Fan connection. On the created frame with a spiral, using a voltage meter, find the area with the lowest alternating voltage. You need to solder the diode to the plus, and connect the wiring from the cooler to the minus. This circuit completely replaces the power supply.

- Execution of the body. The side walls are screwed to the cooler lid, and a grille is inserted into the remaining empty wall and fixed with glue from a hot-melt gun.

The resulting device consumes little electricity, operates silently and can easily heat certain places in the room. For example, if your feet get cold while working in the workshop, you can install a fan heater under the table and it will warm them.

If you need to ensure high-quality heating of the room before turning on the central heating or after its completion, during a period when there are particularly cold days, then you can’t imagine a better homemade fan heater. It is compact, economical and productive, it can be created from available materials

Homemade #2 - mini heater made of foil and glass

The following homemade device works on a similar principle to the previous one. To make it you will need:

- two pieces of glass of the same size;

- aluminium foil;

- sealant;

- regular paraffin candle;

- wire with a plug at the end;

- epoxy adhesive.

A device for holding the candle while working, cotton swabs for removing soot, and a cloth for cleaning glass will also come in handy.

The inner surface of the glass is coated with soot to create a conductive layer

Let's start assembling:

- We thoroughly clean the glass of all kinds of contaminants: traces of paint, dust, grease, etc.

- We form a conductive surface. To do this, using a candle, we evenly apply soot to one side of each glass blank, which will act as a conductor. To facilitate the process, it is better to cool the glass before the operation - this way the soot will settle more evenly.

- Using a cotton swab, carefully remove excess soot from the edges of the workpiece so that you get a transparent edge about half a centimeter wide.

- We cut out two strips of aluminum foil, the width of which corresponds to the size of the conductive surface. They are designed to perform the function of electrodes.

- We lay the workpiece soot-covered side up and apply epoxy glue to it. We place the foil electrodes along the edges so that their edges extend beyond the workpiece.

- We cover the part with a second sheet, directed with the smoked layer inward, carefully press and glue. All connections are well sealed.

We carry out tests and measure the resistance of the conductive layer. Now you can calculate the power of the device, which will be equal to the product of the surface resistance and the square of the current. If the obtained value is within the limits permitted by regulatory documentation, the device can be plugged into a power outlet. If not, you will have to reassemble it. It should be taken into account that the wider the soot layer, the lower the resistance of the device and, accordingly, the higher the heating temperature of the glass.

Model of a homemade glass plate heater

Another simple homemade device works on the principle of using infrared radiation, which can be assembled in a few minutes. This device consists of a sheet of aluminum foil mounted on a radiator and oriented towards the room. The heat emanating from the radiator is collected by the foil mirror and reflected into the room, without unnecessary losses in heating the walls.

There are many ways to make a heater with your own hands. You can choose different principles of operation of devices and the materials from which they will be made. The main thing is not to forget that the devices must be safe. There is no need to be lazy, measure the resistance and calculate the power in order to determine whether it is permissible to plug the homemade product into an outlet or not. All device contacts, wires, and conductive parts must be carefully insulated. A safe, efficient and practical heater will delight you with its impeccable service for many years.

Doesn't respond when turned on

If the fan heater does not turn on when connected to the network and pressing the button, there may be several reasons for the malfunction. The first thing to do is check the electrical cord; perhaps it was broken somewhere during summer storage. Did not help? We take a screwdriver and a multimeter, after which we proceed to repair the fan heater ourselves. Most likely the cause of the malfunction is the fuse box, one of which tripped due to overheating.

Using the example of the Scarlett SC158

Let's look at step-by-step instructions on how to fix a fan heater with your own hands:

- First, we unscrew the screws on the back cover, there are usually 6 of them, as shown in the photo.

- Next, we use a multimeter to test the main elements of the circuit: thermal fuses, thermostat, thermal switch. The first fuse can be seen immediately without removing the blade. To find the second one, which is located on the engine, you will have to remove the fan. You test the circuit yourself with a multimeter and if this type of breakdown is really the cause, buy exactly the same element in the store and replace it (cost no more than 30 rubles).

- If the thermal fuses are working, check the Polaris heater control unit. It can be found according to the diagram provided in the instructions for the device.

Please note that replacing fuses with thin wires (bugs) is strictly prohibited. With this method of repairing a fan heater with your own hands, you will make a fire-hazardous heater that will not work if it overheats!

Video repair instructions:

Video repair instructions:

Operating principle of the device

There are three components in any fan heater model:

- fan;

- a heating element;

- frame.

