Unfortunately, the characteristics of mass-produced buildings, especially old housing stock, are not characterized by increased noise insulation characteristics. A standard reinforced concrete slab as a wall of a panel house, and gypsum-based analogues in brick buildings, have a high vibration transmission coefficient, including in the frequency range perceived by human hearing.

In other words, neighbors can perfectly hear not only loud music, the TV, but also ordinary speech. The external walls are also insufficiently soundproofed. Street noise easily penetrates into homes, annoying its inhabitants.

The situation suggests two ways out of the current situation. Move to another place, or isolate yourself from extraneous sounds. The first method is undoubtedly radical and it is not always possible to take such a step. But in the second case, you can change the situation in ways that are affordable and labor intensive. A wide selection of materials with soundproofing characteristics will help with this.

Expanded polystyrene foam

The main materials for the production of polystyrene foam are:

Table of physical and technical characteristics of polystyrene foam.

- polystyrene;

- polyethylene;

- polyvinyl chloride;

- polyurethane;

- polypropylene;

- phenolic, epoxy, urea, silicone resins.

Production involves heating, thermal expansion and molding of polystyrene granules. Due to the fact that the slabs consist of 90% air, this material is considered one of the best insulation materials. Expanded polystyrene boards have different thicknesses.

This material is very popular when insulating the facade or foundation of a house. One of the main positive aspects of polystyrene foam is its low price. In addition, polystyrene foam boards are lightweight, but at the same time have excellent strength and durability characteristics.

Installation is not difficult. Expanded polystyrene is a hygroscopic material. That is, even if exposure to moisture occurs, the foam will not lose its thermal insulation properties.

Scheme of building insulation with mineral wool and polystyrene foam.

But, along with all the advantages, polystyrene also has disadvantages. Speaking about which is better, polystyrene foam or mineral wool, it is necessary to note the advantage of mineral wool over polystyrene foam in sound insulation properties. Polystyrene foam does not have the same soundproofing properties as mineral wool. Foam plastic, compared to mineral wool, has a much lower vapor permeability coefficient. Foam plastic is deformed at t +60°C. Organic solvents destroy the material, meaning it is not resistant to such organic liquids. In construction, it is used only for insulating residential premises; industrial buildings and high-rise buildings (above 30 m) are not insulated with polystyrene. The biggest disadvantage of polystyrene foam is its susceptibility to flame. Expanded polystyrene boards, when ignited, go out on their own, unless, of course, the requirements of the standard are violated during production.

Why choose polystyrene foam for soundproofing your home?

To soundproof rooms, a wide range of products with the necessary qualities are used. If certain conditions are met, identical results can be achieved in all cases.

The answer to the question why polystyrene foam is so popular among both craftsmen and users will be its following qualities:

- affordable price. In comparison with other types of soundproofing materials, polystyrene foam is not only competitive, but is among the top materials in this area;

- ease of installation. The dimensions of the sheets allow you to form the required dimensions of the parts from which the soundproofing layer is mounted. Processing foam plastic is not difficult. It cuts easily with a knife;

- ecological and sanitary-hygienic cleanliness. There has been much debate over these characteristics, but studies have shown that the volatiles emitted are not in sufficient concentration to cause harm to human health. Exceptional cases of allergic reactions are caused by individual intolerance and are extremely rare. Fears about foam soundproofing are clearly overblown;

- long service life. The material is not susceptible to infection by mold, fungi and other microorganisms;

- stability of geometric dimensions. The coefficient of dynamic change in dimensions is extremely small and does not depend on humidity and non-critical temperature fluctuations;

- good sound insulation properties. The porous structure of the foam effectively dampens vibrations. Proper installation will reduce household noise to the required level.

The functional characteristics of polystyrene foam necessary for the implementation of a housing soundproofing project can be supplemented with a number of related qualities. Light weight makes transportation easy. It can be stored for a long time in unheated and utility rooms without compromising the quality of the product.

Among the disadvantages, there is a relatively low melting point of polystyrene foam, which actually has no practical significance:

- simple foam softens at 140° C;

- epoxy at 170° C;

- polyurethane foams soften at temperatures above 230° C.

Anti-foam is added to construction foam, which blocks the combustion process. The material itself does not support fire for more than 4 seconds. After which it goes out. But in the case of an open fire nearby, the process continues.

conclusions

Extruded polystyrene foam is considered a highly effective sound insulation material. Therefore, you can safely use it instead of expensive mineral slabs and other similar materials.

For information

Extruded polystyrene foam has a durable, integral microstructure that looks like closed cells filled with gas molecules. This is a chemical substance with strong intermolecular bonds, which are tens of times stronger than in polystyrene foam. Individual cells are impenetrable due to the fact that, unlike polystyrene foam, they do not have micropores, which prevents the penetration of water or gas from an adjacent cell

Sound insulation materials

Ceiling soundproofing diagram.

Insulation of internal walls is necessary primarily to ensure that peace and quiet reign in the house. Therefore, when working on sound insulation, choose:

- extruded polystyrene foam;

- products based on basalt fiber;

- drywall;

- steel panels;

- plasterboard membranes;

- polyurethane foam materials;

- polystyrene insulation boards created by extrusion;

- rigid boards made of extruded polystyrene foam. In their production, polystyrene of the highest strength is used.

To install foam panels, they must first be cut. And this is not easy, since the foam crumbles when cutting. But there are several options thanks to which you can easily cut a piece of the required shape without deforming it.

To complicate the design and improve the soundproofing of the room, plasterboard is added to the base of foam boards as a frame. This method can achieve very good results.

