The problem of maintaining heat in a house can be solved by laying traditional thermal insulation, for example, mineral wool, expanded polystyrene or foam. They have excellent insulating characteristics, but at the same time they have to put up with serious disadvantages, such as heavy dusting and the release of unsafe styrene or toluene vapors. As an option, you can insulate the floor with isolon; the material is quite new, but has already proven itself as a leader, without bad habits.

Izolon can be laid on both wooden and concrete floors

Types of isolon for thermal insulation of floors

There is nothing new in the technology of insulation with isolon. The material has been produced for quite a long time, so insulating the floor in a private house with isolon could have been done a decade and a half ago. Another thing is that insulation was used on a large scale mainly in industrial equipment, and only recently attracted everyone’s attention with its rather interesting characteristics.

The material is polyolefin foam with an additional reflective coating of aluminum foil. Due to this, it is easily recognizable by its characteristic surface pattern.

In order to get the desired effect from the installed thermal insulation, you need to imagine what kind of isolon structure is suitable for the floor in a wooden house as insulation.

The industry produces isolon with different structures:

- The classic version of foamed polyethylene filled with a pore-forming gas agent, this includes Izolon 100 and its foreign analogues;

- Foamed polyethylene, reinforced with catalyst additive. As a result, chemical bonds appear between individual pores—cells—that improve the durability and strength of the insulation. A typical representative is Izolon 300;

- Heavy and dense PET, which has undergone special treatment by sintering at elevated temperatures and irradiation. As a result, cells are crosslinked at the physical level, without the participation of reagents. The most striking representative of this type is Izolon 500.

Important! The greater the depth of additional processing of polyethylene foam, the higher its strength, the greater the number of air cells, and, accordingly, the lower the thermal conductivity coefficient.

Brands with a soft and viscous structure perfectly absorb noise and vibrations; Izolon 100 is suitable for soundproofing the floors and walls of a building. The more internal connections between the cells, the harder the material is, and the worse the sound insulation of the floor based on isolon works.

Izolon 300

In addition, thermal insulation based on foamed polyethylene is available with one-sided foil, with double-sided foil and also with a self-adhesive base on one side.

Izolon 300

This type of thermal insulation can be considered as a universal material, equally suitable for noise control and floor insulation. The three hundredth Izolon has good noise-absorbing characteristics, within 22-25 dB. The material is able to withstand prolonged heating and constant alternating load.

Laying isolon 300 on the floor guarantees effective protection against any vibrational low- and high-frequency noise and sounds. Isolon is especially good as insulation and sound insulation on concrete floor slabs. Available in rolls, in the form of a sheet with a thickness of 5 to 10 mm.

Material marking uses a numerical index, a sequence of four digits. The first two indicate the foaming ratio of the material, usually it is 30, which means an increase in the volume of polyethylene during processing by 30 times. The second pair of numbers indicates the thickness in millimeters.

Important! A good argument for using Izolon 300 as floor insulation in a wooden house is the fact that three hundredth polyethylene foam is the main material for heat and sound insulation of modern car bodies.

The cost of insulation directly depends on its thickness, on average the price is 1-3 dollars per meter.

Izolon 500

One of the most common and widely used insulation options for walls and floors of wooden houses, stone and brick buildings. In a situation where complete floor insulation is required, “Izolon 500” is subjected to special thermal and radiation treatment, as a result of which the insulation surface is quite rigid and durable.

Material characteristics:

- The compressive strength is 0.036 MPa, which means that you can walk on the insulation laid on the floor as if you were walking on EPS. Unlike penoplex, isolon retains fairly high elasticity and the ability to stretch without destruction by 130-180%;

- The thermal conductivity coefficient is only slightly higher than expanded polystyrene and mineral wool. It is 0.031 W/m*K versus 0.028 W/m*K for competitors;

- Izolon's flammability class is at the G2-G4 level.

Izolon 500 is somewhat inferior in noise insulation and sound absorption efficiency to its closest relatives. This figure is 20 dB versus 22 dB for the 300th brand and 26 dB for the 100th.

