Due to a number of advantages, heat insulators based on basalt fiber are very widespread today.

The main argument for many users is the fact that this material is natural.

However, one should not neglect the danger that basalt insulation can pose: its harmfulness is sometimes very noticeable for human health.

The purpose of this article is to take a closer look at this heat insulator and understand whether you should expect trouble from it.

Should we be concerned about phenol formaldehyde?

Mineral wool is safe for health.

The main arguments in favor of the fact that mineral wool is harmful to health are based on the presence of phenol-formaldehyde in it. It is part of the binder. In its pure form it is a poison and very strong, but is it really that dangerous in the composition of mineral wool, which allegedly stinks of formaldehyde?

If the manufacturer follows all the rules for the production of mineral wool, no harmful substances are released, except perhaps a small (minuscule) part, which will not affect health in any way. In this regard, the harm of mineral wool is too exaggerated. In addition, there have long been materials where the binder is made on the basis of acrylic. For example, Knauf insulation, made using the latest ECOSE technology, or the Ursa PureOne line of mineral wool. This is an absolutely safe insulation for the home.

The danger of phenol-formaldehyde in mineral wool is far-fetched.

This synthetic resin is part of many items without which our life is simply impossible:

- sockets, switches, plugs for electrical appliances, electricity meters;

- mobile phone, camera, computer housing;

- handles of knives, pots, pans, etc.

Not to mention adhesives, varnishes, impregnating compounds for plywood and wood boards. In other words, formaldehyde is everywhere, so why is so much attention focused on the dangers of mineral wool? You need to solve the issue either comprehensively, or not bother yourself with trifles.

You can make induction heating yourself only with a factory-made boiler. This is a complex unit that cannot be made at home.

Read all about electric heating elements for home heating here.

Harm to health of mineral wool microparticles

It is believed that maximum harm to the body is caused by inhaling mineral insulation fibers. It's true: getting microparticles of basalt and resin into your lungs will not bring anything good. When cutting mineral insulation during construction work, fine dust is released, so you should work in a gauze bandage.

But once the insulation is already in place, it does not produce dust on its own. In addition, in most cases, the material is covered with a film to increase thermal insulation properties and waterproofing. This ensures the safety of the mineral wool.

There is mineral insulation of the latest generation, which does not chip and creates almost no dust. The reason lies in the elasticity of the acrylic contained in its composition: the fibers associated with this material do not break off and do not fly apart in the form of microparticles. This is not the only advantage of the material; it has improved soundproofing characteristics also thanks to acrylic, which absorbs sound waves more effectively. Thus, it is possible to completely avoid the appearance of dust when using mineral insulation.

Irritation of the epidermis by mineral wool

The objective health hazard of mineral wool is irritation of the epidermis during installation. Indeed, there are prickly insulation materials among glass wool or basalt wool. But again, there are materials that can be used to cover yourself and there will not even be a hint of tingling or scratching of the skin.

Glass wool is harmful to skin health only if sufficiently large fibers of glass are used in its manufacture. Slag wool, which is made from waste from the metallurgical industry, is very itchy; it is not used for insulating houses, since it is really not a safe insulation for walls. Stone wool can also chip when, during installation, small pieces of fiber break off and land on the skin. To prevent contact of mineral wool with skin, it is enough to wear gloves and long-sleeved work clothes.

Considering the question of whether infrared heating is harmful to health, we came to the conclusion that it is even beneficial.

More details about infrared heating (characteristics and reviews) here.

Structure and technical features of the material

Basalt is a type of rock, in other words, stone.

It often reaches the surface of the earth in a molten state, pouring out from the craters of volcanoes in the form of magma.

In one of these places, basalt fibers were first found, attracting attention with their surprisingly high strength.

The randomly discovered fiber began to be produced artificially:

- Basalt is heated to one and a half thousand degrees.

- The resulting melt is loaded into a special drum with blowing. Streams of molten stone quickly solidify, turning into fibers with a diameter of about 7 microns and a length of about 5 cm. To assemble them into longer structures, a binder is used - phenol-formaldehyde resin.

- Next, a portion of basalt fibers is pressed, resulting in the final product - stone wool.

In its “device” it is completely identical to ordinary cotton wool: between numerous thin fibers there are equally numerous air layers, which provide high thermal resistance.

Basalt wool has “relatives”: glass wool, the fibers of which are obtained from molten glass, and slag wool, the raw material for which is blast furnace slag. For these and similar materials, the general name “mineral wool” is used.