Typically, the problem of increased noise transmission in domestic premises arises after unsuccessful repairs (redevelopment). Therefore, for sound insulation, it is imperative to carry out measuring work to establish the noise level. Such calculations will be done better by a specialist - an acoustician.

Insulation methods

When insulating a private house, it is recommended to insulate the ceiling of the upper floor from the attic side

You can insulate the ceiling with polystyrene foam yourself from the outside and from the inside. The cold air side option provides greater efficiency and is scientifically correct. When insulating a private house, it is best to insulate the ceiling of the upper floor from the attic side.

This method is difficult if insulation is carried out in an apartment building. In this case, insulation from the inside is practically the only possible option. Insulation in the apartment is carried out not only to protect from the cold, but also from noisy neighbors.

If you insulate the ceiling from the inside with foam plastic, you can significantly reduce the noise level and create favorable conditions for relaxation.

As mentioned earlier, the combination of water and polystyrene foam is undesirable, therefore, when laying, two additional layers are provided: on the cold air side - waterproofing, and from the inside of the room - vapor barrier.

The procedure for carrying out work when insulating from the attic:

- clearing the surface of debris, dust and dirt;

- leveling if necessary;

- vapor barrier;

- laying logs (if they are needed);

- laying foam plastic (it is necessary to provide a small gap between the insulation boards or between the insulation and the joists; the foam expands slightly after laying);

- waterproofing;

- pouring the screed (for the method without logs) with laying wire reinforcement with a diameter of 3-4 mm;

- clean floor.

The last point is an optional step. You can leave a cement screed as a floor covering in the attic.

Thermal insulation of the ceiling in a private house from the inside is carried out in the following order:

- ceiling cleaning;

- installation of a frame (wooden or aluminum profile, this step is not necessary);

- securing foam sheets;

- vapor barrier;

- ceiling trim.

Characteristics of foam plastic

Polystyrene is one of the few that is not capable of releasing substances harmful to the human body. Expanded polystyrene is a type of plastic that, when burned, emits vapors identical to wood. Thanks to manufacturing technology, this material has the property of quickly fading. Water is not capable of destroying it, much less causing the proliferation of microorganisms. Therefore, polystyrene may come into contact with food. Expanded polystyrene can come into excellent contact with asphalt mixtures, fertilizers, paints, and soap.

It has been proven that the external environment does not destroy the composition of polystyrene foam. But water wears away stones. Therefore, excessively long exposure to ultraviolet radiation can significantly reduce its resistance to moisture and air currents. It would be best to cover the foam structure with a special material.

Thanks to the perfection of technology, a fire retardant was introduced into the composition of the foam. Due to this, he gained the ability to resist fire for 4 seconds. A sheet of polystyrene foam 3 cm thick can protect the room to a fairly good extent. If you increase the foam layer, you can achieve a very high level of noise absorption. The insulation is made from several sheets of expanded polystyrene, sealing the outer layer with a rigid facing material. This design can absorb almost 100% of noise.

Wall soundproofing diagram.

But it is worth remembering that polystyrene foam is afraid of contact with chemical compounds (ethyl alcohol, acetone, white spirit, gasoline, kerosene). This is explained, first of all, by the structural features of the foam, which contains cells filled with air.

When using penoplex and expanded polystyrene in construction, a number of positive aspects can be highlighted. These include:

ease and ease of processing; use without additional precautions; non-susceptibility to deformation.

Foam plastic - acoustic material or not?

Author: Nurumov R.B.

acoustic engineer, Ph.D. A difficult dispute with designers and builders at one of the facilities in Almaty about the material for filling the air gap in the structures of frame-sheathing partitions prompted me to the idea of conducting a mini-research on the topic - what materials do construction specialists offer to improve the original structures of frame-sheathing partitions and cladding with soundproofing ability. Strange as it may seem, the following materials are most often recommended - packaging boxes for eggs, cork coverings, “special” wallpaper, soundproofing paints (it turns out there are such), of course, fibrous materials, but the undisputed leader in the survey was polystyrene foam. Moreover, almost all respondents believed that polystyrene foam is an “excellent sound insulator.” That is, a large number of people have formed a stable stereotype about what kind of material, if necessary, can solve all the problems of insufficient sound insulation.

Let's try to figure out together the question - does polystyrene foam (or any other type of polystyrene foam) have soundproofing (or sound-absorbing) properties? Perhaps acoustic engineers, who professionally deal with the issues of sound insulation by enclosing structures and claim the absence of practically significant acoustic properties of polystyrene foam, are hopelessly behind, and polystyrene foam is really an “excellent sound insulator” and it works according to, perhaps, not yet discovered laws of building physics?

Firstly, it is immediately necessary to define the concept of “soundproofing material”. There are NO soundproofing materials , because... Sound insulation is a property of the structure, not the material. Those. we can talk about a certain level of soundproofing ability, for example, of a brick wall, but not of an individual brick or the clay from which it is made.

Secondly, porous materials (which, to some extent, include foam) are part of multilayer structures that have a certain level of sound insulation ability, as an intermediate elastic absorbing layer between the dense solid materials of the outer shells. The physical model of such multilayer structures is described as “mass – spring – mass”.

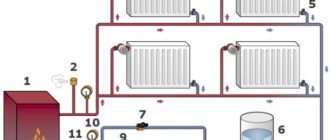

Figure 1 – Enclosing structure consisting of a concrete wall 125 mm thick and additional cladding (plaster) on an elastic layer (foam plastic) 35 mm thick.

