The quality of insulation of a house or apartment largely depends on how the floor insulation was done. Today there are many different technologies and thermal insulation materials. This can significantly reduce heat loss and also helps maintain the temperature at the desired level. Now that heating is expensive, energy-saving technologies have become very relevant. An excellent solution is floor screed with foam. This is an affordable method of insulation, and the whole process can be seen in the video in our article.

Design and features of the screed

Concrete floors with polystyrene foam or any other insulation materials are called “floating” screeds. It literally “floats” on the insulation sheets. The need for floating screeds arises when there are sufficiently high temperature differences on the floor surface. These changes can lead to deformation of the base.

Unlike traditional foundation pouring technology, when installing a floating screed, a separating waterproofing layer is created between the foundation and the screed. Because of this, it is impossible to create a rigid structure.

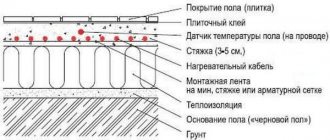

Such concrete floors are similar in design to a layer cake. So, the floor consists of several layers:

- Leveling coating as needed;

- Waterproofing layer;

- Screed;

- Sheet insulation or polystyrene foam;

- Reinforcing mesh;

- Screed.

The arrangement process begins with preparing the subfloor. Then waterproofing is laid, which will prevent the accumulation and exposure of moisture between the subfloor and the insulating material. Next, foam plastic of the required density and thickness is pricked, and the joints between the sheets are necessarily foamed. Then this entire structure must be covered with reinforcing mesh. At the last stage, the concrete is poured directly.

Introducing foam granules into the solution

Introducing foam granules into the solution

To create a concrete screed with foam plastic, slab material is not always used, because the surface can be given additional performance properties by introducing granules into the cement mortar. Foam granules will create an air layer, thereby ensuring good thermal insulation performance of the screed. This process is carried out in several stages.

Foam chips with cement

- A solution is prepared consisting of a small amount of water and the volume of cement required to obtain a mixture of creamy consistency. The mixing process becomes much faster and more efficient when using a drill with a suitable attachment.

- Continuing mixing, foam granules are added to the mixture. The ratio of ingredients varies: one part of concrete can contain three, four or even six parts of granular material.

The higher the percentage of granules in the solution, the better the thermal insulation properties of the screed. However, at the same time, it will be less durable, and when pressed it may even crumble, therefore, it will lose the lion’s share of its performance characteristics.

Foam chips are a material that solves the most pressing problems, being an ideal insulation material that is resistant to fires, severe fires and other types of damage, and at the same time economical and high quality

The choice of the desired proportion largely depends on how durable and rigid the finishing floor covering will be. For example, if you plan to use linoleum, then the volume of granules in the solution should be minimal, parquet - vice versa.

Video - Polystyrene foam granules. Mixing with cement

Features of foam

These materials are best suited as insulation. They can solve two problems at once. Polystyrene foam does not allow moisture and steam to pass through, and also provides sufficient thermal insulation.

The material has record low thermal conductivity. For example, a sheet 120 mm thick retains heat just as well as brick plaster 2 m thick. Polystyrene foam conducts heat three times less than expanded clay or wood. Polystyrene foam does not absorb ground moisture. Even a sheet measuring 1 square. m. is able to withstand high loads without collapsing.

Foam plastic, as insulation, goes well with water and electric underfloor heating systems. Not every material is suitable for use with heated floors - many can be deformed and destroyed under the influence of temperatures. Polystyrene foam does not collapse and withstands temperatures normally.

Also among the characteristics is excellent resistance to various biological or chemical factors. Foam flooring under the screed is very easy to install, and it will perform its functions for a very, very long time. The price for this material is reasonable and more than affordable.

Some advice from professionals

Despite the fact that creating a screed with foam plastic is not a very complicated process and even an amateur who carries out all the technological steps can cope with it, there are several nuances that need to be remembered:

- The optimal thickness of the foam used in screeding is considered to be 5 cm, but this rule applies to apartments located above the second floor. If the apartment is on the ground floor or we are talking about renovating a private house, then the material should be taken with a greater thickness, for example 10 cm;

- As a rule, the foam layer is located between the waterproofing material and the floor screed, that is, as if “under the cement.” However, sometimes it is laid on a screed under the finishing floor covering; this approach is possible when using wood as the last layer;

- When choosing a reinforcing mesh, you definitely shouldn’t save money, because it will serve as a frame that takes the main load on the floor and protects the heat-insulating layer from deformation.

