Piping for hot water supply

The hot water supply scheme includes a system of pipelines, fittings and devices that either supply already heated water or themselves ensure its heating before supplying it to the consumer. Depending on the heat source, there are open and closed hot water supply schemes. They represent two systems that are opposite in action, each of which has its own positive and negative sides.

What are they, and how are they different? We will talk about this in our material, reinforcing the video theory in this article.

Features of an open system

It is characterized by the circulation of coolant obtained from common communications.

An open hot water supply system is when water enters the batteries from the main hot water pipe. From the same source from which hot water goes to residents' taps. The operation of the system is based on natural circulation. Due to physical phenomena, the cooling water, acquiring greater mass, will displace the hot flow, giving it acceleration. In some cases (in large systems), circulation is forced using pumps.

Open type heating is usually installed in high-rise buildings. The main advantage here is that there is no need for special mechanisms or devices for heating the coolant. For private households, such a system will be unnecessarily expensive, because the heating pipe will have to be connected to some high-rise building or a hole must be dug to connect it to the main line.

Main advantages

Let's list the main advantages:

- energy independence and centralized supply;

- smooth circulation of the carrier in the system without sudden pressure surges;

- ability to work in case of emergency due to redundant hot water mains.

However, an open heating system is not ideal.

Flaws

The main disadvantages include:

- high heat loss and, accordingly, unnecessary costs for heating water;

- dependence on the performance of large highways; in the event of an accident, the supply of hot water supply may stop in a large number of houses;

- water quality decreases due to defects in pipelines, in particular, rusty pipes;

- branched open systems require constant monitoring and careful calculations of supply volumes, heating temperatures and pressures.

Let's consider an alternative option.

Elements

Is a water metering unit a piping unit for a water supply network? consisting of shut-off valves, measuring instruments and fittings. The elevator unit is an element of the heating system that allows you to reduce the temperature of the coolant supplied from the thermal power plant to the set level.

The heating elevator mixes high-temperature coolant from the thermal power plant and cooled coolant from the return heating line of an apartment building.

Features of a closed system

The thermal main is designed as a separate closed circuit. The water in it is heated through heat exchangers from the CHP mains. Additional pumps are required here. The temperature is more stable, and the water is better. It remains in the system and is not collected by the consumer. Minimal water losses are restored by automatic replenishment.

A closed autonomous system receives energy from the coolant supplied to the heating points. There the water is brought to the required parameters. Different temperature conditions are supported for heating systems and hot water supply.

The disadvantage of the system is the complexity of the water treatment process. It is also expensive to deliver water to heating points located far from each other.

About terminology

First, a few words about how correct the very definition of “open water supply scheme” is.

It is a linguistic error and represents a distortion of a completely different concept. The correct term is open heat supply scheme. It is called open because it is possible to extract coolant from the heating system - heated in the boiler of the thermal power plant or local boiler service water.

However: we will respect the established system of definitions and will henceforth use the term “open water supply scheme”.

Housing and communal services in Russia

Hot water supply systems (DHW) based on their operating principle are divided into open and closed.

An open DHW system is a system in which water for hot water supply is taken directly from the supply and return pipelines of the heating network (heating system), mixed in special devices - hydraulic elevators and supplied to water taps. A closed DHW system is a system in which it is taken from the water supply network cold water is heated by the heat of network water in special heaters - boilers located in heating points (in basements) of houses, without coming into contact or mixing with the coolant - the water of the heating system, and then goes to the water taps of the MKD DHW system.

There are independent open hot water systems in which there are no connections between hot water and heating pipelines, and cold water for hot water needs, taken from the water supply network, is heated at thermal power plants, in district or house (roof) boiler houses and supplied to the apartment building through separate hot water supply networks .

The pressure (and, accordingly, flow) of water in hot water systems is created by pumps located at thermal power plants, in district or house (roof) boiler houses.

Most hot water supply systems, in accordance with regulatory documents, have a circulation system - pipelines and/or circulation pumps through which water continuously circulates. As a result, along the entire length of the hot water pipelines, including near water taps, the water temperature is constantly maintained in accordance with the requirements of the standards - not lower than 60 degrees C.