Figure 2 – Deterioration of insulation from airborne noise by the enclosing structure shown in Fig. 1

A. The dash-dotted line is a reinforced concrete wall 125 mm thick without additional. facing (dB);

b. Solid line – a)+ additional. cladding – plaster on polystyrene foam (dB);

As shown by numerous acoustic tests carried out both in laboratory conditions and on-site, the sound insulation of fences that include polystyrene foam will not increase, and in most cases even decreases at certain frequencies (see Fig. 2). To deal with this seemingly paradox, let us again turn to the basics of building physics.

The fact is that the DETERIORATION in the SOUND INSULATING ABILITY of a multilayer structure consisting of a solid wall (or ceiling) and plasterboard or plaster cladding using an acoustically rigid material such as foam polystyrene (foam plastic) as an air gap filler is associated with resonance phenomena. Like any oscillatory system made according to the classical “mass – spring – mass” scheme, this design has a resonant frequency. It is around the resonant frequency that a sound insulation failure is observed (Fig. 2), which can reach a value of 10 15 dB!

What parameters (or characteristics) determine the resonant frequency of the enclosing structure? Let's look at some regulatory documents.

Fragment of the document “Manual for MGSN 2.04-97 “Design of sound insulation of enclosing structures of residential and public buildings”

...When filling a gap in a multilayer frame-sheathing enclosing structure with a porous material with a rigid skeleton (foam plastic, expanded polystyrene, fiberboard, etc.), the resonance frequency should be determined by the formula

Returning to Fig. 1, depending on the thickness of the foam and plaster, the resonant frequency of this structure is in the frequency range 200÷500 Hz (both according to the results of acoustic tests, see Fig. 2, and according to calculations using formula 1), i.e. falls into the normalized frequency range, or more precisely in the middle of the speech range. It is at this frequency that the “failure” of the soundproofing ability of this fence occurs.

Let’s deal with a similar, very common situation, using, again, construction physics to help (practice should always be based on theory, and theory should be confirmed by practice - dialectics of development).

First, let's define what sound absorption is and whether it differs (if at all) from sound insulation.

Sound absorption is the ability of a material to convert the sound energy of moving air molecules (kinetic energy) into thermal energy in the structure of the material.

One of the main characteristics of sound-absorbing materials is the sound absorption index (the ratio of the amount of energy absorbed by the material to the energy incident on the surface of the material), which is assessed by the average in the standardized frequency range 100-3150 Hz. This index can take a value from 0 to 1.

An effective sound-absorbing material - a specialized material for which sound absorption is the main function - must have an average sound absorption index of about 0.7. If a sound-absorbing material is used to fill the air gap in the structures of frame-sheathing partitions and cladding, then it must also have optimal elastic characteristics - the main one of which is the dynamic modulus of elasticity (or Young's modulus), the value of which should not exceed 1.5 MPa.

Thus, the higher the sound absorption index and the lower the dynamic modulus of elasticity, i.e. the more plastic the material, the higher its acoustic efficiency as an element of a multilayer sound-insulating enclosing structure.

A physical sign of a sound-absorbing material is its porosity, and, as a result, airflow. Those. molecules of air - the carrier of sound energy, entering a labyrinth of communicating pores and fibers of such a material, spend the energy of the sound wave on friction of the fibers against each other, on collisions with each other and with the walls of the labyrinth, on rocking the entire fibrous “skeleton” of the material.

An important conclusion follows from this : in order for a material to absorb sound energy well, it must be open-porous, i.e. air purged.

Expanded polystyrene is a windproof material, mainly with a closed cell structure (with air bubbles inside). A layer of foam plastic mounted on a rigid surface of a wall or ceiling has a low sound absorption coefficient. In addition, the dynamic modulus of elasticity of foam plastic, , is an order of magnitude greater than that of open-porous fibrous materials (see Table 1), which makes its use as an elastic layer, even in floating floor structures, also ineffective.

It is precisely because of the great importance of polystyrene foam that such a phenomenon is often observed, especially after installing a floating floor, as a “ringing” floor. This is due to insufficient “loading” of the elastic foam layer with the cement-sand screed. In order to obtain the 23 dB reduction in impact noise claimed by the foam plastic manufacturer using a floating floor structure, a c/p screed with a thickness of about 100 mm and a mass of at least 120 kg per square meter of the c/p screed must be “laid” on the foam plastic. And if we add to this size the thickness of the foam and the finishing floor covering, then we can “steal” at least 150 mm from ourselves in terms of the height of the room. I think that not everyone can do this, given that the average ceiling height of our apartments is 2.75 m (the range of apartment ceiling heights is in the range of 2.5 - 3.2 m. Moreover, to achieve this, and often more, The acoustic effect can be achieved using other materials, for example, multilayer fiberglass (see Fig. 3).

Figure 3 – Impact noise reduction levels under floating floor structures

Table 1 - Acoustic and elastic characteristics of some materials

| Type of material | Sound absorption index (at a frequency of 1000 Hz) | Dynamic modulus of elasticity , at a load of 2KPa, MPa |

| Polyethylene foam (10 mm) | 0,08 | 1,02 |

| Expanded polystyrene (foam) | 0,15 – 0,35 | 0,5 – 1,3 |

| Cork | 0,2 – 0,3 | 0,5 – 1,5 |

| Pile carpeting | 0,2 – 0,25 | 1,5 |

| Wood-fiber boards, soft | 0,4 – 0,8 | 1,4 |

| Mineral slabs made of basalt or glass fiber | 0,7 – 0,9 | 0,045 – 0,2 |

Ceilings, their sound insulation with penoplex

Soundproofing work requires an integrated approach, only then will everything be done efficiently and reliably.