Screed diagram with foam plastic

Taking into account the opinion of experts and following the stages of technology for arranging an insulated screed, you can make your home much more comfortable to live in. It is not for nothing that polystyrene foam is considered the optimal material for thermal insulation, because a 12 cm thick slab retains heat no worse than brickwork 2 meters thick. Foam boards are not afraid of high humidity, since they practically do not absorb water.

Speaking about the environmental friendliness and safety of polystyrene foam, it is worth noting that it is in boxes made of this material that donor organs are transported and food is packaged. In addition, it does not cause allergic reactions. There is no more effective material for insulating concrete floors yet, which explains the popularity of this design, which can last for many years, maintaining all its performance characteristics and providing a comfortable room temperature.

Choosing foam for the floor

Often, pressless self-extinguishing polystyrene foam - PSB-S - is used for insulation. These materials are most often used for finishing walls, floors and houses. This type of foam was invented in 1951 by specialists from the BASF Corporation. It is this that can be found in chopped form during most construction work.

Manufacturers suggest using materials with a density of 15 to 50 kg/cubic meter. m. For flooring in residential premises, it is recommended to use sheets with a density of at least 35. Professionals say that in most cases a density of 35 kg/cubic meter is sufficient. m. Some experts use materials with a density of 25.

Characteristics of PSB-S foam grades.

The choice must be made responsibly. Sometimes manufacturers deliberately deceive the buyer. For example, instead of a sheet with a density of 35, the buyer will receive material with a much lower density. Therefore, if you purchase a density of 35, then the result will be 25.

As for thickness, many recommend for these purposes a material with a thickness of 20 to 300 mm. But for floors, foam plastic is best suited, the thickness of which is from 40 to 50 cm. This option is both warmer and more reliable.

You can also use extruded foam, but it is used when the volume of the ceiling cannot be exceeded, and it is simply necessary to thermally insulate it.

general information

In construction, concrete is defined as an artificial stone that is obtained by forming and hardening a mixture of cement with water, crushed stone and sand. It has a number of advantages: good sound insulation, strength, long service life, frost resistance, but the thermal insulation characteristics of concrete are not the best. Buildings made from it are cold and require additional insulation. Foam plastic, which is a building material containing polymers, is excellent for this purpose. It is characterized by excellent moisture resistance and thermal insulation, which allows you to protect the facade of the building from the penetration of liquids, and the interior of the room from the cold.

Preparing the base

If the screed is to be installed on the ground, then the first step is to level the surface. If the soils are loose enough, they are compacted. Then the site is covered with a layer of gravel or crushed stone. The layer thickness must be at least 10 cm. This gravel bed must also be thoroughly compacted. Then sand is poured on top of the gravel. The layer is made of the same thickness, after which the sand is compacted.

If the screed will be done on a concrete floor, then the surface should be clean, free of debris and dust. Then, on this basis, all defects and various irregularities are repaired. You can use tile adhesive for this. If at the construction stage the slab is not laid level, all unevenness is leveled with sand or foam chips. Before proceeding to laying waterproofing materials, the entire surface must be carefully checked with a level. Then, a waterproofing layer is laid.

In order to obtain a flat floor as a result, markings are made on the surface of the walls. Using a water level, marks are made in each corner and on the walls along the boundaries of the height of the future floor. Next, using upholstery cord and a special strip, all the marks are connected into a line. At the pouring stage, this mark will prevent the screed height from going beyond the permissible limits.

Afterwards a layer of waterproofing is laid out. Builders call it a “trough.” It must be completely continuous and extend onto the walls. The edges should be higher than the intended screed level. If it is impossible to use this layer as a whole, then the joints are glued together with tape. Cement-sand mortar is poured onto the finished surface. The layer thickness should be about 40 mm. It is necessary for the floor screed to dry well, and then you can continue further work on the foam.

Solving the price-quality issue

When protecting a structure with your own hands, polystyrene foam and extruded polystyrene foam can be used together to maintain the quality of insulation and reduce the price.

In this case, the concrete floor pie will be:

- Reinforced concrete slabs or monolith;

- foam layer, approximately 50-100 mm;

- layer of extruded polystyrene foam, approximately 30-50 mm;

- layer of cement-sand mortar;

- flooring.

The thermal performance indicators of these materials are similar, so the thickness will increase slightly due to the addition of polystyrene foam. The top durable layer can withstand high loads and save on screed reinforcement.

Also read about floor insulation with polystyrene foam in a wooden house.

Laying foam and pouring screed

Foam boards can be laid on the mortar almost immediately after the floor is poured. The slabs are placed from the far wall and then directed towards the door. Lay the slab on the first layer in a checkerboard pattern. To fix the slab, you need to slowly move the foam towards the laid slabs. The joints of the plates must be taped with construction tape.