A hotline may not have a circulation line only if it is not designed by illiterate “specialists” or if thieving builders “forget” to build it with the connivance of their accomplices - city authorities, or if housing and communal services plumbers steal it for scrap metal.

However, in cases where hot water is constantly drawn from the DHW system (in bathhouses, in technological installations) and when the supply pipelines from the heat source to the water collection points are short, the DHW system may not have circulation.

Both open and closed hot water systems during design, installation and reconstruction must be equipped with devices for automatically maintaining the water temperature within standard values - not lower than 60 and not higher than 75 degrees. WITH.

(bases:

— clause 5.2.4 of the Code of Rules SP 30.13330.2012 “Internal water supply and sewerage of buildings” Updated version of SNiP 2.04.01-85; clause 15.14 of the Code of Rules SP 124.13330.2012″SNIP 41-02-2003. Heat networks" Updated version of SNiP 41-02-2003 (approved by order of the Ministry of Regional Development of the Russian Federation dated June 30, 2012 N 280); — clause 5.3.1 of the document “Rules and Standards for the Technical Operation of Housing Stock” (approved by the Post of the State Construction Committee of Russia dated September 27, 2003 N 170)).

The quality of water in open and closed hot water systems must comply with the requirements of SanPiN 2.1.4.1074-01 “Drinking water. Hygienic requirements for water quality of centralized drinking water supply systems. Quality control".

However, although the hot water of the DHW system should correspond in quality to the quality of cold drinking water, sanitary doctors do not recommend using it as drinking water, especially with an open DHW system, since in practice its contamination is not excluded. For example, at the beginning of the start-up period or after repair of hot water supply equipment, the water becomes contaminated with dirt and sediment washed out of the pipes. Therefore, it is recommended to use hot water mainly for laundry, washing dishes, and other sanitary and hygienic needs.

Use of heating points

This is a separate room. It must contain thermal power plants connected to the heating network. Heat exchangers for hot water supply in an apartment building must have tools for regulating consumption, distributing hot water among apartments, and setting up the equipment itself.

An individual heating point in an apartment building is usually located in the basement. Previously, the system was installed in attics. In the event of a breakthrough, streams of boiling water spilled throughout the room and flooded the apartments. If an emergency occurred at night, it could lead to serious injuries or even casualties.

An alternative option is to build a heating station in a separate building next to the building. The purpose of the equipment is to convert the coolant, regulate the supply of hot water or heat, distribute the resource among apartments and turn off its supply.

Principle of operation

The hot water supply system can be dead-end or circulating. A dead-end circuit is used when hot water is constantly used. When the water intake is not constant, the water in the pipes cools down and is no longer too hot. In order to get water at the required hot temperature, you will have to drain it for quite a long time, which is not very convenient. With a circulation circuit, water is always supplied hot, but such a system is more expensive. This scheme is well suited in cases of periodic water intake. The water temperature is constantly maintained and users receive hot water.

The circulation system in such systems can be of two types.

- Forced. This type uses pumps, just like a building heating system. Forced systems are used in multi-storey buildings, with a height of two floors or more.

- Natural. In one- and two-story houses, natural circulation is used, since the length of the pipelines is short. It operates through a system of circulation pipes, based on the difference in the mass of water at different temperatures. This method is the same as the water heating method using natural circulation.

Hot water supply consists of the following elements:

- water heater or generator;

- pipeline;

- water intake points.

Generators can be water heaters of several types.

- High-speed water-to-water heaters work on the basis that hot water, which comes from either the boiler room or the central heating supply, passes through brass pipes. They are located inside steel pipes, and the space between them is filled with heated water. Thus, heating occurs.

- A steam-water water heater operates using steam entering the heater. The water is heated by passing through brass pipes located inside. Such systems are used in homes with constant water flow and high consumption.

- In houses with periodic and low water consumption, storage water heaters are used. They not only heat, but also accumulate hot water.

Pipelines for both hot and cold water supply are a single system; they are laid in parallel. Mixers are installed at water intake points, which allow you to obtain different temperatures (from +20 to +70 degrees Celsius) by mixing hot and cold water. It is better to use galvanized or plastic pipes in the hot water supply system to prevent corrosion. It is better to insulate pipelines and risers to avoid unnecessary heat loss. In modern houses, meters are installed for hot and cold water to account for water consumption, which allows you not to overpay for consumption, but pay only for the water used.

