Tent hangars are based on a soft roof, so the technology for their insulation differs from the insulation of hangars with a hard roof. A suitable option for protecting the structure is polyurethane foam. It can be applied both from the inside and outside of the hangar. We will tell you further how to properly insulate PPU hangars and what nuances to take into account.

Insulation with polyurethane foam (PPU)

The material is a synthetic insulation, which consists of polymer foam, a group of plastics. Today it is one of the most used insulation materials.

Advantages

Let's start with the advantages of polyurethane foam:

- the possibility of spraying on any shape, which reduces the number of possible cracks and holes;

- continuous, seamless spraying increases the efficiency of insulation;

- will not support combustion - self-extinguishes;

- high vapor permeability, allowing excess moisture to be removed;

- long service life - from 25 years;

- resistant to aggressive environments;

- is not allergenic.

Flaws

Despite the excellent characteristics, the product has its disadvantages:

- high price - about 27 thousand rubles per 100 kg;

- a good result is possible only if the technology is followed;

- There is a rumor that the material is harmful to health.

Sequence of work

All work can be completed in a couple of days:

- First of all, remove everything that is crumbling, greasy stains, paint. Even with good adhesion, surface preparation will not be superfluous.

- Everything that should not be covered with the material should be covered with polyethylene, which is secured with tape. It should be secured very carefully so that there are no gaps.

- At the beginning of installation, a permanent sheathing is made.

- Using cylinders, the required thickness of polyurethane foam is applied.

- After work, the surface is cleaned.

- Wooden or metal strips are attached to the wall, to which the exterior trim is attached.

Where are frameless hangars used?

Of course, frameless arched hangars are the most popular in industry - they are used as warehouses and workshops, as markets, bases and storage facilities, for temporary or permanent placement of working equipment, and, if suitable conditions are provided, for personnel.

In addition, the arched hangar can be used as an indoor stadium or skating rink, parking lot, workshop, gallery, studio - the range of possible uses is so wide that there is no point in using it completely. However, let’s consider possible ways to use this structure in a private sector:

- garage is the most popular and cheapest option for placing cars, trucks, agricultural and other types of equipment;

- a barn is an ideal option for owners of country and village houses and farms. The range of applications is extremely wide - the hangar can be used as a storage area for harvested crops, a chicken coop, a cattle pen, etc.;

- attic floor - in this case, a frameless arched hangar is installed directly on the roof of the house, provided there is a flat roof. This is very convenient if, for example, you want to build an insulated greenhouse - the structure is compact and has extremely low weight, putting almost no load on the building;

- a work space - a hangar - may be suitable for an entrepreneur to place a temporary office. This use has many advantages, in particular, placement in almost any location with low space consumption and savings on rent;

- room for leisure – in winter, the insulated hangar can be used as a children’s playground, gym, tennis court or indoor swimming pool.

Advantages and disadvantages

Frameless hangars are insulated with lightweight materials.

Structures based on a metal frame are distinguished by their strength. The service life with proper use and prevention is twice as long as that of frameless models.

The technical advantage is explained by:

- the presence of a strong foundation;

- installation of durable load-bearing elements;

- high level of hangar stability.

The disadvantages of construction include the duration of construction of the foundation. Typically, if the weather is good, pouring the base can take up to two weeks. With constant rain it will take a month. The frame is assembled after the concrete has completely hardened.

The main advantages of frameless construction include water impermeability and tightness of seam fasteners, which reduces operating costs.

The disadvantages include:

- reduction in the usable area of the hangar due to giving the building an arched shape;

- limiting the overall dimensions of the building;

- low height indicator.

Frameless models are installed once, as they cannot be disassembled. If damaged, the building cannot be repaired. It is possible to replace only part of the arches at the edge. The elements in the middle are not restored. The fasteners of the structure also have disadvantages.

Equipment for the manufacture of frameless models must be located on the construction site, although some companies offer a service for installing the finished structure.

Advantages of polyurethane foam

- High-speed technology for installing thermal insulation. During one work shift, the installer applies from 300 to 400 m2 of coating to the surface of the hangar.

- Light specific weight and the absence of additional fasteners make it possible to insulate the room without loading the foundation and load-bearing supports of the hangar.

- High adhesion of polyurethane foam. The material is applied by spraying and penetrates under pressure into the pores, cracks, joints and seams of the surface. When hardened, it expands and sticks without additional fasteners or adhesive mixtures.

- PPU forms a dense monolithic layer, which increases the rigidity of hangar structures, which increases resistance to wind and snow.

- Thanks to its adhesive properties, it holds firmly on inclined and sloping surfaces and does not slip over time under the weight of its weight.

- The finished design of the PU foam insulation has no seams or joints, so there are no “cold bridges”, and the appearance of condensation on the walls and corrosion on metal parts is eliminated.