After the foam boards are fixed tightly enough, it’s time to move on to further operations. So, a metal reinforced mesh is laid on the slabs. It is recommended to choose one where the cell has dimensions of 10x10 cm. It is important to take into account that the mesh should in no way lie on the insulating material. This will significantly reduce its functionality. To lay the mesh, special subcortex is installed on the foam. After this you can proceed to filling. To evenly distribute the solution over the base, you will need to install beacons. It is important that the distance between them should not be greater than the length of the rule. Beacons are placed in random order.

Freshly prepared cement-sand mortar is poured onto the mesh and foam. You should start from the door, and then move further into the depths. When the mesh is completely hidden in the solution, the layer must be compacted. Then there are two possible options. The first is the alignment of the screed along the beacons, and the second involves the use of drywall profiles and alignment along them. The floor is poured to a thickness of 8 cm along with polystyrene foam.

After about 72 hours or three days it will be possible to walk on the floor. After 8 hours, you can safely continue with the rest of the repairs. But it will take approximately 28 days for the floor to completely harden. During this period, it is necessary to ensure that the floor does not dry out. The screed is periodically moistened.

Often, here and there, users complain that the screed becomes covered with cracks. This situation is quite real if the filling technology has been seriously compromised. One of the popular mistakes is ignoring expansion joints. This is relevant for large areas. Such seams are made 12 hours after the filling process. To do this, you need to use a special tool.

Penoplex trimming

Two types of connecting edges of Penoplex insulation panels

If you need to lay insulation in non-standard rooms, or cut communication holes in sheets, use several methods of cutting the material.

Use any sharp knife. This trimming ensures relatively even edges of the sheet.

Trimming using a jigsaw. The cutting edge is very uneven; construction foam is used to tie sheets cut in this way.

Using hot wire. In this way, you can quickly cut a thick slab; for cutting, a nichrome string is heated with electric current and communication holes are easily cut out.

As an additional insulation element, mineral wool (as an additional thermal layer), construction foam (to fill possible gaps and for sealing), and mounting nails are used.

Floating screed and typical mistakes

You can often find information that says that for floating screeds, a thickness of 30 mm or more is allowed. This is not true. Theoretical experts who spilled the solution once argue that a screed with foam plastic 30-40 mm thick is normal.

Practice shows that the most optimal thickness of floating screeds on soft bases should be at least 60 mm. Locally, a thickness of 45 to 50 mm can be allowed. However, this is only allowed in small areas.

If the layer is too thin, the surface will simply crack. It may not move underfoot, but if you knock on it, it begins to “make noise” and “breathe.” This is one of the typical mistakes. It is very difficult to repair such a foundation - it must be completely redone.

Also, one of the mistakes is the reinforced mesh pressed into the foam, which has practically no contact with the weight. Many people claim that the mesh must be laid as low as possible under the screed, and when walking on the floor it will rise. This is wrong.

Even if the mesh had been laid correctly, it still would not have saved the 30 mm thick screed. With such a thickness, it does not have enough load-bearing capacity. You also cannot do without a reinforced mesh, otherwise such a base will “move” under your feet.

How to choose polystyrene foam

So, you have decided to insulate your home with expanded polystyrene. Let's look at how to choose the right quality material

When purchasing insulation, pay attention to the following criteria:

- Appearance. The material must be free of flaking granules, uniform white in color, free from damage and splinters.

- Smell. The material must not have a chemical or other foreign odor.

- Structure. The granules should be well sintered, approximately the same size, the fault line when broken should pass both between the granules and directly inside them.

- Package. By purchasing material in unique labeled packaging with information about the manufacturer, regulatory document, its brand and recommendations for use, you can be sure that you are purchasing high-quality polystyrene foam.

- Information on the characteristics of expanded polystyrene. The packaging must indicate thermal and physical-mechanical characteristics, as well as sheet dimensions.

- Place of sale. The material must be purchased from legal sales outlets that have an indoor warehouse.

Creating waterproofing

Although foam plastic is resistant to moisture, it is still worth taking care to create a high-quality waterproofing layer. According to the standard, thick polyethylene film is used for this. It is laid with an overlap with a spacing of sheets of 5-10 centimeters and an approach to the walls of the room along the entire perimeter with a height of 7-10 centimeters.

The sections are glued with adhesive tape so that the layer does not deform before laying the next materials. Also, special mastic can be used as a waterproofing material. They simply coat the entire base with it.