Low heating radiators are found in any group of heating devices. This category includes equipment whose height does not exceed 45 cm. Such small batteries are usually sought for aesthetic reasons: with panoramic glazing or low window sills. Sometimes you need to heat an entire cold wall, in which case this is one of the most effective options. After all, low radiators have low heat transfer, which means their length will be significant, which is what is needed to heat a cold or “wet” wall.

It is clear that you want everything to look stylish, but in heating you cannot focus only on aesthetics: technical data are also very important. That’s why they pay attention to the metal from which they are made. After all, it is its properties that largely determine the characteristics of radiators and their scope of application.

Aluminum

The lowest aluminum radiators have a height of 245 mm. The Sira campaign has such models: Alux 80 and Alux 100, Rovall 80 and Rovall 100, Swing. They have a good heat output for such miniature products - 89-97 W. Global has a low radiator - model Gl-200/80/D. This model is cast, with a working pressure of 16 bar.

The lowest radiator at Global Gl-200/80/D has a height of 200 mm

There are aluminum radiators with a center distance of 200 mm from the Russian manufacturer – Rifar [/anchor] – these are Rifar Base 200 and Rifar Forza 200. Moreover, their back wall is solid. You can safely place them with your back to the window and not worry about the appearance from the street.

But these are the smallest radiators. There is a large selection of models, the height of which will not be higher than 45 cm. Every company has such sizes, in almost every line. A center distance of 300 mm, 350 mm or 400 mm also fits into the low category.

Advantages, disadvantages

In any line there are low batteries, with an interaxial distance of 300 or 350 mm.

Advantages of aluminum radiators: lightweight, have high heat transfer, small capacity (little water can be placed), quickly respond to temperature changes.

The most important disadvantage is the chemical reactivity of aluminum and its softness. For normal and long-term operation, a high-quality coolant is required: Ph 7-8, operating pressure - from 5-6 Bar for extrusion models, to 10-12 for cast ones. It is imperative that the coolant contains a small amount of oxygen and suspended matter. Oxygen promotes the oxidation and destruction of aluminum, and suspensions wear down the metal.

But each manufacturer has its own requirements. For example, Chinese aluminum Radena radiators operate at 16 Bar pressure and coolant with Ph 6.5-9. And Sira extrusion models have a working pressure of 16 Bar and a warranty period of 25 years. There are probably other aluminum radiators whose characteristics go far beyond the average: and there are too many manufacturers and models.

When choosing, do not forget about all these technical subtleties: only if the operating conditions coincide with the manufacturers’ recommendations, the heating will work for a long time and without failures.

When installing the system, it is worth remembering that aluminum cannot be combined with copper (or copper-based alloys) directly. This means that when installing copper pipes, it is better to install other radiators. And also do not install bronze or brass fittings. Galvanized fittings and fittings work well with aluminum.

Application area

Scope of application: in individual heating there are practically no restrictions, it is only worth paying attention to the temperature of the coolant, especially if the system has a coal or wood boiler. It is risky to install them in apartments. Unless they are very reliable and proven, and only if the coolant in the system meets the manufacturer’s requirements.

Read about the choice of radiators for an apartment and a house in the article “Aluminum batteries: types, selection, connection”

Expert advice

There are quite a few popular options for heat supply using floor products.

- In-floor radiators - the main device is located below the floor line, and on the surface there is only a grille, through which cold air masses penetrate into the convectors, and warm ones rise upward. Such installation is quite labor-intensive, and the liner itself is often hidden, which is extremely undesirable in case of emergency situations.

- The use of fan coil units is a system in which the heat exchangers are blown by built-in fans, which optimally redistribute warm air flows. This design ensures uniform distribution of heat over the entire area of the room, and in addition, completely frees the floor from additional communications, since they are all located above and do not “steal” the usable space of the room.

Floor radiators are still considered little-known devices, although there are quite a few situations where they are truly irreplaceable. The devices are connected in the same way as the simplest radiators; they are practical, ergonomic and energy efficient.

See the following video about the advantages of floor heating radiators.

Bimetallic

Bimetallic radiators are usually called heating devices in which the collectors through which water flows are made of steel (sometimes stainless, sometimes black). An aluminum “jacket” of ribs is then fused onto this frame (to increase heat transfer).

Bimetallic radiators do not have very small radiators

Such batteries have a high operating pressure - up to 20-24 Bar, can work with almost any coolant (stainless steel manifolds work with any), and have a fairly high heat transfer. Their disadvantage: often a small cross-section of vertical ducts, as well as a high price.

The situation here is almost the same as in aluminum ones: some manufacturers have very small radiators with a height of 245-265 mm (the same Sira and Rifar have them), and almost all of them have a height from 350 mm to 450 mm.

