Sealing threaded connections in heating, water and gas supply systems is perhaps the most important task for a plumber or gas equipment installer. Not only the normal functioning of the system, but also the safety of the structure in which it is installed depends on the quality of the work performed. The threaded connection itself is very strong, but it is not capable of holding liquid or gas without special treatment. There are quite a few means for sealing, one of them is a special polymer thread for sealing threaded connections, which will be discussed.

“Moment Germent”, length 15 m.

What is plumbing thread

Sealing plumbing thread is 280 polymer microthreads impregnated with a special composition that increases the sealing properties of the thread. In addition to all kinds of fillers, the plumbing thread contains silicone , which protects the threaded connection from corrosion.

Disadvantages, negative points

Despite the large number of advantages, natural sealant is not without its disadvantages. They are especially obvious when installation and repair technology is violated. After short-term use, rust may form at the joints, making it difficult to dismantle structures during subsequent repairs. In view of this, it is recommended to regularly inspect connections for leaks and take measures to eliminate damage.

The material is very sensitive to the quality of work, so it is recommended to use it only by experienced craftsmen.

Attractive physical properties are compensated by the low chemical sensitivity of the material. Thus, flax fibers will be destroyed under the influence of antifreeze if they are part of the mixture passing through connected communications.

What is plumbing thread used for?

Plumbing thread is essentially a universal sealing material. It is used with equal success in the following areas:

- Hot water supply.

- Cold water supply.

- Drinking water supply.

- Gas supply.

- Heating systems .

is used mainly in domestic conditions to seal threads of any diameter. Thus, in domestic conditions, various fittings, taps, mixers, internal and external wiring of the water supply system are installed using plumbing thread.

For a sealing thread, of the working surface of the thread does not matter , since only the consumption of the thread itself changes depending on the condition of the thread. The thickness of the threaded connection also does not matter ; the thread is equally effective for thick and thin threads.

Non-hardening pastes

Another suitable sealant for gas or other pipes is a special non-hardening paste in the form of a viscous substance based on synthetic resins, acrylic and silicone, oils and various fillers. Such products are very easy to use: they need to be applied to the threads and the pipes are connected.

Positive qualities of pastes:

- the presence of additives against metal rusting;

- quick and easy thread tightening;

- easy dismantling of the system;

- no thread jamming during assembly.

Unfortunately, such pastes are only suitable for pipes under low pressure. If the pressure is high, the composition will soon be squeezed out of the thread. You should also not rely on strong fixation of pipes, as well as on the resistance of the products to sudden changes in temperature or the effects of aggressive chemicals.

It is best to use non-hardening pastes with flax or artificial threads to increase the reliability of the joint.

Characteristics of plumbing thread

Plumbing thread is made of polyamide or fluoroplastic . Depending on the material, the thread has some differences in characteristics.

Polyamide thread

- Withstands temperatures up to 130 °C.

- Inertness to aggressive environments.

- Withstands water pressure of 16 atm.

- Gas pressure

Fluoroplastic thread

- Temperature range up to 200 °C.

- The composition and properties of fluoroplastic thread are similar to FUM tape.

- Withstands pressure up to 30 atm.

- Superior to polyamide thread in wear resistance and resistance to aggressive environments.

Advantages of plumbing thread

- High temperature maximum.

- High wear resistance .

- Long service life. More than 15 years.

- Ability to adjust the connection without the risk of leakage.

- Does not require thread surface preparation.

- Easy to use.

- Immediately after pairing the parts, it is ready for use.

- Vibration resistance.

- Resistant to temperature changes.

- While working with plumbing thread, your hands and the surface of the material remain clean .

Disadvantages of plumbing thread

- Despite its high resistance to aggressive environments, it is not advisable to use the material in contact with chlorine, pure oxygen, gasoline, or diesel fuel.

- High material consumption on large diameters (an inch thread requires an average of up to 140 cm of material)

- Quite a high cost.

- Not suitable for tapered threads.

Useful tips

Around the wound flax it is necessary to treat it with a special paste intended for plumbing or use any other sealing material, the application of which should be carried out in a circular motion. This procedure must be carried out as carefully as possible. The second end should be glued closer to the edge of the thread and before tightening it is necessary to check whether the pipe lumen is filled with sealing material.

Important! Organic tow cannot be used for gas connections, since under the influence of gas it, together with the additionally used silicone, will be destroyed. For this task, the best option is fum tape.

How to wind plumbing thread

To seal a threaded connection, there are two winding methods depending on the technical condition of the thread.

Winding the sealing thread onto the new thread

- thread should be wound clockwise for a right-hand thread (the right-hand thread is one that also twists clockwise), i.e. along the thread.

- start winding the plumbing thread overlapping the first turn.

- We wind the sealing thread crosswise onto the new thread so that the fibers run as if across the thread turns. Due to its strength and the presence of lubricant, the thread will not break between the connections.

- The number of turns usually indicated on the packaging of the material.