The fan drives a stream of air through the body, the spiral heats this air, and the warm air flows throughout the room. If you add automatic control elements to the device, you can set an acceptable air temperature. The device will turn on and off without human intervention, which will save energy.

Household fan heaters are compact devices that can easily be installed in almost any suitable place. To operate the device, you need electricity: both for the fan and for the heating element. Such devices are often used in apartments, garages, and even for heating workshops, greenhouses and other premises. It all depends on the power of the device.

To make a homemade fan heater, a regular household fan, the dimensions of which correspond to the body of the device, is suitable. Sometimes the housing is made based on the size of the fan

When operating the fan heater, you must adhere to safety rules. Do not place any objects or materials directly on the fan heater body or too close to the protective grille. If the device is equipped with an overheat protection system, it will simply turn off. But if this module was not installed during assembly, the device may overheat, break down, or even catch fire.

A self-made fan heater can be of almost any suitable size and power. As a housing, you can use a piece of asbestos-cement pipe, a metal pipe, a rolled sheet of metal, or even a housing from an old system unit. Usually, a fan is first selected and a heating coil is made, and then the type of device housing is determined depending on its filling.

The most important point when creating this heating device is safety: fire and electrical. The heating coil in homemade devices is most often of the open type; it is simply twisted from suitable wire. Direct contact with a heated coil can lead to fires, burns, etc.

To make a fan heater with your own hands, you will need the most common tools, as well as basic knowledge of installing household electrical equipment

Therefore, the spiral must be properly secured inside the case, and the outside of the device must be covered with a reliable grille. The installation of the device's power supply also requires attention. All contacts must be insulated; the base below is usually made of materials that do not conduct current: rubber, plywood, etc.

Image gallery Photo from As a basis for the construction of a fan heater, it is worth taking an industrial model, the design of which will serve as a template

To assemble a fan heater you will need a motor, a centrifugal or axial fan, wires and a housing; the components can be assembled from literal trash

At the stage of selecting suitable available means, you should immediately decide on the type of heating element and the method of its fastening

The photo shows a typical example of a homemade heat gun. An old fan from a dismantled ventilation system and a PEV 50 resistor are attached to a board base.

Osonov for the manufacture of a fan heater

Tools at hand in assembling the device

Tungsten Helix for Heater

Heater made from an old resistor and fan

What do we need to connect fan heaters?

First of all, we need to measure the distances from the installation site of the command controller to all fan heaters. We need to take into account that we draw two lines at the same time. One line, cable - to control the fan rotation speed, on and off (two wires, cross-section 0.5 mm - 2 x 0.5 mm). The second line, cable (2 x 0.5 mm) – for connecting external temperature sensors.

It is best to take the wire with a reserve, because it is impossible to accurately calculate the molding.

I note that this scheme is used in our case. It may have a different configuration, for example, complete with servo-driven taps. Or, you can install your own command controller for each fan heater. This will make it possible to flexibly configure the operation of the fan heater to suit the needs of each individual room.

In our case, only one command controller was used.

Directional heat gun

Our own heat gun has enough power to easily heat a garage, utility room or office in the house

For assembly you will need:

- a piece of plywood 16 mm thick;

- fan (duct);

- temperature and speed controllers;

- PBEC heating element (2.2 kW);

- fasteners (clamp, bracket, studs, nuts, washers);

- wheels.

We cut out a rectangle of approximately 47 cm x 67 cm from plywood, sand the rough edges and corners.

The plywood base was not chosen in vain: it is light, flat, and most importantly, it does not conduct electric current, which is important in the event of force majeure circumstances

We connect two central parts with a coupling - the fan and the heating element. We fix the resulting structure on a plywood base using a bracket and a plumbing clamp.

We select fasteners in such a way that they firmly fix the elements of the device and do not cause them harm. For example, self-tapping screws are perfect - they do not destroy plywood

Self-tapping screws (16 mm) are suitable for fastening. We install a temperature sensor (for example, TG-K 330), which is necessary to control the temperature, next to it there are two more devices - for adjusting the speed and temperature.

When connecting the parts of the fan heater to each other, do not forget about the safety of the device: the connection points of wires and cables must be insulated

Pulsar 3.6 is suitable as a thermal regulator. After installing all the necessary devices and parts, we connect them according to the diagram.

Device control circuits can be found in specialized literature, instructions for devices such as an electric fan, or on specialized websites

For ease of use, we screw wheels to the plywood base.

Small rollers screwed on the bottom side make the homemade fan heater more convenient to move around the room, especially if it is heavy.

Well, that’s all - the homemade heat gun is ready.

