Hello, dear friends! When planning construction work, special attention is paid to the materials used. If you make a mistake, the house may turn out to be cold, not stand for long, and also provoke a number of other problems. Among the materials, it is worth highlighting insulation. Today we are considering Penoplex Foundation.

This is a universal insulation. Don't be embarrassed by the word foundation in the title. In fact, it is not necessary to use penoplex for foundation formwork, or exclusively as part of the foundation of a house or other building.

Penoplex, which is sometimes called Penoflex Foundation for some reason, has a dense structure and a polystyrene base. In terms of its performance characteristics, the insulator is significantly superior to conventional foam plastic. It does not absorb moisture and is not afraid of biological influences.

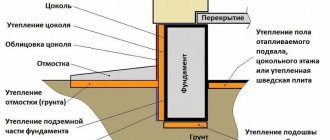

The characteristics of such a material as Penoplex Foundation allow it to be widely used at the base of buildings. This is a special type that was designed for installation in loaded structures, as well as those that are in constant contact with the ground. This includes different types of foundations, basements, blind areas, as well as plinths.

There is nothing complicated about the installation technology. This makes it possible to use penoplex under the foundation slab and other structures with your own hands, performing effective insulation.

Calculation of thermal insulation thickness

The outside temperature in winter in the Far North differs significantly from similar indicators in the Krasnodar Territory.

Different climatic zones require different thicknesses of the heat-insulating layer to protect the foundation from freezing. Therefore, before insulating the bases, a thermal engineering calculation is carried out using the formula: R=h1/λ1+h2/λ2, where:

- R - standard heat transfer resistance (m²/°C W), determined in accordance with SNiP 23-01-99 “Building climatology”;

- h1 - foundation thickness (m);

- λ1 is the thermal conductivity coefficient of the construction material (W/m°C), found from the table SNiP 11-3-79 “Building Heat Engineering”;

- λ2 is the thermal conductivity coefficient of Penoplex, equal to 0.032 W/m°C;

- h2 is the required thickness of the insulation layer (m).

The value is rounded up.

It is convenient to use an online calculator, where in the initial data you need to indicate the base material, its thickness and the standard value R.

Calculated thermal insulation thicknessesSource mastergrad.com

For the Moscow region, as a result of calculations, h2 = 0.096 m, i.e., the optimal thickness of the Penoplex Foundation slab is 100 mm. In the climatic zone of Belgorod, a reliable layer will be created by insulation no thinner than 50 mm.

Types, characteristics, properties

Penoplex is available in several categories:

- Comfort. For insulation of walls, balconies, loggias.

- Foundation.

- Pitched roof.

- Wall.

Types and purpose of Penoplex insulation

As you can see, the manufacturer clearly delineates the areas of application of the material. With the general technology, they differ in density. The densest ones are for the foundation and floor, since they must withstand considerable loads for a long time. The manufacturer claims that the service life of Penoplex Foundation is up to 50 years.

Design differences

Some of the types of Penoplex have structural differences:

- Penoplex Wall slabs have a rough surface; stripes are applied to the surface of the slab using a router. All this improves adhesion to the wall and/or finishing materials.

- Penoplex Comfort is distinguished by an L-shaped edge, which during installation guarantees the absence of through seams.

- Penoplex Roofing has a U-shaped edge, which increases the reliability of the connection.

Can be distinguished by external signs

This is what concerns external differences. Next, let's look at the technical specifications. First, let's pay attention to what is common to all types, then to what distinguishes them.

General characteristics

Since the production technology of all types of Penoplex is similar, they have many of the same characteristics:

- Water absorption is very low: when immersed in water for a day, no more than 0.4% of the volume;

- when immersed for 28 days, 0.5% of the volume.

As you can see, according to temperature indicators, any type of Penoplex can be used in any part of the country - from the south to the north. Moreover, if you leave it to “winter” unprotected, nothing will happen to the material. This is not the merit of Penoplex, but a general property of extruded polystyrene foam.

What distinguishes different types

The manufacturer divided the types of Penoplex into areas of use. Their properties are optimal for a specific application. For example, the increased density of EPS required for a screed will not be needed when installing it on a plinth. Taking into account the fact that the price differs significantly, it makes no sense to use the “Foundation” brand for other purposes. But the difference in locks, with other characteristics being equal, can be neglected. Here we are talking about ease of installation. Although, this is also important.

| Parameter | Comfort | Foundation | Roof | Wall |

| Density | from 20 kg/m³ | 27-35 kg/m³ | 26-34 kg/m³ | from 20 kg/m³ |

| Elastic modulus | 15 MPa | 17 MPa | 17 MPa | 15 MPa |

| Thickness | 20, 30, 40, 50, 100 mm | 50, 100 mm | 100 mm | 50 mm |

| Static bending strength | 0.25 MPa | 0.4 MPa | 0.4 MPa | 0.25 MPa |

As can be seen from the table, Penoplex for foundations and roofs is denser, stronger, and better able to withstand bending loads. Designed for walls and the “Comfort” brand are less durable, since their area of application does not require resistance to mechanical stress.

Thermal insulation of columnar foundations

Columnar or pile foundations are used for light or small buildings - frame houses, bathhouses, extensions or verandas. Even if the structures rest on solid soil below the freezing level, the supports experience uneven lateral soil pressure and loads from heaving forces that tend to twist or push the pillars outward.

