Cast iron stoves for a long-burning home are one of the best options, as they have many advantages over conventional heating devices that run on solid fuel. Due to their technical characteristics, as well as the external design of many models, they are perfect for installation in both a small country house and a large, well-kept mansion.

Cast iron stoves for long-burning homes

Even if there is a gas supply to the house and a completely effective water heating system is created, a cast iron stove may not be superfluous, as it will help maintain comfortable living conditions in the off-season or on inclement summer days. In addition, the “living warmth” from the stove always creates some special comfort.

Manufacturers of long-burning stoves claim, and practice proves, that devices with a classic design are not as effective as their products, since they heat the room only due to the active combustion of fuel in a conventional firebox. When the firewood is completely burned out, appliances with a conventional fuel combustion scheme quickly cool down, therefore, in order to maintain the desired temperature in the room, it is necessary to constantly add fuel. When using long-burning stoves, the frequency of loading the stove with wood is reduced to two or even once a day.

Basic operating principle of long-burning furnaces, features of their design

Long-burning furnaces are often called pyrolysis furnaces in another way, since their operation is based on the principle of using the latent potential of pyrolysis gases to obtain thermal energy.

During normal wood burning, combustion products, giving off heat to the walls of the device, simply go into the chimney. Fuel reserves burn out quickly, and, in fact, the use of its natural calorie content turns out to be very ineffective. It's a different matter if you use the phenomenon of pyrolysis.

Pyrolysis is the decomposition of solid fuel, in this case wood, under the influence of elevated temperature and the artificial creation of a lack of oxygen. To do this, in the furnace firebox, after the start of active combustion of the fuel, the access of air is almost completely blocked, and the process of thermal decomposition goes into the smoldering stage, during which the wood almost completely burns out, releasing pyrolysis gas, and leaving a small amount of solid waste in the form of fine wood ash.

Next, pyrolysis gas, mainly consisting of methane and carbon monoxide, rises, mixing with secondary air, which is supplied naturally or forcedly using a fan.

Then, the gas-air mixture enters the afterburner chamber, ignites and burns, giving very high heat transfer. In this case, almost complete burnout of soot and heavy fractions occurs, and the remaining flue gases have practically no impurities. When this gas-air mixture burns, the flame should have a bright white color, which indicates complete combustion of the substances with an excess of oxygen.

It turns out that the fuel gives off heat twice, and this factor increases the productivity of the heating unit several times compared to conventional stoves, and also allows the fuel to be used more efficiently.

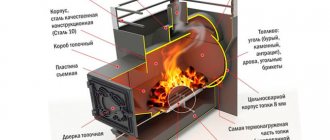

Scheme of fuel combustion in a pyrolysis furnace

This figure clearly shows the entire combustion process. At the bottom there is a primary air supply channel - its flow is regulated by a door installed at the inlet. Above the combustion chamber there is a secondary air supply channel, which will promote intensive combustion of the gas released during pyrolysis in the upper combustion chamber.

However, in order for such a combustion process to be carried out in the most efficient way, it is necessary to strictly observe the dosage of the supplied primary air - it is this that directly affects the intensity of combustion of solid fuel. So, if the combustion is very active, then the pyrolysis process will not occur, and the fuel will release heat only once.

If you “break down” the entire heating process of a long-burning stove into stages, it will look like this:

Putting firewood into the stove

- The entire space of the firebox, almost to the very top, is filled with firewood of the same length. One or two layers of thin logs and chopped wood chips are placed in the upper part of the chamber - they are necessary for quick ignition. All firewood must be sufficiently dried, otherwise it will not give high heat transfer, the pyrolysis process will be “sluggish”, and the stove will not function at full capacity.

Ignition of wood is carried out from above

- Having laid the firewood, they are set on fire from above, using paper. Particular attention must be paid to this fact, since all other furnaces are ignited from below, and the combustion occurs as if from the inside. In them, paper and thin wood chips are placed under the main layers of firewood.

In pyrolysis furnaces, combustion and then smoldering of fuel begins at the top and gradually falls down.

After the firewood from above has ignited and the necessary temperature conditions have been created in the firebox, the flow of primary air is minimized

- Burning wood should flare up at full power when the blower door or damper is open - the combustion temperature should rise to at least 200÷250 degrees. Then, the combustion door is hermetically closed, and the ash hole is only covered, since the minimum amount of air that is necessary to maintain the process of smoldering firewood must be supplied through it. Sometimes the primary air supply channel is even blocked completely.

