In private houses there are always several utility or technical rooms, where the requirements for the interior are low. But you still need to heat them, and in order not to spend money on buying modern radiators, you can install a steel register welded from pipes there. And, although everyone has seen such simple heating devices with their own eyes, not everyone knows their structure. This material is to help those homeowners who want to independently manufacture, install and connect heating registers to their system.

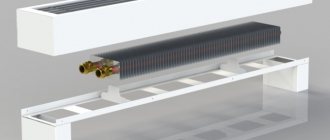

Construction of heating registers

Despite the fact that such heaters are considered outdated and do not have a very attractive appearance, they continue to be widely used in a variety of areas, for example:

- for heating production premises of industrial enterprises;

- as an autonomous heater in garages;

- as a water heating element built into a brick oven.

Note. A stove register made of smooth heating pipes is calculated and manufactured depending on the power and design of the stove.

By design, heating devices are divided into 2 types: sectional and in the form of a coil. In the first case, the role of 1 section is played by each horizontal pipe, the flow of coolant through them is ensured by vertical jumpers. They are made of smaller diameter pipes in order to create artificial resistance to flow and increase heat transfer from each section. The pipes from which the sectional heating register is made are plugged at the ends, and the coolant is supplied according to the “top to bottom” scheme.

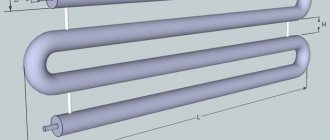

The design of the heater in the form of a coil is clear from its name. Here the diameters do not narrow; water flows freely through the entire device, changing direction several times. The heat transfer of this register is lower than that of a sectional one, but the hydraulic resistance is less and it is somewhat simpler to manufacture.

Advice. It is preferable to make sectional heaters for utility rooms or garages, where uniform heating and comfortable air temperature are important. It is better to install coils as standby heaters at the very end of a two-pipe system. They work great there because of their low resistance.

Heating registers from smooth pipes of round and rectangular cross-section are welded. However, the generally accepted design is ordinary round pipes made of low-carbon steel such as St3, St10 and even St0. If the battery is intended to work with a steam system, then St20 steel is used. It is not recommended to make sections with a rectangular cross-section; they are less washed by the convective air flow, which means they will give off less heat. For garage heating, autonomous registers are made, filled with antifreeze or transformer oil, and an electric heating element is built into the lower section at the end.

Surface preparation

Before electric welding pipes, you need to prepare them for the joining process. Surface preparation sequence:

- Pipes must comply with all parameters specified in the project. They should have uniform wall thickness along their entire length, and the cut should be round.

- The pipe is cut at an angle of 90° and cleaned to a shine at a distance of 1 cm from the cut.

- Then the cut is degreased. To do this, remove all oil stains and clean off rust. If there is paint, it is removed.

If necessary, the end is further processed. The edge of the pipe cut should have an opening angle of 65° with a blunting value of up to 0.2 cm. Such a cut will help to qualitatively connect the products.

Advantages and disadvantages

Before you start making heating registers, you need to evaluate all the pros and cons of these heaters, so that your expectations are not disappointed later. So, first about the advantages:

- low cost and ease of manufacture;

- low hydraulic resistance: thanks to this, the heater can be used in the “tail” of any system;

- reliability and durability: a register, qualitatively welded from ordinary pipes, will quietly serve for at least 20 years;

- resistance to pressure drops and water hammer;

- The smooth surface facilitates easy removal of dust when cleaning premises.

Unfortunately, a home-made heating register also has a lot of disadvantages. The main one is low heat transfer with a significant mass of the device. That is, in order to provide a comfortable temperature in a medium-sized room, the register must be of decent size. Let's give a simple example taken from technical literature. If the temperature difference between the coolant and the room is 65 ºС (DT), a register welded from 4 DN32 pipes 1 m long will deliver only 453 W, and from 4 DN100 pipes – 855 W. It turns out that, based on heat transfer per 1 m of length, any panel or sectional radiator is at least twice as powerful.