To avoid skewing of the pillars, it is necessary to insulate the foundations using one of these methods:

- thermal insulation of the false base and blind area, in which the soil under the house does not freeze during the winter;

- insulation of the area directly around the support, when a small volume of soil adjacent to the pillar is protected from freezing.

In the first case, penoplex is mounted on a sheathing attached to poles or piles. From the outside, the false base is covered with finishing materials - base siding, corrugated sheets or plastic panels. You can lay out the base with facing bricks on a pre-filled monolithic reinforced concrete strip or metal supporting profile.

In the second case, a hole is torn out around the support, polystyrene foam slabs are laid as tightly as possible and sprinkled with sand or dry soil. This is a more budget option than the first. It is used if the basement is not planned to be finished or the building is unheated.

Why insulate the foundation

Some owners of private houses refuse to insulate the basement, trying to save as much money as possible. At the same time, experts in the field of construction work insist that thermal insulation of this part of the house is simply necessary, and it is better to attach the insulation to the outside of the structure.

General scheme of foundation insulation with penoplex

The following arguments are put forward in favor of insulation:

- After insulation, the foundation becomes protected from the negative effects of sub-zero air temperatures. This factor is especially important in places with high humidity. If, when the temperature drops, moisture gets into concrete cracks, it begins to rapidly expand and ultimately tears and damages the concrete structure;

- The degree of protection of the foundation from temperature fluctuations increases. The concrete structure experiences much fewer cycles of compression and expansion, as a result, the service life of the building without major repairs to the foundation is significantly increased;

- The insulation becomes an additional barrier to groundwater that tends to penetrate to the foundation.

Areas of application

Thermal insulation has a wide range of uses, although there are limitations. The Penoplex Foundation product is intended for installation in places with high pressure and low temperatures .

The structure of polystyrene is destroyed by contact with sunlight , so insulation boards must be covered with finishing materials .

Foundations

Basements and underground floors suffer the most from the effects of harsh climates. The main bottlenecks of the foundation:

- Waterproofing membrane . The material preserves the thin film from tearing when backfilling.

- Freezing . The insulator has low thermal conductivity, so negative temperatures are not dangerous for basements and floors.

- Groundwater . The insulation does not absorb moisture, which ensures unhindered drainage.

- Soil heaving . The dense structure of the polymer protects the foundation structure from the pressure of deformed soil.

Penoplex has high biostability . It does not decompose in the ground under the influence of microorganisms and is able to flawlessly solve its problems for 50 years after installation.

Garden paths

If the surface of garden paths is laid on loam, in the spring cracks may appear in the asphalt, and the bricks of the paving slabs will move out of their places. The insulation copes with the following problems:

- Frost deformation . Durable material will “absorb” soil pressure, like a shock absorber, and prevent the coating from “creeping”.

- Ice . "Penoplex Foundation" will protect the paths from continuous icing, and the owners of the site will not slip.

- Cooling down . Polystyrene will retain heat on paths with a heating system, thereby reducing utility bills.

Insulation should not be laid on bare ground. First you need to cover the soil with a layer of geotextile and pour a sand-gravel mixture on top.

Septic tanks

The material reliably insulates septic tanks, preventing them from freezing even in extreme cold. As a result, the number of accidents is reduced and the risk of sewerage blockage disappears.

Pipelines and drains

The insulator keeps drains from icing, clogging and failure in severe weather. Water and sewer pipes are especially vulnerable in winter. Polystyrene will protect their contents from frost.

“ Penoplex Foundation ” is one of the few Russian-made materials that can be safely used when arranging protection for a private home from winter cold.

Absolute inertness to the effects of bacteria and mold , high strength and low thermal conductivity - thanks to these qualities, builders and owners of country real estate choose domestic insulation.

Extruded polystyrene (Penoplex)

Extruded polystyrene foam in our country is better known under the brand name “Penoplex”. Expanded polystyrene, or more precisely, its extruded variety, is the general name for a polymer insulation material produced on the basis of styrene. Penoplex is the brand name. Thermal insulation is produced in the form of sheets or plates, the thickness of which can vary from 2 to 15 centimeters. The sheet size is 60*120 centimeters; there is a special groove along its long side to facilitate installation.

The advantages of this material include:

low thermal conductivity coefficient;

high level of strength compared to brittle foam;

low moisture absorption rates by the material;

long service life due to resistance to destruction and rotting - up to 50 years;

good resistance to temperature fluctuations.

Penoplex has only one main drawback - its increased flammability. Since during external insulation of the foundation the bulk of the material will be below ground level, this nuance will not have a negative impact on the structural parts of the foundation. However, if you decide to insulate the entire building from the facade with this material, this point should be taken into account.

Material package dimensions and number of sheets in each package

Penoplex is sold in packages in the form of a stack of sheets.

The length and width of the package coincide with the standard dimensions of the insulation sheet and are equal to 120 cm and 60 cm. Table 1. Dependence of sheet thickness on their quantity in the package

| Sheet thickness (cm) | Number of slabs (pcs) | Packing thickness (cm) | Total area of all insulation sheets (m2) |

| 2 | 20 | 40 | 14,4 |

| 3 | 14 | 42 | 10,08 |

| 4 | 10 | 40 | 7,2 |

| 5 | 8 | 40 | 5,76 |

| 6 | 7 | 42 | 5,04 |

| 8 | 5 | 40 | 3,6 |

| 10 | 4 | 40 | 2,88 |

| 12 | 3 | 36 | 2,16 |

| 15 | 2 | 30 | 1,44 |

Non-standard Penoplex roofing sheets, which are 240 cm long, 60 cm wide and 10 or 15 cm thick, are packaged according to the same principle: 4 or 2 pieces. A package of sheets with a thickness of 10 cm will have an area of 5.76 m2, and a package of sheets with a thickness of 15 cm will have an area of 2.88 m2.