- Thus, the operation of the stove from one load of firewood can last from 5 to 12 hours, depending on the volume of the combustion chamber. Long-term combustion is especially convenient when you have to heat a large area of the house, and therefore a unit with a water circuit is purchased. Such a fireplace with a water circuit or a stove, flooded in the evening, will heat the house until the morning, and then the next batch of firewood is placed in the firebox to heat the house during the day.

As is probably already clear from the above, long-burning cast iron stoves are often without a water circuit. To heat a small house and with the correct location of the heating device, such a circuit, in principle, will not be needed. An approximate diagram of such a furnace is shown in the diagram:

Scheme of operation of a long-burning cast iron stove

1 – Combustion chamber

2 – Damper for adjusting the supply of primary air to maintain combustion

3 – Secondary combustion chamber.

4 – Partition-deflector separating the combustion chamber and the secondary combustion chamber.

5 – Chimney pipe

6 – Loading door equipped with fireplace heat-resistant glass.

— Blue arrows show air supply paths:

a – primary, to ensure smoldering of the fuel and the pyrolysis process.

b – secondary, necessary for afterburning pyrolysis gases.

c - if the door is equipped with glass, then it is usually provided with airflow, which promotes self-cleaning and maintaining transparency.

— Orange arrow – direction of movement of the formed pyrolysis gases.

— Purple arrow – the combustion products remaining after afterburning are discharged into the chimney.

If the area of the house is large, and only the flow of heat emanating from the stove body will not be enough to heat it, even with its constant long-term burning, then it makes sense to purchase a similar device equipped with a water circuit. In this case, you can install radiators in the rooms, and it appears the ability to heat all rooms of the house from one device.

The design of such a long-burning cast iron stove is somewhat more complicated. An example of the design of such a heating device is shown in the diagram:

Construction of a long-burning cast iron stove with a water circuit

1 – Main combustion chamber. As a rule, in the design of a long-burning furnace it is large enough for a large fuel load (item 2).

3 – Ash pan door, which is used during the firebox as a damper for primary air supply.

4 – Ash pan with door.

5 – Grate separating the combustion chamber from the ash pan. In this case, we are showing a variant of a grate made of pipes through which the coolant circulates.

6 – Fire door for loading fuel. Can be equipped with clear fireplace glass.

7 – Secondary air supply channel

8 – To heat the coolant, a water jacket of a rather complex configuration is continued throughout the entire furnace body - for maximum heat exchange area. The figure is shown in blue.

9 – Pipe for connecting the “return” of the heating circuit.

10 – Heating circuit supply pipe pipe.

11 – Heat exchanger for maximum heat transfer to the heating circuit.

12 – Chimney connection pipe.

13 – Outer body of the furnace. Often it is given one or another design design.

14 - door for cleaning the afterburning chamber of pyrolysis gases.

In all long-burning furnaces, the manufacturer carries out the necessary adjustment of the combustion intensity of the fuel in the factory. These settings do not always take into account all the operating features of the device, its operating conditions and the specifics of the fuel used. Therefore, sometimes the functionality of a heating device is not fully used, to the full declared efficiency, and it makes sense to change the preliminary settings set by the manufacturer to more suitable ones. Such changes may be made in the following cases:

- If the intensity of the primary combustion is very high, and adding firewood lasts only 3–4 hours, even if high-quality, well-dried fuel is used.

- Low percentage of firewood combustion, that is, unburnt and undecomposed remains of wood or other fuel remain.

These signs indicate a discrepancy between the set settings of the unit, or that there was incorrect, voluntary or involuntary, user intervention in its operation. One way or another, in order to achieve efficient operation of a long-burning stove, it is necessary to make appropriate adjustments. But to perform such an operation, it is still better to invite an experienced specialist, explaining to him the essence of the problem.

Which company should you choose?

There are many companies producing such heating devices. Experts recommend paying attention to well-known brands that use higher quality and proven materials.

These include:

- Kratki is a Polish brand with an optimal pricing policy and high efficiency. Wood-burning models have high power, sophisticated ergonomics and adjustable door pressure. The appearance of the fireplaces is modest, but the company focuses on functionality.

