It is impossible to imagine a bathroom in an apartment or country house without a dryer, which performs the functions of heating the room and drying linen, towels and the bathroom itself. In order for the device to operate effectively for a long time without leaks, the installer needs to know how to correctly install a heated towel rail step by step with all the fittings.

Due to the variety of designs of wall-mounted bathroom dryers, different spatial placement and several ways to connect them, installation work requires certain knowledge and plumbing skills. You should also take a responsible approach to the choice of heated towel rails, fastening and shut-off valves, and sealing materials.

Rice. 1 Coil dryers

Types of heated towel rails

The retail chain sells a wide range of bathroom dryers (their standard diameter is 32 mm), which can be classified into the following groups:

According to the method of heating the working surface:

Mermen. The most common type of heated towel rails installed in all apartments of multi-storey buildings. They are usually connected to a separate hot water supply pipe running through all floors.

The coil can be installed in the pipeline gap in series or parallel to it through a bypass and shut-off ball valves. In individual houses, the dryer is connected to a common vertical riser with hot water.

Electrical. These are completely autonomous devices in the form of a coil or ladder, inside of which there is a tubular electric heater (TEH) and oil is filled.

The heater can be mounted on the wall anywhere (bathroom, kitchen, loggia); some models have a floor-mounted design. To heat the coolant, the device consumes an average of 60 watts of electricity. An important advantage of electric dryers is the ability to regulate the heating temperature using an external thermostat.

Combined. A type of heated towel rails that is not so common in the retail chain. The device has two separate, unconnected circuits. One of them is connected to the hot water supply, and the second, with the coolant oil, is connected to the electrical network.

Combined appliances are convenient because they can be efficiently connected to the heating circuit. When the heating system is operating, the room will be heated by hot water passing through the coil, and when the heating is turned off, by an oil radiator powered from the electrical network.

Rice. 2 Electric dryers

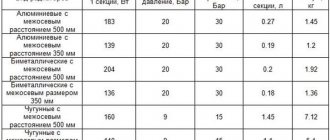

Based on the material used, the following types are distinguished:

Steel. These are budget types, for the production of which a metal pipe galvanized on both sides is used. Typically, dryers of this type are produced in a simple U-shaped or M-shaped form.

The coil has a gray, not very aesthetic appearance, but it can always be painted in a color suitable for the user.

Made of stainless steel. The vast majority of bathtub dryers are made from stainless steel. To give it a shiny, aesthetic appearance, the surface is usually chrome-plated.

Stainless steel can withstand temperatures up to 450 °C, has high corrosion resistance and strength, and a long service life. The disadvantages include much lower thermal conductivity than non-ferrous metals, as well as susceptibility to corrosion when used in the production of low-quality cheap alloys.

Made of brass. Brass with chrome, silver, gold or other plating is used in the production of expensive brands of heated towel rails. Its main advantages are excellent thermal conductivity, four times superior to conventional steel, as well as high corrosion resistance.

Bronze, copper. Dryers made from these materials are practically not found on the market; they are mainly used for the manufacture of exclusive models. Bronze and copper coils have the best thermal conductivity of all metals and favorably emphasize the design styles of retro, classic, and Italian interiors.

Rice. 3 Combined electric water dryers

Related article:

How to connect a heated towel rail to a heating and water supply system . It may be interesting to read an article on our website that describes in more detail how to connect a heated towel rail to the heating system.

Depending on the design of the heating pipeline, dryers are made in the form of:

Serpentines. These are S-shaped single-link and multi-link, U-shaped and M-shaped heated towel rails. Products of simple shapes have fairly low heat transfer and are typical for budget models. All these devices are designed for lateral connection to a water riser.

Combined type. These are models of more complex shapes, combining, for example, U-shaped and M-shaped, U and C-shaped contours. Many types of combined products include coils of a more complex design.

Ladders. The ladder dryer consists of two large-diameter vertical pipes with a number of smaller horizontal jumpers. The number of fragments in a heated towel rail-ladder can be as large as desired; in some cases, instead of straight horizontal jumpers, curved S and U-shaped ones are used.

Most ladder heated towel rails are equipped with an air vent and a plug in the upper part, which can be swapped.

The disadvantages of ladders include the possibility of accumulation of mud deposits in the lower part of vertically located pipes. To combat this phenomenon, some dryers are equipped with plugs that unscrew from the bottom.

In addition to the most common dryer options listed above, in the retail chain you can find more complex and original in terms of design models of various shapes and colors.

Also, some exclusive devices have rotating stands that are connected to the main structure using gland sealing units.

Rice. 4 Dryers of complex shapes

What not to do

All the above schemes work stably. As you noticed, all bends go straight, without bends in the form of an arc or rings. This is not accidental - air accumulates in all irregularities, which interferes with, and sometimes completely blocks, circulation.