Try to place the device parts in such a way that, if necessary, it is easy to disassemble each of them and replace failed elements

Like any homemade fan heater, this device has disadvantages. For example, when the device is stopped, the voltage on the heating element remains, and this is quite dangerous, since overheating occurs and an emergency situation is possible. The situation can be corrected by installing a relay to timely turn off the power supply to the temperature controller. Another disadvantage is inadequate heating of the room, but this is a disadvantage of almost all stationary fan heaters.

What else you need to know

The device is mounted in the ventilation duct. In this case, you need to check one thing - the incoming air should not contain aggressive substances and abrasive particles. If this is not the case, then everything necessary must be done to achieve this requirement. Otherwise, there may be problems with the functioning of the heater.

Design of a two-row water heater

Water heaters successfully perform their functions in enclosed spaces. But if it is necessary to install an air heater outside, then you cannot do without the use of special freezing mixtures.

Among all the currently existing options for heating rooms, the operation of a heater is considered the most convenient and profitable. Installation of the device is simple, and the equipment itself is not that expensive. In addition, water heaters have the following advantages:

- Absolutely environmentally friendly and clean;

- Easy care and maintenance;

- Fast heating of air masses;

- Possibility of DIY installation;

- Availability of components and tools.

The main factor influencing the long service life and uninterrupted operation of the heater is the correctness of installation measures. If everything is done in accordance with technology and without gross errors, then no problems will arise in the future.

It is impossible to heat an entire house or even one large room with a conventional household fan heater, but it is ideal for creating a comfortable atmosphere in a work or sleeping area, as well as in a small room.

Types of heaters

Depending on the method of heat transfer, electric and water heaters are distinguished.

Electric heater

The design of such a device implies the presence of steel filaments or spirals of metal wire. When current passes, metal elements offer a certain resistance to it, which leads to the conversion of electrical energy into thermal energy.

Among the advantages of electric heaters we note:

- Ease of calculating the required power of the device.

- Availability and relatively low cost.

- Easy to install and connect.

- Small pressure drops.

There are also a number of disadvantages. Thus, a large inertia is created in hot metal threads. This can lead to overheating of the device and even its failure. Improper handling of the device often causes a fire. To counter this phenomenon, electric heaters are equipped with additional protection against overheating.

Another negative point is low efficiency. The operating costs of electric heaters are an order of magnitude higher than those for water devices, in which electricity consumption is minimized.

Water heater

Due to numerous advantages, heaters of this type have become much more widespread than electric ones.

The obvious advantages of water heaters include:

- Fast heating of room air.

- Availability of structural elements.

- Possibility of assembling and installing the device on your own.

- Ease of repair and maintenance.

- Environmental friendliness of the device.

- Long service life.

- Economical.

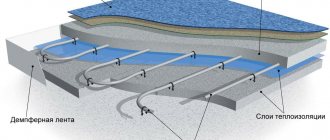

Water heaters include the following parts and components:

- fan;

- heat exchanger;

- circulation pump (not required when connected to a central heating system);

- three-way valve;

- Control block.

A mandatory element of the design of a water heater is the piping unit, which is responsible for supplying hot water to the heat exchanger.

In addition, air heaters differ in form factor. The shape of the duct can be round or rectangular. This does not have any serious impact on the performance and cost of the device. The main condition is that the heater must be optimally integrated into the system.

The procedure for manufacturing a fan heater

Homemade heat gun

The device body is mounted on insulated stands to the base. A fan is attached to one of the ends of the tubular housing, inside. It is carefully attached not only to the body, but to the base material. It is advisable to cover the fan with a protective grille to prevent foreign objects from entering the housing.

A heating element with a power of 2-2.2 kW is attached to the front of the housing. If necessary, metal clamps are used. A temperature sensor (for example, TG-K 330), a temperature regulator (Pulsar 3.6 type device), and also a device for adjusting the speed are attached to the body. Power is connected to the fan and heating element.

This will prevent the heating element from burning out if the fan suddenly stops. A homemade heat gun will work more efficiently the more powerful the heating element you install.

To make it easier to move the device, screw casters or small wheels onto the bottom of the stand.

Design solution for space heating system

Any model of the device is equipped with the main elements, these are:

- Fan to distribute air flow.

- Heating device in the form of a spiral.

- The housing that contains all the heating elements.

The principle of operation is simple: with the help of a fan, heated air is distributed throughout the room, creating the desired room temperature. Even better, set a temperature regime that gives a certain temperature and saves electricity perfectly.

For domestic purposes, small devices are used; they can be installed anywhere, as long as there is a connection to the electrical network.