Note. The presented data were determined experimentally at a high coolant flow rate of 300 kg/h.

Other negative aspects of smooth-tube registers are not so critical, although significant:

- holds a large volume of water: the disadvantage does not play a big role if there are 1-2 such heating devices for the entire system;

- During operation, it is very difficult to increase or decrease the power of registers made of smooth pipes. You can’t do without dismantling the welding machine;

- are susceptible to corrosion and require periodic maintenance with painting;

- They have an unpresentable appearance: the defect can be corrected; if necessary, the heater is hidden behind a decorative screen.

Having analyzed the advantages and disadvantages of smooth-tube devices, we can conclude that their scope of application in private housing construction is very limited. As already mentioned, registers can be used for heating various rooms with low requirements for comfort and interior design.

Selecting a welding machine

There are three types of welding machines. Which one to choose depends on the welding method and the material being processed. Device types:

- Step-down welding transformers. This is a reliable device that is used for welding carbon steel. The quality of the seam is average.

- Welding rectifiers. Suitable for carbon and aluminum materials, as well as stainless steel. The seam quality is high.

- Welding inverters. A universal device that is suitable for any material.

You cannot use damaged equipment when welding heating pipes using electric welding. Therefore, before starting work, the equipment is carefully checked.

Manufacturing recommendations

When selecting materials, you need to decide what pipe diameters to take and what their total length should be. All these parameters are arbitrary; you can make a heater from any pipes, and take its length convenient for placement in the room. But in order to supply the required amount of heat, it is necessary to ensure a sufficient heat exchange area. To do this, it is recommended to perform an approximate calculation of the register based on the surface area.

Making such a calculation is quite simple. It is necessary to calculate the outer surface area of all sections in m2 and multiply the resulting value by 330 W. Proposing this method, we proceed from the statement that 1 m2 of register surface will give off 330 W of heat at a coolant temperature of 60 ºС and room air temperature of 18 ºС.

Advice. You don’t have to do manual calculations, but use a simple EXEL program and then correctly weld the register according to the exact parameters. You can download the program in one click from the link: https://al-vo.ru/wp-content/uploads/2014/02/teplootdacha-registra-otopleniya.xls.

For a person who has welding skills, it will not be difficult to independently weld the register according to the available drawings. It is necessary to prepare and cut pipes into sections and lintels, and cut plugs from a steel sheet. The assembly sequence is arbitrary; after welding, the heater should be checked for leaks. When manufacturing and installing registers, consider the following recommendations:

- you should not take pipes with too thin or thick walls: the former will cool faster and last less, and the latter will take a long time to warm up and are difficult to adjust;

- do not forget to build a Mayevsky valve into the end of the upper section for bleeding air;

- when welding coils, the rotating section can be made from two ready-made elbows if it is not possible to use a pipe bender;

- Place a tap at the coolant inlet and a valve at the outlet;

- remember that the registers are installed with an invisible bias towards the connection of the supply pipe. Then Mayevsky's crane will be at the highest point.

How to weld heating registers with your own hands - Metals, equipment, instructions

Any device or device made by yourself is an economical approach to solving your plans. This fully applies to the heating system.

You won’t be able to make a radiator yourself, but a person who has the skills to work with a welding machine can assemble a register from smooth or profile pipes.

For manufacturing, you only need pipe sections, two bends and several electrodes.

ontakte

Odnoklassniki

These devices are rarely used in everyday life. They are usually installed in production and warehouse premises. This is a cheap alternative to expensive radiators.

A distinctive feature of the devices is the large volume of coolant inside, which heats up quickly and cools down slowly. Hence the high heat transfer .

They are installed in exactly the same way as conventional radiators, according to the same schemes, standards and rules.