Among all the representatives of this family, basalt insulation is definitely the best: it is the most moisture-resistant (all mineral wool materials absorb water, turning from heat insulators into “thermal conductors”), more environmentally friendly compared to slag wool, and does not hurt your hands like glass wool.

Harm of mineral wool to the respiratory tract

You need to wear a respirator and cover exposed skin.

Dust poses a major health hazard. There are types of mineral wool that are very dusty, especially basalt wool, since its fibers are inelastic. A safer insulation for floors, walls and roofs is glass wool, since it consists of long and soft fibers that do not break, and therefore there is no dust from it. Therefore, it is not dangerous in any way; glass wool is one of the best materials in terms of environmental friendliness and safety.

Why is dust getting into your lungs so dangerous?

- dust is not removed;

- blood oxygen saturation deteriorates;

- the physical potential of the body decreases;

- asthma may develop.

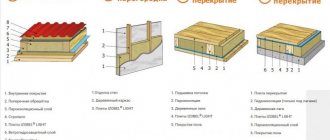

Dust appears both during installation and during further operation. You need to work in a respirator - this is mandatory, and a vapor barrier will help prevent dust from entering the room after installation. It is always used when insulating walls, floors, ceilings and roofs (attics included). The film creates a vapor-impenetrable barrier; naturally, hundreds of times larger dust particles will not be able to get inside the room.

How to choose mineral wool

Mineral wool is a fibrous building material that is used for heat, sound, steam and fire retardant insulation of premises, utilities, and industrial equipment.

At the same time, mineral wool is characterized by low cost. Disadvantage: toxicity (releases phenol and formaldehyde). Important: the degree of danger of mineral wool is an open question. To minimize possible harm to health, purchase materials from well-known brands that value their reputation. Mineral wool must have documents certifying quality and safety (certificate of conformity, SES conclusion).

- Stone wool

- Glass wool

- Slag

Glass wool - made from waste glass, various minerals (limestone, dolomite, sand, borax, soda). Advantages: relatively low price and weight, high bending strength, good elasticity and vapor permeability, no dust during installation. Disadvantages: susceptible to shrinkage when moistened, particles cause irritation to the skin and upper respiratory tract.

Scope of application - mainly interior finishing work (insulation of attics and walls indoors). Also suitable for external insulation.

Stone / basalt – made from rocks of the basalt group. Advantages: resistance to deformation and shrinkage when moistened, high compressive strength, durability, easier installation. Disadvantages: relatively high cost and weight, low elasticity and vapor permeability, dust generation during installation.

Basalt wool differs from stone wool in its higher heat resistance. This insulating material, along with basalt fiber, contains clay, dolomite, limestone, mixture, and blast furnace slag.

Scope of application - mainly external finishing work (insulation of building facades, roof slopes, walls of baths and saunas, garages). Sometimes used indoors.

Important: although stone wool does not chip, when working with it you must use the personal protective equipment required for glass wool - goggles, a respirator, rubber gloves, closed overalls.

Slag wool – made from blast furnace slag (metallurgical waste). The only advantage is the low price. In terms of thermal insulation, chemical resistance, water and sound absorption it is inferior to other types of mineral wool. Practically not used.

Technical – used for insulation of pipelines, chimneys, ventilation pipes, baths and saunas. This material can withstand temperatures from -180°C to +700°C. Execution – slabs or rolls with foil coating.

Lightweight - used for insulating frame structures, withstands only light loads. Density varies between 10-90 kg/m3. Execution – slabs or rolls.

Rigid - designed to isolate the contours of structures, withstands high loads. Density is 90 kg/m3 or more. Execution: slabs.

What is the safest insulation

Ursa PureOne - formaldehyde-free, acrylic based.

There is no point in determining which insulation is safe for health among natural materials, so only modern insulation of artificial origin should be considered. The most used thermal insulation materials:

- mineral wool;

- Styrofoam;

- polyurethane foam.

What is stone wool made from?

Stone wool is produced from rocks, usually the basalt group, by melting at temperatures above 1500 degrees and then spraying onto the fibers under the influence of a powerful air flow. During the production process, special water-repellent and binders are added. After this, the material is pressed into a dense carpet so that the mineral wool acquires the required density.

Synthetic substances are used as binding components. As a rule, these are phenol alcohols, phenol-formaldehyde, and urea resins. Bitumen and bentonite clays are also used. Currently, a composite synthetic binder consisting of phenol-formaldehyde resins and water-repellent additives is most often used. It provides the best thermal insulation performance.