Important! A homemade device can be equipped with a protective element against overheating of the device, this is the best protection to protect yourself from troubles associated with fire or breakdown

The device’s spiral must be installed with all precautions, since any error will lead to irreversible processes. The spiral must be secured so that it does not touch the body and is well insulated at the joints

The base of the heat fan is made of different materials, as long as it does not conduct current

The spiral must be secured so that it does not touch the body and is well insulated at the joints. The base of the heat fan is made of different materials, as long as it does not conduct current

The device’s spiral must be installed with all precautions, since any error will lead to irreversible processes. The spiral must be secured so that it does not touch the body and is well insulated at the joints

The base of the heat fan is made of different materials, as long as it does not conduct current.

Features of operation

1.1 Electricity consumption, if this heating device is selected, is minimal, since water or propylene glycol from the central heating system is used as a heating element. At that time, electricity is used only to ensure the operation of the fan, which is designed to supply air.1.2 Water fan heaters are compact and small in size, which is a significant feature when installing this equipment; you will not need to think about where to place it and what it will be on fasten. In order for your fan heater to work for a long time and efficiently, it is necessary to carry out technical inspections of the condition of the working elements. In heated rooms, it is necessary to observe the level of environmental pollution and the concentration of chemical elements that can cause damage to equipment. If these rules are not followed, a conventional fan heater will soon stop working for your intended purpose.1.3 For such premises, for example, “greenhouses”, fan heaters with chemically resistant housings and protection classes IP 54 and IP 65 are used. Water fan heaters from the manufacturer Reventon model have this protection class "Farmer MC 47 kW, Farmer HCF IP54-3S 47 kW and Farmer HCF 53 kW."

General information about the unit

The operating principle of such equipment is based on heat distribution due to hot water circulating through the circuits of the generator set. Moreover, heating of the surrounding air and objects is carried out not in passive mode, as is the case with conventional radiator pipes, but with the support of an axial fan. It passes air flows through the surfaces of the heat exchanger, which return to the room heated. And on the contrary, the design can operate in fan coil mode, that is, air cooling, while collecting dripping condensate in a special tray.

To technically support both functions, not only a heat exchanger with a fan and local communications is used, but also guide blinds, the regulation of the position of which allows for local heating. In terms of thermal power, heating with a water fan heater can reach 150 kW, but average values are 20-40 kW. The water heating temperature ranges from 40 to 200 °C.

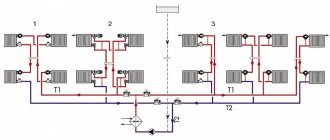

Connection diagram for Volcano VR fan heaters Vulcano

ATTENTION! Before connecting the fan heaters, you must turn off the power supply! Cable connections must be made by qualified personnel in accordance with the instructions. Due to the fact that VTS Euroheat has updated its line of VOLCANO VR water fan heaters, and now they all have a three-speed electric motor, in our opinion, it is advisable to use the 3 most popular methods of electrical connection of VOLCANO VR fan heaters. The nominal cross-section of the connected wire is 1.5mm2, for example, PVA 3x1.5

The nominal cross-section of the connected wire is 1.5mm2, for example, PVA 3x1.5.

Method No. 1 Direct connection of VOLCANO VR fan heaters to the network

The diagram clearly shows how to connect the VOLCANO VR fan heater directly to the network. Where:

"L" - PHASE;

"N" - ZERO;

"PE" - EARTH.

Let's look at it in detail:

At number 1, we have a 1-phase power supply 220V-50Hz, VOLCANO VR fan heaters are powered from a regular household 220V network, which expands the scope of their application.

Number 2 is the main switch and fuses. Recommended protection: overvoltage (fan heater VOLCANO VR - 4 A), as well as differential protection.

Depending on where to connect the phase supply wire, the choice of rotation speed of the electric motor and its productivity in m3/hour (air flow) will depend:

- Maximum power, connect the phase to connector No. 8;

- Average power, phase connected to connector No. 7;

- Minimum power, connect the phase to connector No. 6.

Advantage:

- Convenient switching between speeds (air flow) of the fan heater; by its structure, it simply switches the voltage supply through a phase, between;

- Room temperature control, when the set temperature is reached on the speed and temperature controller WING/VR (TR110C-B), it turns off the power to the fans;

- Possibility to turn fan heaters on and off via a switch on the TR110C-B panel.

A maximum of one such speed and temperature controller TR110C-B can be connected to:

It is recommended to use a 5x1mm2 cable.

The maximum cable length from VOLCANO to the TR110C-B regulator should not exceed 100m.