Advantages, disadvantages

Advantages - high working pressure, compatibility with any metals (aluminum does not come into contact with the coolant or supply pipelines). Works with coolant in a wide range - Ph 6.5-9 in models with steel collectors and Ph from 5 to 10-11 in models with stainless steel (Royal Thermo, Calidor, Nova Florida, Radena). Another good quality is the high heat transfer of the section, as well as low inertia (allows you to accurately regulate the temperature in the room using an automatic boiler or a temperature regulator for the radiator).

Disadvantages: high price, which is due to the high complexity of the technology. And one more drawback: some companies make vertical collectors of small diameter, and if there is a high content of suspended particles in the coolant, they can become clogged. Therefore, it is advisable to install filters at the inlet (and they need to be cleaned regularly).

Application area

This type of radiator was developed specifically for the conditions of our central heating. That’s why they need to be installed in high-rise apartments. They will work great in individual heating, but why pay a lot of money for an unnecessary safety margin (almost tenfold)?

Features of operation

It is recommended to use steel radiators when organizing private heating.

Radiators made of steel or aluminum are not always suitable for use. Aluminum is not compatible with copper elements, which are often used for plugs or as connectors and taps. The presence of large amounts of oxygen is unacceptable for steel, since under its influence it begins to quickly rust.

Batteries made from these materials can be used in apartments if all operating requirements are met. It is equally important to take into account that it is rational to install radiators made of light and thin alloys when organizing individual heating.

Narrow radiators with a large height must be equipped with an air duct. It is installed opposite the pipeline in the upper manifold. To simplify operation, it is better to choose automatic mechanisms.

Cast iron

Long gone are the days when cast iron batteries were of only one type. The “Soviet” accordion is far from the only option; there are also modern, palace, and art nouveau styles. There are wall and floor models. Wall-mounted ones are basically the same “accordion” - MS-140, etc., as well as ordinary sectional ones, the style familiar today. Floor-standing ones are more often referred to as design radiators. And, unfortunately, they cost a lot. But they look stylish. Read about the types and types of radiators, their manufacturers and technical characteristics here.

Cast iron radiators are now available in a modern style

“Accordion” is also being produced today, and it is in good demand. Called MS-140, MS-110 and MS-90. There are also low models: with an interaxal distance of 300 mm, and a mounting height of 382-388 mm (the height varies slightly among different manufacturers).

Cast iron radiators are available in a modern style: they look very similar to aluminum and bimetallic ones. In this group, the smallest radiators will also be slightly less than 400 mm.

Retro style cast iron radiators are often small

And the third group of cast iron batteries is design radiators. They are mostly floor-mounted - on legs. And their sizes are also about the same: around 40 cm (with legs). But some companies have very compact ones:

- model BOLTON 220 with installation height 330 mm;

- The Hellas 270 from Viadrus has a height of only 340 mm.

There may be other low cast iron radiators: there are so many different offers, it’s impossible to track everything.

Advantages, disadvantages

The undoubted advantages are a long service life, low price (except for design radiators) and the ability to work with any coolant. Disadvantages - large mass and fragility, difficult to process, cannot be repaired, low operating pressure - 9-10 bar.

There are also properties that in one case are an advantage, and in another - a disadvantage:

- Great inertia. Thick walls take a long time to heat up when the system is overclocked. But they also take a long time to cool down. This feature allows them to smooth out temperature fluctuations when using a conventional coal boiler.

- Large cross-section of sections. A lot of water is placed in them, which again leads to increased inertia of the system and the use of a more powerful pump in systems with forced circulation. But for systems with natural circulation, the low hydraulic resistance of wide collectors is a definite plus.

Application area

All these properties determine the scope of use of cast iron radiators, including low ones: they are optimally suited for individual heating systems (houses, dachas, cottages). They work well in small high-rise buildings: where the operating pressure in the system does not exceed 9-10 bar. They make no other demands on the coolant: they don’t care whether there is oxygen, how many suspended particles are contained, or what its acidity is. With periodic washing they will last a long time.

Read how to clean the battery here.

Materials used

Bimetallic products are the most durable due to the characteristics of the coolant movement.

Based on the type of material used in manufacturing, radiators for French windows are divided into the following types:

- Cast iron batteries produced by casting and representing a continuous heating section.

- Steel structures assembled from individual plates in combination with a pipe base.

- Aluminum radiators produced by casting or extrusion.

- Bimetallic products, in the manufacture of which two metals of different structure and characteristics are used.

Cast iron is a brittle material, which limits the permissible water pressure inside the battery sections. In addition, due to the rough surface, various contaminants accumulate on their internal planes, reducing the effect of heat transfer. On the other hand, cast iron water radiators retain heat well within the working area and are not subject to the destructive effects of salts dissolved in the coolant.