For wooden floors, insulation with a self-adhesive layer is best suited

The material is produced in the form of sheets with a thickness of 20 mm to 100 mm. Polyethylene foam can be easily cut and cut into any configuration for installation both on the screed and between load-bearing floor joists. The cost of Izolon 500 is 40% higher than that of the three hundredth brand.

The presence of full aluminum foil instead of a metallized lavsan coating, like penofol or polyisol, guarantees high thermal resistance when heated and at the same time provides almost complete, at the level of 97%, reflection of radiant heat.

What to choose for a specific situation

There is no universal recipe for using isolon. For example, for laminate flooring, it is recommended to use a 25 mm thick sheet for insulation and sound insulation. If the room is heated with infrared heaters, then insulation with a foil screen can be installed.

For interfloor ceilings, especially in modern houses where the floors are made of concrete slabs, it is recommended to use dense isolon 500 with a thickness of 8-10 mm. If you plan to install a heated floor in the room, then it is best to use double-sided foil-coated insulation material up to 10 mm thick.

Isolon may be inferior to mineral wool in terms of insulation efficiency, but there will definitely be no problems with it due to water, condensation or pathogenic microflora

A similar material can be used under classic concrete pouring or in a dry backfill screed. For insulation along joists or in two-layer versions using mineral wool, Izolon with a thickness of 20 mm and above is used.

Basic performance properties of isolon

To get a complete picture of the proposed thermal insulation material, read the description of its main performance properties given in the following table.

ISOLON - elastic thermal insulation, available in a wide range of densities and thicknesses

Table. Properties of isolon

| Properties of isolon | Description |

| Reflective effect | One of the main advantages of isolon is its high reflective effect, which contributes to an additional and very noticeable reduction in heat loss. |

| Compatibility with other materials | The properties of isolon allow it to be used both in combination with wooden structures and for insulating concrete floors. |

| Thickness | Compared to many other thermal insulation materials, isolon stands out favorably with its modest thickness, averaging 2-10 mm (sometimes up to 15 mm). Despite this, the material copes with the tasks assigned to it without any complaints. |

| Moisture permeability | The insulation does not absorb moisture, which makes it possible to count on its maximum long-term operation without reducing its thermal insulation characteristics. |

| Environmental friendliness | Isolon is not harmful to human health or the environment, which allows it to be used in premises for any purpose. |

| Other properties | Izolon is characterized by a long service life. The material is not subject to rotting. If necessary, izolon can be used in combination with other insulation materials. In addition to excellent thermal insulation characteristics, izolon has good noise absorption properties, which is an additional advantage. |

Which side should I place the isolon on the floor?

Experts advise in any case to carry out insulation with the foil surface directed towards the inside of the room. In this way, it is possible to block the leakage of radiant heat and at the same time strengthen the vapor barrier of the floor.

An exception may be a scheme with two-layer insulation of plank floors on wooden logs, provided that water heating is used in the house. For example, when laying the bottom layer of mineral wool, you can lay foil-coated polyethylene foam with aluminum foil to the mineral wool. This is done in order to block the seepage of supercooled water vapor through the layer of polyethylene foam insulation. The foil perfectly traps vapors, prevents moisture from condensing and forces it to escape through the air gap between the isolon and the mineral wool.

Let's sum it up

Insulating the floor of a log house is a very responsible job. The comfort of living in the house will depend on how correctly and efficiently it is done, so it is best to entrust it to specialists.

will help make your home warm and cozy. We have been providing finishing and insulation services for wooden houses for more than ten years and have accumulated vast experience in this area, which we want to share with you. We will be happy to provide our services to residents of Moscow and the region. Leave your requests, and we will send a specialist to you for free to inspect and draw up a preliminary estimate of the work.

On the Contact page you will find detailed information on how to contact us.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

How to attach isolon to the floor

It is clear that the method of fixing the insulation depends on the nature of the base. Foamed polyethylene, even with great thickness, remains a plastic material. Therefore, it is impossible to lay Izolon on the floor using point fastening with self-tapping screws or metal brackets. Under load, isolon can break at the fastening points.