Water heating equipment

A standard water heater can be used for domestic hot water or heating. In case of equipment breakdown, housing and communal services tariffs will not be reduced. Repair work will also fall on the shoulders of consumers, who are obliged to monitor its good condition.

Thermal energy component

It is responsible for heating cold water. Moreover, counters are not installed on the component. Before calculating the thermal energy for DHW, the following parameters must be taken into account:

- tariff for hot water supply;

- system operating costs;

- costs for coolant transfer;

- calculation of heat loss.

Also taken into account is the fee for regular water supply, calculated on the basis of consumption (RUB/cubic meter).

Main menu

Hi all! The hot water supply system for centralized heating comes in two types: open and closed. In this article, we will take a closer look at the open DHW scheme. First of all, what is the fundamental difference between these two schemes. With an open DHW circuit, hot water is drawn directly from the heating network, that is, to put it simply, the hot water running from the mixer tap is the same as in the heating radiators.

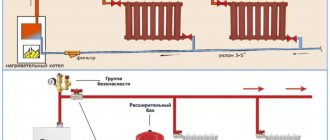

The hot water supply system is connected directly to the heating point of the building. The photo below shows how this happens. One branch is cut into the supply pipeline,

and the second branch is from the return pipeline.

These two branches are mixed in a hot water supply temperature regulator, the function of which is to provide the consumer with hot water with the necessary parameters, namely not lower than 60 ° C for an open DHW circuit, and not higher than 75 ° C for both a closed and open circuit according to SNiP 2.04. 01-85 "Internal water supply and sewerage of buildings."

And after the temperature regulator, hot water enters the internal hot water system of the building.

A closed DHW circuit is characterized by the fact that the hot water circuit is separated from the heating circuit. That is, water enters the heating circuit through the supply, passes through the building’s internal heating system (pipes, radiators) and returns to the return line, simultaneously heating the hot water supply circuit in the building’s heating point through a heat exchanger. The hot water supply circulates separately along its own circuit, and the water withdrawal in the building is compensated by replenishment from the cold water supply line. This is the essence and difference between these two DHW systems.

For a closed DHW system, there are several types of schemes - single-stage, two-stage, parallel, sequential. An open hot water system is connected exactly according to the same scheme as in the photo in the article below.

For an open DHW circuit, there are variations - circulation and dead-end wiring. As is clear from the names of these schemes, with a circulation scheme, hot water circulates through the internal hot water system, and ideally, when you open a hot water tap, hot water should flow out of there almost immediately. But this is ideal, and this is not always the case.

Dead-end circuit - with this circuit, hot water does not circulate in the system, and in order to get water at the desired temperature, it must be discharged through the tap. That is, you open the tap, wait for the cooled water to drain, then hot water pours out.

An open hot water system is more common in percentage terms, since the installation cost is relatively low (less pipe consumption and no heat exchangers). Personally, in the vast majority of buildings I service, I have encountered and continue to encounter an open hot water system. But besides the advantages (relatively small investment during installation, simplicity of design), this scheme also has disadvantages.

First of all, the quality of water in such a scheme must correspond to drinking water, that is, oil products should not get into the water, for example, from the stuffing box on large-diameter valves, rust and scale should not get into the water, and there should not be an excessive amount of hardness salts in the water. Unfortunately, this is not always observed. For example, in the city where I live, I practically never encountered the problem of poor water quality in the hot water supply system. The water in the hot water system meets the standards. But I know that the situation is not the same everywhere, not in all cities.

And the second problem with an open DHW circuit is the frequent failure of the DHW temperature regulator, its incorrect operation in the overall circuit. I wrote about this in this article.

I will be glad to receive comments on the article.

What is hot water recirculation (DHW) in a private home: diagrams and definitions

This is a supply line - a circuit piping - in which the coolant constantly moves through the system. It is needed to increase efficiency, and therefore the operating efficiency of boilers, which will result in an improvement in the level of consumer comfort.

Its arrangement solves several pressing problems at once. For example, when using it, the liquid does not have time to cool down, since it moves non-stop through pipelines - to the points of intake and back to the heating element (where it is heated) - which allows you to use it at any time, if the need arises, rather than waiting half an hour to take a bath .