For our speed and temperature controllers that we brought especially for ourselves, the connection diagram is slightly different.

The numbering for connecting fans to the speed and temperature controller has been slightly changed. This regulator is PROMOTIONAL, it costs much less than the VTS regulator, we can give it to good clients.

Method No. 3 Connecting VOLCANO VR fan heaters via WING/VR speed and temperature controller (TR110C-B) + two-way valve with servo drive

Homemade electric walk-behind tractor

To make an electric walk-behind tractor with your own hands, you will need some materials that are available to owners of personal plots. The manufacturing process of such a device can be divided into several technical operations:

1.

The supporting frame is one of the main elements of the equipment. To make it you will need a channel and a corner. The width of the frame must correspond to the dimensions of the engine and gearbox. You can use pieces of pipe of the required size as handles. The pipes should be welded to both sides of the metal frame. After this, you need to screw a bronze insert to the pipes with screws, which will serve as an axis.

2.

For the sliding effect, you can use ball bearings that are selected with the appropriate diameter. To fix the handles to the pipe, you need to weld special brackets. In order to secure the cultivator and the plow holder, you need to weld the bracket in the middle part of the pipe. Using screws, you need to install a platform on the frame body in special slots in the side ribs. To mount the electric motor, special holes should be made in the platform.

3.

By means of a belt, the pulley on the bronze axis is connected to the same element on the electric motor. Using a chain, the movement is transmitted to a sprocket located slightly lower. For these purposes, you can use a regular bicycle chain.

4.

The movement of the walk-behind tractor will be carried out due to the working device, which directly cultivates the soil. Curved knives need to be secured to a square plate, and they will be held in place thanks to a key located on the lower axis. When the shaft rotates, the soil will be loosened and the entire module will move. Reduction is created through the relationship of pulleys and sprockets.

5.

The movement is controlled by a switch that must be placed on the handle of the holder. You can connect the motor to the network using a wire wound on a reel.

In general, making a homemade electric walk-behind tractor does not require special technical qualifications. When manufacturing it, basic ergonomics and safety rules for the owner of such agricultural equipment should be observed.

Doesn't work well

If the fan heater does not heat the air well, then this problem is considered the last. Usually this breakdown can be caused by contamination of spare parts. If your heating element is covered in dust, then the heating will be weak. This repair is not considered difficult and you just need to clean the device. To do this, take a vacuum cleaner and go through all the elements of the chain. Following this process will help resolve the issue. You also need to check that the electrical plug is working properly. Perhaps the cause of the breakdown occurs precisely because of it. If the wire is broken, then you need to replace the plug.

These are all tips for repairing a fan heater yourself. When choosing a fan heater yourself, it is better to give preference to models that have a ceramic heating element. We hope this article will help resolve all problems.

If you are interested, read: electric warm baseboard.

Fuel filter heater for diesel engine separator configuration

It is important to know

To manufacture a fuel filter heater for a separator configuration of a diesel engine, you will need a lathe.

Before installation, it should also be taken into account that the drain unit in diesel engines is used to remove liquid from the sump. Accordingly, if this device is to be removed, it is necessary to use only proven high-quality fuel.

What will you need?

Tools and materials required for installation:

- set of wrenches;

- a piece of metal pipe for making a bushing;

- wires for connection;

- a lathe that will be used to cut threads.

Algorithm of actions

You can install a diesel fuel filter heater of a separator configuration as follows:

- A metal sleeve of the required size is made. The outer circuit of the device must match the drain valve of the system.

- Using a drill, drill a central hole.

- Internal and external threads are cut. The outer pitch should correspond to the drain element, and the inner pitch should correspond to the thread for the glow plugs.

- The completed structure is assembled from candles. The resulting mechanism is screwed into the body of the separator device. The shape of the part itself needs to be corrected - a pin should be made on the hexagon. To do this, a screw or bolt is welded on the side.

- After installation, the wiring is laid. On the positive line you need to install a switch button and a four-pin relay. The entire electrical circuit must be protected by a safety device to prevent voltage surges and short circuits.

- After installation, it remains to connect two terminals. Grounding or “ground” goes to the bushing, and the positive contact must be connected to the glow plug. The installed device is being tested.

Video: features of the use of fuel heaters

Roman Romanov in his video spoke about the nuances of using heating devices for fuel filters of separator design.

Manufacturers

The most popular manufacturers among domestic car enthusiasts are:

- Lifei is a Chinese manufacturer of automotive components. It gained popularity due to its favorable price. Small units can be purchased for between 1500-2000 rubles, which is significantly cheaper than their closest competitors. However, the disadvantage of the manufacturer is the unstable quality inherent in all budget manufacturers, while all installation work can be done with your own hands.