- Meta is a Russian company that has been on the market for a long time. Produces optimal fireplaces for small spaces. A distinctive feature is that they do not tolerate damp and resinous firewood; it is recommended to burn with dry hardwood fuel.

- Spartherm is a German brand that produces models with and without a water circuit, as well as fireplaces burning coal, gas and peat briquettes. We also manufacture fireplaces upon customer request.

Main types of long-burning furnaces

In addition to the fact that these devices can be conventional and have a water circuit, they are also divided according to other criteria.

Thus, units of several modifications are produced:

- Heating models.

- Heating and cooking stoves with a hob and even an oven.

- Stoves with a tank for heating water.

- Multifunctional stoves that include all of the listed functions in their design.

Long-burning stoves can have different shapes and sizes - this variety allows you to choose the right option, depending on the area and installation location.

- Corner models of long-burning cast iron stoves usually have a compact size, so they can be installed even in the smallest room. It must be said that corner fixtures are most often made of various materials used in combination. For example, the body is made of high-quality steel 4÷5 mm thick, and the grate, combustion chamber and other internal elements in contact with open fire are made of cast iron.

Corner oven

- Wall heating devices can also vary greatly in size, depending on their functionality. They are intended for installation both in kitchens and living rooms, as they are often given a very original design design.

Cast iron stove with ceramic exterior

Quite often, cast iron stoves are lined with various types of ceramic tiles, or even artificial stone. This finish performs several functions at once:

— helps to retain the generated heat for a longer period;

- the surface of such a finish does not heat up to dangerously high temperatures, since ceramics have lower thermal conductivity compared to metal - there is a much lower chance of getting an accidental burn.

— finishing tiles will be an excellent decorative decoration for the surfaces of the stove, as they can have a variety of colors and relief patterns. Some of its types imitate tiled cladding.

You might be interested in information about what can be done from an old cast iron bathtub

Questions and answers

What factors are determining when choosing a fireplace stove?

The determining factor in choosing a fireplace stove is its ability to heat a certain volume of the room. The remaining selection criteria are determined by the requirements for the functionality of the unit, taste preferences and financial capabilities of the buyer.

In what ways are cast iron fireplace stoves fundamentally better than steel ones?

Cast iron stove units take longer to cool down, allowing them to heat a room for a longer period of time. Compared to steel structures, they have higher thermal conductivity.

Is it possible to install fireplace stoves yourself?

Furnace units are fire hazardous equipment. Despite the ease of installation of fireplace stoves, it is better to seek the help of specialists. This recommendation is given by all manufacturers of fireplaces and stoves. The installation of each model has its own nuances. Improper installation of equipment can lead to its rapid failure, smoke in the premises and poor draft.

Advantages and disadvantages of long-burning cast iron stoves

Recently, owners of private houses are increasingly choosing cast-iron stoves with a long-burning function built into them, preferring them even to “classic” brick structures, and this is explained precisely by the numerous advantages of such factory-produced devices.

Long-burning cast iron stoves have many advantages that distinguish them

The advantages of such furnaces include the following qualities:

- High efficiency.

- With correctly selected oven power, it can effectively and quickly heat rooms from 0 to 20 °C in 25–30 minutes. But of course, in order for the device to function according to the characteristics declared by the manufacturer, it is necessary to properly thermally insulate the house.

- The stove can operate autonomously for 5÷12 hours, depending on the volume of the combustion chamber and the correct settings of the device. This quality allows you not to wait for the fuel to burn out before closing the chimney damper and keeping the house warm, since there is no danger of smoke in the rooms.

- Well-functioning cast iron stoves are convenient and easy to operate, which consists of adjusting the supply of first primary and then secondary air.

- Ease of installation and lower total costs when purchasing and installing such a device, compared to the construction of brick versions of stoves.

- The compactness of the unit allows it to be installed in any, even very small, room.

- Possibility of cooking and heating water.

- The modern design of cast iron stoves allows them to fit into an interior designed in any style.