- Provided with environmental and biological safety certificates.

- Polyurethane foam is a non-flammable material and is classified as a fireproof insulation material.

- It has vapor and waterproofing and sound-absorbing properties.

- Retains its thermal insulation properties for over 30 years.

Internal installation of thermal insulation is preferable. These works are not tied to the time of year and can be performed at any time. After spraying, the walls are reinforced for greater strength and plastered.

External insulation is carried out only at an air temperature of +10 degrees, in the absence of wind and precipitation. After hardening, reinforcement also occurs and coating with special paint is required. PUF is sensitive to direct sunlight, so it is protected by painting.

The price of insulation using polyurethane foam is not much different from the price of thermal insulation work using classical materials. The difference pays off in the speed, durability, and versatility of polyurethane foam.

Are you interested in economical, fast, effective insulation? Leave a request for a consultation on our website. We will call you back and choose the most appropriate options for thermal insulation of your premises.

With our company “PPU Insulation”, quickly means quality!

Important Rules

First of all, polyurethane foam is distributed over internal structures. At the same time, due to its high adhesion, it quickly adheres to any surfaces, forming a monolithic connection.

Application technique

The mixture is applied in liquid form while maintaining the highest possible pressure. Hardening occurs quickly - in 10-12 seconds. This allows you to obtain a monolithic 2-layer structure.

When treating with polyurethane foam, the product is distributed between 2 sheets of steel or in 1 layer over the entire interior.

Even under harsh climatic conditions, polyurethane foam provides a high degree of thermal protection. Additional investments are not needed, since the material is held in place without installing fasteners.

The mixture hardens quickly.

Rigid subtypes of polyurethane foam have low vapor permeability. Therefore, laying a vapor barrier membrane is not necessary.

The main advantages of thermal insulation with polyurethane foam

Despite the high cost, polyurethane foam thermal insulation has a number of important advantages. It allows you to protect the hangar room from heat loss, street noise and other negative factors.

Environmental friendliness

PU foam does not contain formaldehyde or phenolic resins, which are found in expanded polystyrene or mineral wool products. Therefore, it can be used to insulate buildings where food, vegetables and grains are stored.

Polyurethane foam does not contain phenolic resins.

Chemical resistance

Polyurethane foam is not afraid of exposure to solvents, chemicals, alkalis and acids. In addition, its composition and density do not change upon contact with steam or water.

Thermal properties

The material has increased thermal insulation properties. With identical thickness, it is 2 times more efficient than traditional solutions. Therefore, developers can reduce the thickness of the insulation layer while maintaining optimal thermal conductivity.

Polyurethane foam has good thermal insulation properties.

Physical and mechanical features

Polyurethane foam is distributed over the surface without installing additional fasteners. After the surface hardens, it becomes monolithic and rigid. This increases the safety margin of the hangar structure and allows it to withstand heavy loads.

Lifetime

Using polyurethane foam, you can form a monolithic coating with a long service life. The service life declared by the manufacturer is 30-50 years. Minor defects and mechanical damage can be eliminated by filling a new portion of the solution.

The service life of polyurethane foam is 30-50 years.

Main stages

Thermal insulation of a hangar with polyurethane foam is carried out in several stages:

- Preparatory activities.

- Preparation of the working mixture.

- Finishing work.

Preparatory activities

Before carrying out work on thermal insulation of a building, the surface must be dried, degreased and cleaned of dust. If you ignore such requirements, polyurethane foam will not be able to reliably adhere to surfaces, so the degree of thermal protection will decrease. Excess moisture will stop the normal course of chemical reactions inside the polyurethane foam, so its insulating properties will deteriorate.

The surface of the building must be dried and cleaned of dust.

Getting the mixture

Initially, the raw materials are delivered to the site where they will be used. In most cases, it is brought in barrels with 2 components - isocyanate and polyol.

To mix liquids, a dosing reactor with a pressure of up to 150 atm is used. The process itself is carried out in a special gun, which is periodically cleaned of adhering debris. Simple air is suitable for cleaning.

Sputtering

At the next stage, the surface of the hangar is developed with an even layer of fine aerosol. It allows you to close all hard-to-reach voids and cracks.

Spraying is applied in an even layer using an aerosol.

Upon contact with a metal surface, violent chemical reactions begin in the solution. The composition foams quickly, but then becomes hard. 95% of strength appears after 2 hours, but the full set of required indicators takes 1 day.

Insulation "Sandwich" (Double-layer hangars)

They are a three-layer structure. Two layers are galvanized metal sheet, and one is insulation. Mineral wool, glass wool, and polyurethane foam are used as insulation.

The essence of insulation is to place two hangars on top of each other, and lay insulation between them.