Do not forget that part of the insulation will be spent on cutting and trimming, so buy material with a margin of 10-20 percent. A small supply and scraps of penoplex will help you with routine repairs.

Penoplex, packaged in the form of a stack of sheets, is not damaged during transportation, it is easy to store and can be moved without special equipment. Knowing the required insulation area, you can easily calculate the amount of insulation for any construction and repair.

What are the advantages of external insulation

Insulating the foundation of a house from the outside is the simplest and at the same time effective way to avoid unpleasant or even dangerous phenomena:

- waterlogging and freezing of reinforced concrete;

- reinforcement corrosion;

- deformations caused by soil heaving;

- heat loss through the base and plinth;

- dampness in the basement;

- waterproofing violations.

Thermal insulation of the foundation and blind area allows you to reduce the laying depth to 30-40 cm, which is important in areas with heaving soils or high groundwater level. Thanks to this, it is possible to effectively reduce construction costs, especially for low-rise or frame buildings.

Extruded polystyrene (Penoplex)

Extruded polystyrene foam in our country is better known under the brand name “Penoplex”. Expanded polystyrene, or more precisely, its extruded variety, is the general name for a polymer insulation material produced on the basis of styrene. Penoplex is the brand name. Thermal insulation is produced in the form of sheets or plates, the thickness of which can vary from 2 to 15 centimeters. The sheet size is 60*120 centimeters; there is a special groove along its long side to facilitate installation.

The advantages of this material include:

low thermal conductivity coefficient;

high level of strength compared to brittle foam;

low moisture absorption rates by the material;

long service life due to resistance to destruction and rotting - up to 50 years;

good resistance to temperature fluctuations.

Penoplex has only one main drawback - its increased flammability. Since during external insulation of the foundation the bulk of the material will be below ground level, this nuance will not have a negative impact on the structural parts of the foundation. However, if you decide to insulate the entire building from the facade with this material, this point should be taken into account.

Insulation properties

The heat insulator is produced in the form of orange plates with dimensions of 1200x600 mm and a thickness of 20-150 mm. For ease of joining, a quarter was chosen at the edges around the perimeter. The raw material is polystyrene in granules, which is treated at high pressure and temperature with a catalyst - a mixture of freon and carbon dioxide. The mass, reminiscent of whipped cream, is extruded - squeezed through molds. After the gas evaporates from the foamed polymer, small closed pores with air remain - 0.1-0.2 mm in diameter.

The properties of the polymer material from which Penoplex Foundation is made and its microporous structure determine the technical characteristics:

- Low water absorption. In tests, only 0.2% of water was absorbed in the first 10 days and 0.6% per month. Sealed cells prevent moisture from penetrating into the slab, and suction occurs into external damaged microcavities.

- Low thermal conductivity coefficient. For Penoplex Foundation it is 0.032 W/m°C. This is the smallest figure among building materials. For example, for brick it is 0.81, and for pine it is 0.18 W/m°C. The polymer is not afraid of moisture and does not lose its high thermal insulation properties even in a humid environment, therefore it is used for insulating bases from the outside without additional waterproofing.

- Vapor tightness. A dense layer of polystyrene foam bubbles prevents moisture vapor from penetrating through the heat insulation board.

- Durability. Manufacturers claim that the service life of Penoplex Foundation is more than 50 years. The NIISF Institute confirmed this during tests.

- The low density of the material 29-33 kg/m³ is determined by the high pore content. According to this indicator, insulation is classified into Penoplex Foundation, Roofing, Comfort, Facade, Geo, Basis.

- High compressive strength. The material can withstand loads of up to 20 t/m², and the densest samples - up to 50 t/m². In this case, the volumetric deformation does not exceed 10%.

- Thermal resistance of Penoplex Foundation slabs is from -50°C to +75°C, in this range all the physical properties of the material are preserved.

- Environmental Safety. During installation and operation of the insulation, no harmful substances and gases are released.

- Chemical resistance. Aggressive acidic, alkaline environments, salts, alcohols, building solutions do not interact with the heat insulator. Substances that destroy polystyrene foam are aromatic hydrocarbons, ethers and polyesters, ketone compounds, oil paints, and tar.

- Biological inertness, resistance to decay.

See also: Catalog of companies that specialize in foundation repair and design.

For roof insulation, Penoplex is produced with increased fire resistance (class G1). This is achieved by adding fire retardants - substances that prevent combustion.

Characteristics of Penoplex insulation Source sv.decorexpro.com

For structures located in the ground, the fire resistance class of the material is not taken into account. Penoplex Foundation is used to insulate the above-ground parts of a structure, followed by protection with a non-combustible layer of at least 30 mm, for example, plaster or screed.

The need for thermal insulation of the foundation

Insulating the foundation of a basement

Insulating the foundation of a private house with polystyrene foam from the outside is mandatory. This also applies to other buildings, especially those containing a basement. To achieve high-quality results in installing thermal insulation, many use foam plastic.