This scheme doesn't work

The installation of the heated towel rail in the photo is incorrect. At least two mistakes were made:

- the bends are made narrower than the center distance of the heated towel rail;

- They are made with a metal-plastic pipe with loops.

This connection simply cannot work. Metal-plastic pipes are an excellent material, but not for connecting heated towel rails. Their fittings have a very narrow lumen, which has a bad effect on circulation. Plus, air accumulates in the loops, and the flow along the upper loop, even when supplied from above, will not flow - too much hydraulic resistance to the water must be overcome.

Unstable circuits

The following two schemes may work, but not always. At the bottom of the heated towel rail, the water stagnates and, given any difference in height, cannot rise. No one can say specifically when it will work and when it won’t. Depends on the pressure in the riser, the diameter of the pipes and the design of the dryer itself.

Unstable connection schemes

With such a connection, even a working connection may suddenly (usually after stopping) stop working. Everything is simple: the pressure has changed, the pipes are clogged, the water from below is not “pressed”, the heated towel rail does not heat.

Another option for an unstable circuit is with a loop on top. Again, it will work under certain conditions. But sooner or later the highest point will become airy and block the circulation. The problem can be helped by installing an automatic air vent at the highest point, but if the pressure drops, it will not save you.

With loop on top

Not true at all

The photo below shows examples of what not to do. Schemes without a tap on the bypass are inoperative. What this threatens is known. In addition, after several years of use, they will stop functioning altogether. Most likely this will happen after the next shutdown - the system will become clogged with dirt. This is because the entire flow of hot water is directed through the heated towel rail. After repairs, the water carries a huge amount of dirt, which safely settles in the bends (in the lowest areas first). Within a few years everything becomes completely clogged. Fortunately, everything needs to be redone and connected correctly, but only flushing can help the fire.

Very bad idea

It is necessary to wash both the heated towel rail and the connections to it. To do this, remove the dryer and wash it in the bathroom, and wash the outlets one by one by connecting a hose to the free outlets, the other end of which is taken to the sewer. By manipulating the taps, pass a flow of hot water through one outlet, then through the other. After washing everything is put back in place. It may be possible to start the system after this.

Options for installing heated towel rails into the riser

Any heated towel rail is an ordinary single-circuit or multi-circuit pipeline of complex shape that performs functions similar to a radiator heat exchanger. Just as in radiators, devices of complex design are equipped with an air vent to eliminate air plugs that interfere with the flow of water.

There are the following two main ways to connect heated towel rails to a hot water riser:

Consistent. This type of connection is initially used in apartment buildings. A coil located in each apartment is connected to the section of the riser located in the bathroom and passing through all floors.

In this case, the continuity of the water flow is ensured by the absence of any shut-off valves in the line.

To reduce hydraulic losses, simple U- and M-shaped coils are installed with a circumferential size corresponding to the diameter of the pipeline. Heated towel rails are connected from the side, water passes through them, flowing into the lower pipe and flowing out of the upper.

The disadvantages of a series connection include the impossibility of using complex-shaped dryers in a line - due to their high hydraulic resistance and heat transfer, the water in the devices on the upper floors may flow at too low a temperature.

Also, to repair and maintain a coil on any floor, you will have to turn off the water supply to the entire riser and drain the water from it.

Rice. 5 Options for sequential connection of coils into the riser Parallel with bypass. A more universal way to connect dryers is a parallel connection to the pipeline. In this case, the section between the inlet and outlet pipes plays the role of a bypass jumper, ensuring continuous water supply throughout the main line.

To connect the dryer, a section of a certain length is cut out and tees are installed on both sides of the cut pipeline. A dryer is connected to the side branches of the tee-splitters, and a bypass jumper from a section of a cut pipe or another of smaller diameter is placed between them.

With this connection option, shut-off ball valves are placed on the inlet and outlet pipes of the coil. This allows the heated towel rail to be removed for repair, maintenance or replacement.

When using a bypass connection, it is prohibited to use any type of shut-off valves in the jumper itself.

It is worth noting that the heated towel rail should not be located at too great a distance from the riser, the recommended distance is no more than 2 m. In a long pipeline, high hydraulic losses will prevent the passage of large volumes of water through the heater and, accordingly, its heat transfer will decrease.

In some cases, namely at large distances from the riser and the complex shape of the heated towel rail, it makes sense to direct more water flow into it than through the bypass jumper. This is achieved by reducing the bypass flow area, using a pipe of a smaller diameter or installing a control valve that is prohibited for installation into it.

Another effective option to direct a significant water flow to a heated towel rail remote from the riser is to use an offset bypass located as close as possible to the inlet pipes of the coil.