In fact, the practical task of any implemented hot water supply scheme with water circulation in the system comes down to ensuring optimal thermal conditions. The temperature of the carrier suitable for operation is constantly maintained, due to which it enters a new cycle with minimal losses, especially since heat is transferred evenly at all stages of consumption.

The simplest wiring option is a ring with a pump that ensures continuous flow movement under pressure. Among its mandatory elements are tees responsible for the return of liquid and installed closer to the point of intake. The shorter the line, the shorter the heating wait time, but also the lower the overall performance.

Now let's turn our attention to solutions for different objects.

DHW circulation diagram in a private house

Here you need to pipe the heater in one or two circuits: most often it is played by a boiler, but a boiler, volatile or not, is also possible.

- The first must be permanently connected to the mains, but it is usually equipped with its own pump for pressurizing.

- The second does not require power from an outlet, but requires a timely supply of firewood or other fuel for combustion.

Using a boiler allows you to implement technically more complex solutions, for example, integrating bathroom and kitchen sink faucets, a heated towel rail and other elements into the line. Yes, as their number increases, energy consumption also increases, but overall savings also increase, which is especially noticeable with active fluid consumption.

Scheme of hot water supply (DHW) recirculation in a multi-storey building

In such cases, not direct, but indirect supply is relevant. The carrier is first heated, then sent to the pipes, passes through them, returns to the heating element, is again brought to the required temperature and goes to the next cycle. Each apartment (room) is a participant in the general wiring, which is characterized by the following features:

- The liquid moves from bottom to top or, much less often, vice versa, but always strictly vertically.

- Power is supplied exclusively from the DHW pipeline, and in the boiler itself, which is constantly running, the environment never cools down.

- The return of the flow is carried out through bends through which it flows back.

Private sector

What hot water supply schemes with circulation are used in cottages?

Actually, there are only two basic diagrams: with circulation through the water heater (for this it must be equipped with an additional pipe for connecting the DHW return) and with a thermal mixer. The water is driven by a small-sized pump with a wet rotor.

Closed circuit with circulation pump and boiler with three outlets

Pump for heating and hot water needs with a wet rotor

A three-way thermostatic valve allows you to implement recirculation even if in your home an electric boiler or an indirect boiler with two pipes (DHW and make-up) is responsible for heating the water.

Scheme with a conventional boiler and a three-way thermal mixer

Legal basis for relations in the field of heat supply

The relationship between energy companies and consumers is regulated by the Federal Law on Heat Supply No. 190, which came into force in 2010.

Chapter 1 outlines the basic concepts and general provisions that define the scope of the legal foundations of economic relations in heat supply. It also includes the provision of hot water

The general principles of organizing heat supply are approved, which consist in creating reliable, efficient and developing systems, which is very important for living in the difficult Russian climate. Chapters 2 and 3 reflect the broad scope of powers of local authorities, which manage pricing in the field of heat supply, approve the rules of its organization, accounting for heat energy consumption and standards for its losses during transmission. The full power in these matters makes it possible to control heat supply organizations that are classified as monopolists. Chapter 4 reflects the relationship between the heat supplier and the consumer based on the contract. All legal aspects of connection to heat networks are considered. Chapter 5 reflects the rules for preparing for the heating season and repairing heating networks and sources

It describes what to do in case of non-payment under the contract and unauthorized connections to heating networks. Chapter 6 defines the conditions for the transition of an organization to the status of self-regulatory in the field of heat supply, the organization of the transfer of rights to own and use a heat supply facility.

All legal aspects of connection to heat networks are considered. Chapter 5 reflects the rules for preparing for the heating season and repairing heating networks and sources. It describes what to do in case of non-payment under the contract and unauthorized connections to heating networks. Chapter 6 defines the conditions for the transition of an organization to the status of self-regulatory in the field of heat supply, the organization of the transfer of rights to own and use a heat supply facility.

Users of thermal energy must know the provisions of the Federal Law on heat supply in order to assert their legal rights.

Advantages and disadvantages

If we talk about the advantages and disadvantages of hot water supply, it is better to consider open and closed systems separately.