A poorly insulated building loses up to 50 percent of heat through holes in the insulating coating, causing additional economic costs for heating. A fatal mistake when installing house insulation is neglecting the thermal protection of the foundation, believing that it will be enough to just finish the walls of the structure.

Good thermal insulation of the base is characterized by two functions:

- minimizing heat consumption;

- Preservation of the foundation from freezing and deformation.

The fact is that the predominant type of soil in our country is heaving. Due to the effects of cold, the depth of soil freezing can be several meters. During a thaw, the volume of soil changes, which in turn negatively affects the structure of the foundation of the house.

Before starting installation work, it is necessary to take into account that the installation of the thermal insulation coating must be complete. The presence of any cracks, defects and parts in the insulation layer has a detrimental effect on the building’s ability to maintain a temperature suitable for comfortable living. Only a dense air layer containing an insulation ball can completely contain the loss of warm air.

What is expanded polystyrene?

This is a snow-white foam material in the form of polystyrene balls, consisting of styrene, which forms its cellular structure, and a foaming agent - pentane. Both constituent components are hydrocarbon compounds obtained as by-products in oil and gas production cycles.

Characteristics of expanded polystyrene:

- High heat-protective qualities, since the insulation has low thermal conductivity in the range of 0.029 - 0.037 W/(m•K).

- Mechanical strength is ensured by the flexibility of the technological process, when it is possible to set a given strength for specific applications.

- It has special abilities to maintain stable dimensions at air temperatures up to + 80 C.

- Low water absorption - the insulation is not hygroscopic.

- High chemical resistance to salts and alkalis, but can easily be destroyed when treated with solvents.

- High resistance to atmospheric influences and aging processes.

- Low fire resistance - insulation is highly flammable. Modification of this material with fire retardants significantly reduces its flammability.

Extruded polystyrene foam: technical characteristics and price of quality boards

This type of thermal insulation material became available to users more than half a century ago. Extruded polystyrene foam, which is sometimes called extruded polystyrene foam, immediately became a universal insulator, in demand for a variety of jobs. Manufacturers offer standard size sheets that can be transparent or colored. Sheet plastic, thanks to its special structure and unique production technology, demonstrates high performance during operation.

Water absorption of the material is minimal

Attention! Before purchasing, you should find out the required insulation characteristics. Penoplex must meet the requirements.

Technical characteristics of 50 mm penoplex may differ slightly depending on the type of material. However, in most cases they change within a fairly narrow range.

Good technical performance is the main key to success

The technical characteristics of penoplex 35 include:

- Low water absorption capacity. The main advantage of this insulation. The heat insulator absorbs water molecules only on the sections, since air cells are open in these areas;

- Low thermal conductivity. On average, this figure is 0.03 W/m·C;

- Versatility. The manufacturer offers material of various thicknesses, making it possible to insulate many surfaces. It is used for thermal insulation of walls, foundations, loggias and balconies;

It will be warm on the balcony

- Low vapor permeability coefficient;

- Long period of operation. Penoplex is able to withstand repeated freezing/thawing without losing its basic performance characteristics. On average, such material can last about 50 years;

- High strength. During operation, the insulation can withstand significant load and pressure due to the presence of tiny air bubbles that prevent compression of the material;

High strength guaranteed

- Easy to install. The material can be easily cut with a sharp knife, giving the elements the required shape. The cut area does not crumble. Installation work can be carried out all year round, since the heat insulator is not afraid of exposure to UV rays and high humidity. The slabs can be installed at any time of the year;

Installation work can be carried out all year round

- Environmental safety. In the process of producing insulation, freon is used, which does not have a negative impact on the atmosphere. During operation, the insulation does not emit substances that can have a negative effect on the human body;

- Fire safety. The material is flame resistant;

- Minimal chemical activity and biological inertness. When performing construction work, a large number of substances with increased surface activity are used. Only a few are able to interact with penoplex. The heat insulator does not rot or decompose.

Penoplex is not the only extruded polystyrene foam that can be purchased for home insulation. Other manufacturers use similar technologies and offer high-quality insulation.

Technoplex is another type of extruded polystyrene

The technical characteristics of Technoplex are somewhat different from those of Penoplex. This contributes to a change in the composition of the raw materials used. A certain amount of graphite is added to the composition of the extruded mass. The result is a highly effective insulating material that is resistant to water.

Technoplex absorbs noise well and has a long service life. At the same time, it is somewhat inferior in strength. It works well at fairly low temperatures typical of the far north and has a lower level of water absorption. Only 0.2%. However, when purchasing this type of thermal insulation material, you will have to pay more. Considering that insulating walls usually requires a large amount of material, this factor may be decisive when choosing.

Video review: extruded polystyrene foam

Penoplex sheet sizes: how to choose the right one?

A special technology for the production of extruded polystyrene makes it possible to form a material with a unique structure, ensuring high strength of the slabs and guaranteeing unique thermal conductivity. As a rule, a material of small thickness is used for thermal insulation of various surfaces. When choosing the appropriate option, you should rely on the manufacturer’s recommendations.

Sheet sizes are standardized

If you have to insulate an object that will be operated in a temperate climate, you can use slabs with a thickness of 35-50 mm. Their technical characteristics will ensure the required level of thermal insulation of walls or roofs.

For regions located in cold climate zones, it is worth purchasing 70 mm thick insulation. Even if the frost is more than -30°C, a comfortable temperature will be maintained inside the building.