It is worth noting that an advisable solution would be insulation using the “Sandwich” scheme during the construction of the building, since carrying out work on a ready-made hangar will be expensive (approximately ½ of the cost of the hangar).

Advantages

Multilayer panels have a number of positive characteristics:

- excellent water-repellent properties;

- installation of wall panels is carried out throughout the year;

- fire safety (the structure does not burn);

- 100% environmentally friendly;

- wide range of colors for galvanized sheets.

Flaws

In most cases, it is the shortcomings that influence the buyer’s choice:

- in the absence of air exchange, condensation may occur;

- damage to a section of material will require replacement of the entire element;

- if the length of the slab is more than 7 m, it will not be able to withstand the additional load;

- improper installation in winter and autumn will lead to icing of the surface;

- fragility of the structure (about 20 years);

- high price.

Sequence of work

Insulation takes at least a week and requires the work of specialists:

- Before installation, the outer surface of the hangar is cleaned.

- If necessary, carry out sealing, internal ventilation and electrification work.

- A grating is installed on the surface of the constructed hangar.

- They produce insulation with material. First in the end parts, wall parts, and then on the roof.

- Another frameless hangar is built on top of the insulation, the radius of which is increased exactly by the thickness of the insulation.

Thermal insulation process using polyurethane foam

Hangar premises can be framed or frameless. The 2 options have both positive and negative properties. At the same time, it is necessary to select the appropriate insulation technology for them.

Frame hangar

The structure consists of a metal frame, is installed on a solid foundation and finished with suitable material. The frame is easy to dismantle and reassemble. All structural elements are secured with bolts. The shape of the frame affects the functionality and efficiency of the hangar.

Channels, pipes, I-beams and other metal products are used as the basis for the frame. The structure can be treated with a primer of any color.

Models based on a metal frame have the following advantages:

- A strong foundation.

- Durable load-bearing structures.

- Resistant to mechanical stress.

However, the construction process takes a long time. Under favorable weather conditions, pouring the foundation takes 2 weeks. If it rains constantly, it can drag on for a month.

Insulation in a frame hangar is applied using generally accepted technology. Initially, the surfaces are prepared, then the components are mixed and the solution is evenly distributed.

Frameless

Such hangars can be erected immediately on the construction site using mobile special equipment. The construction process involves profiling and corrugating steel in rolls to give an optimal radius. Then the arched structures are connected into blocks using edging equipment, lifted by a crane and secured to the finished foundation. The hangar elements are fixed by spot welding and bolts.

Frameless structures do not allow water to pass through, have sealed seam fasteners and are aesthetically pleasing. However, due to the arched layout, the usable area is reduced. Such a hangar can only be installed once, because... it cannot be dismantled. If damage occurs, it will be impossible to repair the building.

The specifics of insulation of frameless hangars provide for a number of restrictions associated with the choice of insulators. Additional elements cannot be attached to metal structures using self-tapping screws or other fasteners, because this will lead to a violation of the integrity of the structure.

When applying insulation to a frameless hangar, there is no need to install wind protection or lay vapor- and waterproofing film.

What is PPU?

Polyurethane foam or polyurethane foam or PPU is a unique thermal insulation material. It is 90% air, enclosed in tiny bubbles. The shell of the bubble is made of the thinnest polyurethane film.

Foam is applied to the surface using a special apparatus in which the components of the future insulation are mixed. The finished mixture is fed into the sprayer under high pressure. As soon as polyurethane hits the surface, it enters into a chemical reaction with atmospheric air and begins to foam. Due to the capture of air molecules, its volume increases 80-100 times.

This application method allows you to insulate a hangar of any configuration, filling even the smallest joints.

PPU is a material with a high degree of adhesion. The foam sticks and is fixed on the surface of any material, even the smoothest.

It does not require any additional efforts to pre-prepare the surface before application - it is enough to mechanically clean it of dust.

Thermal insulation options

To carry out thermal insulation work in warehouses, different materials are used. Some solutions are suitable only for external or internal work, while others are universal.

Minvata

The hangar is insulated with light subtypes of mineral wool with a density of 130-140 kg/m³. Such insulators do not lose their initial properties and shape during temperature changes, and are characterized by resistance to chemical reagents, mechanical stress and corrosion.

Mineral wool is the most popular insulation.

Mineral wool is suitable for thermal insulation of any type of premises. It can even be used when processing frameless buildings.

The disadvantage of insulation is the gradual accumulation of moisture. To eliminate this effect, you need to apply a membrane film for waterproofing.

Sandwich panels

If the hangar is built from sandwich panels, there is no need to insulate it additionally. The material consists of 3 layers: 2 are made of galvanized sheet metal, and 1 is insulation, for example, mineral wool. Models for walls and roofs are available in different colors.