Ratio of metal thickness to electrode diameter

| Metal thickness, mm | 1—2 | 3—5 | 4—10 | 12—24 | 30—60 |

| Electrode diameter, mm | 2—3 | 3—4 | 4—5 | 5—6 | 6 or more |

The current strength is selected depending on the diameter of the selected electrode. The dependence is as follows: I=Kd, where K is the coefficient of correlation with the diameter of the electrode.

| Electrode diameter, mm | >2 | 3 | 4 | 5 | 6 |

| Coefficient - "K" | 25—30 | 30—35 | 35—40 | 40—45 | 50—60 |

Calculation of the number of ribs

Heating registers must be calculated before purchasing them. The diameter of the pipes is very important: experts believe that pipes with a cross-sectional diameter in the range from 3 cm to 8 cm are suitable for a private house. This decision is determined by the fact that a conventional heating boiler is not capable of producing a larger amount of heat, so too large surfaces will not warm up completely .

When making calculations, you need to pay attention to the length of one register rib and the heat transfer per meter of this length. For example, a meter-long pipe with a 6-centimeter cross-section can heat one square meter of area

When calculating the required number of edges, the result must be rounded up. The calculation of the number of heating registers must also take into account the characteristics of the building. For example, if a building has a large number of windows and doors, or if the walls are thin and poorly insulated, then the number of registers can be increased by 20-50%.

Video

In private houses there are always several utility or technical rooms, where the requirements for the interior are low. But you still need to heat them, and in order not to spend money on buying modern radiators, you can install a steel register welded from pipes there. And, although everyone has seen such simple heating devices with their own eyes, not everyone knows their structure. This material is to help those homeowners who want to independently manufacture, install and connect heating registers to their system.

Connection

Connecting devices to the heating system can be done using welding, threaded and flange connections - the selection of one or another type of connection depends on the useful features of the heating system. If the device consists of a significant number of parts and pipes of larger diameter, it is important to use stands and fasteners that support the register not only at the bottom, but also in the middle, in order to share the weight and not form an excessive load on the lower sector. Please note that for best performance, it is preferable to install the register closer to the floor.

Heating registers made of smooth pipes: do-it-yourself welding and connection

Not only radiators, but also factory-made and home-made heating registers can be used as heating devices. Previously, such heating devices were most often installed in garages, warehouses, industrial workshops and other commercial facilities.

In order to reduce the cost of installing autonomous heating systems, similar products began to be used in low-rise residential buildings. It’s worth noting right away that heating rooms using heating registers is less effective compared to batteries.

The latter benefit due to the larger heat transfer area formed by additional plates that are absent in the registers of the basic design. If desired, the owner of the facility can eliminate this drawback by welding vertically oriented metal plates to round pipes.

Otherwise, this problem can still be solved by increasing the number of welded pipes of smaller diameter. This modification of the design of heating registers is resorted to not only in order to increase the heat transfer of the device, but also to implement design ideas.

For the manufacture of heating registers, smooth-walled pipes of the same diameter and the same length are prepared. The diameter can range from 32 to 80 mm.

Wider pipe products should not be used, because domestic boilers will not be able to provide the heating device with sufficient coolant.

The registers will not be able to warm up well, which means they will not provide heat to the room in which they are installed.

Using gas welding or electric welding, these workpieces, located parallel to each other, are welded together with pipes of smaller diameter. Through these transverse tubes (pipes) the coolant flows, circulating in the heating system of the house.

Option #1 - horizontal register

Most often, when manufacturing a heating register, two or three parallel pipes laid horizontally are connected. The distance between adjacent sections in the register must necessarily be 50 mm greater than the diameter. Coil designs of registers are also popular, divided into several types depending on the method of connecting devices to the heating system.

Heating registers of coil type: L - length of the heating device, D - pipe diameter, h - distance between pipes (50 mm greater than the diameter)

The length of the heating devices is selected in accordance with the dimensions of the room or room in which it is planned to install the heating system. In addition to the listed types of heating register designs, there are also:

- single-pipe products;

- four-pipe devices;

- five-pipe models, etc.