The design features of steel batteries, assembled from individual plates, make it possible to increase the level of convection and heat transfer. But they are also the reason for the frequent formation of blockages in the places where the plates are attached to the tubes.

The main advantage of an aluminum-based battery is its low weight and the ability to “hold” increased coolant pressure. On the other hand, their convection performance is worse than that of products made of cast iron and steel. In addition, aluminum is not as strong as other metals and is not designed to withstand frequent water hammer.

Bimetallic radiators, which combine two different materials, are usually made of copper tubes with aluminum or steel plates placed on them. The pipe base of such a product can withstand pressure corresponding to several tens of atmospheres. At the same time, it is not subject to the destructive effects of the coolant, long-term contact with which is not a problem for copper.

The service life of such batteries is comparable to that of a cast iron product.

Bimetallic radiators are not too large in size, however, due to heat loss in the areas where the plates are attached, the heat transfer efficiency is slightly less than that of their aluminum counterparts.

Steel tubular

This category has the largest range of low radiators. And the low ones here are:

- from 150 mm height for Purmo - Delta Laserline model;

- from 180 mm, Arbonia has almost all models of the “standard” range, there is also a radiator-bench, with a height of 180 mm;

- from 190 mm for Zehnder, Charleston model and bench radiators from 400 mm and 410 mm.

- With an axle distance of 300 mm from the Russian KZTO.

Tubular radiators are very decorative

At any manufacturer of tubular radiators you will find those that can be classified as low. They can have from two to six columns of pipes, respectively, they will have different depths - from 50 mm to 250 mm. Each of the models can be installed on the floor or hung on the wall (specify when ordering).

Advantages and disadvantages

Tubular radiators can have a nonlinear shape.

The advantages include a large selection of models, with different widths and depths, ease of cleaning, attractive appearance, and a large number of decorative options. The large cross-section of the pipes creates little hydraulic resistance, and such radiators rarely become clogged.

Disadvantages are caused by steel: susceptibility to corrosion, high requirements for coolant, low operating pressure, short service life - from 5 to 10 years. Exception: Zehnder Charleston Pro

, which is internally treated with two compounds. They resist corrosion so well that this option can stand at Ph 5-11. The warranty period is 25 years.

Application area

Basically, tubular radiators are designed for individual heating. Moreover, they can work both in systems with forced and natural gravity. The only requirement is that the system must be closed.

Steel panel

Steel panel radiators are low: they are usually made from 300 mm in height (here it is the height of the radiator, and not the interaxal distance). Any manufacturer has them: Russian Prado and European Purmo and Kermi.

There are also lower ones, but they are rare. So ]Purmo[/anchor] has models Ventil Compact, Purmo Planora and Ramo Compact. Their height starts from 200 mm (center distance 150 mm). We haven't found any others this small.

Steel panel radiators can be very low

Advantages and disadvantages

The advantages of steel radiators include their compact size and the lowest price per kilowatt of power. In addition, steel is a non-capricious metal that does not conflict with other components of the system.

The main disadvantage is the tendency to corrosion, and hence the demand for coolant: Ph 7-8 and lack of oxygen (closed systems). The panel walls have a thickness of 1.25 mm or 1.4 mm. If the coolant is of poor quality, they can be corroded within a few seasons. There is another disadvantage, which is due to the design: the small width of the channels through which the coolant circulates. If there is a large amount of contaminants in the coolant, they quickly become clogged. But flushing such a radiator is a problem. Another disadvantage is the difficulty of cleaning in the presence of plates with convective ribs.

Read more about steel radiators here.

Application area

Normally, panel radiators are installed in individual closed systems (with a closed expansion tank). Coolant circulation must be forced: these heating devices have high hydraulic resistance.

It is not recommended to install them in high-rise apartments; the pressure rarely allows this (working 10 bar). Only in systems that have their own water treatment (independent type of connection) with a mandatory deaeration stage (air removal).

Copper-aluminum radiators

This type of radiators and convectors, with their small sizes, is characterized by high heat transfer. This is usually a copper pipe on which aluminum plates are attached. This device is hidden in a painted steel casing (sometimes found in stainless steel). Most of the manufacturers on the market produce low copper-aluminum radiators:

- “Thermia” - height from 200 mm, bottom and side connections.

- Regulus-sistem - all models with a height of 215 mm;

- "IzoTerm" - from 215 mm;

- Mars - sectional type with a height of 385 mm.

Read about manufacturers and models of copper-aluminum and copper radiators here.