Disadvantages of cast iron stoves:

It must be said that this device, seemingly impeccable in design, has its negative aspects, which, however, are completely surmountable. The “disadvantages” of long-burning stoves include the following features:

- It is necessary to insulate the chimney pipe, since without this condition the operation of a long-burning stove is impossible. Heated gases entering a cold pipe immediately form condensation and layers of soot deposits on its inner walls. In this regard, the chimney quickly becomes clogged and requires frequent cleaning, otherwise backdraft may form.

- If the settings are incorrect, complete decomposition of the wood and combustion of flue gases does not occur, which indicates that the capabilities of the stove are not fully used.

- For this type of unit it is necessary to purchase high quality fuel.

- High cost of the device. However, this drawback can be compensated for quickly enough, since fuel consumption when operating long-burning furnaces is several times less than for devices with a conventional firebox design.

For the dacha

The mark of the Balezinsky Foundry and Mechanical Plant and the country cast iron stove of the PCH series produced by it

A country house with a plot of land owned by a simple worker or small employee is a typically Russian (more precisely, still Soviet) phenomenon, unknown in the West. Therefore, the products of the Balezinsky Foundry and Mechanical Plant have been firmly in the market for country cast iron stoves since those times. At dachas you can see cast-iron “balezinka” stoves with a brand mark (stylized BZ, see the figure on the right), which are over 50. And nothing - they cook, steam, even warm in winter. They can withstand working with a hog (horizontal section of the chimney) made of a steel pipe up to 3-3.5 m long, providing a stove efficiency of more than 65%.

In Balezino they produce country cast iron stoves PCh-1 and PCh-2. In Rubtsovsk there are PChM(A), PChM-1, PChM-2, very similar to them. Both of them have a power of 7-12 kW. The PCh-1 and PChM(A) stoves are collapsible: disassembled they can be transported in the trunk, and individually transported in parts from room to room. The heaviest of the Balezin and Rubtsov stoves weighs approx. 150 kg.

The secret of the Balezin and Rubtsov stoves is in the well-chosen grade of cast iron SCh15-32. It is quite heat-resistant, flexible (withstands repeated spills of liquid on a hot stove), and transmits IR well, which makes it very difficult to burn out a Balezinsky or Rubtsovsky stove: these stoves can withstand repeated boosting of the firebox for approx. 2.5 times in power (up to the light red heat of the oven) without visible damage to yourself. However, recently, “balezines” and “rubtsovkas” have had strong competitors in the form of the same Tver Berezoks, but not for bathhouses, but for country houses. Country cast iron stoves Berezka are made using modern materials and technologies. Therefore, firstly, one person carries the entire Berezka stove. Further, the residents of Tver equipped their stoves with a firebox with a glass door, turning them into mini fireplace stoves. Thanks to a well-calculated configuration of the body and cooling fins, Tver country cast iron stoves. Being very compact, they heat the room well by convection and are not burned by IR. Finally, the resistance of Berezka cast iron stoves to thermal shock is impressive: a red-hot stove can be covered with snow, and no matter what, see the video:

Furnace fuel

The fuel for long-burning stoves is wood with a moisture content of no more than 20% - this can be whole logs of the same length, waste from the wood processing industry, wood chips and other lumber. In addition, pellets, fuel briquettes, and coal are used. For this type of furnace, it is better to choose brown coal, since other types are more energy-intensive, which can lead to burnout of the surfaces of the walls of the device, especially if the furnace is made in a combined version, that is, assembled from different materials, and steel is used as the walls of the firebox.

The quality of heating is greatly influenced by the moisture content of the fuel, since damp wood significantly reduces the efficiency of the device and also contributes to the formation of soot deposits on the walls of the chimney. In addition, the pyrolysis processes in such wood are defective.

Why modernize?

The potbelly stove is a very simple heating device, although today it is deeply modernized. Such a stove, which has become a favorite solution for heating small country houses, can have not only a single-chamber, but also a two-chamber design. A modernized potbelly stove can provide heat even to houses where residents live permanently.

The simplicity of design and manufacture makes it accessible to purchase and use. In addition, a significant advantage for the construction of such a structure is the absence of a foundation. But, despite so many positive properties, the potbelly stove also has significant disadvantages:

- Its efficiency is quite small, the simplicity of the design carries with it an inherent drawback - a huge part of the heat from the potbelly stove “flies into the chimney”.

- To work with such a stove, strict safety requirements must be observed, since falling combustion elements can damage nearby premises and even lead to a fire.