- The surface of the ceiling is cleaned of plaster so that the working surface of the ceiling is better and of higher quality.

- To prevent mold and mildew from appearing over the years, the prepared ceiling should be treated with an antiseptic.

- Apply a layer of liquid waterproofing agent.

- The reinforcing mesh must be fixed to the ceiling surface.

- Using special glue, attach the penoplex to the fixed mesh.

- Next, cover everything with plasterboard, after which finishing work is carried out over the entire surface of the ceiling, depending on wishes and taste.

As you work, you should not forget about things like cracks on the surface of the ceiling, as well as where the most noise comes from. You may have to sew up not only the ceiling, but also the floor, and maybe the walls. Some surfaces may not provide the desired soundproofing effect, since extraneous sounds do not travel through them, and the work done will be unnecessary.

Experienced builders use penoplex foam with a specially shaped edge to work on heat and sound insulation. This feature of the material makes installation much easier, avoiding the formation of “cold bridges”, and sound insulation is more effective.

If you resort to the help of specialists who carry out work on insulation and soundproofing of the ceiling in 2 layers, then the price on average can be about 1800 rubles for a room up to 30m2. The cost of the work usually includes all necessary materials, delivery and loading and unloading operations.

Classic technologies

There are a lot of fairly simple and quite affordable ways to equip high-quality soundproofing of the ceiling in an apartment. Get rid of annoying screams, stomping and noise from upstairs neighbors once and for all. Equip your ceiling with reliable sound-absorbing materials, and you will be surprised how much calmer you will live in your apartment. For this purpose, you can use any of the many possible materials. Fortunately, today there are dozens (if not hundreds) of such options. Modern technologies in the field of construction and engineering offer us the latest substances and innovative techniques. However, the following traditional materials still remain the most popular.

Styrofoam

This is perhaps the most popular and widely used method, having been extremely popular for many years and receiving only positive reviews. Polyfoam is quite affordable and easy to use, in addition, it has excellent sound insulation properties. Watch the video carefully and you can get acquainted in more detail with the process of insulating the ceiling using polystyrene foam.

Mineral wool

This method is perhaps almost as popular as the technology based on the use of foam plastic. You can install this design yourself. The main advantage of mineral wool is its amazing soundproofing abilities and excellent noise absorption properties. This method has one drawback - the thickness of the entire structure, which includes insulation, will be quite significant (up to fifteen centimeters), which will significantly reduce the height of the ceiling. However, reviews of such installations are mostly positive, which is explained by the excellent quality of sound insulation.

In addition to these common classic materials, there are more modern and relevant methods for isolating sound waves. Let's talk about them in more detail.

Common Methods

The most relevant and effective method of sound insulation today is to cover the ceiling with plasterboard on top of special sound-absorbing modern materials.

Quite often there is also a method that is based on the installation of special acoustic suspension systems. In this case, polyurethane blocks, cork, basalt wool, etc. can act as soundproofing agents.

Do not forget that soundproofing a ceiling traditionally involves all sorts of accompanying work. One of the main tasks is the installation of an auxiliary structure. These can be the following types of systems:

- Tensile structures. In this case, special parts are attached directly to the surface, onto which fabric or other coverings are attached.

- Hemming systems. The metal frame is covered with sheets of plasterboard.

- Suspended structures. Soundproofing boards are suspended from the ceiling surface.

In all these cases, the use of special insulating substances is required (today you have a huge choice). All cracks, cracks, gaps and holes must be securely sealed with such materials. Only then will you be able to provide yourself with high-quality, effective and long-term sound insulation, which will give you a feeling of calm and confidence.

Don't tolerate annoying sounds coming from above. If you are familiar with this problem, you can ask your neighbors to install soundproofing flooring in their home. However, if you fail to come to an agreement with them, do not be discouraged. Having carried out competent, high-quality and reliable sound insulation of the ceiling, you will forget about this problem once and for all. And from now on, you will always be in a good mood and will be able to properly rest and relax when you return home from work in the evening.

Properties of penoplex and expanded polystyrene

From everything stated earlier, we can conclude that this material is a fairly valuable and useful building material that has a number of positive qualities.

To all of the above properties you can add a few more:

- low weight, due to which the use of such insulation can significantly reduce costs during construction work, while saving money on the use of any special equipment and greatly reducing installation time;

- the material is quite easy to process. The fact is that working with some materials necessarily involves the use of various equipment: protective overalls, respirators, gloves and goggles. Polystyrenes are odorless, do not emit dust during processing and do not cause skin irritation;

- polystyrenes are resistant to biological influences and chemical environments; they are highly resistant to various substances: sea water, cement, various saline solutions and many others. They are not digestible by animals or microorganisms, and do not create a breeding ground for fungi or bacteria;

- transportation, storage, cutting and installation can be carried out without the use of special protective equipment;

- when pressed the materials are very durable;

- expanded polystyrene is breathable;

- penoplex and polystyrene have excellent energy saving indicators, for example, polystyrene foam, which is only 3 cm thick, is equivalent to 64 cm of brickwork, 123 cm of concrete and 11.3 cm of wood;

- Penoplex has very low breathability.

Noise insulation with polystyrene foam: disadvantages of the method

To list the disadvantages of the penoplex soundproofing method, it is necessary to clarify the disadvantages of the material.

The main drawback of the master is considered to be the percentage of fire. In a fire, penoplex emits toxic smoke.

Penoplex is not used as a soundproofing material in wooden houses and buildings. The material cannot remove moisture from a wooden structure. Subsequently, a fungus appears on the tree; the tree does not “breathe.”