- Webasto is one of the market leaders producing equipment for heating cars. It is distinguished by consistently high quality and the same high cost. Units from this company are characterized by high endurance (on average they can last for 7-8 years);

- KRC is an automotive components company. It has been present on the market not long ago and is fighting against competitors by balancing attractive prices and fairly high quality products. According to the developer, the service life of the product is about 4-5 years.

Advantages

The undoubted advantage of electric walk-behind tractors is their compactness. The unit is easy to store and does not take up much space. This point is no less important during transportation. Most models can be transported in the trunk of a car by first removing the handles.

Electric models are much easier to drive than gasoline or diesel cars. At the same time, as already noted, the units do not pollute the air and do not make noise. The price of most models is significantly lower than the cost of cars with an internal combustion engine or a diesel component. The payback of the unit should also be taken into account. An electric walk-behind tractor is cheaper to operate, does not require fuel and constant complex maintenance.

If the site is small (within 10 acres) and at the same time electrified, the choice seems obvious. It is worth purchasing an electric walk-behind tractor. In most cases, such a unit will satisfy the needs of the summer resident. And if it is planned to build greenhouses on the site (or they are already present), then such a machine will be simply irreplaceable.

Communications liner

It is necessary to take into account that the heating main must provide the required cross-section (the diameter must meet the technical requirements). And yet, the necessary flow of coolant through the fan heater must be ensured. If the diameter of the pipes and the temperature of the coolant are sufficient, but the speed of movement (flow) is very weak, this will negatively affect the thermal power of the device!

Also, think about how to supply power and control circuits. Calculate the required distances to purchase the required footage of electrical wire.

And one moment. Make sure that the wall (or ceiling) on which the fan heater will be mounted is of sufficient strength to withstand the load.

Dark color

If you paint the radiator dark, the heat transfer efficiency will increase - this is a law of physics. It won’t give a big increase in heat, but it will raise the room temperature by 1–2 degrees. It is necessary to paint not only the outer edges of the battery, but the entire radiator; it is advisable to select heat-resistant paint.

There is only one drawback - a dark radiator spoils the appearance of the room, and you can only paint the old cast iron structure - painting new bimetal is not the case. The method has been tested and works, so don’t look for extreme things in it.

Wall mounting

2.1 Installation of such a device must be carried out in rooms where the temperature does not fall below 0°C; compliance with this recommendation is required so that

avoid water freezing

in the fan heater tubes, or use a liquid in the form of an antifreeze substance, for example (

propylene glycol

).

2.2 Before starting installation of the air heating device, you must carefully examine all parts for various defects. To connect the fan heater to the heating system, 3/4” pipes (male thread) are used.

2.3 The piping of this system, including

water fan heater

and its insertion into the heating system, installation of shut-off valves is a very simple process, but if you are not sure, then it is better to turn to specialists for the correct and high-quality installation of your system.

2.4 When using water as a coolant, the fan heater can operate effectively in an enclosed space. Antifreeze liquids can be used to install this equipment outside the building. Considering the availability and ease of installation, we can say that a water fan heater is the most effective option for heating a room.

3.1 The mounting console is supplied complete with the Volcano fan heater. To install the console to the fan heater, you need to cut holes in the top and bottom of the device as shown in Figure 1, and then install bushings into them. You need to slide the mounting console onto them. The next step is to tighten the screws (M10) into the lower and upper bushings, and also fix the position of the fan heater in relation to the console. When the device is in the desired position, you should then install the plugs on the holder.

- console (1 pc. type A or B)

- mounting holder (type A or B)

- M10 screws with washer and nut for installing holders (2 sets)

- M10 screw for attaching the console to the fan heater itself (2 pcs.)

- plugs (2 pcs.)

- mounting sleeves (1 pc.)

The maximum range of air flow in the vertical direction is 8-15 meters, depending on the size of the air heating device. The maximum range in the horizontal direction is 14-25 meters.

Types of heaters

A home craftsman who wants to acquire a homemade “hot water bottle” can choose from several options:

It is a container equipped with a tubular electric heater (TEH) and filled with oil.

The main element of the heating element is a spiral made of nichrome or other material with high electrical resistance, which begins to heat up when an electric current is passed through it. The spiral is placed in a copper tube filled with sand.

The oil removes heat from the heating element, distributes it over the surface of the body and, in addition, serves as a heat accumulator (after a power outage, the device continues to heat the surrounding air for some time).