Rice. 6 Options for parallel side connection of dryers

Related article:

How to hide a gas pipe in the kitchen - various legal options . It might be interesting to read about how you can hide or play around with gas pipes in the kitchen. A separate article describes interesting options for decorating a gas pipe.

Finally about combined dryers

A double-circuit heated towel rail perfectly solves the problem of seasonality when connecting to home heating. During the cold season, the water circuit is heated; at the end of the heating season, you can turn on the second electric coil. The mounting of the device is quite ordinary - on brackets, the connection is made immediately to 2 networks - electrical and heating.

If it is necessary to change the old Soviet coil in an apartment, then the new one does not have to be installed in the same place and connected to the existing fittings. It is very advisable to replace the riser - it is probably “overgrown” with rust. Choose a suitable location for the heater, sketch out the connection diagram and install the heated towel rail according to the new requirements.

Features of dryer installation, pipes and fittings used

It is worth noting that in modern new buildings and individual houses, polymer pipelines are widely used when laying hot and cold water supply lines. Among several types (cross-linked and heat-resistant polyethylene, adhesive polyvinyl chloride), the leader in use is polypropylene (PP) pipes. They are the ones most often used for laying pipeline lines to heated towel rails.

If the hot water supply (DHW) riser is made of steel, metal outlets with external or internal threads are welded to it to connect the dryer.

There are the following three main installation methods and the corresponding design of popular ladder heated towel rails:

External side connection. To implement it, two side outlets are made in one of the vertical pipes of the dryer as close as possible to the pipe ends.

The connecting pipes are located in the same plane as the coil and usually have external threads of different diameters (3/4, 1, 1 1/4, 1 1/2 inches).

The disadvantages of the external side connection scheme include the low aesthetic appearance of the connection - often all fittings, as well as shut-off ball valves, are in plain sight.

In principle, it is possible to organize a hidden connection with side fittings extending to the side to pipes hidden in the wall. But for this you will have to use corner shaped elements connecting the coil outlets to the water sockets.

Rice. 9 Designs of dryers with side outlets and fittings for their connection to the hot water pipeline

Directly into the wall. With this design of the heated towel rail, the connecting threaded pipes are located behind the grille perpendicular to its plane. Usually they come off from the side or bottom; less common are options for a diagonal connection. To connect the dryer, straight adapter couplings (futorki), extensions in the form of barrels with double-sided threads, and American type detachable connections are used.

The main advantage of this design is the minimum number of butt joints when installing the dryer due to the use of straight types of fittings.

Corner into the wall (universal). This is one of the most common designs of ladder heated towel rails.

To implement it, internal threads (or external threads on the two lower ones) are cut at the four ends of two vertical pipes. Usually, a Mayevsky valve is screwed into the two upper threaded pipes to bleed air from the convenient side and a plug. The two lower pipes with external (internal) threads are connected to the hot water supply pipeline using corner adapter fittings.

The universal design of the dryer allows, in addition to the bottom, to easily implement its lateral and diagonal connection, if you rearrange the plugs and direct the water supply to other pipes.

Also, in some designs of dryers with bottom connections, instead of corner connections, tee adapter fittings with valve axle boxes (shut-off and control valves) are installed. With their help, you can disconnect the ladder heated towel rail from the water main, as well as carry out work to start it up in the absence of heating.

Rice. 10 Equipment, fittings and bottom installation of the heated towel rail-ladder

Article on the topic:

Connecting bimetallic heating radiators - instructions from “A” to “Z” . On our website there is a separate article about bimetallic radiators and their connection to the heating system of a house or apartment; it may be interesting to read it before connecting a heating radiator to polypropylene pipes.

Common Mistakes

You cannot install shut-off valves or taps on the piping (bypass) . Since the coil is part of the water main, narrowing the cross-section of the jumper is allowed only in some schemes. Otherwise, the operation of the hot water supply system on all floors will be disrupted.

When restoring the water supply after a temporary shutdown, you need to bleed air using the Mayevsky tap, even if the coil is heated in the apartment without problems.

It is necessary to check the pressure in the water supply network . If it is below normal, you cannot install the coil at a distance from the riser. It is not recommended to use “American” ones with narrowed fittings and a union-type nut for connection. Any narrowing, turns, or bends of less than five sections of the pipe will shorten the life of the heated towel rail.

It is impossible to groove in load-bearing walls and ceilings , especially for horizontal channels, which weaken the strength of vertical fences.

Methods of tapping into a riser

Before connecting the heated towel rail to the hot water supply system, a number of preparatory work is carried out. To cut into a vertically located metal hot water supply riser, the following methods are used:

Welding. Often a piece of pipe is cut out in the riser, and tees with threaded elbows and a bypass jumper are welded on top and bottom. If necessary, the bypass is made narrower by one standard size smaller than the main diameter of the riser.