The final stage of production is cutting basalt wool into slabs and mats of the required sizes; molded products (cylinders, segments) can also be produced.

Results

Mineral wool is a safe material, and its health hazards are greatly exaggerated. Of course, there are types that create a lot of dust during installation, but this can be solved by using a respirator. The dust is subsequently neutralized by a vapor barrier film. There are prickly materials that make your skin itch. But again, if safety precautions are followed during installation, this problem does not arise. And the fact that mineral wool contains phenol-formaldehyde does not mean that it somehow leaves the structure of the material. In addition, this component is present in all plastics, not to mention other materials.

Manufacturers such as Knauf and Ursa have a line of materials that use an acrylic-based substance as a binder. This insulation is definitely safe. If these arguments are not enough, then you can insulate with natural materials of natural origin, for example, sawdust, straw or expanded clay.

The first thing that can be said that basalt wool is harmful to health after reading many publications on the Internet is that the writers themselves completely misunderstand what is the difference between basalt wool and ordinary mineral wool and even glass wool, not to mention slag wool. For them, basalt wool is the entire construction market: ROCKWOOL, PAROC, Izovol, TechnoNIKOL, etc. In fact, all of the above is ordinary mineral wool obtained by centrifugation, but not basalt. The manufacturers themselves write that this is mineral wool. To produce mineral wool, when preparing the charge before loading it into the melting furnace, the basis is made up of basalt group minerals, but limestone or dolomite must be added, otherwise fibers will not be obtained. Mineral fibers obtained by centrifugation are very small, 1-3 microns in diameter and short. You cannot see elementary mineral fiber without a microscope. It will probably be a discovery for the “writers” that the mineral, glass or slag fibers themselves, which they call basalt, would be safe if they were not coated with phenol-formaldehyde resin to form thermal insulation boards. It is phenol that is a carcinogen and the causative agent of many dangerous diseases, primarily cancer. And the amount of phenolic dust in such a slab is up to 3÷4% of the total mass of the insulation. Calculate for yourself how much phenolic dust is in the walls and roof, if an average house uses about 80 m 3 of insulation with an average density of 60 kg/m 3, i.e. about 6 tons of mineral wool and phenol-formaldehyde resin will contain about 150 kg.

Therefore, by formulating the headline: “basalt wool is harmful to health,” the authors of the site’s articles pursue the goal: to divert the consumer’s attention from the harmful components of mineral insulation, because of which mineral wool insulation cannot be called environmentally friendly, focusing on small fibers that can actually get into the human lungs , like all the dust from the streets of big cities. And another question is which is more harmful: fine fibrous dust of mineral insulation with phenol, or dust from highways. Both are harmful. Yes, such mineral basalt wool is harmful to health.

Therefore, in all technical conditions for the installation of glass wool, mineral wool, slag wool and basalt wool, it will be written that when installing insulation it is necessary to work with the use of respirators, gloves, and tightly buttoned overalls. It is no secret that the most sick among construction workers are installers of mineral insulation.

And this is what happens when you see the headline: “Basalt wool is harmful to health , what we mean is basalt-based mineral wool using phenol-formaldehyde resin.

But where did the name basalt wool come from, if almost all the insulation is made of mineral wool?

Why do sellers of mineral wool, glass wool and slag wool call their product basalt insulation?

Basalt insulation without phenol and formaldehyde

Each manufacturer of basalt insulation assures that its product is harmless, despite the use of synthetic resins as a binder, and explains this by the introduction of new technologies in which phenol is completely neutralized. In this regard, a logical question arises: why, in this case, do some manufacturers replace cheap synthetic components with environmentally friendly ones, which are more expensive?

Features of the production of basalt insulation without phenol and formaldehyde

Against the backdrop of increasingly frequent allergic and oncological diseases, the question of how to choose basalt insulation, which not only saves energy resources, but also creates safe and comfortable living conditions, is becoming increasingly pressing.

The basis of any technology for the production of basalt fiber insulation is the principle of the volcano. From igneous metamorphic rocks, mainly of the gabbro-basalt group, under the influence of high temperatures (about 1500ºC) a liquid fiery melt similar to magma is obtained.

At the next stage of the technological process, this molten mass is placed in a centrifuge and a huge air flow is directed at it, resulting in basalt fibers. Then water-repellent (hydrophobic) and binding components are introduced. The environmental cleanliness of the insulation largely depends on the composition of the latter.