The advantages of an open system can be considered the following:

- it is easy to fill it and bleed air, which happens automatically through the expansion tank;

- It's quite easy to recharge. Since the pressure in the system does not require special attention, you can draw water without fear;

- the system functions well even in the presence of leaks, which is due to the high operating pressure in it.

The disadvantages include the following:

- constant monitoring of the water level in the tank;

- the need to replenish it.

The advantages of a closed hot water supply system include the following:

- savings associated with constant temperature;

- It is possible to install a heated towel rail.

A very important point in the hot water supply system is the presence of a hydraulic accumulator. It helps prevent some problems associated with pressure drops in the system. The hydraulic accumulator is a sealed tank containing a membrane partially filled with water. It divides the tank into water and air parts. If the volume of water in the hydraulic tank increases, then the volume of air correspondingly decreases.

If increased pressure parameters occur in the system, a signal is given and the pump is turned off. There is a pneumatic valve to regulate the pressure. Air is pumped through the nipple. Its quantity can be either added or reduced.

The hydraulic accumulator has the following advantages:

- preventing rapid pump wear. Since there is a supply of water in the tank, the pump will turn on less often, which contributes to its longer service life;

- stable air pressure in the system. The device helps to avoid sudden changes in pressure and temperature in the hot water supply system;

- resistance to water hammer. They practically do not occur and cannot harm the pump and the entire system;

- increased reserves of hot water. There is always a supply of it in the hydraulic accumulator tank, and it is constantly updated.

Malfunctions

Main malfunctions of the water supply system valve:

- when closed, it allows water to pass through,

- liquid flows through the rod,

- presence of leakage through threaded connections.

The causes of malfunctions are wear of the rubber valve gasket, seat shell, worn rod threads, worn out stuffing box, weak seal of threaded connections.

If a mixer with a ceramic axle box begins to make noise, then the cause is a sagging silicone washer. It is best to replace the ceramic valve axle with the same new one or an analogue.

Lever mixers make virtually no noise, but if this does happen, the only solution is to normalize the pressure in the system. To do this, reducers are installed in front of the mixer, which limit the pressure, then the noise stops. A similar approach can be used to eliminate noise in a hygienic shower mixer.

The video shows how to correctly calculate the cost of hot water.

Which option is better?

To understand which design of the heating system is better: open or closed, it is worth considering how they differ.

The main difference between a closed structure and an open one is the location of the expansion tank. In an open structure, it must be placed in the highest place of the house. But in a closed design, the tank can be installed anywhere, even on the same level as the boiler.

Insulation in a closed type of heat supply from the environment prevents air masses from getting inside. As a result, the service life of all equipment becomes significantly longer. Also, additional pressure is created in the uppermost components of the structure, which reduces the risk of air locks in the heating elements.

The open type of heating is distinguished by larger diameter pipes, which lead to additional inconvenience. In this case, the pipes have to be installed at a large angle to ensure circulation. Thick-walled pipes cannot always be hidden. In addition, in order to ensure correct hydraulics, it is necessary to take into account tilts, lifts, narrowings, turns, and connection options to radiators.

For a closed structure, pipes of a smaller circumference are needed. This makes the design cheaper

However, in such systems it is very important to ensure that the pump is installed correctly, otherwise it will become very noisy.

The closed type of heating, unlike the open one, is more durable and reliable. At the same time, it is able to maintain pressure at a constant level, and it is also possible to regulate it. The coolant in this design can be antifreeze rather than water. Simplicity of installation and quick start-up are also characteristic of a closed type of heating supply.

Among the advantages and differences, it is also worth noting the ability to connect additional equipment. Heating of this type is characterized by high efficiency, cost-effectiveness and the absence of the need for constant monitoring.

Of course, there are differences in the closed type, which cannot be classified as advantages. For example, the volume of the tank must be large and there must be an electrical network. Operation of a closed structure from other sources is possible, but only for a short time and in emergency cases.

The open design has a simpler installation scheme. It operates more silently than a closed one, and heats at a faster rate. You can fix faults in it very quickly, as well as turn it off completely. It does not need a power grid, nor does it need recharge in an emergency. Installation of the circuit does not require large expenses and a lot of time.

Air can get into the open type of heating, which causes various problems - for example, air congestion, rust. Unlike the closed type, such a system can boil or freeze.