It is best to lay the insulation on an adhesive basis, and the glue should not dry out. These can be viscous oil mixtures, silicones, but it is best to use self-adhesive polyethylene foam or double-sided construction tape with a metallized surface.

How to attach isolon to a wooden floor

A slightly different scheme is used when laying the panel on a wooden base. If you need to insulate a plywood floor, it is best to lay insulation without fixing it to the base. Only the joints between sheets or panels are sealed. This method is recommended for a wooden base under flooring in the form of linoleum or laminate.

When laying isolon on joists, fixation is performed using staples, glue and wooden slats.

Preparing the base

Unlike penoplex, polystyrene foam and even mineral wool, Izolon is quite sensitive to mechanical load, so the material can only be laid on a flat horizontal surface. Especially if the flooring is supposed to be laminate or, even worse, linoleum. In this case, the height difference in a one-meter area should not exceed 2-3 mm, and in principle there should be no bumps and depressions.

The concrete floor must be cleaned of loose “cakes”, dust and dirt must be removed. We carefully knock down the cones with a hammer and chisel, and clean off the remains with a grinder. Any depressions must be filled and smoothed to floor level. Next, it is advisable to wash the concrete and cover the floor with a primer. Not with paint, not with varnish, but with a primer for concrete.

Important! Additional treatment does not affect the insulation of concrete with isolon, but the concrete surface, even if covered with thermal insulation, will mercilessly collect dust. This is especially true for thin screeds.

When people walk on the floor, the Izospan cloth will work like an air pump, and all the dust will slowly move from the surface to the walls, and then get inside the room through the baseboards.

Completely worn-out floors need to be overhauled before insulation; a new screed may have to be made. It is impossible to lay Izolon on a surface full of cavities and cracks; under load, the glued panel will separate into separate sheets or strips.

If you plan to insulate the floor with isolon in a wooden house, then first you will need to remove the old floor covering, clean or sand off the paint, and treat the wood with a bioprotective solution. The floorboards are wedged together with wooden inserts, but the cracks cannot be completely sealed, otherwise the floor will rot under the insulation. After sanding, they can be selectively blown out with foam.

Plywood floors are prepared in the same way as concrete floors, you just need to additionally check that all the sheets lie on the base without “popping” or “bubbles”. Holes are drilled in problem areas, foam is blown in and immediately loaded with pressure weighing at least 10 kg.

Types of material

Izolon is a brand under whose brand various polymer sound and heat insulating materials are produced.

The product line includes:

- non-crosslinked polyethylene foam;

- chemically cross-linked polyethylene foam;

- cross-linked polyolefin foam;

- adhesive tapes;

- reflective heat insulators.

For the purposes of this article, we are most interested in the last position in the list. It is this material, as insulation, that will be discussed.

The heat insulator is presented in the following types:

- with one foil layer;

- with double-sided foil. This material is used to enhance thermal insulation characteristics;

- with a layer of foil on one side and an adhesive base on the other, this type is usually used on inclined and vertical surfaces.

Classification according to the composition and properties of the starting material:

- The insulation is based on ordinary polyethylene and has a porous closed structure. Its main disadvantages: low resistance to deformation and tendency to shrinkage.

- Thermal insulator based on cross-linked polyethylene. It is resistant to mechanical loads, has good strength, and regains its shape.

How to properly lay foil-coated isolon on a concrete floor under linoleum

Oddly enough, many problems arise with the alignment of the panel. Izolon is usually purchased and stored in rolls; when it comes to laying insulation, the sheet unrolled on the floor acquires a wavy surface. You shouldn’t even try to stick such a “wave” evenly; the isolon will need to be laid out on the back side on the floor, slightly stretched and pressed along the edges with a light weight. After a couple of days, the isolon will become almost flat.