Sandwich panels consist of three layers.

Insulating buildings with sandwich panels is a profitable investment. Such products have heat insulating properties, and also create a natural fence and protection for the building. They look aesthetically pleasing and do not require additional finishing.

Ecowool

Ecowool is produced from paper industry waste and is not susceptible to mold or rotting. It is an environmentally friendly material, so it is suitable for use in hangars where food is stored.

The material is fixed both inside and outside. For this, 2 technologies have been developed:

- Dry.

- Wet.

Ecowool is not susceptible to mold.

In the first method, cellulose fibers are blown using special equipment between 2 surfaces. The second option involves wetting the raw material with water to which glue is added. It is customary to apply insulation using the spraying method.

Foamed polyethylene or foil penofol

Polyethylene belongs to the class of lightweight insulation materials that do not place excessive load on the building. The main raw material is foam mixed with reflective foil. The use of such a composition for insulating hangars is a new method of thermal insulation. The thickness of the penofol does not exceed 1 cm, and the foil layer - 20 microns. Models with a thickness of 40 mm are being developed for the northern regions.

Foamed polyethylene is a lightweight insulation material.

Foil penofol has reflective properties, so the building is always cool in summer and warm in winter. In addition, it weighs little, which simplifies installation and delivery to the site. Disadvantages include low rigidity, high adhesive properties and electrical conductivity.

Polyurethane foam (PPU)

The insulation is applied to the surface of the hangar using special equipment in which insulating components are mixed. The finished solution is sent to a sprayer under high pressure, after which the reaction of the polyurethane with air begins and the formation of foam. As a result of such processes, the volume of the mixture increases 80-100 times. Polyurethane foam solves a number of problems due to its characteristic properties and specific application. The method is often used by private developers, because... it is quite simple and fast.

Polyurethane foam is a common material used for insulation.

Using polyurethane foam you can level the surface, eliminating gaps and cracks. The service life of the material is 30 years. The disadvantage is the high cost.

Materials

Insulation systems are attached to the internal or external surfaces of metal structures. These can be sandwich panels, sheet or liquid insulation (ecowool, sprayed polyurethane foam) - determined by the type of structure and scope of its use.

Sandwich panels

Sandwich panels are moisture resistant and do not freeze

Standard sandwich panels are foamed polystyrene foam, mineral wool (density from 100 kg/cubic m) or polyurethane foam (PPU) between steel profile sheets. Manufacturers offer roofing, ceiling, wall, corner “sandwiches” for internal or external installation.

Wide choice of design - the outer sheet can be painted or imitate wood, plaster, masonry. A good option for buildings where high demands are placed on the appearance.

Plate and roll materials

Flexible boards, rolls of natural or synthetic materials - mineral wool, glass wool, polyethylene foam, non-woven fabrics (holofiber, plant fibers) allow you to create an effective thermal insulation system.

Materials for insulating hangars

The problem of cold bridges is solved by using rolled materials laid overlapping. The use of sheet insulation is complicated only by its installation features:

- sheathing;

- fastening elements - adhesives, screws, etc.

The fastening system not only creates additional loads on the metal structure, but also violates the tightness of the waterproofing and vapor barrier panels. Additional “cold bridges” are created. Foil materials simplify the creation of modern multilayer thermal insulation systems.

It is difficult to insulate surfaces with a complex configuration - with protrusions and recesses. In addition, the “soft” insulation of a metal hangar is subject to mechanical stress and to protect it from damage, installation of a “hard” layer of external finishing will be required.

Ecowool, polyurethane foam spraying

The use of liquid heat insulators is a fairly new direction in construction. They will penetrate into any, most inaccessible place, creating a homogeneous continuous coating.

Ecowool is an excellent insulation for frame structures. The technology involves the construction of a rigid structure into which cellulose material is blown. Be sure to use moisture and vapor barrier.

Insulating a hangar with polyurethane foam is the most effective method

Polyurethane foam - insulating hangars with polyurethane does not require any additional fasteners. PPU is simply sprayed onto the surfaces of metal structures - like painting. Several layers are applied. The resulting monolithic surface is not afraid of mechanical damage; it can be left unfinished or plastered or painted. Sheet finishing materials - plasterboard, PVC panels, etc. - can be easily mounted onto a dense frozen mass.

The polyurethane foam system is resistant to moisture and temperature changes, but if direct exposure to UV and water is possible, then additional protective measures should be taken.

It is difficult to insulate arched hangars or other types of frame and frameless metal structures: tent, polygonal, straight-walled polyurethane foam or ecowool on your own. The technology requires the presence of expensive professional equipment and experienced craftsmen. Fastening sheet materials - sandwich panels, rolls, mats - can be done on your own.