The difference between the systems is quite significant. It is possible to say unequivocally which one is better only individually. To do this, it is worth once again emphasizing the main advantages and disadvantages of each system.

The closed design saves energy and supplies high-quality water, but the process of preparing this water itself is more complex and expensive.

The open design is very economical. However, due to long pipelines, the water there is of low quality. If you try to purify the water so that it has a better color and smell, then such a system will lose its dignity.

Connection diagram for DHW recirculation: how to make it yourself

There are at least several popular strapping options that have emerged due to fundamental differences in the design, layout and configuration of houses.

Therefore, before starting work, it is necessary not only to select a specific solution (taking into account the type, volume and features of the heating element), but also to draw up a drawing with installation points for all elements - pump, consumption devices, etc.

In practice, there are 4 types of connections that are most in demand - we will consider each.

Through an indirect heating boiler

At its core, it is a reservoir with a coil connected to the boiler in such a way that the coolant moves in a closed circuit and in no case mixes with household liquid. For this purpose, it has five pipes:

- straight, from container to spiral;

- reverse, providing return movement;

- cold make-up;

- supplying the flow to the point of consumption;

- reverse, leading to the tank.

Attention, for successful circulation of hot water, the scheme also provides for installing the pump strictly on the return pipe. Such an engineering move will prevent overheating of the elements, and therefore helps maintain normal operation. It is important that all installed heated towel rails will be constantly hot, and this is the key to a healthy and comfortable microclimate in the bathroom, as well as the absence of mold and mildew.

Through a storage boiler

This is already a tank with thermally insulated walls, which receives the required volume of liquid from the boiler - 100-1000 liters, depending on the number of residents in the building and their needs.

Its contour is a loop, with a forward feed and a return line. The latter is connected to the make-up pipe, and so that its entry point is behind the shut-off valve assembly. It also houses a pump equipped with control devices.

This solution has two important features:

- The medium that is in the tank has one temperature, and the other that runs along the replenishment line has a second temperature, due to the cooled “return” and/or the effect of mixing layers.

- Heating is carried out solely by adding flow after spending part of the reserves.

When idle, the media cools down very quickly. Therefore, a hot water recirculation system with a storage tank is relevant only for those houses where water consumption is constant and quite high, that is, for multi-storey buildings, but not for country houses.

Using a double-circuit gas boiler

This option is usually chosen when there are a small number of end-use points and when only one type is intended to be used at a time, for example, exclusively washbasins. In such cases, a medium-power flow heater capable of providing up to 20 l/min is also quite suitable. It will turn out to be quite simple (and therefore reliable and durable) and economical.

To install it, you only need to organize the supply of cold liquid to the tank and ensure that the flow of the required temperature is output. Keep in mind that during the run through the pipes the medium may cool down somewhat. Because of this feature, the option is poorly suited for buildings of large area and number of floors.

Installation of a gas boiler with built-in boiler

When you need to organize the circulation of hot water in a private house, a scheme with an integrated heating element is better suited than with a remote double-circuit one. Why? For three reasons at once:

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

- heating is more stable;

- It’s more convenient to use plumbing – you can turn on all the appliances and open every tap;

- It is not difficult to create a supply of 40-60 liters of well-warm liquid (albeit gradually cooling).

But there are also disadvantages, and these are:

- large dimensions - a set of equipment and space takes up a fair amount of space and weighs a fair amount, which is not always convenient;

- high cost – implementation of such a solution is relatively expensive;

- serious associated costs - to ensure and maintain the required fluid temperature, you have to spend a lot of fuel.

In practice, these disadvantages outweigh the advantages, so this option is being implemented less and less.

Differences between open and closed heating systems

There are the following distinctive features of open and closed heating systems:

At the location of the expansion tank. In an open heating system, the tank is located at the highest point of the system, and in a closed system, the expansion tank can be installed anywhere, even next to the boiler. The closed heating system is isolated from atmospheric flows, which prevents air from entering. This increases service life. By creating additional pressure in the upper components of the system, the possibility of the formation of air locks in radiators located on top is reduced. An open heating system uses pipes with a large diameter, which creates inconvenience, and the installation of pipes is carried out at an angle to ensure circulation. It is not always possible to hide thick-walled pipes

To ensure all hydraulic rules, it is necessary to take into account the slopes of flow distribution, lifting heights, turns, narrowing, and connections to radiators. A closed heating system uses smaller diameter pipes, which reduces the cost of the design.