Next, we install the insulation according to the following scheme:

- We lay a waterproofing film on the floor. The procedure is mandatory for basement rooms and rooms on the first floor. For apartments, waterproofing on concrete floors can be omitted and replaced with a primer;

- Using a tape measure, measure the distance between the opposite walls of the room and cut off the Izolon strip with a margin of 10-15 mm. Knowing the width of the insulation roll and the dimensions of the room, we cut the required number of strips. Each time before cutting a new panel, we measure the length along the floor from wall to wall;

- We lay insulation on the floor along the starting wall. We are trying to adjust it so that the side edge of the canvas fits as tightly as possible to the wall. We lay the rest on the floor end to end, but without gluing with tape. Typically, one of the Isolon strips will have to be cut to fit into the overall width of the room;

- Place double-sided tape on the floor along the wall and lay the first strip of insulation on it. After leveling, we attach the remaining edges of the panel to the floor in a similar way. We add the remaining strips of Izolon to those already laid and connect them with tape;

- We lay fiberboard sheets on top of the insulation.

Due to the low strength of Izolon, you should not walk on the insulation; even without shoes you can easily damage the material. Therefore, when carrying out insulation work, it is necessary to use several small sheets of fiberboard, on which they move around the room.

Next, we lay the wood-fiber board, and glue the sheets together at the joints with mounting tape. It is impossible to glue fiberboard directly onto Izolon or lay linoleum on insulation without an intermediate layer. If the thermal insulation thickness is more than 8 mm, then plywood will have to be used instead of fiberboard.

Izolon under fiberboard. Insulation technology

Before laying insulation under linoleum on a wooden floor, you should prepare all the required materials and tools.

To work you need:

- insulation isolon or penoplex;

- backing for linoleum made from natural materials;

- sheets of plywood or fiberboard;

- polyethylene film;

- scotch;

- materials for fastening (screws, glue);

- screwdriver;

- knife;

- scissors;

- jigsaw

After this, you can proceed directly to the insulation process:

- First you need to inspect the surface under the top layer of flooring. To do this, you need to remove it. If the boards are good, then insulation can be done from this level.

- The substrate is laid. It is better to make a choice in favor of natural materials, as they are safer. However, there are also disadvantages here: such substrates may quickly wear out and insects may appear. Also, when choosing a substrate, you need to take into account its thickness, so that it does not work out, so that because of it the floor level will rise so much that it will be impossible to open the door.

- To avoid problems in the future, Izolon or penoplex is laid on top. All existing sheet joints must be glued together with construction tape.

- The next layer is laid plywood sheets or fiberboard. Next, everything needs to be secured using self-tapping screws.

- If fiberboard is chosen, then waterproofing should be done to prevent its swelling. To do this, first a polyethylene film is laid, then fiberboard is laid on top, which must be primed, and the film is laid on top again (for more details: “How to lay fiberboard on the floor under linoleum correctly”).

How to lay isolon under OSB, plywood on a wooden floor

Thermal insulation procedures for plank and plywood floors are slightly different; in the first case, you will have to do thorough preparation to avoid damage to wooden parts, joists and supports. Thermal insulation of a plywood floor is somewhat simpler, but this reduces the height of the ceilings of the room.

We insulate the plank floor

The first step is to remove the floorboards. The boards are carefully unfastened, inspected, rejected or repaired.

Floorboards need to be removed

Only the joists will remain on the floor. If the beams are simply laid on a concrete base, then the procedure for laying Izolon is significantly simplified.

You will only need to lay insulation in the space between the beams. If the logs of the plank floor are raised above the ground on supports, then before laying the insulation, the beams will need to be hemmed with a plank on the cranial blocks, otherwise there will be nowhere to put the thermal insulation.

The general insulation scheme is as follows:

- We remove dust and dirt with a vacuum cleaner, treat the beams with an antiseptic impregnating solution and dry for at least two days;

- We cut Izolon sheets individually, according to the measured distance between the beams;

- If there is additional insulation with mineral wool under the Izolon layer, then first we lay a vapor barrier, then mineral wool, and only then sheets of polyethylene foam and always with staggered seams.

Izospan V or Izolon 100, 2-3 mm thick, can be laid on top of the beams. In both cases, the material is secured with a stapler and glued with tape. The thickness of the main insulating layer must be at least 50 mm.