Penoplex slabs have standardized dimensions. The manufacturer offers slabs 1.2 m long and 0.6 m wide of various thicknesses. The last dimension can be in the range of 20-150 mm. The selection of a suitable thickness should be made taking into account the operating conditions of the insulated surface.

Before purchasing thermal insulation material, you should calculate the required quantity. To do this, you need to know the area of the insulated surface. You should definitely find out when choosing 50 mm penoplex how many m² are in the package. The number of packages that are worth purchasing will depend on this. Sheets are also sold individually, and therefore the missing quantity can be purchased additionally.

The number of sheets per package may vary

For those who buy penoplex, how many pieces are in the package matters. This indicator depends on the thickness and type of slabs. For material 50 mm thick the ratio is as follows:

| Type of insulation | Image | Number of slabs per package, pieces |

| Comfort | 7 | |

| Wall | 10 | |

| Foundation | 8 |

Advantages of external insulation

If your house has not yet been insulated, then the answer to the question - is it necessary to insulate the foundation of the house from the outside with Penoplex - is obvious - it is absolutely necessary.

High-quality external insulation of the foundation will reliably protect it from the negative influences of the external environment and increase indoor comfort. In general, it is recommended to carry out such work at the stage of erecting the foundation of the building.

If we summarize the main advantages of external insulation of the foundation and basement of a building, they look like this:

increased resistance to temperature changes;

The trench must be of sufficient widthSource modernizacija.ru

- it becomes possible to maintain a constant temperature in the basement regardless of the time of year;

- a reliable barrier is created that prevents groundwater and rainwater from penetrating into the basement;

- The service life of the foundation increases significantly due to the reliable protection of concrete from the effects of low temperatures and moisture.

Thermal insulation of the foundation has another undeniable advantage - the ability to move the dew point. This is the moment when water vapor condenses into water. In winter, the difference in temperature inside and outside the room leads to the appearance of droplets of moisture. They gradually destroy the finish and infect the walls with fungi.

What is Penoplex: features, advantages, types

Penoplex is extruded polystyrene foam, which gets its name from the trademark of the same name. It belongs to the category of the most popular thermal insulation materials due to its unique technical characteristics and reasonable cost. It is actively used for insulation of various surfaces during the construction and reconstruction of residential buildings and public buildings.

Suitable thermal insulator for multi-storey buildings

During the production process, polystyrene granules are foamed under high pressure and temperature conditions. The process catalyst is carbon dioxide and light freon. The finished mass, similar to cream whipped with a mixer, is blown out through special nozzles of the extrusion unit. Here the freon evaporates, and the resulting voids are filled with air.

Extruder is an indispensable equipment

This production technology makes it possible to obtain a finely porous material, inside which adjacent cells with air are isolated from each other. The diameter of the air pockets does not exceed 0.1-0.2 mm. Thanks to its uniform distribution throughout the entire volume of the material, the manufacturer ensures the required level of properties. The material is highly durable and demonstrates excellent thermal insulation properties. By selecting a material of sufficient thickness, the desired effect can be achieved.

Unique structure – guarantee of high quality

For your information! Penoplex 50 mm is used for insulating buildings, roads, and runways.

Insulated fabric will last a long time

The manufacturer offers various types of thermal insulation material:

- Foundation capable of withstanding significant loads during operation. The minimum thickness of the slabs is 50 mm. If necessary, you can order a heat insulator of greater thickness if the structure will be operated in the northern regions;

- Roofing , which has a special shape that facilitates the process of laying slabs. Using this type of thermal insulation material, it can provide high-quality protection for the roof from external cold. In this case, it becomes possible to use the attic as a living space;

- Comfort . A penoplex thickness of 30 mm is usually sufficient for high-quality thermal insulation of the walls of a residential building or loggia;

- Wall . A suitable option for insulating walls inside and outside the job. The thickness of the material can be 20-50 mm. If the work will be done from the inside, it is better to choose a thinner material. For the facade it is worth ordering thicker slabs.

The manufacturer offers various types

Attention! A penoplex thickness of 10 mm is not enough for high-quality insulation of the walls of a building used in winter. You should choose thicker slabs, for example 70 mm.

Related article:

In our article you will learn what types of penoplex there are, how the facade is insulated with penoplex (technology) , as well as the pros and cons of this facing material.

Main technical characteristics of penoplex for the foundation

According to the technical characteristics, Penoplex GEO corresponds to the old type Penoplex 35, the production of which was carried out without fire retardant. It is used for thermal insulation of surfaces whose fire resistance is not subject to increased requirements. The material belongs to group G4.

The foundation is in demand in private construction

The main area of application of a heat insulator is the insulation of loaded structures with the subsequent application of a protective layer. The material is in demand when installing cement-sand screed, thermal insulation of foundations, floors, building bases or garden paths. The slabs become reliable protection for the waterproofing layer, providing groundwater drainage and reducing their impact on the underground structures of buildings.

The foundation must be reliably protected

For your information! Biostable durable insulation is in demand when constructing shallow foundations on heaving soils.

The service life of shallow foundations has been increased

The minimum thickness of the penoplex Foundation is 50 mm. If necessary, you can also purchase slabs with a thickness of 80 mm. The slabs are able to withstand significant loads throughout their entire service life. Their strength at linear deformation of 10% is 0.25 MPa. Water absorption by volume over 4 weeks does not exceed 0.5%. The insulation can last for more than half a century, including when used in the harsh climate of the northern regions.