Penoplex sound insulation dampens impact noise worse. These are repair and restoration work, construction. A smaller percentage of sound suppression from neighbors is a minus.

And also a minus - it requires skill and time.

Penoplex is a unique building material that combines several functions:

- thermal insulation – saving on electricity, heating costs;

- sound insulation – comfortable rest after a working day;

- smooth surface - even when carrying out plastering and puttying work, there is no need to waste time on leveling.

The disadvantages of the material are minor; during installation, the craftsmen do not mention fire safety or do not emphasize that penoplex will make the room completely quiet.

The use of penoplex for sound insulation

The material is produced in slabs with a thickness of 2 to 10 cm. For sound insulation, penoplex 5 cm thick is used. Installation is carried out on the floor, walls, ceiling, but it is not at all necessary to cover all these surfaces to avoid unnecessary costs. First you need to find out where the source of the annoying noise is: from above, below or from neighbors through the wall.

Soundproofing walls and ceilings

The principle of laying penoplex on walls and ceilings is similar. First you need to prepare the surface: clean it of the old layer of plaster, level it, treat it with an antiseptic, and prime it. Then the slabs are glued end-to-end without gaps onto a smooth surface, secured in several places for strength with special dowels with wide heads, the joints are treated with polyurethane foam and leveled. Then a layer of plaster is applied to the walls or ceiling, after it has dried, they are puttied, primed and then a finishing coat is applied or wallpaper is glued.

Soundproofing the floor

First of all, the old floor covering is removed and the logs are dismantled. If glass wool insulation was laid underneath them, then that must also be removed. Before laying the penoplex, it is necessary to assemble a wooden frame for the stiffeners with cells according to the size of the slabs. Treat all cracks with polyurethane foam and seal with special tape. Then install the slabs, insulate all joints with foam and tape. The next stage is the installation of a base made of plywood or other material. And only after this the finishing floor covering is laid.

How to finish walls and ceilings yourself

In order for the room to be warm and quiet, it is necessary to make sound insulation with polystyrene foam 3-4 cm thick. If these are load-bearing walls facing the street, the thickness must be increased to 15 cm. Also, the silence in the room depends on the material of the walls - brick, concrete, slab.

To finish yourself with penoplex, you need to perform a series of steps in stages.

What you need

Before you start, you will need the following tools:

- construction knife and set of blades;

- container for adhesive solution and construction mixer;

- perforator;

- level;

- hammer.

Materials you need to purchase:

- dowel-nails;

- penoplex;

- adhesive mixture for laying tiles;

- primer;

- polyurethane foam;

- fasteners (fungi).

After the material is prepared and the tools are assembled, work begins.

Work progress

Installation of material on the ceiling. This is done if you need to protect the room from sounds from above. The material is attached to the ceiling using an adhesive solution.

- Clean the surface from dust, whitewash, and previous coating. Cover with primer.

- Using a mixer, mix the solution.

- Glue the slabs to the ceiling. To do this, glue is applied in a thin continuous layer to the entire surface of the penoplex.

- The slabs are secured on top with self-tapping screws. Each is secured at the corners with screws for strong fixation.

- After the adhesive solution has dried, the joints are sealed with foam.

- After 24 hours, excess foam is cut off. Apply a layer of plaster according to the rules.

- After drying, the surface is puttied.

- After the next layer has dried, the ceiling is coated with a primer and the finishing coat is applied.

The final coating is painting, wallpapering, and decorative plaster.

Work procedure for soundproofing walls:

- Preparatory process. The walls are cleaned (dust, cobwebs, old coatings) and primed.

- Mix the adhesive solution in a clean container according to the instructions on the package.

- Each slab is fixed to the wall using an adhesive solution and fasteners.

- After the glue has dried, the joints between the plates are filled with foam.

After the foam has hardened, the excess is cut off. The surface is covered with plaster and putty.

Finishing

After the adhesive solution and polyurethane foam have dried, the surface is plastered and puttied.

Plastering work consists of the following stages:

Each step is important for a strong and level surface.

The preparatory process includes preparing tools and purchasing the necessary materials:

- Plaster. You can purchase a gypsum-based mixture, but there are compositions for polystyrene foam.

- Deep penetration primer.

- Reinforcing fiberglass mesh.

- Spatulas with different blade widths.

- Metal corners.

You need to inspect the surface. If necessary, trim the foam to make the surface even.

The next stage is reinforcement.

Fixing the mesh is an important stage of work. If the reinforcement is done incorrectly, the plaster may crack and fall off. To attach the mesh, a layer of plaster mixture up to 3 mm thick will be applied to the penoplex. The mesh is applied to the wet layer in such a way that there are no folds and at the same time it is not too tight. After application, it must be pressed into the mixture. A spatula is used for this.

Direct application of plaster. For this you need a beacon profile. It is fixed to the solution. The distance between the beacons is 1 m. Plastering the surface requires skills and knowledge.

After the plaster layer has dried, the surface is treated with a primer. This is necessary for better adhesion to the surface.

The layer of putty applied should not exceed 2 mm. After drying, grouting and priming are carried out.

Wallpaper is glued onto such a surface, painted, tiled, liquid wallpaper and decorative plaster are applied.

How to avoid common mistakes and get the desired result

Polystyrene foam is an excellent material for insulating interior walls from extraneous sounds. However, you can also hear a negative opinion, to the point that no positive effect is observed or it is insignificant. Why do many craftsmen prefer to install polystyrene foam rather than mineral wool and similar materials? The answer is simple. Incorrect installation.