Laying thermal insulation on a plywood base

First of all, you need to lay a beam on the plywood; it will act as a load-bearing frame that absorbs loads and protects the insulation from loads. The bars can be attached to plywood sheets with self-tapping screws using a vapor barrier film or without it, if the wooden base has been pre-treated with varnish.

The next stage is to lay Izolon between the bars. It is best to use sheets 20 mm thick; the thermal insulation is pushed between wooden guides and connected with tape.

A vapor barrier needs to be laid on top of Izolon. This solution reduces moisture absorption and deformation of the timber in the autumn-winter period. You can sew plywood or OSB on top.

How is thermal insulation performed with isolon?

Insulation of the floor in a house made of timber can be done in three ways. Below we will look at each option separately.

First way

Extruded polystyrene foam slabs are laid on the leveled ground, and the seams between the sheets are foamed with polyurethane foam.

A concrete screed is placed on top of the insulation. It is necessary that the concrete base is level, without cracks or other defects. If there are cracks, they must be filled with putty and then sanded.

After cleaning the surface from dust, rolls of isolon are placed on it (the protective film must first be removed from the material), which are fixed to the floor with glue or dowels. The sheets are glued together with foil tape.

Second way

The pre-leveled soil is covered with a waterproof membrane, then mineral wool slabs are placed on it. A waterproofing film is also laid on top. The lower hydromembrane protects the insulation from moisture coming from the ground, and the upper one does not allow it to enter the room.

Floor joists are installed on which boards are laid. The floor is insulated on top of them. Isolon is spread over the insulated surface and secured with a stapler or screwdriver. The joints are sealed with tape with a foil layer. Then the floor covering is laid.

Floor insulation along joists:

- Remove old flooring.

- Lay wooden logs on the rough base at a distance of 600-1000 mm from each other. Before laying, beams must undergo antiseptic treatment to prevent rotting.

- Between the lags, boards or plywood sheets are laid on special cranial bars.

- A layer of waterproofing is laid on the prepared wooden base, and then sheets of insulation are laid out so that the upper edge of the material is lower in height than the joist. Izolon itself has vapor barrier properties, so there is no need to lay a vapor barrier film on top.

- A finishing flooring is laid on top of the heat insulator. To arrange it, boards more than 3 cm thick or sheets of plywood are usually used, which are laid in a perpendicular direction to the beams.

- The finishing floor covering is laid on top of the insulated base.

How to lay Isolon under a floor screed

Very often, tiles, ceramics or any other floor coverings that require a sufficiently strong and rigid supporting surface are laid on an insulated concrete base. Isolon is an excellent type of insulation, but it is not strong enough, so it will need to be hidden under a screed.

Installation of thermal insulation under a concrete screed is carried out in the following way:

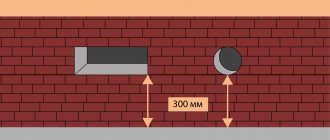

- We lay a waterproofing membrane on the subfloor, be sure to overlap the edges onto the walls to a height of at least 20 mm at the level of the final floor covering;

- We glue the joints between individual pieces of waterproofing twice, the first time with tape during installation, the second time with a primer, before laying the Isolon-based insulation;

- We roll out the roll into sheets and immediately lay the insulation on top of the waterproofing. Moreover, we change the laying direction to 90°. The edges of thermal insulation must also be laid on the walls with an allowance;

- Next, we install the reinforcing mesh; it will need to be raised on chips above the surface of the foil Izolon to a height of at least 20 mm;

- We install beacon chips on the insulation and fill the screed with a cement-sand mixture. The thickness of the screed must be at least 40 mm for insulation up to 10 mm thick. With a larger layer of thermal insulation, the layer is increased to 50 mm;

- After 4-5 hours, the chips are pulled out and the holes in the concrete are sealed.

The edge allowance for waterproofing and insulation is trimmed and fixed with a stapler. The gap is filled with foam and carefully trimmed. All that remains is to glue the tiles and nail the baseboards.

Warm floor on isolon, dry-laid under laminate

The procedure for installing thermal insulation

You are offered instructions for arranging thermal insulation, including isolon and additional insulation in the form of mineral wool (can be replaced with polystyrene foam/expanded polystyrene or other insulation of your choice).