To insulate the floor surface, there are also several ready-made solutions using bulk, sheet, and liquid building materials. They can be mounted directly onto compacted soil. If necessary, it is possible to install electric or water heated floor systems.

Important! No need to plan to insulate your hangar on the cheap! First of all, insulation must be effective. The method and materials are selected depending on the functionality of the building

When planning a thermal insulation system, ventilation, air conditioning systems, and other communication lines are provided. High insulation efficiency can be achieved only by competent calculation of insulation “pies” and strict adherence to construction technologies

The method and materials are selected depending on the functionality of the building. When planning a thermal insulation system, ventilation, air conditioning systems, and other communication lines are provided. High insulation efficiency can be achieved only by competent calculation of insulation “pies” and strict adherence to construction technologies.

Table of contents:

- Hangar insulation technologies

- Requirements for insulation of hangars

- Insulation of hangars with slab and roll materials

- Insulation of hangar by spraying method

- Advantages of using polyurethane foam for insulating hangars

A hangar is a technical structure used for storing goods, production needs, repairing equipment, livestock breeding and other purposes. All hangars are divided into two groups: frameless semicircular and frame rectangular.

What both types have in common is the widespread use of metal with good thermal conductivity. Therefore, in such a room it is cold in winter and hot in summer. Without insulation, all attempts to heat and cool the hangar will be futile.

Advantages of insulating vegetable storage with polyurethane foam

PPU is a universal material. It can be used to insulate a hangar from the inside and outside, to waterproof basements and create the necessary microclimate in vegetable storages.

To preserve vegetables until the next harvest, it is important that the correct microclimate is constantly maintained inside the warehouse where they are stored - certain parameters of humidity and air temperature are observed. This can be achieved by using foamed polyurethane for thermal insulation - it not only insulates heat, but also waterproofs it - it prevents both the evaporation of moisture from inside the storage facility and the penetration of its excess from the outside

It is the waterproofing properties that make insulating a grain warehouse with polyurethane foam the optimal option - a low level of humidity is very important for storing grain crops. Otherwise, the grain may bloom, which will lead either to its complete loss or to a decrease in its grade.

In addition, thermal insulation of wooden granaries with polyurethane foam helps prevent woodworms and other harmful insects from breeding in the wood, since the coating has protective properties.

Insulation technology

Thermal insulation of arched hangars is carried out using traditional materials: polystyrene foam, expanded polystyrene, basalt wool.

In relation to arched hangars, the concept of “insulating a hangar in 3 days with your own hands” can hardly be applied. Considering the total area of the structure, it will not be possible to cope with insulation on your own. In any case, the work will be carried out by a team of qualified specialists, but what materials will be used is the choice of the owner of the structure. Modern construction companies, even at the stage of erecting metal structures, offer a choice of three options:

- cold hangar. No insulation is provided; the premises are used for storing equipment and things that do not deteriorate due to temperature changes;

- insulated hangar. Thermal insulation is carried out using traditional materials: polystyrene foam, expanded polystyrene, basalt wool. This is an economical way to equip a room, but not the highest quality or durable;

- hangar insulated with polyurethane foam. Thermal insulation is performed using foamed polymer. The layer is thin, strong, sealed and durable.

The radius of curvature of a metal surface can vary depending on the area and height of the interior. But even wide and low hangars are considered problematic objects from the point of view of thermal insulation. It is almost impossible to ensure a tight fit of sheet insulation to the surface. And this is provided that the frame can still be attached smoothly and firmly. Read more about the insulation of metal hangars here - /osobennosti-utepleniya-metallicheskih-angarov/.

When choosing a heat-insulating material, special attention should be paid to its weight. The light metal frame of the hangar should not be overstressed, because in winter it still has to withstand the weight of the snow cover, and this is not small

PRICE LIST for thermal insulation services

| The cost of insulation with polyurethane foam (PPU) depending on the area with a thickness of 50 mm. | ||||

| Type of work | The cost of insulation when ordering an area | |||

| Up to 200 m2 | 200-400 m2 | 400 -1000 m2 | >1000m2 | |

| Spraying polyurethane foam with an average density of 25 kg/m3 | 700r/m2 | 650r/m2 | 600r/m2 | Negotiable |

| Spraying polyurethane foam with an average density of 35 kg/m3 | 800r/m2 | 750r/m2 | 650r/m2 | Negotiable |

| Spraying polyurethane foam with an average density of 45 kg/m3 | 1000r/m2 | 920r/m2 | 870r/m2 | Negotiable |

| Special conditions for construction companies and architectural bureaus! |

| The cost of insulation with polyurethane foam (PPU) depending on the volume in m3. | ||||