- Material consumption may vary among different manufacturers, due to different thicknesses of plumbing thread.

- The number of turns indicated in the table is a recommendation.

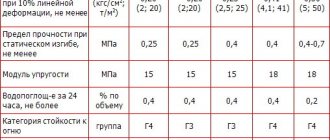

Conditionally recommended number of turns of the sealing thread.

Winding sealing thread onto old threads

The technique for winding sealing thread onto old threads is slightly different.

- The thread should be wound into each thread pitch.

- Then crosswise as for a new thread.

Video on how to properly wind plumbing thread

What sealants does the building materials market offer?

There are several types of sealing materials that differ in cost, ease of use and reliability of use:

- FUM tape (fluoroplastic sealing material)

- Sealing thread

- Linen thread

Among all the FUM proposals, tape is quite difficult to use, sealing thread has good qualities, but is too expensive, and only flax is an impeccable product that has proven itself over many decades.

To ensure a strong and tight connection, the threaded areas must be cleaned of rust using fine-grained sandpaper

At this stage it is important not to damage the threads. Then you should check whether there are notches on the thread - with them, the laid flax threads are fixed and do not move when connecting the parts

If there are no notches, they can be applied with a file or a plumbing wrench.

Check the tightness of the connection with a clean, flax-free thread to understand how thick the winding should be. Take a bunch of flax and separate a strand of sufficient thickness from it to obtain a tight connection. The flax hairs must be the same length, without lumps, straw and debris. Twist a loose rope from the strand of such thickness that it can fill one groove of the thread.

Here it is important not to overdo it with the number of layers, there should be no more than two, otherwise the connection may burst when tightened or from hot water during operation. If the bundle turns out to be short, winding should be continued with the next bundle. Inspect the reverse side of the winding and make sure there are no bald spots. Apply a layer of special paste or silicone on top of the flax and tighten the connection until the paste hardens

The use of a sealing composition contributes to the durability of the connection, prevents rotting of the flax, and makes it easy to disassemble the structure in the future. Sealant should not be used as a sealant; such a connection is difficult to disassemble.

Using a sealant when threading pipe systems is easy. This approach does not require the use of expensive equipment, and can be easily performed by both a professional and a home plumber.

1. Purpose of tow and how it works.2. Types of sealing materials.3. Method of sealing pipe threads with tow. In plumbing work, tow is used to seal pipes and transitions connected by threads. It is made mainly from flax waste and is a coarse fiber of small size.

If you wind the tow correctly, protection against leaks will be provided throughout the life of the pipeline. Answering the question of how to wind tow on a thread, it should be said that the quality of workmanship prevents the risk of a leak in the plumbing system. There is a gap between the threaded connections through which water freely flows out of the pipeline.

Comparison of plumbing thread

Against the backdrop of the variety of different thread sealants, many are reasonably interested in the question: Which is better? Sealing thread or FUM tape, sealing thread or plumbing flax? Etc. There is no clear answer to this question. Any seal should serve one purpose, namely to prevent leaks. The main thing is to know where and when to use this or that sealant.

Plumbing thread or FUM tape

- Plumbing thread can be wound onto worn and old threads without special preparation.

- The connection on the sealing thread can be adjusted up to 180° (adjust the connection for unscrewing) without losing the tightness.

- Unlike FUM tape, plumbing thread is not afraid of temperature changes and vibration.

- FUM tape is more resistant to aggressive environments.

- Grade 2 FUM tape is used in oxygen pipelines and connections of oxygen storage tanks.

- Plumbing thread is more expensive than FUM tape.

Plumbing thread or plumbing linen

- When working with plumbing thread, and the surface of the thread remain clean

- When working with thread, the time for thread processing significantly

- Plumbing flax is much cheaper than sealing thread.

- When working with thread, you do not need strictly adhere to the number of turns.

Plumbing thread or anaerobic sealant

- Upon completion of installation of the threaded connection using a sealing thread , the connection is immediately ready for use.

- After the sealing thread, the connection can be easily dismantled .

- Anaerobic sealant a wrench to tighten

- Anaerobic sealant is used for systems with new threads, or carefully prepared old threads.

In general, anaerobic sealant is the only sealant that does not require reaching the plumbing fixtures after installation.

Rewinding consumption

- DN 15. 5-8 turns required (35-55 cm) - DN 20. 7-10 turns required (60-85 cm) - DN 25. 8-12 turns required (80-125 cm) - DN 30. 9 required -15 turns (120-200 cm)

Establishing a connection takes about 1 minute. The same amount will be required to clean the thread if the thread comes out a little when twisting. This is not difficult to do - you just need to trim the protruding threads and remove traces of paste. By the way, the paste, unlike the impregnation of flax, is removed with one movement of a napkin. The connection is neat and clean, as is the work area around it. There is no hair, like flax, that flies and settles in all directions.

Manufacturers of plumbing threads

Brief characteristics of the most popular brands of plumbing thread.