Indeed, basic errors when forming a soundproofing layer will not give the expected effect. When carrying out work, you must adhere to the main rule - do not leave cracks or gaps, ensuring a tight fit to the base and to individual parts of the structure.

Very often, plaster is made over polystyrene foam. It is very convenient, practical and inexpensive. In order for the layer of building mixture to be firmly held and have the necessary strength characteristics, a reinforcing mesh is first fixed onto the prepared area. Most often this is a synthetic material, but you can also use a metal analogue made from small-section wire or a manufactured stamping method.

External sound insulation is carried out according to the following algorithm:

- Careful preparation of the base and elimination of irregularities.

- Installation of ridge and drip cornices.

- Applying primer to the surface.

- Installation of polystyrene foam using adhesive.

- Application of dowels.

- Elimination of joints.

- Installation of a vapor barrier film - it will help to better dampen extraneous sounds.

- Finishing the facade with the first layer of plaster with mesh.

- Finish wall cladding.

The differences with indoor work are minor. But you still have to work. Therefore, in the absence of sufficient experience, it is worth ordering the services of specialists.

Penoplex sound insulation

This material is known to many as an effective heat insulator, but it also has other advantages, one of which is sound insulation.

Penoplex is considered the most popular in the construction market; it is made from extruded polystyrene. The strong walls of penoplex with insulated cells, filled with air, have an arbitrary shape, and this structural feature provides high strength. In the USA, penoplex foam began to be used as a building material more than 50 years ago. Penoplex has many positive characteristics, such as:

- Low water absorption

- Minimum thermal conductivity

- Low vapor permeability

- Flexural and compressive strength

- High level of sound insulation

It’s worth talking about this quality of penoplex in more detail. Given this characteristic of the material, it can be used to insulate any surface in the room. It can be called the most advantageous soundproofing material, since to work with it you do not need to have special tools or extensive work experience; all installation work can be easily done with your own hands.

When working with penoplex, it is necessary to lay it correctly, without leaving gaps, and foam the joints well. Even after years, the soundproofing qualities of the material do not decrease; for a maximum time it will also retain its other advantages. Penoplex will not rot, so the walls, floors or ceilings will be reliably protected from destruction.

Reviews of sound insulation made of polystyrene foam

Buyers who have tried Penoplex in action note the light weight but large volume of the panels. The mats take up a lot of space in the room, but are easy to cut and, if desired, quickly transported to the next room. If soundproofing is installed correctly, your home can be finished in one day. The work does not require special tools or special skills; all steps can be easily completed with your own hands.

According to reviews of Penoplex sound insulation, the material does an excellent job of thermal insulation of floors. It is a good layer between other layers, together with them forming an impeccable coating that completely retains heat in the house. Carpets, runners, and other coverings are no longer needed, since the floors are warm and your feet do not freeze when in contact with them.

Types of foam

The construction industry offers a significant range of products in this class. Foam grades reflect its origin and characteristics. There are two types of material. Pressed and non-pressed. It is not difficult to distinguish from. The first is a single porous body, and the second is produced by sintering ready-made granules, which is clearly visible visually. For sound insulation, preference is given to non-pressed soft foam. It effectively dampens vibrations and is easy to process.

In construction, the most popular types are the following, which indicate the following foam markings:

- PSB. Pressless foam plastic of several modifications. The last digit in the abbreviation means the strength class. For example, PSB-S-50 is the most durable material in this category. Used where mechanical strength is required. PSB-S-25 is a universal material widely used in construction for many purposes. The softest product is PSB-S-15. Due to excessive fragility and fragility, it is rarely used. It can become attractive solely because of its low price. If the letter F appears in the name, this means that the product can be used in facade work.

- PPU. Foamed mass based on polyurethane. One of the modifications is foam rubber. The material is elastic and very convenient to use, but its cost is quite high. For this reason it is used in limited quantities.

- PPE. The polyethylene base provides elasticity and wear resistance. This marking can be found in hardware stores on many products, but is rarely used for sound insulation.

- PVC. Polyvinyl chloride foam. It is distinguished by the absence of substances harmful to health. The environmental friendliness of the material, which manifests itself under normal operating conditions, is attractive, but danger arises during combustion. Exceeding the critical temperature leads to the destruction of structural bonds and the release of extremely dangerous hydrogen chloride, which, in combination with the liquid, begins to release hydrochloric acid. For the respiratory tract, the smoke emitted by PVC foam is very dangerous.

The most popular and widespread type of polystyrene foam is considered to be the material labeled PSB. Excellent performance combined with an affordable price make it attractive in all respects.

Advantages

There are a large number of advantages of the material in question. Consumers value it primarily because it repels water perfectly. This is one of its important positive characteristics. The value of this property is determined by the fact that such materials are very often used in conditions characterized by excessive humidity and temperature fluctuations, which lead to condensation.

It is important to consider that it is necessary to hide open sections of the material, since they differ in their ability to absorb moisture from closed cells. The following qualities should be highlighted as the main advantages:

- Thermal conductivity. This material is characterized by a low degree of thermal conductivity. Thanks to this property, combined with the ability to reject moisture, penoplex can be used on any object. It can be mounted not only on walls, but also in attics and basements.

- Low vapor permeability. Penoplex retains steam remarkably well, which is why it is compared to roofing felt. The material in question can be used for a long time. When used, it will withstand various external aggressive factors. Plates can survive a huge number of freezing and thawing cycles, while maintaining their original properties. Many manufacturers say that penoplex can be used for about 50 years. If this material is properly fastened, the service life can even be extended.