| Type of work | The cost of insulation when ordering an area | |||

| Up to 5 m3 | 5-10 m3 | 10-20 m3 | >20 m3 | |

| Spraying polyurethane foam with an average density of 8-12 kg/m3 | 6000r/m3 | 5500r/m3 | 5000r/m3 | Negotiable |

| Spraying polyurethane foam with an average density of 25 kg/m3 | 11000r/m3 | 10500r/m3 | 9500r/m3 | Negotiable |

| Spraying polyurethane foam with an average density of 35 kg/m3 | 14000r/m3 | 13500r/m3 | 13000r/m3 | Negotiable |

| Spraying polyurethane foam with an average density of 45 kg/m3 | 18000r/m3 | 17500r/m3 | 16000r/m3 | Negotiable |

| Special conditions for construction companies and architectural bureaus! |

The price may change depending on the difficulty of accessing the surface. Minimum order 30,000 rubles.

will perform seamless insulation of hangars of any geometric shape (arched, hipped, straight-walled) using sprayed polyurethane foam. We work at facilities in Moscow and the Moscow region, and are ready to consider applications from neighboring regions.

Our offer

The group provides professional services for insulating frameless hangars using polyurethane foam or mineral wool. The cost of our company’s services for insulating a hangar with mineral wool is from 1,800 rubles per square meter; when using polyurethane foam, the cost of the service will be from 1,100 rubles per square meter. If you need to get an approximate calculation taking into account the individual design parameters of the hangar, you can use our online calculator, which is posted on the official website. Each customer receives from us the highest quality services, certified materials, competitive prices and a long warranty on work. We are waiting for your calls at the numbers listed in the “Contacts” section or leave a request through a special form on the website. After which our specialists will get in touch as soon as possible.

A metal hangar has advantages over brick and concrete structures. Such buildings are easier and faster to erect; if necessary, they can be easily dismantled and moved to another location. However, the thermal insulation of metal structures leaves much to be desired, and in some cases a warm hangar is needed (for example, if the building is used as a warehouse or workshop). Several standard materials are used for insulation.

Hangar insulation is one of the main conditions for saving in business

Thermal insulation of the hangar will expand the functionality of the room. An insulated building can be used as a sports or shopping complex, as an administrative and even residential premises. Thanks to modern materials, it is possible to create a comfortable microclimate, while the building will comply with technical standards, remain fireproof, and the insulation will not harm health. Insulating a hangar will not be cheap, but as a “side effect” it will solve several other problems.

Noise insulation

Metal structures are poorly insulated from noise. At the same time, sound insulation, along with insulation, is a key point if the hangar is used for domestic or industrial purposes, such as:

- trade area;

- workshop;

- administrative or sports building;

- dormitory;

- vegetable store;

- facilities for keeping animals and poultry.

After insulation, the hangar not only makes less noise when it rains or hails. The interior space is also protected from “regular” background noise from the street.

Heat protection

Thermal insulation maintains a comfortable temperature level in the building. In winter it protects the space from heat loss, in summer - from overheating

This quality of thermal insulation is especially important when the building is used for storage, warehouses or for domestic purposes.

Strengthening

Thanks to several layers of thermal insulation, the building walls receive increased rigidity. After installing the insulation, the metal structure will be protected from another enemy of the base material - condensation, the appearance of which over time can lead to the formation of rust on the walls.

Frameless insulated hangar

On the one hand, construction technology significantly simplifies and speeds up the construction process, on the other hand, it has some limitations. And one of the essential ones is insulation. Since the shape of the hangar has an arched structure, and it is not advisable to attach any additional elements to the arches themselves, including insulation, this does not allow the use of the entire range of heat-insulating materials used in industrial construction. We described the main types of insulation used in the construction of insulated hangars in the article “Insulation of hangars. Technologies. Choice of insulation." The most reliable frameless insulated hangar is considered to be a double hangar with insulation between the arches. Essentially, two hangars of different diameters are being built with insulation between them. Therefore, in order to avoid significant expenses on insulation in the future, it is necessary to immediately include in the project the possibility of insulating it, even if you are building a cold hangar.

Typical arched hangars

Arched hangars, despite the previously listed advantages, have a number of limitations. One of which is the number of floors of the building. Arched hangars are one-story buildings. And unlike straight-walled hangars, they have only one span.

Arched hangar width

Since no additional columns or supports are installed inside the arched hangar, their width is limited by the capacity of the supporting structures and can reach 40 meters. The minimum width of an arched hangar is considered to be 6 meters. The width of the hangar can be any in this range, since roll forming equipment allows the production of arches of any diameter. The most common arched hangars are hangars with a width of 10, 12, 15, 18 and 24 meters.

Arch hangar length

Unlike width, the length of an arched hangar is limited only by the boundaries of the site. There are certain technical requirements for strengthening the frame when building long hangars, but theoretically you can build a hangar of any length.