The number of pipes used in one heating register depends on the area of the heated room, the quality of the object’s thermal insulation, the presence of other heat sources in the room, etc. By sorting through the possible pipe diameters, the optimal dimensions of the products are calculated, at which the optimal temperature regime will be maintained in the heated room.

Horizontal heating registers made of smooth pipes are used for lower piping. In this case, the products are carefully placed around the perimeter of the room closer to the floor surface. In a residential building, pipes go under the windows. In industrial premises, the location of heating devices depends on the height of the ceilings, the layout of the facility and the placement of industrial equipment.

Heating registers successfully heat social facilities. Caring for such heating devices is much easier than cast iron radiators.

Option #2 - vertical registers

When remodeling apartments and expanding their living space with balconies and loggias, it is necessary to dismantle the batteries installed by the developer when handing over the property.

In this case, the dismantled radiators are replaced with vertical heating registers welded from a large number of round pipes of small diameter.

These heating devices are placed in a wall located next to the window opening.

If necessary, vertical heating registers are covered with decorative grilles, which turn an essential element of the heating system into an interior decor item.

You can disguise the location of the “bundle” of parallel pipes using mirrors, colored glass, mosaics, wrought iron grilles, as well as by placing shelves, hangers, cabinets and other useful items of non-bulky furniture.

It is possible to ensure the movement of coolant in a vertical register installed in an autonomous heating system of a private house using a circulation pump. Horizontal registers are also used for natural coolant circulation, if they are installed with a slight slope (0.05% is sufficient).

How many registers are needed to heat a house?

Pipes supplying coolant to heating devices can, to some extent, also be considered registers. And the heated towel rail installed in every bathroom is also a kind of heating register. When calculating the exact number of heating registers required for comfortable heating of a room, a number of factors are taken into account that influence the amount of heat loss:

- thickness of load-bearing walls and material of their manufacture;

- glazing area;

- Number of doors;

- thermal insulation of floor and ceiling;

- orientation of the house to the cardinal points, etc.

A simplified calculation takes into account the heat transfer of one meter of pipe. For example, it has already been calculated that one linear meter of 60 mm diameter pipe heats one square meter of living space (provided that the ceiling height is no more than 3 m).

If you purchase ready-made heating registers instead of radiators, you will not be able to achieve significant cost savings.

It is possible to reduce financial costs only if you independently manufacture register-type heating devices from materials purchased in bulk at discounts on the market. Welding work must also be done by hand.

Otherwise, the cost of a professional welder’s services will cover all the benefits from the wholesale purchase of pipes and connecting elements.

Installation methods: welding or threading?

The biggest problem when carrying out installation work on assembling and installing heating registers is welding work.

Heating appliances are assembled from individual parts outside the room, and then the heating system is installed from the prepared blanks using gas welding.

Welded seams can be replaced with threaded connections, which are inferior in strength and durability, but if the work technology is followed and modern materials are used, they can ensure long-term operation of heating equipment.

A heating register in a garage or warehouse is an independent device that allows you to heat a technical room using electricity

Homemade registers from round pipes

On the market you can purchase homemade heating registers sold by professional welders. If the finished products do not fit your size, then welding experts will make heating devices to order. The quality of home-made products is not in doubt, therefore they are built into autonomous heating systems without fear or risk.

“Samovars” with heating elements are also popular among consumers. This is the name for heating registers that independently heat individual rooms using electricity. Instead of water, oil, antifreeze or any other non-freezing liquid is poured into the pipes.

Heating of the coolant is carried out by a conventional heating element operating from a network with a voltage of 220 V. “Samovars” in their design resemble oil radiators, produced and used in extensions where it is impossible or impractical to build a water heating system.

Heating devices operate in autonomous mode, and their performance depends only on the availability of electricity.