- Strength and other properties. The soundproofing material penoplex is characterized by good strength. This indicates that it is able to withstand intense loads and high pressure. This quality is due to the fact that the penoplex base contains small bubbles that prevent its compression. The use of slabs is characterized by simplicity. If necessary, they can be easily cut, and the material will not crumble. To carry out this procedure, you can use a regular knife.

Using penoplex as sound insulation can significantly reduce the amount of noise penetrating into the room. Consumers of this material claim that after this sound insulation, the room became much quieter and warmer. The cost of the material is affordable, which is an additional advantage. It shows itself remarkably in residential areas in soundproofing the ceiling. A definite advantage is that to work with penoplex it is not necessary to have certain skills in this area. Therefore, you can do sound insulation yourself, even with a suspended ceiling.

The soundproofing properties of the material have only positive reviews.

Is extruded polystyrene foam suitable for sound insulation?

Probably, the question of whether it is possible to use extruded polystyrene foam for sound insulation has visited many people. Looking at this finely porous material, it seems that it absorbs sound perfectly. On the other hand, it is still a heat insulator, not a sound insulator; it is not intended to dampen noise. However, extruded polystyrene foam has some sound-absorbing abilities, and those who have used it to insulate walls and especially floors in an apartment note that the room has become quieter. The truth lies somewhere in the middle - if certain rules are followed, extruded polystyrene foam can serve as sound insulation, but the additional use of special sound absorbers is still more effective. And one more important point: if anyone doubts, a vapor barrier is needed when laying penoplex.

Features of decorative finishing for soundproofing with foam plastic

Many questions arise when finishing a soundproofed wall. For example, is it possible to glue wallpaper onto foam plastic? How to install drywall? Will the tiles stick securely if the tiles are glued to foam plastic? Any job can be done, but whether the result will satisfy you is a big question. To successfully complete finishing work, you need to understand the principle of working with foam plastic.

The material is quite soft and subject to deformation under physical influence, even minor. Having created a reinforcing layer on the surface, you can use absolutely any finishing material.

If you need to glue tiles in a room, then doing it directly onto the foam is impractical. In this case, it would be wise to first make a layer of plaster or install drywall, and then glue the tiles to your health; they will last as long as a concrete or brick wall. The same principle should be applied when wallpapering.

Moreover, the glue for this type of work is water-soluble and you will have to wait a long time for it to dry, since it cannot be absorbed into the synthetic mass. First the reinforcing, leveling compound, and then the wallpaper. If all operations are done correctly, the performance characteristics of the surface will not be affected, but the noise in the apartment will be reduced.

People, as a rule, do not think too often about sound insulation when building a house.

And indeed, when carrying out such complex processes, there is already something to pay attention to

A floor that is protected from noise loads by insulating with penoplex

But if a built house or a lived-in apartment is poorly protected from extraneous noise, then the problem of sound insulation will come first. Agree, it is unlikely that anyone will enjoy living in a house where sounds from the street or neighbors are constantly heard. We also recommend installing siding with insulation.

Working with foam plastic

Now let's talk about how to soundproof walls. To create sound insulation with foam plastic, special boards are used. These plates are made using 2 lead plates with a sheet of polystyrene foam sandwiched between them. It is worth noting that it cannot be an independent material for removing a noise source. Its effectiveness is manifested only in the vicinity of additional components.

In practice, closed cell foam is widely used. It is very good for soundproofing rooms with increased noise penetration. For example, this product is used in the construction of walls and partitions of motor ships. Closed foam with the addition of vinyl film becomes an ultra-resistant solution in the fight against noise. This material is used to lay the structures of ventilation and heating systems. Due to the high resistance of vinyl foam to negative natural phenomena, it is used for external insulation of walls. This innovative product is suitable for isolating reflected noise. For example, vinyl foam layers are widely used to insulate air conditioning systems and to absorb engine work in cars. Vinyl foam is good in shooting range structures because it cleans well and dries quickly.

Polystyrene foam is divided into various types of grades. The most common of them are:

Floor soundproofing diagram.

- PSB-S-50. Differs in versatility and hardness. It is used for internal and external sound insulation, for sound absorption of roofs and floors. It is used to cover the floors of refrigeration equipment and to insulate the underground in auto repair shops and garages. Widely used as coatings to protect subfloors from freezing.

- PSB-S-35. It is characterized by low cost. Soundproofing foam of this brand is applicable for insulating walls, foundations, and ceilings. Used in the manufacture of reinforced concrete panels, insulation of underground communications, to prevent soil shrinkage.

- PSB-S-25. This type of polystyrene foam boards is mainly used for insulation in domestic conditions.

- PSB-S-25F. The basis is the insulation of facades.

The foam is attached using various compounds and tools. These include:

- glue;

- special mastic;

- cement mortar;

- metal elements for installation.

Alternatively, the insulating structure can be installed directly on the wall: indoors or outdoors.

It is imperative that after the foam structure has been installed, it is necessary to begin facing work. To do this, some kind of base is laid on top of the polystyrene foam sheets, and then the surface is plastered. Insulation works can be covered with brickwork, tiles or other finishing materials.

The best option for sound absorption are PSB-S slabs, which are installed on the inner surface of the walls.

This manipulation will help achieve increased acoustic comfort and thermal insulation.

Types of PSB boards by size

Before purchasing the material, you need to decide on the dimensions of the PSB boards that you will need. There are several standard sizes of such plates:

- 1000×1000 mm (1×1 m)

- 1000×500 mm (1×0.5 m)

- 2000×1000 mm (2×1 m)

Also, all slabs come in different thicknesses:

- 10 mm;

- 20 mm;

- 30mm;

- 40 mm;

- 50 mm;

- 100 mm.