Plumbing thread Tangit UNI-LOCK (Tangit Unilok)

Europe . The German company Henkel, under its control, produces the Tangit UNI-LOCK brand.

- Temperature range: gas: -20°С + 70°С hot water: + 130°С

- Pressure: For gas : up to 5 atm. For hot water + 130°C, withstands pressure up to 7 atm . For hot water up to + 85°C, withstands pressure up to 16 atm.

- Possibility of adjustment up to 180° within three days after installation of the connection.

- Service life in conditions of high temperature and vibration is 10-12 years.

- Not used for pipelines with oxygen, gasoline, diesel fuel, chlorine.

- It is allowed to use gases of 1-3 categories of aggressiveness (the difference in pressure in the gas pipeline system is from 5 kPa to 1.2 MPa ).

Plumbing thread Record

Russia . Plumbing thread Record is priced significantly lower than its most popular competitors, but according to professional plumbers, the quality is no worse.

- Temperature range -60°C + 120°C.

- Possibility of adjustment to 180°.

- Service life is 20 years.

- The lowest price from the presented manufacturers of plumbing thread.

- Despite the relatively low price, there is little difference in quality.

- Not very convenient container for sealing thread.

Plumbing thread Loctite (Loctite)

Europe. The Loctite brand, like Tangit UNI-LOCK, belongs to the German company Henkel.

- The product 68 atm pressure test for cold water.

- Loctite tape also passed a steam test with a pressure of 2 atm for 1,000 hours.

- Withstands gas pressure of 20 atm.

- Temperature range -10°С + 150°С.

- Recommended maximum diameter is 4 inches.

- Possibility of adjustment up to 45° within three days after installation of the connection.

- Can be used for gases of 1-3 aggressiveness categories.

Plumbing thread Sprint (Sprint)

Russia. It is also a very good option for inexpensive and high-quality products.

- You don’t need to buy new plumbing thread every time just change the bobbin .

- Operating temperature -60°С +120°С.

- Recommended pipe diameter is 1 1/4 inches.

- Withstands pressure of 24 atm.

- Possibility of adjustment by 180°.

- Manufacturer's warranty for 5 years.

Varieties, alternatives and selection rules

Flax is good for laying almost all metal pipes, including cast iron, stainless steel, non-ferrous metals, including copper, and their alloys, such as brass. The only exceptions are aluminum and metal-plastic products, as well as those made from polymer compositions. For them, professionals recommend using fum tape.

Fibers of various qualities are available on sale. All of them are produced on the same equipment - a carding machine. They are distinguished by numbers, which contain a description on the label. They vary in the range from 8 to 24. In this case, fibers with a higher number will have fewer impurities and vice versa. They are also characterized by a degree of flexibility, which is less important in their work.

Fibers are packaged in coils, as well as braids of fixed weight and size. Their color can vary from white to light gray, as well as beige due to the use of natural raw materials.

Using FUM for a gas pipeline

To fasten gas pipeline parts and install gas equipment, you should use only special FUM tape for gas. It must be supplied with a certificate of conformity confirming its suitability for use on gas pipes.

The special film for gas is yellow. It is made wider - up to two centimeters in width.

Yellow FUM tape for gas Source megastroy.com

The use of the material is possible only when sealing can only be achieved using a sealant. In the case of rubber hoses, as well as metal hoses, the sealing function is provided by a special gasket. In this case, the additional seal will not add tightness to the connection, and may even break it, as it will interfere with the tight fit of the gasket.

Briefly about the main thing

FUM tape is one of the popular and effective sealing options. It is affordable, easy to use, and does not create problems during subsequent repairs.

There are several simple rules on how to wind FUM tape onto a thread:

- the winding area must be cleaned;

- the tape is wound along the thread - how the nut will move along it;

- When winding the tape, you need to tighten it a little;

- Usually four layers are enough, but sometimes more are required;

- After winding the tape, the thread relief should be palpable.

Gas pipe connection

Oversized steel pipes with welded seams are usually used for gas pipelines with a cross-section of ½–2. Pipes that are seamless are suitable for larger connections in a gas system. It is best to lay steel bituminized pipelines underground without seams, which have threaded joints rather than welded ones. The principle of adhesion of their parts is similar to that used for water pipes (like fittings). In this case, the sockets are sealed with modern sealants or flax with special impregnation.

It is not advisable to seal shut-off valves of gas pipelines, because in this case it will be problematic to open them in case of urgent need. Such taps should be tightly fitted to each other and closed manually or with keys. In basements, pipes are joined with clamps and brackets, and where they pass through the wall, they are protected with a special cover. In slag concrete masonry, the surface of the gas pipeline is additionally coated with insulating anti-corrosion paint.

Sealants for gas pipe connections are necessary compounds and devices, the use of which cannot be ignored. They ensure the proper level of reliability of joints and allow you to extend the service life of the equipment.