Main technical characteristics of penoplex Comfort

This type is universal. The technical characteristics of Penoplex Comfort 50 mm allow for thermal insulation of many surfaces. With its help, the roof, basement, walls, floor and foundation of the building are simultaneously insulated. The low level of water absorption, not exceeding 0.5% for 4 weeks, makes it possible to use Comfort when insulating a sauna, swimming pool or bathhouse. It is possible to insulate other objects that are operated in conditions of high humidity.

Comfort is suitable for sauna insulation

Tight joining of elements among themselves helps to increase the stability of enclosing structures. Not biodegradable. There is no need to fear that insects will appear inside the heat-insulating material and destroy the structure of the slabs from the inside. Capable of serving for more than 50 years, maintaining its technical characteristics. Can be used in various regions, including the northern ones.

The house will be warm in winter

The material is quite dense, and therefore does not sag when attached to a vertical structure. It is necessary to carry out installation correctly and reliably protect all plates. The density of Penoplex Comfort is regulated by TU 5767-006-54349294-2014. When cut, it does not crack or crumble. Compressive strength depends on the thickness of the slabs: if less than 60 mm - 0.12 MPa, more than 70 mm - 0.18 MPa.

It is possible to insulate vertical surfaces

Attention! Finishing must be done on the insulated surface.

Applying the finishing layer allows you to:

- Give penoplex an aesthetically attractive appearance. The material itself does not allow the formation of a beautiful surface that could be used without additional processing;

- Prevent discolouration of slabs;

- Avoid destruction of the material.

Finishing is required

Main technical characteristics of penoplex Roofing

Penoplex Roofing slabs are in demand in the construction industry. The characteristic orange color material is produced with a density of 35 kg/m3. Allows you to form a hard and moisture-resistant heat-insulating layer that is lightweight. It can be used for the installation of roofs of various types, thermal insulation of building facades, floors and walls of erected and reconstructed buildings, basements, and laying utility lines.

With thermal insulation boards the roof will be warm

The material is classified as moderately flammable. During the combustion process, it emits a large amount of smoke. This feature should be taken into account when choosing insulation for a living space.

Combustion features should be taken into account

A special connection of tenon and groove elements allows the formation of a homogeneous layer that does not have cold bridges. Thanks to the refusal to overlap adjacent elements during the installation process, it is possible to optimize the thickness of the installed thermal insulation layer and more rationally manage the free space.

The sheets fit tightly together

Water absorption by volume of the slabs does not exceed 0.5%, and therefore the thermal insulation layer practically does not absorb moisture. High strength allows it to withstand significant loads to which the heat-insulating material may be subjected during the installation of slabs and subsequent operation of the insulated object.

You can walk on the roof

If you need to insulate the façade of a building, instead of foam roofing, you can use a special type of heat insulator. Its characteristics were initially adapted for this type of work. The price of Penoplex insulation for walls outside the house is acceptable for many. It depends on the thickness of the slab. To insulate a balcony, you can purchase material 20 mm thick, for a residential building - 50 mm.

The wall is suitable for the facade of a building

Advantages and features of penoplex

Penoplex is a Russian product. It is actively used by builders and residents of the private sector who decided to do the insulation of the old foundation themselves. It is polystyrene foam, which during manufacturing was extruded (foamed under the influence of high temperatures), thereby improving its technical characteristics:

- moisture resistance – 0.5% of the total volume of the material;

- operating temperature range from –500 to +750 C;

- compressive strength – 27 t/m2;

- service life – 50 years and above.

And this is not all the advantages of penoplex. You will find more information about the composition and properties of the material here: “Foundation insulation”.

Photo: thermal insulation material “Penoplex”

Insulation comes in 3 main types:

- Penoplex 45. Expanded polystyrene with maximum density. Designed for insulation of complex structures with high loads - airfields, industrial buildings, highways.

- Penoplex 35. Another name is Penoplex Foundation. It is used for thermal insulation of tapes, monoliths, and pile foundations. Suitable for vertical or horizontal installation.

- Standard. Made in the form of slabs. Widely used. They are used to insulate utility networks, walls, and wooden floors.

Each type is made according to the “tongue and groove” principle. This ensures that the elements are tightly fastened to each other without gaps.

Photo: tongue and groove system

Thematic material:

- Types of strip foundations for a private house

- Pile-screw foundation

- DIY tire foundation

Main characteristics

Now it’s worth taking a look at the Penoplex Foundation insulation in more detail, having studied the technical characteristics of the insulator.

In general, polystyrene foam insulation is in high demand nowadays.

The raw material for the production of such insulation as Penoplex Foundation is polystyrene, which is melted and foamed with carbon dioxide. This allows you to form a structure from closed cells, the cross-section of which does not exceed 200 microns.

The material does not contain phenolic resins, as well as additional harmful impurities. The insulator is not afraid of the process of organic decomposition, and it does not release toxins.

The structure is porous, but completely closed. This allows you to protect recessed structures from possible freezing, as well as direct contact with groundwater. The average heat loss through the base of a building when using such an insulator is reduced by 20%, which is a very good indicator.

Penoplex Foundation is a slab whose size is 1200x600 mm. In this case, the thickness can vary from 20 to 150 mm. The most popular sizes are 50 mm and 100 mm.