If you wish, you can not arrange the second layer of the structure. For example, in the case of installing thermal insulation in an apartment in combination with a heated floor heating system, or while simultaneously using insulation as a substrate for laminate, you can limit yourself to using only isolon. The relevant instructions remain the same. For the rest, be guided by the features of the location and operation of the premises being equipped and your personal preferences.

Floors with heating pipes and ducts, the so-called “warm” floors, have become widespread in the construction of residential buildings. Foil-coated ISOLON is used as reflective insulation in the construction of such floors. Possible material options ISOLON 500, ISOLON 300 3-5 mm foil

First stage. Dismantling the coating

If you plan to insulate a floor that has already been in use, you will have to perform a number of preparatory measures, the first of which is the dismantling of the existing floor covering. We get rid of it and take the garbage out of the room.

The old floor should be removed

Second phase. Preparing the foundation

After getting rid of the old finishing, examine the condition of the underlying structure. Get rid of peeling and cracked screed down to the very base. If the finishing was laid on top of a wooden structure, replace the damaged elements with new ones or, if there is significant damage, install a new structure after first getting rid of the old one.

If necessary, strengthen the base, focusing on the characteristics of a particular situation. For example, if the floor of a balcony is being insulated, examine the condition of the parapet, make sure that the joints of the structural elements are intact, etc. Blow out any cracks found with foam. To eliminate individual defects in the concrete floor, use appropriate building mixtures, for example, cement-sand mortar. If significant differences in surface height are detected, it makes sense to pour a new screed with a thickness of about 30-40 mm.

floor screed

Floor leveling screed

In the case of insulation of a wooden structure, isolon, as a rule, is laid on top of the subfloor, presented in the form of a flooring made of material chosen by the owner (plywood, boards, etc.). This provision may vary, depending on the specifics of your specific situation. For example, it may be necessary to insulate the floor with isolon along the joists.

Laying isolon

Laying isolon on the subfloor

In this case, the following is done:

- beams are fixed on top of the subfloor in increments of up to 1 m;

- Boards or plywood panels are fixed between the joists. Wooden blocks are traditionally used for fastening;

- Isolon is laid on top of the boards/plywood and secured with tape.

Third stage. We arrange waterproofing

The necessary hydro- and vapor barrier of the floating floor is provided by a layer of IZOLON material. For hydro- and vapor barrier of a floating floor, the material ISOLON 500, ISOLON 300 4-8 mm is suitable

Cover the base with a suitable primer. Let the coating dry for the time recommended by the manufacturer of the selected primer. After this, we cover the surface with a simple plastic film or a special waterproofing membrane.

When laying waterproofing, we place the edges of the film at approximately 10-15 cm of the height of the walls and secure them with a stapler, nails or other suitable method. Pieces of film are laid with a 10-15 cm overlap. The joints are fixed with adhesive tape.

If desired, you can give preference to coating waterproofing. The work comes down to applying two layers of bitumen mastic, each 1-1.5 mm thick, onto a previously dust-free base. Before applying a new layer, wait a period of time as recommended by the manufacturer of the waterproofing compound.

waterproofing

Fourth stage. Laying the first thermal insulation layer

The necessary thermal insulation of the floor is provided by a layer of ISOLON. Material used: ISOLON 500, ISOLON 300 4-10 mm

If necessary, we adjust the rolled/sheet insulation material to size and lay the cut on top of the waterproofing layer. We fill the entire surface with pieces of isolon, making sure that there are no gaps at the joints, because because of them, the thermal insulation properties of the structure will deteriorate. We glue the joints directly with foil tape.

Foil tape

If laying a second layer of insulation is not provided, cover the isolon with waterproofing material and proceed with arranging the final finish in accordance with the chosen technology. When installing two-layer insulation, follow the steps described below.