A samovar is one of the types of heating registers that are not connected to the home heating system, but heat one of the rooms using electricity

Radiator installation

Before purchasing and installing heating appliances for your home, it will be useful for the owner to learn about how a heating battery works, the principle of operation of a heating battery, their classification by design (sectional, plate, tubular, panel), volume and material of manufacture (cast iron, steel , aluminum, copper, bimetallic). In general, bimetallic panel and sectional radiators are considered the most optimal, albeit expensive, option.

Necessary equipment and materials

When the heating devices have been purchased and the connection diagram has been selected, you can begin installation. Whatever the devices, proper connection of a heating radiator is impossible without the following (common for all types of pipes and batteries) set of tools:

- screwdriver;

- hammer drill;

- pliers;

- a set of keys;

- building level;

- pencil;

- roulette.

Among the materials needed for connection:

- plugs;

- shut-off valves and quick-release connections;

- Mayevsky valve (air vent);

- transition nuts;

- brackets for fastening.

The need for additional tools and materials is influenced by the methods of connecting heating radiators and the material of the pipes. Before you properly connect a heating radiator to a metal pipe using the welding method, you will have to acquire a gas welding machine and, of course, the skill to work with it.

If you plan to connect using threaded connections, you will need to purchase:

- tees/angles of suitable diameter;

- couplings;

- steel bends;

- sanitary linen;

- socket and pipe wrenches;

- a hacksaw or grinder.

To connect radiators to metal-plastic pipes you will need:

- pipe cutter;

- pipe bender;

- press jaws;

- sliding or ring wrenches;

- calibration;

- brass or chrome-plated tees and angles.

If the owner is wondering how to properly connect heating radiators to polypropylene pipes, he will need to get:

- cutter or special pipe cutter;

- machine for welding plastic pipes;

- spanners;

- fittings and/or adapters.

Installation procedure

So, the apartment owner has purchased tools, consumables and the heating radiator itself, how to connect it to the heating system?

The installation procedure is generally similar for all types of devices:

- First of all, the main line is blocked and the old battery is dismantled (if the house is not new).

- Then you should mark and drill holes for installing the brackets. The optimal location for installing the device is under a window opening. The best circulation of heated air is ensured with the following location of the radiator: from the battery to the floor - 10-12 cm; from the battery to the bottom edge of the window opening - 8-10 cm; between the wall and the surface of the device - 2-5 cm. In addition, even at the purchase stage, you should remember that the ideal radiator width is at least half the width of the window.

- Plugs, nuts, thermostats (or shut-off valves), and a Mayevsky valve are attached to the radiator. Different types of heating radiator connections and different types of pipes, as already mentioned, differ in some nuances. Threaded connections are covered with flax, and on top of it - silicone sealant.

- The heater is suspended on brackets and, using a level, is leveled relative to the floor and window opening.

- Pipes are connected to the radiator using adapters or quick-release connections. The joints are carefully sealed.

- The system is pressure tested and water is supplied for testing. If the heating batteries are connected correctly, not the slightest leak should occur.

It is also necessary to remember: if the radiator is new, it is not recommended to remove the plastic film from it until installation is completed. This will prevent scratches and dirt during installation.

Application area

Currently, water heating registers are mostly used in industries (workshops, workshops, warehouses, hangars and other buildings with large areas). The large volume of coolant and large dimensions allow the registers to efficiently heat such rooms.

The use of heating registers in industrial buildings ensures the most optimal efficiency of the heating system. Compared to cast iron or steel batteries, registers are characterized by better hydraulics and heat dissipation. The relatively low cost of their manufacture reduces the cost of installing the entire factory heating system. In addition, they are not expensive to operate.

Registers are also recommended for use in premises with high sanitary safety requirements (medical institutions, kindergartens, etc.). The devices are easily washed from dirt and dust.

Despite this, the concept of efficiency does not apply to this type of heating device. As noted above, heating a large volume of coolant requires a lot of energy.

Heating registers made of steel electric-welded pipes can be used in both single-pipe and two-pipe heating systems with forced or gravity circulation of the coolant (based on water or steam).