Steam-drip

In its design, a vapor-drip heater is very similar to an oil heater, only water vapor is used as a medium that distributes heat. It is formed from a small amount of water, which is poured into the body.

This solution provides two significant advantages:

- When freezing, the vapor-drip heater will not burst, since water occupies only a small part of its volume.

- Steam is an extremely capacious heat accumulator. More precisely, not so much steam as the evaporation process: it is during the transition from liquid to gaseous state that water accumulates a large amount of thermal energy, which is returned when steam condenses on the walls of the heater.

Having transferred heat to the body of the device, the condensed steam in the form of water flows to the lower part, where the heating element is installed. The power of the heating element and the volume of water are selected in such a way that rupture of the heater by steam pressure is excluded.

Due to the fact that the device body is hermetically sealed, its internal walls do not rust due to high humidity.

A candle flame is known to emit not only light, but also some heat.

Only it usually evaporates to the ceiling in the form of convective air currents and is “smeared” over the entire area of the room.

Why not place a heat trap above the candle? We will tell you what it is in the next section.

Infrared (IR)

Any substance with a temperature different from absolute zero emits “thermal” electromagnetic waves, which are called infrared.

The intensity of this radiation is directly dependent on the temperature of the substance. Water and oil radiators also emit IR waves, but in very small quantities because their surface is relatively cold.

To turn a metal object into an IR emitter, it is enough to heat it to a red glow temperature. If you use special materials, for example, graphite, then quite noticeable “heat” waves can be achieved at relatively low temperatures.

Knowledge of these subtleties will help us make our own IR heater, which will give us heat directly, that is, without the participation of air as an intermediary.

Other types

Since electricity is not available everywhere, structures running on gas or solid fuel have the right to life. The latter include potbelly stoves.

How to install correctly?

In addition to high-quality assembly, it is necessary to pay attention to the operating conditions, which should include:

- Placement: lower part of the room;

- Dry room;

- The absence of nearby “knocking” units: emitting heat or cold (electrical equipment, air conditioning, open door with a draft).

Having figured out how to connect a thermostat with your own hands, you can start using it regularly. The main thing is that the power of the manufactured device is designed for the relay contacts. For example, with a maximum load of 30 Amps, the power should not exceed 6.6 kW.

Fan

The structure of this module determines the service life, the level of noise produced and the need for cleaning.

Axial

It looks like a propeller in the usual sense. It has 3-8 blades, which are made of plastic or metal. This is a simple and inexpensive mechanism, so it is most often found in household versions. Another advantage: the part does not require maintenance and it is enough to occasionally lubricate it with machine oil.

And everything would be fine, but such products make a loud noise. Therefore, turning them on at night is not very comfortable.

Radial

This element is typical for flat horizontal heaters. It looks like a wheel with frequent parallel blades around its circumference. Air is pumped due to centrifugal acceleration.

Their blown flow is smoother than that of axial ones. If the wheel is well balanced and the blades are lubricated with oil, then little noise is created.

Tangential

It has a cylindrical shape and 20-30 wings arranged in parallel. It is the most productive and quiet, but due to its design features it is not used in all devices. Among floor-standing models, this type is not found in columns. But in wall and ceiling versions, this type of accessory is not uncommon. The only downside is the need for regular cleaning.

Options for a homemade heating element

Before you start making a homemade fan heater, it is important to choose the right heating element for your device. Let's look at what options are suitable for these purposes.

The following can be used as such a heater:

- metal spiral;

- heating element;

- ceramic device.

You can make a spiral coiled from wire yourself without any problems. This limits the advantages of metal spirals as heaters. When the device operates for a long time, there is too little moisture and oxygen in the surrounding air.

The heating element is a metal pipe containing sand inside, which accumulates heat well and then gradually releases it to the air flow.

Heating elements do not dry the air and do not require oxygen, so they are much safer than coils. The heating element for the fan heater can be removed from an old household appliance, for example, from an electric stove.

A heating element - one of the heater options for a fan heater - may look different. It is considered an effective and safe heating element option

Ceramic heaters are complex and expensive elements, but extremely safe and effective. They are a complex of plates with an uneven surface, similar to a honeycomb.

Such elements do not heat up too much; the effect of their influence is achieved due to the large area of contact of the heaters with the air.

The likelihood of getting burned on a ceramic heater is much lower than when using a metal coil. But in home-made devices, it is spirals that are most often used, since they are simple and affordable.

Manufacturers rating

The leading manufacturers of water fan heaters are:

Teplomash. For more than 25 years, the manufacturer has been producing high-quality and durable heating equipment for Russia, the CIS and foreign countries, including the USA and Canada. The company's customers are commercial enterprises, large industrial facilities and individuals. The plant's arsenal includes a wide range of models, among which any client will find what he needs.