Fifth stage. Installing logs

Laying lags

We cut the wooden beam pre-treated with antiseptic impregnation into the required number of elements along the length (for small rooms such as a balcony, it can be along the width) of the base and install it on top of the insulation. We place the outermost logs directly next to the walls. We place intermediate ones in 0.5-0.6 meter increments. We check the evenness of the installation of the logs using a level. After making sure that there are no differences, we fix the elements using dowels and self-tapping screws. There must be at least 4 fastenings for each lag. We screw in the outer fasteners, departing from the ends of the beam about 70 mm.

Sixth stage. Laying the second thermal insulation layer

Insulation is laid between the joists

We place the selected thermal insulation material in the space between the joists. The insulation must first be adjusted to the size of the formed cells and laid as tightly as possible, without gaps. If there are cracks, we get rid of them in a suitable way, for example, by blowing them out with foam.

Example of laying mineral wool

We lay a layer of waterproofing material on top of the mineral wool insulation. To fix the film to the joists, we use any suitable method. For example, protective material can be secured using a stapler.

Vapor barrier Izospan

If you decide to replace mineral wool with polystyrene foam or expanded polystyrene, you will not have to install an additional layer of waterproofing material.

expanded polystyrene

Seventh stage. Finishing the job

Finally, all we have to do is lay the finishing flooring on top of the joists. For its arrangement, boards with a thickness of 3 cm or sheet plywood are traditionally used. We lay the elements perpendicular to the joists and fix them with nails or self-tapping screws.

Finally, all we have to do is lay the finishing flooring on top of the joists.

Now we only need to arrange the selected finishing material - it will lie on a flat and insulated area without any problems.

| Type of coverage | Service life, years | Decorativeness | Ease of maintenance | Resistance to mechanical loads | Environmental friendliness | Maintainability |

| Parquet | 15-20 | average | average | not high | high | low |

| Linoleum | 3-7 | low | easily | not high | low | Can not be repaired |

| Tile | 5-15 | average | average | average | high | average |

| Carpet | 1-5 | low | hard | not high | low | Can not be repaired |

| Laminate | 3-7 | low | average | not high | low | Can not be repaired |

| Polymer | 10-30 | high | easily | high | high | high |

| Evaluation criterion | Laminate | Parquet | Cork materials | Solid floor board |

| Environmental Safety | Completely artificial material | Without varnish and glue, it is completely natural | Absolutely environmentally friendly and safe coating | Environmental friendliness at the highest level |

| Duration of operation | Traditionally up to 5-15 years | Up to 50 years, depending on the thickness of the base layer | At least 45-50 years old | Average – 35-40 years |

| Moisture resistance | Low | Low | Increases after waxing | Increases after impregnation with appropriate products |

| Thermal insulation indicators | Low | High | Very high | High |

| Difficulty of installation | Easy to set up | Requires professional skills | Can be installed independently, depending on the chosen installation method | Self-installation possible, basic skills required |

| Difficulty of care | The material is undemanding and easy to care for | Requires regular maintenance and careful use | Does not require special care. You can use a vacuum cleaner. The main thing is to avoid over-wetting the material. | Requires regular care |

Good luck!

Technological map for sound insulation of interfloor ceilings and floors using physically cross-linked polyethylene foam Isolon 500 as a sound insulation layer

isolon 500

How to put isolon under an electric heated floor

The first thing you will need to do is lay out the base for laying the thermal insulation. The subfloor can be poured in the form of a screed or assembled from a moisture-resistant plasterboard sheet. In any case, the surface should be as smooth and flat as possible.

Installation of isolon is carried out in the following order:

- We treat the base with a primer;

- We lay Izolon 100 without foil on the floor, carefully glue the joints, the edges should be laid on the walls with an allowance of 30 mm;

- The next layer is made of foil Isolon 500, it is best to lay two layers 10 mm thick with seams spaced apart;

- The sheets are laid out on the floor with the foil facing up and also taped with metallized tape;

- Depending on the design of the heated floor, it will be necessary to install fastenings for heating pipes or cables on the insulation surface. In this case, the floor is covered with screed under the tiles.

For wooden floors, before laying the heating elements, support bars are laid, and only after that the cable or plastic pipes for the coolant are installed. All that remains is to connect the heating, check and cover the floor with a tongue and groove board.