- To heat a room with a potbelly stove, it is necessary to consume a significant amount of fuel elements, which is due to the fact that this type of heating is used only for short-term operation.

But this is not a reason to be discouraged; over the years, our “Kulibins” have found several simple but effective ways to increase the efficiency of a potbelly stove. In this article we will look at the modernization of the stove design itself.

Features of installing a cast iron stove

A few words need to be said about the features of installation work on installing a long-burning cast iron stove and preparation for it.

The installation of a cast iron appliance itself is not particularly difficult, with the exception of transportation - due to the large weight of the unit. However, before buying it, much less installing it, you need to carry out preparatory measures:

- To choose the right device, you need to collect some data - this is the size of the heated area, it is necessary to determine the power of the stove. In addition, you need to take into account the height of the ceilings of the rooms.

- Next, you need to draw up a plan of the room where the stove will be installed and the attic floors located above it. The last parameter will be needed if the chimney will go outside through the attic floor and roof.

- Having received all the data, you can go to the store to buy the device and all the additional accessories that are necessary for its installation. Very often, for such an installation, sandwich chimney kits are purchased - they are perfect for devices of this type.

The site for future installation of a cast iron stove must be prepared accordingly

- Next, you need to prepare the place where the stove will be installed. To do this, the walls and floors are finished with ceramic tiles, bricks, artificial stone, or the surfaces are sheathed with non-flammable material - this can be asbestos (for residential premises - not recommended) or plasterboard. Drywall must have a heat resistance designation - GKLVO. A screen can be installed on the wall using these materials. If necessary, the ceiling under the flooring is reinforced, and their surface is leveled with a screed, and then decorated with ceramic floor tiles.

- The stove is installed on a prepared surface, leveled to the building level. All chimney pipe connections are sealed with a special heat-resistant sealant. The material from which it is made is heat-resistant silicone. Additionally, it will be necessary to insulate all chimney penetrations through walls or ceilings.

- The section of the chimney located on the street must be insulated, or special sandwich pipes that already have an insulating layer must be used for its installation.

- If a cast iron stove will be installed in a wooden house, then in addition to arranging the installation site with heat-resistant materials. a number of certain rules must be followed. Such requirements include:

— the combustion chamber must be of a closed type with heating of gases no more than 400 degrees;

— the outer surface of the chimney should not heat above 85 degrees, and in passages through ceilings or walls, the pipe is separated from them by heat-resistant insulation with a width of at least 100-150 mm.

Brick heating panel.

The scheme is as follows. As you can see in the figure, smoke valves are made in the upper part of the shield. The second valve is responsible for the summer flow of gases. The third is the winter mode (it is open, and the gases go into the smoke circuits of the shield, the second valve is closed). While the gases pass through the channels, they cool, giving up part of their heat to the shield, and in a cooled state they go into the pipe. .

The dimensions of our thick-walled heating panel are 89 x 38 x 224 cm. Weight - 1.2 tons. Heat transfer: one good firebox - 430 kcal/h; two fireboxes respectively - 600 kcal/h. As a rule, the panels are plastered or laid directly from beautiful refractory bricks. Three smoke dampers make it possible to regulate the movement of gases. The operating modes are as follows.

Shield operating modes.

- In winter, the winter valve is closed, the first and second valves are open. Going along all the passages of the shield, the gases lose their heat, giving off their heat to the shield.

- In summer, valves 1 and 3 are open, the second is closed. Gases, bypassing the chimney of the shield, go directly through the pipe. For better ventilation of the room, a special channel is installed in the mounted pipe. It opens with a grille having louvers (valves). Their presence allows the ventilation system to be operated in 3 modes: open, half open and closed. Next we will see the laying of the heating shield.

Material for laying the heating shield:

- refractory brick - 400 pcs.;

- river sand - three to four bags;

- clay mixture - three bags;

- roofing felt for waterproofing - 1-2 m.

- cast iron valves 13 x 13 cm -3 pcs.;

- ventilation draught with valve (15-20 cm);

- cast iron doors 14 x 13 cm - 3 pcs.

When laying the foundation under the shield, it is not brought up to the level of the finished floor by two rows in height. One row of brick is placed on top of the foundation, waterproofing is laid over it, after which the shape of the stove is marked out. Next, the second row is laid, with its upper surface reaching the level of the finished floor. After this, you can start laying out the shield.