Arch hangar height

The height of the arched hangar is regulated by building codes and regulations. The most resistant to loads is a hangar where the height of the hangar is equal to half its width. In this case, the hangar will have the correct geometric shape, which allows the load to be evenly distributed throughout the entire frame of the structure.

Analyzing the applications received on our website, we found that the most popular arched hangars are 10x24, 12x24, 15x30, 18x30, 18x60, 20x50. This is why most contractors have developed standard designs for these hangar dimensions.

Materials used for insulation of hangars and warehouses

Today, there are a huge number of different materials with which the process of thermal insulation of various buildings is carried out. However, in relation to hangars, the situation changes radically, since based on the size of a structure of this type and since they do not have high thermal insulation characteristics, traditional insulation materials are unlikely to be suitable for it. Therefore, to insulate this type of premises it is necessary to use an integrated approach. You can read more about the materials used for insulation of hangars and warehouses here - /kakie-materialy-tehnologii-ispol-zuyutsya-pri-uteplenii-sklada/.

The following traditional materials are considered to be the most suitable options for insulation:

- Styrofoam. It retains heat well in the room and does not allow moisture to pass through, since, thanks to its porous structure, which includes 98% of air, it has increased waterproofing qualities. However, for complete thermal insulation of a large area, a fair amount of it will be required, since the foam must be laid in several layers. Therefore, it can be considered an excellent option for insulating only small buildings, but not massive hangars, including from the point of view of economic benefits. In addition, the use of such insulation implies the presence of frame elements on which the foam will be installed. As a result, they will significantly increase the load on the hangar, which will lead to a decrease in its service life.

- Mineral wool. It is a time-tested traditional material, which is characterized by increased thermal insulation characteristics and allows achieving an optimal insulation effect. For a hangar, the most suitable type of wool is made in the form of slabs, with guide rails and fasteners installed during installation. It should be noted that insulating prefabricated buildings in this way is not the best option, since additional fastenings will increase the load on the steel sheets, which will negatively affect the stability of the entire structure as a whole, due to its weight. In addition, mineral wool is absolutely not protected from moisture upon contact, as a result of which it loses its original qualities over time. We discussed earlier why you shouldn’t insulate a hangar with ecowool. Therefore, when choosing this particular material for thermal insulation, you will need to provide an additional waterproofing shell in the form of a vapor barrier in order to avoid the greenhouse effect and prevent moisture from entering the mineral wool. At the same time, the vapor barrier material, although slightly, will reduce the thermal insulation characteristics of the entire hangar structure.

- Polyurethane foam. This material as insulation is considered the best in all respects and its choice can be considered optimal. Thermal insulation of hangars and warehouses with its help allows you to achieve maximum effect in achieving the necessary insulation.

In general, the use of polystyrene foam and mineral wool makes it possible to increase the thermal insulation characteristics of the hangar, however, significant financial investments will be required for laying insulation in several layers, as well as for installing fasteners and using a waterproofing board. In addition, a significant drawback when laying polystyrene foam and wool can be considered the formation of seams and gaps through which heat losses occur (more than 60% of all heat is lost through the holes between the fasteners). In addition to all of the above, it is worth noting the fact that polystyrene foam is also flammable.

Criteria for choosing thermal insulation

When choosing one or another insulation material, a number of important points should be taken into account. So, what should you pay attention to when choosing a material? Below we list some of the most important points:

- Price . The price of the material is the main selection criterion for many. It is important to understand and remember that savings can often be very expensive later. So, for example, in some cases, the use of a budget heat insulator, namely polystyrene foam, although beneficial from an economic point of view, is unacceptable from the point of view of exposure to various types of chemically aggressive substances.

- Technology . Here it is worth paying attention to the fact that in the case of internal insulation, environmental safety and the thickness of the material are of primary importance, while external insulation can be done using almost any heat insulator.

- Resistant to moisture . You should not ignore the fact that a hangar is a room with a high level of humidity, and therefore, in addition to the thermal insulation characteristics of the material, it is worth taking into account such parameters as moisture absorption and resistance to corrosion.

Separately, we consider it necessary to note that in addition to what was mentioned above, it is worth taking into account such a factor as the material from which the hangar is built. In particular, if we are talking about a metal structure, then its walls must additionally be lined with plywood sheets, under which the thermal insulation material will be located. If we are talking about brick walls, then in this case it is best to build additional walls in which to place the insulator.

Insulating a hangar with penofol

Foamed polyethylene foam and polished foil or metallized film are used to produce a new generation of thermal insulation material penofol. It has high heat, hydro and sound insulation qualities, which are supported by the reflective properties of a metallized film that can reflect up to 97% of heat rays. The low thermal conductivity of polyethylene, combined with the reflective characteristics of the foil, effectively protects the hangar from dampness and drafts, providing over 30% savings in energy costs.