Foil backing for plywood. backing for plywood

The plywood underlay allows, even without a “warm floor” system, to significantly increase the floor temperature. The substrate cuts off the cold. Prevents cold from penetrating into the room.

Plywood backing

The main task that the underlay performs is to prevent cold from penetrating into the room through the floor. It acts as a separating barrier between cold and heat. The floor covering accumulates heat and remains warm. The reflective layer prevents heat from escaping into the subfloor and thus heat is not wasted. The use of a reflective substrate allows you to increase the room temperature by up to 30%.

The underlay performs a waterproofing function, protecting the floor from the penetration of moisture and steam into it, both from above and from below. The substrate also levels the surface. When using material more than 2 mm, the substrate performs an acoustic function, reducing the amount of noise and vibration.

one of the options is what an insulated floor looks like; the void is often filled with mineral wool

Laying features

The substrate can be laid with the reflective side in any direction. The reflective effect will remain in any case. It must be laid with a continuous carpet and have the same thickness over its entire area. The individual panels are joined end-to-end, and the seams must be taped.

Operating procedure

- Preparing the subfloor

- Laying the insulation underlay

- Leveling layer of fiberboard, chipboard, OSB (in case of using a thick substrate)

- Flooring

More installation options

Material

The substrate/insulation consists of NPE with a closed cell structure; it is this structure that gives a low thermal conductivity coefficient, good elasticity and zero moisture absorption. The reflective layer consists of a composite of aluminum and lavsan, this combination gives the material unique characteristics - it does not conduct electric current, and is very resistant to concrete and alkaline solutions. The material has increased mechanical strength. The low density of the substrate allows the material to act as sound insulation.

The most important characteristics of the underlay/floor insulation

- Low thermal conductivity coefficient (0.037 W/m°C)

- high reflectivity (up to 95%)

- Resistance to temperature changes (from – 60 to +110 C)

- Good hydro- and vapor barrier properties (0 mg/m.h.Pa)

- Good sound insulation properties (0.04-0.14)

- Resistance to deformation (1.08 - 2.54 MPa)

- Environmental Safety

You can order or find out more by calling the toll-free number: 8-800, which is listed in the contacts.

Recommendations and common mistakes

The first mistake appears due to the desire to save. Insulation based on Izolon is quite expensive, so even pieces and small pieces are used. In practice, this means the appearance of a large number of cold bridges at the joints. Pasted tape provides only a mechanical connection; it will not protect against heat loss. Therefore, insulation must be laid with a minimum number of panels.

The second mistake is related to the refusal to use vapor barrier and waterproofing. Membranes must be used without fail; Izolon is capable of absorbing moisture up to 0.01%. This is not much, but it is enough to lead to a sharp increase in the thermal conductivity of the material upon contact with water.

Basement insulation with isolon. Floor insulation from inside and outside

If during the operation of the house it becomes necessary to carry out work on insulating the floor, which is the ceiling of the basement, this does not mean that it is necessary to open the white finish. Treatment can be carried out both externally and internally, from the basement side.

Read more: ways to insulate basement floors.

Heating in the basement is one of the insulation options. But in severe cold weather, having a heating system may not be enough. In addition, unnecessary communications take up part of the usable space and interfere with the placement of racks for storing workpieces.

Insulation is one of the main elements in construction

The algorithm for insulating a basement in a wooden house is not much different from identical work in a brick or concrete building. The first step is choosing the material. When choosing insulation, first of all you need to pay attention to the thermal insulation properties of the material.

The next parameter when assessing the quality of floor insulation in the basement is hygroscopicity. Condensation concentrates at the boundaries of warm and cold rooms. This means that during installation the insulation must be protected with a vapor barrier membrane. The peculiarity of floor insulation from the basement side is that the vapor barrier is placed above the material, and not under it.

And finally, it is necessary to take into account the fire resistance of the selected insulation. Some materials are not recommended for use in residential premises due to their high flammability, but they are quite acceptable for thermal insulation of a basement. Let's look at how you can insulate a basement from the inside.