For ease of installation, craftsmen most often use PSB boards with a size of 1000×1000 mm and a thickness of 50 mm.

Types of polystyrene foam sound insulation

Is it possible to soundproof with polystyrene foam? Penoplex and expanded polystyrene are the most popular soundproofing materials on the construction market. Both products are produced using polystyrene foam.

Penoplex is a derivative of expanded polystyrene. It makes excellent sound insulation.

Expanded polystyrene is an environmentally friendly, harmless, heat-resistant, soundproof material. Its quality characteristics have been known for a long time and are in great demand. This material is easy to use and economical.

Floor soundproofing diagram.

Another type of foam is polyurethane foam. The cells of this foam are of arbitrary shape with fairly strong walls. In this regard, very high strength of the foam is achieved. This type is flexible and has excellent thermal insulation. One of the disadvantages is destruction from penetrating ultraviolet radiation.

The next type of foam is polyethylene foam. This type is characterized by a high level of flexibility, increased strength and elasticity. Outwardly it looks like a translucent panel up to 2 cm thick. It is not used for the installation of soundproofing structures, but is good for packaging materials.

Installation features

At the installation stage, the future characteristics of the soundproofing layer are laid down. The installation method is a key factor. Sound insulation will be satisfactory if there is an understanding of the processes taking place. This will allow you to most effectively protect your home from extraneous sounds and avoid mistakes.

To do this, it is necessary to consider all installation methods with an assessment of the final result:

- Fixation with glue. Convenient, economical and most effective installation method. If foam plastic is glued to concrete, brick, plaster, then the most complete fit is ensured. Vibrations in this case are damped well. Do not use adhesives

- Installation of foam plastic with fasteners. The method is good for external use. Often used for insulation and soundproofing of walls.

Inserting into the cells of the sheathing. A large number of individual elements creates risks for complete shelter. It is difficult to avoid gaps and cracks. Rigid metal profiles that transmit vibrations well also do not contribute to good sound insulation.

Methods of insulation and fastening

From a scientific point of view, insulating the ceiling with polystyrene foam from the outside is the most correct and effective way of thermal insulation . If there is such a possibility, the external type of installation . But in apartment buildings, where internal insulation is the only possible option, this method is used. Its advantage is also that it simultaneously provides good sound insulation .

Sheets of material can be secured in two ways:

- special adhesives;

- special umbrella nails.

On the attic side there is no need for fixing with glue. The quality of fastening is especially important for internal insulation. The glue is not applied to the entire surface of the foam; you can only cover the perimeter and a cent of this will be enough. When using adhesive mixtures on water, the thickness of the adhesive layer is added to the thickness of the foam.

External insulation - work order

Foam boards do not have sufficient moisture resistance , therefore, when laying external insulation, additional layers are required:

- on the outside it is a layer of waterproofing;

- on the inside (from the room side) there is a layer of vapor barrier.

How to insulate a ceiling with foam plastic from the outside:

- Surface preparation: removal of dust, debris, leveling.

- Laying a vapor barrier - it is secured using a stapler.

- For installation using lags, logs are installed; for installation without lags, pouring is done using wire reinforcement.

- Laying foam.

- Installation of the waterproofing layer - it must be laid over the walls.

- Laying the floor and trimming the waterproofing film around the edges. The finished floor is laid on top of the screed only in the case of a residential attic, otherwise a screed is sufficient.

The foam is cut so that it fits tightly between the beams, and the gaps between the beams and the insulation must be filled with polyurethane foam. The insulation with the beams must form a common plane. If the thickness of the beams is not enough, it is sharpened with wooden planks. A small gap is left between the insulation and the joists to ensure ventilation.

Technology of internal ceiling insulation with foam plastic

A significant disadvantage of internal thermal insulation for a city apartment is that foam boards and fine finishing take away precious centimeters. Calculating the final ceiling height requires the correct choice of foam thickness and fastening method.

When using material 5 cm and lathing for finishing with clapboard, for example, a total of about 8-10 cm of room height . If suspended models of plasterboard ceilings are used, even more height is hidden.

How to insulate a ceiling with foam plastic from the inside:

- Surface preparation: cleaning from finishing and dust. Check the surface using a level. If there are noticeable differences, the surface is puttied. For very large irregularities, plastering and grouting are required. If there are irregularities less than 0.5 cm, it is enough to just seal them and then sand them with sandpaper.

- Treating the surface with an antiseptic primer.

- Dry the surface.

- Foam boards are specially roughened using scrapers, sandpaper, and a special knife. A layer of adhesive solution is applied evenly over the entire surface of the sheet. Start installing the sheets from the corner, pressing them to the surface and supporting them for 1-2 minutes. Laying is done specifically with each subsequent row offset by half a slab.

- After gluing and drying, holes are drilled in the center and corners of the sheets, umbrella dowels are inserted into them and hammered with metal pins.

- If it is decided to lay polystyrene foam on the frame, after leveling the surface, a sheathing made of wood or an aluminum profile is installed, then laying foam plastic and laying a vapor barrier.

- Installation of a finished ceiling.

When insulating from the inside, waterproofing is not required. If the finished ceiling is mounted on a lathing - these are plastic panels, plasterboard ceilings, lining, no additional foam fastening is required.

In rooms with high air temperatures, additionally foil and foam foil insulation in rolls can be laid on the foam plastic, while the finishing ceiling is made only on the frame .