- 1st row - made of solid brick.

- 2nd and 3rd rows - according to the picture.

- 4th row - during the laying process, a window is left for entry to the furnace panel and 2 cleanings are installed.

- The 5th row is similar to the fourth, the ligation of the seams is exactly as in Fig.

- 7th row and next. odd, up to the 25th - according to the figure with the formation of three channels.

- 8th row and next. even numbers up to and including the 26th - according to the order in the picture.

- Rows 10, 11, 17, 23 and 24 are similar to the previous ones. However, for the purpose of better reliability, ligation of sutures occurs differently.

The 18th row is placed similarly to the 10th and 24th. A valve is installed in the channel on the right wall. The 21st and 22nd rows are placed with the installation of a samovar. 27th row - during the laying process, the two left channels converge into one and overlap. samovar. 28th row - a cast iron valve is installed during the laying process. 29th row - according to the order

Pay attention to the dressing. 30th row - during masonry, a valve is placed on the right side of the shield, on the left it is crossed

channel. In the 31st and 32nd rows we bandage the seams differently

The top of the shield will be covered in three rows. This can be seen in the figure. This scheme is completely made according to fire safety requirements. 33, 34 and 35th rows - according to Fig. 36th row - during masonry we make a ventilation and smoke passage

In kitchen wood stoves, most of the heat energy literally goes up the chimney, and only a small amount of heat is used to heat the stove. To trap hot gases and use them to heat your home, you need a heating panel - a brick wall with smoke circulation channels inside. A heating and cooking stove with a shield is ideal for a summer house and summer kitchen - it does not take up much space, effectively heats the room and can operate in winter and summer modes.

Several popular models of long-burning cast iron stoves

In order to make it easier to choose a long-burning cast iron stove, it makes sense to consider several models that, perhaps, will immediately appeal to someone.

Long-burning heating and cooking stove “ISOTTA CON CERCHI”

Cast iron stove "ISOTTA CON CERCHI", designed for additional or main heating of residential premises. It can operate in normal mode or as a long-burning device.

Cast iron stove "ISOTTA CON CERCHI"

The oven is made of high-quality cast iron and has double walls, between which heated air flows circulate. The model is equipped with a hob that can be closed with a protective lid if necessary. During cooking, this hinged panel serves as a protective screen for the wall and prevents greasy drips, steam and other contaminants from entering it.

The oven design includes a side loading door for loading longer logs.

The combustion door has panoramic heat-resistant glass that can withstand heating up to 750 degrees. The glass door also allows you to use this stove model as a fireplace, since the playing flames are clearly visible through it.

The drawing, with the dimensions indicated on it, looks like this. Using it, you can “try on” this version of the stove in its intended place.

Drawing of the furnace "ISOTTA CON CERCHI"

The table below summarizes the main technical characteristics of this device, which will also help you make your choice:

| Name of characteristics | Options |

| Manufacturer country | Italy |

| Material of manufacture | cast iron |

| Rated thermal power | 9 kW |

| Heated area | 258 m³ |

| Hob | Equipped with one burner |

| Chimney diameter | 150 mm |

| Structure height (including cover) | 830 mm |

| Width | 795 mm |

| Depth | 520 mm |

| Device weight | 203 kg |

| Efficiency | 0.85 |

| Fuel combustion coefficient. | 0.97 |

| Firebox size "Ghisa" | 597×422×350 mm |

| Fire door size | 519×305 mm |

| Hourly fuel consumption | 2.5 kg/h |

| Primary air supply | Yes |

| Secondary air supply | Yes |

| Side loading door | Yes |

Additional useful information provided by the manufacturer:

- This model is capable of working on firewood, pellets and fuel briquettes; the use of brown coal is acceptable.

- The service life declared by the manufacturer is at least 35 years.

- A sufficiently large surface area of the stove warms up well and transfers heat to the premises.

- The door of the air supply channel, which serves as a regulator of the combustion intensity of the fire, can be closed completely, creating the necessary conditions for long-term combustion, that is, the smoldering of firewood with the release of pyrolysis gases and their subsequent afterburning.