The use of acrylic-latex compositions, bentonite clay and PVA dispersion instead of phenol-formaldehyde resins makes it possible to obtain basalt insulation that does not pollute the room with highly toxic compounds.

How to determine the environmental friendliness of basalt insulation

The vast majority of certificates issued for products indicate the composition of the materials used, including the binder component. For example, the certificate of conformity issued for Basalt-Most products states the following: basalt-fiber heat-sound-insulating slabs with a clay binder (BVTPG), (thickness 30, 40, 50, 60 mm with a density of no more than 100 kg/m3), produced according to TU 5769- 004-1781963-01. This is also confirmed by the sanitary-epidemiological Conclusion. These documents are posted on the manufacturer's official website.

If the certificate does not indicate a binder, then it is in other permitting documents. Thus, the ingredient composition of GreenGuard TechnoNikol thermal insulation boards is indicated in the expert report and these are: mineral fiber and biopolymer binder. Confirms the environmental friendliness of the product. Conclusion from the Scientific Center for Children's Health.

Insulation materials: “white list” (environmentally friendly materials)

- Important

- Registration: Apr 2008

- Posts: 540

Answer: METTEMPLAST (Penoizol) - what kind of miracle is this?

I'll be happy to start.

1. Burnt clay in all its forms (both balls and bricks) is a (rare) problem, a slightly increased yield of gamma quanta, you can forget it;

2. Concrete with mineral (cement or lime or some other) binder and without organic fillers. These include cellular and silicate (in the form of the same brick) and light ones. For some varieties it is also worth checking the radiation.

3. Peat and products made from it. Limit the dusting of the overdried by creating between peat and placing screens, for example, made of paper (the same wallpaper - already a screen).

4. Fluffy antiseptic cellulose (aka Ecowool). composition: cellulose, borates (boric acid salts). Borates are not volatile; they were used to poison cockroaches in the 70s. If you don’t eat this salted cellulose and, as with peat, limit dust, it’s a very good ml.

5. Well, straw, manure, clay with sawdust, etc. – these are handicrafts and should be put in the “very local materials” section, I can’t talk about that seriously.

6. Of the synthetic polymers, I would recommend polyethylene foam. And not even because its breakdown products are not harmful, but because the decay rate is extremely low. Durable, infectious, just need to be hidden from the sun, otherwise it will quickly become brittle and crumble.

7. Oh, I forgot the tree. Solid wood (although it depends on what they use to prevent it from frying).

8. As for mineral wool, I would say this: low-density basalt fiber is tolerable. There is little astringent organic matter, and cotton wool fibers, once in the lungs, will calmly dissolve there - cotton wool melts with a bang in acidic water.

And glass fiber is acid resistant. Therefore, if there is a leak in the roofing pie, it will live longer, but once it enters the body it will never leave it.

9. I forgot the foam glass. There's nothing to complain about there unless you chew on it.

10. What else? Cork is exotic. Hemp, broken into fibers, but not tied into hemp ropes - romantic, of course, but also exotic.

Choosing basalt insulation according to its main characteristics

When choosing a material, in addition to environmental friendliness, such characteristics as thermal conductivity, vapor permeability, water absorption and density are taken into account:

- thermal conductivity. The chaotic arrangement of fibers in basalt insulation contributes to the formation of air layers, which are an excellent heat insulator. For this reason, this material has a very low thermal conductivity coefficient: from 0.032 to 0.049 W/mK. The lower this indicator, the smaller the basalt insulation layer can be;

- vapor permeability. The moisture contained in the air, penetrating through the basalt insulation, does not form condensation inside. The vapor permeability coefficient ranges from 0.3 to 0.37 mg/m.h.Pa depending on the density of the material (the higher it is, the lower the coefficient);

- water absorption. It is measured as a percentage of the amount of water absorbed by the dry material to its original mass. Therefore, when choosing basalt insulation, choose the one with a lower percentage of water absorption;

- density. Varies in the range from 35 to 200 kg/m3. For frame structures, a material with a density of 35 to 75 kg/m3 is used, and basalt insulation with a density of 150 and higher is used as the main thermal insulation layer in reinforced concrete coatings.

As for indicators such as durability and fire resistance, they are the same for all basalt insulation materials: service life is 50 years, and the flammability group is NG (non-flammable). The material can withstand temperatures up to 1000°C, and does not melt.

Manufacturers of environmentally friendly basalt insulation

Most manufacturers of basalt insulation use synthetic resins based on phenol and formaldehyde as a binder, even though the word “eco” may appear in the product name. In fact, the list of enterprises producing environmentally friendly and harmless insulation based on basalt rocks is still small.