The photo shows copper-aluminum radiators Regulus-sistem

Advantages, disadvantages

The advantage of this type of low radiators is a fairly large heat transfer with small sizes (a 200mm * 400mm radiator produces 240 W). The second good property is that copper does not require a closed system, and Ph should be in the range of 7-9. Quite a high working pressure - 16 Bar.

But, despite such characteristics, it is not recommended to install it in systems with centralized heating: if the copper itself reacts little to the quality of the coolant, then it corrodes the solder and leaks appear at the soldering points. And, in addition, copper is incompatible with some metals, and also reacts poorly to a high content of abrasive particles, which simply erase it (copper is soft and gradually wears off, and this is one of its main disadvantages). Another drawback is the high price, as well as creaks and rustling noises that occur when radiators cool and heat up (but this is only for domestic models, European manufacturers have learned to deal with this, ours have not yet).

Inside copper-aluminum radiators there is this or a similar design

Application area

Again, these radiators will work well in individual systems (with forced circulation). But the wiring is preferably made of copper, polymer or metal-polymer pipes. In apartments, low copper-aluminum radiators will work normally provided that the coolant and operating pressure requirements are met. It is also necessary to install a filter at the inlet.

Why are batteries placed under our windows and nothing else?

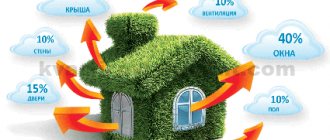

We remember from the physics textbook that warm air is lighter than cold air, so it always tends to occupy the upper position.

Even a schoolchild can explain these features of the movement of air flows. You also need to take into account that the temperature of the window glass is always lower than the temperature of the wall. It turns out that in winter, when the central heating is turned on, the following process of movement of air masses in the apartment occurs:

- near the window the air cools and tends to move from above to the lower part of the room;

- then the cold air spreads across the floor throughout the house, displacing warm air that accumulates above the ceiling;

- As a result, an unpleasant atmosphere is created in the room when the area where people are located becomes cold.

To avoid such a development of the situation, you need to place a heating radiator under the window. In this case, the warm air flow, rising from the heater, will mix with the cold air flow from the window. This mixing allows you to maintain a comfortable air temperature in the lower part of the home, cutting off cold currents descending from the window opening.

Now it’s clear why radiators are placed under the window and not moved to other places.

In addition, you need to understand that the radiator under the window also helps prevent fogging and freezing of the window. Remember how in a private village house, in which the main source of heat is a stove, frost often accumulates on the windows, the glass becomes covered with a pattern of frost and does not allow sunlight to pass into the home.

In general, the correct location of the heating elements of an apartment depends on the climate and the materials from which the house is built. In the southern regions, where there are rarely frosts below 20 degrees and relatively dry air, when glazing the room with high-quality double-glazed windows, the batteries can be placed anywhere, while the windows will remain clean without frost, and the apartment will have a comfortable temperature.

Baseboard heating

This type of heating devices appeared in our country not so long ago. These are devices very similar to copper-aluminum radiators: the same copper tube on which copper or aluminum convective plates are placed. They just have a different connection method, layout and different dimensions. Heating elements can be inserted into heating modules (tubes with plates) or they can be assembled into closed circuits through which the coolant circulates. They are located along the floor along the perimeter of the walls, covered with metal decorative overlays. The width is about 3 cm, the height is 12-20 cm, depending on the power. Exactly low radiators.

This is what baseboard heating looks like. No more other heating devices

Advantages, disadvantages

The advantage is that most of the heat (70-80%) is transferred by thermal radiation. The heat rising from warm baseboards heats up the walls first. They then begin to radiate heat. Therefore, a more uniform temperature is observed in the room, and warm air does not accumulate at the top.

Another plus is its very compact size and quite high heat output: one meter produces 180-280 W at average temperatures. In addition, they are not conspicuous and provide wide scope for design solutions.

The only downside is the high price.

Application area

Excellent in individual heating systems. It is possible to install electric heated skirting boards in apartments. Connecting to central heating requires a complex system: for optimal operation, the difference between the supply and return pipelines should not exceed 5oC, therefore each circuit should be no more than 12-14 meters long, and a mixing unit must be installed to maintain normal temperature.

How to choose the right low battery

In modern stores you can find a wide variety of models of low batteries, both domestically produced and from well-known brands of manufacturers in other countries. In order not to waste money on purchasing a battery with unused properties, it is recommended to rely on the following:

- It is better to heat rooms with panoramic windows with batteries made of aluminum or two or more different materials.

- In private houses that are not connected to the central heating mains, but use their own boiler, steel or aluminum radiators should be installed.

- The radiator must create an effective thermal curtain when placed in a window opening. To do this, its length must be greater than the width of the window.

Tubular radiators for home heating Bimetallic heating radiators Flat heating radiators Heating radiators for a private home