- The secondary air supply channel plays an important role in the process of afterburning the released pyrolysis gas. In addition, it serves to blow glass to protect against deposits formed during combustion - soot and soot.

- A well-adjustable gate valve will help ensure optimal traction, extend the service life of the device, as well as ensure quick ignition without smoke and increase efficiency.

- The lid installed on the hob has an automatic stopper that snaps into place when it is opened and locks it in the desired position.

The oven is capable of heating up to 260 m³ (100 ²) of volume in less than an hour. While in the heat maintenance mode, the outer walls of the stove heat up to 80–85 degrees, and it works like a decorative fireplace that heats a small area.

When the stove is set to long-burning mode, it is able to maintain heat for 8-10 hours, and its efficiency can reach 90%.

Prices for ISOTTA CON CERCHI

ISOTTA CON CERCHI

Long-burning heating stove "INVICTA Carolo"

Long-burning cast iron heating stove “INVICTA Carolo”

The INVICTA Carolo long-burning heating stove model is equipped with heat-resistant glass and slot convectors. This model has the following technical characteristics:

| Name of characteristics | Options |

| Manufacturer country | France |

| Material of manufacture | cast iron |

| Rated thermal power | 10 kW/h |

| Chimney diameter | 150 mm |

| Structure height | 690 mm |

| Width | 620 mm |

| Depth | 439 mm |

| Device weight | 118 kg |

| Efficiency | 0.783 |

| Heated volume of premises | 130÷400 m³ |

| Fireplace glass size | 500×400 mm |

"INVICTA Carolo" is made entirely of cast iron and has double walls, which significantly increases the efficiency of the device. The heating device is equipped with two channels for supplying primary and secondary air, which allows the use of a system for afterburning pyrolysis gas released from wood. The design of the device ensures constant slow combustion from 6 to 10 hours on one load of fuel.

The stove is capable of heating rooms with a total area of 100 m², subject to high-quality insulation of the house.

"INVICTA Carolo" is made in a classic style and has a rectangular shape. A fairly large heat-resistant glass is equipped with a self-cleaning system, which allows you to see the mesmerizing reflections of the flame. Therefore, the stove can easily be used as a fireplace for spending pleasant evenings, sitting with a cup of tea near the fire. And this despite the fact that about 25% of thermal radiation enters the room through the glazed door.

You may be interested in information about what types of long-burning wood-burning fireplaces for summer cottages are available

Long burning stove made of cast iron "Gomont"

The Gomont fireplace stove has a rather elegant appearance, different from the appliance options mentioned above. Made in a discreet style, it will fit into any modern interior. The glass in the door is made from heat-resistant glass ceramics “SCHOTT ROBAX”, which is resistant to high temperatures. The large size of the transparent part of the door, which is equipped with a self-cleaning system, allows you to observe the beautiful processes occurring in the combustion chamber.

Cast iron fireplace stove “Gomont”

The technical characteristics of the Gomont stove are as follows:

| Name of characteristics | Options |

| Manufacturer country | France |

| Material of manufacture | cast iron |

| Rated thermal power | 10 kW/h |

| Chimney diameter | 150 mm |

| Structure height | 977 mm |

| Width | 513 mm |

| Depth | 415 mm |

| Device weight | 103 kg |

| Efficiency | 0.76 |

| Heated volume of premises | 130÷400 m³ |

The furnace has channels for supplying primary and secondary air. There is a spacious ash drawer, which is hidden behind the oven door. Adjustment of the fire burning intensity, as in all long-burning stoves, occurs by supplying more or less air flow.

The manufacturer's warranty for this product is 5 years.

You may be interested in information on how to build a flint stove with your own hands (drawings)

Another example of a long-burning cast iron stove made in France is in the attached video:

Video: Tomera cast iron stove

Long-burning stove-fireplace “La Nordica Rosa”

This version of the stove has an original design, which is perfect for both modern and retro-style furnishings. Its external decoration is not only decorative, but also functional, as it is capable of keeping the device hot for a long time, but preventing its external surfaces from heating up to too high, dangerous temperatures.

A very original and functional model - long-burning stove-fireplace “La Nordica Rosa”

This version of the heating and cooking stove is made of several materials, so it can be called combined.

Its internal structure is made of high-quality cast iron, and the body is made of high-grade steel. The cladding made of natural stone or ceramics gives the model an aesthetic and elegant appearance.