The company specializes in the production of environmentally friendly basalt insulation. Manufacturer's slogan: 100% basalt insulation without phenol - warmth and comfort for your home! PVA dispersion or bentonite clay with a water repellent is used as a binder.

A comment

- Registration: Sep 2009

- Posts: 75

Answer: METTEMPLAST (Penoizol) - what kind of miracle is this?

I'll be happy to start.

6. Of the synthetic polymers, I would recommend polyethylene foam. And not even because its breakdown products are not harmful, but because the decay rate is extremely low. Durable, infectious, just need to be hidden from the sun, otherwise it will quickly become brittle and crumble.

Regarding polyethylene, I will add that it becomes embrittled in the sun due to the evaporation of the plasticizer. And so there can be quite a lot of additives in polyethylene, for example: p - pigment or dye, s - stabilizer, t - sliding additive, a - antistatic additive, f - modifying additive. And unlike polyethylene, their environmental friendliness is questionable. And their volatility is obvious, we smell it when we open a polyethylene canister, and we see it when the polyethylene crumbles, having lost the plasticizer.

With polymers, things are not so simple.

Mineral wool: how dangerous is this insulation to health?

According to a number of experts, one of the most harmful building materials is mineral wool. Mineral wool is used for heat and sound insulation of residential premises everywhere. Some experts believe that the components included in its composition - mineral fibers, resins that bind them, which reduce the moisture absorption of the impregnation - cause serious diseases of the respiratory tract, eyes, and skin in people. The Association of Russian Thermal Insulation Manufacturers insists on the safety of its products. Builders, however, continue to use this thermal insulation material, which causes so much controversy. And officials don’t even try to figure out whether residents of mineral wool houses are endangering their health.

Today, the main share of the domestic market of thermal insulation materials is occupied by mineral wool producers. Mineral wool, especially slabs and sandwich panels based on it, are quite popular insulation in Russia. Where to buy mineral wool? Anywhere. Mineral wool is sold on any construction market, including on specialized websites on the Internet. Mineral wool is used for insulating pipes, utility rooms or houses from almost all sides: for insulating the walls of a house (outside and inside), facades, ceilings, attics, attics, loggias, as well as for sound insulation and noise insulation.

At the moment, you can buy mineral wool from various manufacturers on the Russian market. There are many of them, including Russian and Ukrainian factories; mineral wool production is established in Zheleznodorozhny, Kstovo, Kharkov and other cities. There are different types of mineral wool: foil, that is, with foil, acoustic mineral wool, in addition, various products made from it - pierced mats, thermal insulation cords, sandwich panels, slabs, cylinders, it is also sold in rolls (rolled), etc. Mineral wool is produced in different sizes and densities.

However, many foreign and Russian construction companies refuse to insulate their facilities with mineral wool. Firstly, due to the widespread and cheaper prices of competing insulation materials (silicate fiber, expanded polystyrene foam, polyurethane foam, polyethylene foam, etc., as well as insulation based on plant raw materials), and secondly, because of the harm, in their opinion damage caused by mineral wool to the environment and human health.

Is mineral wool the scent of death?

People began to argue and write about the dangers to human health and the environment from mineral wool relatively recently. Previously, it was believed that mineral wool as insulation was completely safe, environmentally friendly and non-flammable. And these qualities compensated for the fact that the price of mineral wool is higher than that of some other thermal insulation materials. But now a number of ecologists, doctors, and builders have begun to argue that the safety of mineral wool is, to put it mildly, exaggerated. In their opinion, the fibers contain carcinogenic components, and the binding material is phenol-formaldehyde or melamine-formaldehyde resin, which releases free formaldehyde, as well as phenol - highly toxic substances, in fact, are poisons for the human body.

A comment

- Registration: Sep 2009

- Posts: 75

Answer: METTEMPLAST (Penoizol) - what kind of miracle is this?

As for ozone, I would not be mistaken; we do not live in the stratosphere, and the amount of ozone in the ground layer is negligible. As for UV, of course there is such a thing, it destroys it little by little. But considering that the connections are saturated and there are few branches, it is quite weak. Why do plastic pots that have been sitting in a warehouse for 10 years crumble? There is no trace of UV or ozone. Alas, polyethylene is a partially crystalline polymer, and over time the degree of crystallinity increases, and with it fragility, and so that it does not crumble ahead of time, plasticizers are added. And smell the new PE canister inside, neither polyethylene nor ethane itself smell, so what does the new canister smell like?