Also, in a closed heating system, it is important to install the pump correctly to avoid noise.

Advantages of an open heating system

- easy system maintenance;

- the absence of a pump ensures silent operation;

- uniform heating of the heated room;

- quick start and stop of the system;

- independence from power supply, if there is no electricity in the house, the system will be operational;

- high reliability;

- no special skills are required to install the system; first of all, the boiler is installed; the power of the boiler will depend on the heated area.

Disadvantages of an open heating system

- the possibility of reducing the service life of the system if air enters, as heat transfer decreases, resulting in corrosion, water circulation is disrupted, and air pockets form;

- air contained in an open heating system can cause cavitation, which destroys system elements located in the cavitation zone, such as fittings and pipe surfaces;

- the possibility of freezing

of the coolant in the expansion tank; - slow heating

of the system after switching on; - constant monitoring of the coolant level

is necessary to prevent evaporation; - impossibility of using antifreeze as a coolant;

- quite bulky;

- low efficiency.

Advantages of a closed heating system

- easy installation

; - there is no need to constantly monitor the coolant level;

- the ability to use antifreeze

without fear of defrosting the heating system; - by increasing or decreasing the amount of coolant supplied to the system, you can regulate the temperature

in the room; - due to the absence of water evaporation, the need to replenish it from external sources is reduced;

- independent pressure regulation;

- the system is economical and technologically advanced, has a longer service life;

- possibility of connecting additional heating sources to a closed heating system.

Disadvantages of a closed heating system

- the most important drawback is the system’s dependence on the availability of a constant power supply

; - the pump requires electricity to operate;

- For emergency power supply, it is recommended to purchase a small generator

; - if the tightness of the joints is broken, air may enter the system;

- dimensions of expansion membrane tanks in large enclosed spaces;

- the tank is filled with liquid by 60-30%, the smallest percentage of filling occurs in large tanks; at large facilities tanks with a design volume of several thousand liters are used.

- There is a problem with the placement of such tanks; special installations are used to maintain a certain pressure.

An open heating system, due to ease of operation,

Great reliability, used for optimal heating

of small rooms.

These can be small one-story country houses, as well as country houses.

A closed heating system is more modern and more complex. It is used in multi-storey buildings and cottages.

Installation process

Now let's see how to recirculate DHW (hot water) in the house. We remind you that all work must be carried out at the construction stage or at the stage of major renovation of the building, in parallel with the installation of the boiler. We also need to assemble and place the outline correctly, so let's decide what we need for this.

Tools and materials

- welding machine of suitable performance and configuration;

- grinder, jigsaw or other appropriate tool for cutting pipes;

- fasteners, adapters, fittings;

- plumbing winding;

- Unipak sealant or similar thread paste.

To place the load-bearing elements, it is also worth arming yourself with an impact drill, a hammer drill, and a set of drills.

Equipment

When choosing a DHW scheme with recirculation for a private home, remember that in any case you will need:

- pipes - of different sections and made of various materials, from copper to plastic, depending on the purpose and characteristics of the line;

- three-way and ball valves, valves, reversing valves and other shut-off valves;

- medium or low power pump.

High pump performance is not even desirable, because it needs to provide only a small pressure - to move the flow along the line, but not to make it run quickly. Well, the nature of the execution of communications may require additional work, for example, soldering brass connections.

Installation algorithm

The answer to the question of how to circulate hot water (DHW) in a private home is quite simple. This problem must be solved step by step - in the following order:

- mark the supporting surfaces (usually walls) according to the drawing;

- install brackets, clamps, clips and other load-bearing elements;

- cut pipes along the entire length of the future communication;

- organize the line by sequentially connecting all the necessary adapters and fittings;

- connect the pump, mixers and similar units, as well as shut-off valves;

- provide outlets for the outflow of used liquid.

If a more complex circuit is planned, deviations from the given algorithm are acceptable, but in practice they will turn out to be insignificant and will consist of adding some additional elements, for example, distributors, and flow control and metering devices.