Ballu. The company produces compact water heaters for cottages, homes and offices. The devices are easy to use and have an original design. Heaters keep oxygen at the right level. Some models have a built-in thermostat that maintains the set mode automatically. The brand highlights an innovative approach to the development of manufactured equipment.

Tropic. The company has been specializing in universal heating technology since 1998 and is distinguished by an innovative approach. Compact devices from Tropic-line are suitable for heating production, warehouses, car washes and service stations. Some models are equipped with a thermostat that turns off when the set temperature is reached. It is very convenient for home use.

Brief overview of the main lines

| Model | Characteristics |

| Teplomash MW KEV-32M3.5W2 | Wall/ceiling water heater. Suitable for heating warehouses, industrial premises and retail facilities. Provides fast and uniform heating of air up to 28 degrees over a distance of 8 m. Electric motor power is 16.1 kW. Productivity – up to 1,700 m³/h. Connects to a single-phase power supply with a voltage of 220 V. The angle of rotation and tilt is adjustable thanks to the mounting bracket. The HL10 remote control allows for convenient control. |

| Teplomash MW KEV-100M5W2 | Wall/ceiling water heater. Suitable for heating large industrial premises and warehouses. It differs from the previous model in power - 50.8 kW - and heat distribution range, 28 m. Productivity - up to 6,500 m³/h. Has three operating modes. |

| Teplomash TW KEV-180T5.6W3 | One of the most powerful models in the line. Thermal power is 120 kW. Productivity – up to 7,600 m³/h. Connects to a three-phase network with a voltage of 380 V. Reinforced with a durable steel case with overheating protection. The temperature is adjustable. There are pipes for connecting to the water supply system. |

| Ballu BHP-W2-100-S | Universal heater with three operating modes. The thermal power of the device is 95 kW. Connects to a single-phase 220 V network. The advantages of the model are low noise level, a three-row copper-aluminum heat exchanger and increased energy efficiency. There is a Fan Coil cooling function. |

| Ballu BHP-W3-15-LN | Suitable for uniform heating of any room with a height of more than 3 m. The device body absorbs engine noise. Equipment power is 18.3 kW, productivity is 2,800 m³/h. Can be installed on walls or ceilings at any angle. |

| Tropic-line AERO 35D40 | Compact water fan heater with a power of 41.4 kW. Equipped with a double-row aluminum heat exchanger. Has a durable galvanized steel body. Capacity – 4,300 m3/h. |

| Tropic-line AERO 25D35 | The power of the device is 29.6 kW. Productivity – 2,400 m³/h. Heated by a double-row aluminum-copper heat exchanger. The body is made of galvanized steel. It is compact and economical in energy consumption. Warranty period – 3 years. |

Sources

- https://dnpruchei.ru/vodyanoy-teploventilyator-svoimi-rukami/

- https://ventilationpro.ru/montazh-i-skhemy-ventilyacii/slozhno-li-sdelat-vodyanojj-teploventilyator-svoimi-rukami.html

- https://millimetr.ru/obogrevateli-i-teplovye-zavesy/teploventilyatory/teploventilyatory-vodyanye/

- https://holodine.net/dopolnitelnoe-uteplenie/teplovoe-otopitelnoe-oborudovanie/teploventilyatory/vodyanoj-teploventilyator-svoimi-rukami/

- https://gscomplect.com/samodelnyy-vodyanoy-teploventilyator/

- https://diam-almaz.ru/article/preimushestva-vodyanyh-teploventilyatorov/

Popular models

Water fan heaters are made by many manufacturers. The products of the Teplomash company, which has developed a line of KEV models with a thermal power of 3–120 kW, are in greatest demand among Russian consumers.

Products from Polish manufacturers of heating equipment, represented by Volcano, are no less in demand on the Russian market.

They manufacture various equipment for heating rooms, including water fan heaters. The company supplies several series of fan heaters to Russia with different thermal outputs.

If we compare the models of water fan heaters from these companies, choosing those that are similar in thermal power, we will get the following results (see Table 1.)

Table 1. Technical characteristics of water fan heaters

| Water fan heater model | Teplomash KEV 25T3 W2 | Volcano V25 |

| Power | 3.1-7.6 kW | 3-20 kW |

| Installation in premises of: | 31-76 m2 | 80-200 m2 |

| Air flow | 600-1200 m3/h | 4000 3/h |

| Installation | wall | wall |

| Remote control | There is | There is |