What does insulation consist of?

Currently, the production of stone wool has reached a large scale. Many companies produce it, offering it at different prices. The product itself may also differ, which is influenced by the amount of resin used. stone wool is available for sale at a price of 400 rubles.

You can also find hard mats in stores, the price of which can reach up to 1,500 rubles. Moreover, this is not the limit for her. The raw materials for basalt wool are rocks. This is precisely what determines its advantage, such as non-flammability. But to bind its fibers together, a resin is used, which can easily catch fire. This component contains formaldehyde and phenols , which are damaged by drafts, precipitation and temperature fluctuations, which negatively affects human health. At the same time, the fiber also causes certain harm: when exposed to the above factors, it turns into fine and sharp dust, creating difficulties for breathing.

A comment

- Registration: Jan 2010

- Posts: 5

Answer: Insulation materials: “white list” (environmentally friendly materials)

Well, if you bring an example with shoes (I wrote on the next branch). The best shoes for Siberia are felt boots! But, we should at least get a little wet. THOSE. go into a warm room with snow on your felt boots, and you’ll freeze very quickly. All cellular concretes have high moisture accumulation. And God forbid, even relying on thermal physics, they will make the thickness minimal and seal it tightly with brick! All. Turn off the lights and drain the oil. The facts have already accumulated - through the roof! AERATED CONCRETE, FOAM CONCRETE. Frozen walls. Black corners. The walls inside the house are icy. Which is not and cannot be in houses made of brick, even 75 cm thick. Verified. Materials for Siberia must be homogeneous. Moisture consumption is no more than 6%. And frost resistance is at least 75. Do you want less wall thickness? Think! Just really think, and don’t fall for advertising appeals!

Glass wool or basalt wool, which is better?

Glass wool is a fibrous mineral material. Nothing more than one of the types of mineral wool. In the production of glass wool, raw materials are used that are exactly the same as those that serve as a component of ordinary glass. Often recycled, collected material or waste from the glass industry is used. But wait, if this is a mineral material, then where is the danger, please explain to me, glass wool or basalt wool, which is better?

We know of three modifications of fibrous heat insulators made from mineral components:

- glass wool;

- basalt wool;

- slag.

If everything is clear with the first, there are no problems with the third either, it is made from molten blast furnace slag, and in fairness, we note that it is rarely found on construction markets, then I think it’s time to find out what the second is made of.

Basalt wool or mineral wool, which is better?

Basalt wool is an artificially produced, inorganic material. It is made by melting natural minerals and further forming them into a fibrous structure. Natural mineral - volcanic stone of basalt rock. That is why we can often hear the definition of mineral stone wool . Accordingly, the question of basalt wool or mineral wool, which is better, after finding out that they are the same thing, disappears by itself.

A comment

- Registration: Jan 2009

- Posts: 875

Answer: Insulation materials: “white list” (environmentally friendly materials)

If you want to see frozen black corners and slopes in a brick house, come to Sheregesh, I saw enough of this stuff there, damp, cold, brrr. The whole village is built of red clay bricks 2.5 thick, 5 floors, and everywhere everyone has the same problem

PS I go there several times every winter, staying in apartments, always different.

Environmental Safety

The main material of this insulation – basalt – is a natural stone.

Even when exposed to heat, it does not emit harmful volatile substances.

This cannot be said about materials from the foam group: when heated, even slightly, polymers emit gaseous substances that are harmful to health.

Therefore, for thermal insulation of hot surfaces, for example, heating equipment or a hot water tank, only basalt insulation should be used. The same can be said about the thermal insulation of the roof: in the summer it heats up to +60 degrees - this is quite enough for the thermal decomposition of polymers.

As for phenol-formaldehyde resin, which plays the role of a binder, it does not pose a danger in high-quality and certified insulation materials, since it is neutralized at the production stage.

For those who want to get an absolutely flawless material from an environmental point of view, some manufacturers offer brands of basalt wool in which phenol-formaldehyde resins are not used.

Formaldehyde resins

Many people want to know whether mineral wool, which contains formaldehyde resins, is harmful. The amount of resin in any basalt insulation is 2-3 %. This substance contains a very small amount of formaldehyde. Thus, mineral insulation contains a minimum amount of substances that affect health.

If you need to completely eliminate the harm of mineral wool, pay attention to manufacturers who do not use harmful substances in production.