The advantages of insulation include:

- elasticity: the insulation is capable of repeating any shape of the insulated surface, which greatly facilitates installation;

- environmental friendliness: polyethylene and foil are widely used in the food industry and do not contain harmful substances;

- high vapor barrier characteristics and hydrophobicity: the material does not absorb condensation and is not afraid of a humid environment;

- fire resistance: class G2 “Refractory materials prone to self-extinguishing”;

- a thin layer of insulation provides high thermal insulation characteristics: 1 cm of penofol is comparable to 8 cm of mineral wool or 4 cm of extruded polystyrene foam;

Disadvantages of foil penofol that limit its use as a heat insulator:

- insufficient density;

- loss of thermal insulation properties due to mechanical damage.

The industry produces two types of penofol:

- foil;

- metallized.

Both of them can have a reflective layer on only one side or be produced in a double-sided version. To facilitate installation, penofol can be applied to an adhesive base.

There is no single recipe for choosing insulation; each object has its own design features, which the customer must take into account. Any method is suitable for thermal insulation of newly constructed structures, because it can be taken into account at the design stage. For hangars that have been in use, it is most advisable to use polyurethane foam insulation. It will not weigh down the structure and will strengthen the arched elements by filling cracks and pores.

Water heating of hangars

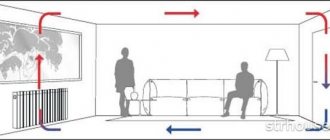

Convection water heating is used mainly in small hangars where the ceiling height does not exceed 4 meters.

With higher ceiling heights, their effectiveness rapidly decreases. This is due, first of all, to the fact that warm air rises, and forced air circulation systems are not provided. Essentially, we are starting to heat the hangar from the ceiling. And to achieve optimal temperatures, it is necessary to have very good thermal insulation to prevent severe heat loss. These systems are used less and less often when heating hangars, mainly in cases where centralized heating lines are located close together and in small hangars. Using your own boiler room to heat large warehouses and workshops is too energy-intensive.

Air heating of hangars

One of the most common methods of heating hangars today is air heating technology. It is easy to install and inexpensive to maintain. And most importantly, it allows you to warm up huge areas in a short period of time. In such heating systems, the air, passing through air heaters, is heated to the required temperature and supplied to the air ducts for uniform heat distribution inside the room. The possibility of combining the heating system with a ventilation system is also important. In this case, air is taken from the street and, passing through a filtration system, is supplied to the general heating and ventilation system.

One of the main advantages of air heating systems is their versatility. Air heaters can operate on different types of fuel:

- Electricity

- Gas

- Diesel fuel

- Solid fuel

- Waste oils

The use of automation allows you to use these systems both to constantly maintain the required temperature and to heat the room according to the operating mode of the room, which can significantly reduce heating costs. In addition, air systems can also be used for zone heating of a hangar. For example, install air ducts only in personnel work areas or where temperature maintenance is necessary.

The use of these systems is also justified in hangars, where exits to the street are often used or the gates are open for a long time, when moving cargo, traffic and people. In such cases, thermal curtains are installed above the gate or exit, and the intense flow of hot air reduces heat loss.

Air heating systems also include fan heaters powered by electricity and gas. When using fan heaters, air ducts are not installed. Heating equipment is mounted or installed indoors in places where it is necessary to maintain the desired temperature.

What requirements must insulation for a hangar meet?

How to insulate a hangar if its design features - material and shape dictate some requirements that the thermal insulation material must meet:

- plasticity - under the influence of temperature changes, the metal surface of the hangar “plays”, i.e. it contracts and expands, so the insulation must be sufficiently plastic so as not to crack from such changes;

- high adhesion – a hangar is a large metal structure, and to insulate it you need a material that has good adhesion and is able to “catch” onto the smooth surface of the corrugated sheet;

- good thermal insulation properties - since the walls and roof of the hangar are very thin, the task of thermal insulation falls entirely on the insulation;

- light weight - frameless and frame hangars are usually built with a vaulted roof, i.e. the walls and roof are a single whole, and it is strictly forbidden to overload such a structure in order to avoid collapse.

All these requirements are met by insulating hangars with polyurethane foam (PPU).

Date: September 25, 2022

conclusions

We looked at four options for how to insulate a frameless hangar. Which method to choose largely depends on each specific case, where not only the purpose of the hangar is taken into account, but also other components that may affect a particular choice of hangar insulation.

The use of polyurethane foam coating will be especially important for old hangars, when it is necessary to minimize the load on the foundation and structures, while for new hangars you can choose any of the insulation options.

In any case, seek help from professionals!