The oven is equipped with a hob and oven, which has an internal heat-resistant enamel coating.

The technical characteristics of this device are given in the table:

| Name of characteristics | Options |

| Manufacturer country | Italy |

| Material of manufacture | cast iron, steel |

| Rated thermal power | 8.1 kW/h |

| Hob | Equipped with one burner |

| Chimney diameter | 150 mm |

| Structure height | 851 mm |

| Width | 1030 mm |

| Depth | 665.9mm |

| Device weight | 183 kg |

| Efficiency | 0.81 |

| Door glass size | 349×235 mm |

| .Heated area | up to 85 m² |

| Weight | 210÷226 kg |

| Firebox type | Closed |

| Double combustion chamber | Yes |

The device has channels for supplying primary and secondary air, which allows you to adjust the air flows entering the combustion chambers from the outside. The glass is made of glass ceramics that can withstand temperatures of 750 degrees.

The stove is capable, with good adjustment, of burning one load of firewood with effective heat transfer to the premises for at least 8–9 hours.

The stoves are available in two color finishes - burgundy and beige (cappuccino), which also helps them adapt to different interiors.

In conclusion, it should be added that the range of long-burning cast iron heating stoves is so large that it is possible to choose an option for every taste and income. There are models that are simple in design and design, which have a relatively low cost - they are perfect for installation in the country. And if desired and possible, you can also find expensive options lined with decorative ceramic tiles, perfect not only for heating needs, but also for decorating any, even the richest, living room. You can find out the calculator for calculating the heating of a private house by following the link.

You might be interested in information about how a two-bell heating stove works

Prices for La Nordica Rosa

La Nordica Rosa

How to choose and what to pay attention to?

A fireplace is not a cheap product, so when choosing a model you should accurately determine its characteristics and not make a mistake.

Experienced engineers recommend paying attention to the following factors:

- Power is the most basic thing required from a fireplace. The required power is selected based on the area and volume of the room. Optimal and simple calculation - at least 1 kW per 10 sq.m. rooms.

- The body material is the key to the durability of the fireplace and its thermal efficiency. Steel models heat up quickly and cool down quickly, so they need to be “refueled” regularly. In addition, steel walls are prone to burning. Cast iron retains heat longer, but it is a fragile material that should be protected from shock and damage.

- Type of fuel - most fireplace stoves consume wood, but there are models that burn peat briquettes and coal. The choice depends on the financial capabilities and personal preferences of the consumer.

- The diameter of the chimney depends on the technical characteristics of the house; the wider the chimney, the better the combustion products are removed.

Loft

This year the style remains in demand. It is often used to equip kitchens combined with a living room. This combination gives more free space, which will only emphasize all the details of the loft.

For example, stylists play with brickwork, wires or concrete walls. The photographs clearly show how successful it can look like a living room that is combined with a kitchen.

For loft, rough and heterogeneous surfaces and rough materials are selected. In apartments decorated in this style, wall lamps are installed. In this case, the light is directed along the walls.

Due to this, shadows fall so that uneven surfaces look three-dimensional. At first, loft was viewed with caution, but it quickly became popular. Designers do not hide finishing materials and even fake them. To imitate a concrete surface and smudges, decorative plaster is used.

Negative qualities

Cast iron stoves are not without their drawbacks. Among them the following are noted:

- Fragility. This applies to almost all similar products. The material has a high fragility factor and therefore requires careful handling. He is afraid of strong blows and falls.

- Large mass. For example, a 9 kW oven weighs approximately 70 kg. In a private home, to install such a device, you need to make a reliable foundation.

- Instability to sudden temperature changes. When lighting the stove, no damage occurs, since the device heats up and cools down gradually. But if cold water accidentally hits a hot surface, the cast iron may crack.

- Price. Of course, the cost is much higher than other analogues. However, this is justified: the product is highly reliable and designed for long-term operation.

- Fire safety. Storing flammable materials near such a stove is prohibited. They can catch fire from the high temperature of the walls of the unit.

- Nuances of operation. The room in which the cast iron stove is installed should not have high humidity. Because of this, rust may appear. Any damage requires immediate repair. Models from foreign manufacturers are heated only with pellets or peat, so there is no need to put long logs in them.