If the foundation is insulated, it is recommended to take slabs with a thickness of at least 50 mm. Thinner sheets are relevant for multi-layer installation. The approximate service life of the material exceeds 40-50 years.

Based on the manufacturer’s data, the extruded polystyrene foam Penoplex Foundation has the following characteristics:

- compressive strength is 0.27 MPa;

- statistical bending strength 0.4;

- thermal conductivity index 0.03;

- fire safety class G4 (highly flammable material);

- destruction temperature is 200 degrees Celsius;

- density about 30 kg/m3;

- daily water absorption rate no more than 0.4%;

- operating temperature range from -100 to 75 degrees Celsius.

Moreover, all these characteristics, as well as properties, do not change provided that the material is exposed to groundwater pressure.

With a thickness of 50 mm, the weight of one slab will be slightly more than 1 kilogram.

Briefly about technology

In 1998, the Russian company PENOPLEX began production of thermal insulation boards from extruded polystyrene foam. A group of enterprises in the cities of Kirishi, Perm and Novosibirsk produces construction and decorative materials using Italian high-tech equipment under quality control by an accredited laboratory. Penoplex Foundation is an effective slab insulation material, widely used in our country for thermal insulation of capital structures in both private and industrial construction. Protecting bases from freezing increases energy savings by 20%.

Penoplex Foundation: sheetsSource vdom36.ru

Do-it-yourself insulation of the foundation with penoplex.

Preparation of the work front.

To carry out the work you will need the following tools: tape measure, construction knife, hammer drill, concrete drill 200 mm long (according to the diameter of the dowel), mixer for mixing glue, wide brush, shovels, tamper.

You can calculate the number of slabs knowing the area of the insulated foundation and the area of the slab. The area of the foundation is calculated by multiplying the perimeter by the height of the foundation, and the area of the slab is 0.72 m2.

It is ideal to carry out insulation during the construction phase

But this can be done in a house that has already been built and it doesn’t matter how long the building costs

To insulate the foundation from the outside, it is necessary to dig it around the perimeter to the depth of soil freezing. This is a different indicator for each region, but usually it fluctuates in the range of 0.6 - 1.2 m, unless we are talking about the permafrost zone.

The width of the trench should allow work to be carried out on fastening slabs and applying waterproofing without being particularly crowded.

The exposed walls must be cleared of any remaining soil and roots. If the foundation wall is uneven, it is necessary to level it with cement mortar. After the leveling layer has dried, you can begin insulation.

The thickness of the foundation walls in private housing construction is usually 0.4 or less than 0.6 m. To insulate such walls, 10 cm thick penoplex is used.

Installation of polystyrene foam boards.

Before installing penoplex slabs, a layer of waterproofing must be applied to the walls. This work is carried out using a wide brush and bitumen mastic. To make the work easier, you can use a ready-made bitumen primer that has the consistency of slightly thickened paint.

The primer has high adhesion to concrete surfaces and adheres well to the wall. The drying time for the primer is one day. The next day you can begin attaching the insulation.

Penoplex boards are attached to the wall using cement adhesives for fastening polystyrene foam. You need to dilute the glue according to the instructions on the package and let it sit for a while.

The slabs can be glued in both vertical and horizontal orientation. It all depends on the depth of the foundation. At a depth of 1.0 m, you can dig below the laying level in order to attach the insulation vertically without cutting off the remainder. If the depth is no more than 90 cm, then you can turn the slab in a horizontal plane, and cut the slab installed in the second row in half along the long side.

The adhesive must be applied pointwise to the slabs. A continuous layer of glue can be applied if the foundation wall is perfectly flat. After applying the glue, the insulation is pressed against the wall and left for a short time. The next slab is combined with the groove of the previous one and thus moved along the perimeter of the house. Fastening the slabs begins from the bottom. The groove in the slab gives a tight fit to each other and eliminates the appearance of gaps, cracks and cold bridges.

Then, additional fixation is performed using dowel nails

This is especially important when the insulation of the foundation is combined with the formation of the base of the house and part of the insulation extends above ground level. On each slab it is necessary to install five dowels in an “envelope” pattern - one in the center and two in the corners

Having finished fixing the slabs with dowels, some of the slabs that extend above ground level and form the base are plastered over a plaster mesh.

Application area

In practice, Penoplex Foundation is recommended to be used when it is necessary to insulate a loaded structure, which does not impose increased requirements in terms of fire safety.

These can be different foundations, insulated floors, plinths, as well as basements and even garden paths. Bricks, concrete, gas silicate blocks, foam blocks, as well as other types of flat surfaces can be used as base materials. That is, the material is quite suitable for insulating foam blocks, as well as insulating aerated concrete.

Such slabs should be used mainly for external insulation. They will be able to counteract soil heaving during frosts, and will also act as part of the drainage system, helping to remove moisture from the foundation.

However, it cannot be said that in terms of internal use there are any strict restrictions. Therefore, penoplex can be used inside. For example, to insulate the basement.

Where is the material used?

Expanded polystyrene penoplex Foundation is usually used for the following purposes and objects:

- Vertically loaded insulation for foundations

. The slabs are mounted without using additional fastenings using dowels. Laying is carried out on a layer of bitumen or roll waterproofing. Sand and soil on top. The upper part of the penoplex will protrude above the ground level by about 40-50 cm; - Shallow foundations

. Penoplex formwork for the foundation is effective. The material should be cut and laid on the base on top of the drainage (a base of sand and gravel that has been compacted). Make it 30-40 cm lower than the future blind area. And the second half is glued to the walls in a vertical plane. As in the first case, the top of the slab should protrude at least 40 cm; - Objects with rare visits

. In this case, penoplex is mounted under the foundation, and thinner sheets are also attached from the outside; - Unheated structures

. To increase their service life and also effectively remove moisture, penoplex is attached from the bottom. Here it is recommended to take slabs whose thickness ranges from 50 to 100 mm; - Columnar foundations and individual supports

. Penoplex should be cut into pieces that will be larger in area than the cross-section of the structures. And then install a drainage mixture of sand and gravel on top; - Strip foundation

. Here, thermal insulation is carried out according to a similar scheme. That is, you need to cut the insulator into appropriate strips; - Insulation of blind areas and garden paths.

As you can see, there are more than enough application options. You just need to decide what exactly the Penoplex Foundation can be useful to you for.

Possible mistakes

Despite the fact that information about the choice of insulation and the technology for its installation on basement surfaces is publicly available in sufficient quantities on the Internet, in practice, contractors make a large number of mistakes that lead to deformation of not only the heat-protective layer, but also the structural elements of the building.

How to eliminate them?

Most errors made during the installation of thermal insulation cannot be corrected; a complete rework of the base thermal protection system will be required. For example, if solutions not intended for this purpose were used as an adhesive or reinforcing mixture, for example, tile adhesive.

You also can’t save money by mixing glue with sand or adding cement to it for “strength.” It is no less dangerous to use cheap reinforced mesh or violate the technology of its installation. It is better if it is alkali-resistant, with a density of at least 140 g/m2.

A common cause of cracks in the thermal insulation of the base is when the reinforcing mesh is mounted directly on a layer of thermal insulation sheets. It needs to be deepened into the reinforcing layer so that it is 1/3 in the center of the layer. Another common mistake when reinforcing is connecting reinforced mesh sheets without an overlap of 10 cm.

Penoplex foundation insulation technology

Vertical option

Before starting work, you need to dig out the foundation exactly to the depth, clean it of dirt, stones, soil residues, etc., and, if necessary, level the surface with cement mortar. Using bitumen or polymer mastic, the water-based coating procedure must be carried out. Under no circumstances should you purchase solvent-based mastic. Contact with it will destroy the insulation.

Glue intended for polystyrene foam must be diluted exactly according to the instructions, then mixed thoroughly and left to mature. On the foundation, the lowest line for laying is first marked. If the base is somewhat uneven, then you can place the insulation slightly below the level where the foundation begins. The prepared glue is applied strictly pointwise in several places at once. The first slab is pressed tightly to the surface, held a little and leveled

The second plate must be firmly secured, carefully aligning the mounting groove

Usually, for more effective thermal insulation, several layers of penoplex are laid at once in a checkerboard pattern so that the slabs of the subsequent layer cover the seams of the first. The technology for laying the next layer is the same.

There is no additional need to secure insulation in the underground part of the foundation. After filling it with soil, it will stay tight. But in the base part, immediately after the glue has dried, the material must be additionally secured with dowels. The length of the drill must correspond to the thickness of the slabs.

If there is a need for some kind of decorative finishing, it can be freely done on top of the slabs of material. You can apply plaster or tile adhesive and then reinforce them with mesh.

Horizontal option

For this insulation option, slabs with a thickness of 6-10 cm are selected.

The site chosen for the foundation is carefully and accurately marked, and the topmost layer of soil is removed to the required depth. The bottom is made perfectly flat, the site is filled with bulk material (most often sand) and then compacted. Temporary formwork is prepared and filled with a thin layer of concrete. In this case, the base is not reinforced. When the concrete base hardens, foam boards are placed on it with full alignment of the mounting groove. There shouldn't be the slightest gap.

A polyethylene film is laid on top of the insulation. Then all joints are carefully taped with tape. This film is a waterproofing layer and perfectly prevents concrete from leaking.

Next, formwork is performed, followed by reinforcement and the final pouring of the foundation.

Correct foundation insulation technology

When starting work, you should draw up a detailed plan for the foundation of the building, prepare in advance the necessary tools and building materials for this.

- foam boards of the required thickness;

- adhesive composition for fixing thermal insulation;

- balloon mounting foam;

- deep penetration primer composition;

- plastic dowels for additional fixation of insulation boards to the base;

- reinforcement mesh on a metal or polymer base;

- a drill with a special attachment or a construction mixer;

- perforator;

- container in which the adhesive solution will be mixed;

- construction or stationery knife;

- Master OK;

- rule;

- bubble level;

- putty knife;

- brush for distributing the primer.

The role of thermal insulation for shallow foundations

Insulating the foundation with penoplex during the construction of low-rise buildings allows you to reduce the cost of construction due to the relatively low price of the material. And most importantly, the use of penoplex prevents deformation of the base of the building due to soil heaving. The benefit is obvious, since the cost of the foundation sometimes reaches up to 45% of the total cost of a low-rise building.

The technology for do-it-yourself insulation of the main load-bearing structures of buildings using penoplex foam is almost no different from other methods of thermal insulation using slabs. The essence and purpose of the process is to increase the durability of the building by reducing deformations due to soil heaving and protecting basements or basements from cold.