Next, shut-off valves are screwed to the side threaded outlets, from which a polypropylene pipeline is laid to the dryer.

Threaded connections. With this method, a pipe section is cut out of the riser and surface threads are cut using a die on the ends of the cut pipes.

Next, metal tee bends are screwed directly to the threads or through adapter couplings, to which a bypass jumper with double-sided threads and ball valves are in turn connected.

After the shut-off valves, fittings with a metal-plastic transition are placed, to which a polypropylene pipeline is then soldered.

The advantage of this method is the ability to carry out work without a qualified welder and welding machine. True, in return for this you will need a die for cutting threads and the services of a plumber with a soldering iron and experience working with polypropylene.

In addition, this insertion method is quite labor-intensive and is not highly reliable due to the large number of threaded connections. As a result, threads on a cut riser and metal threaded tees are used quite rarely.

Switching to polypropylene. Sometimes, after cutting out the pipe section and threading the ends of the upper and lower pipes, a bypass jumper made of plastic (polypropylene) with pre-soldered side threaded bends for metal is screwed to them. Ball valves and a polypropylene pipeline are in turn connected to their threads.

This technology is used a little more often than the method described above, but its implementation is also associated with certain difficulties when cutting threads on pipes and installing a bypass jumper with tees into their section.

Rice. 11 Examples of inserting dryers into a riser using welding threaded adapters

Clamps. The easiest way to connect a heated towel rail to a pipe is to use overhead saddles or clamps with a threaded outlet.

When installing them, a hole is drilled into the riser pipe, onto which clamps with a sealing gasket are applied and secured by clamping them with bolts and nuts.

Despite the speed and simplicity of this method, it also has a number of significant disadvantages. Fastening the clamps to bolts and nuts is not very reliable and during operation it is possible that they may unscrew themselves. But the main drawback that makes this connection scheme practically unsuitable for use is that the diameter of the hole drilled in the pipe is too small. As a result, the volume of water entering the coil may be insufficient to fully warm it up.

Rice. 12 Examples of connection to a pipeline using clamps and tee couplings Zhebo

Compression fittings. The retail chain sells Zhebo tee couplings, with which you can connect metal pipes and make bends on them.

What designs are there?

Heated towel rails come in different shapes. When choosing them, people are often guided solely by aesthetics, which is not entirely justified. These devices work normally with good water circulation, but not all models provide such circulation. With some you have to spend a long time trying to find the right connection diagram, otherwise they simply refuse to work.

So, all heated towel rails can be divided into four groups:

- U-shaped or U-shaped. The simplest models, basic connection (lateral). Ideally, when replacing the old one, you find a model with the same center distance. Then, if you're lucky, you won't even have to redo the bends.

- Ladder. Modern designs with a certain number of crossbars. Also a good option from a hydraulic point of view. The connection can be bottom, side or diagonal. But it is not chosen arbitrarily, but according to a set of conditions (where the supply comes from, location relative to the riser).

- Snake. Another classic model with side connection. Installing a heated towel rail of this type, as a rule, does not present any problems.

Types of heated towel rails

- Complex shape. There are very unusual heated towel rails. They can even be an interior decoration, but their proper connection is a problem. As a rule, consultation with a competent specialist, a plumber who is well versed in hydraulics, is required. As you understand, finding one is not an easy task.

It often happens that after installing a heated towel rail it simply does not work. If the error is serious, the riser to which it is connected also stops working. Therefore, it is necessary to know and follow the connection rules.

Installing a heated towel rail step by step with all fittings

Heated towel rails are connected in two ways - directly to the riser through a pipeline, adapter fittings, or water sockets placed in the wall. The latter are laid in wall grooves if the pipeline is laid hidden.

To install water sockets, corner adapters from polypropylene to metal, equipped with internal threads, are usually used.

Rice. 13 Options for inserting dryers into a pipeline using sections of polypropylene pipes and fittings

Installation of heated towel rails with side outlets

If the dryer is connected to the riser in parallel, two threaded outlets with external threads are made from it through tees, and the standard center-to-center distance of the coil is taken to be 500 or 600 mm.

Next, installation of the dryer is carried out in the following order:

- Ball valves are screwed onto the threaded elbows, usually having an internal thread on one side and an external thread on the other for an American-type connection, the mating part of which is also included in the fitting kit.

- A polypropylene pipeline is laid from the ball valve, equipped on both sides with transition fittings from polypropylene to metal.

- The side of the pipeline that is connected to the shut-off valve is equipped with a polypropylene-to-metal adapter with internal thread. Next, screw the American counterpart from the ball valve into it and use a union nut to connect the pipe and valve.

- To attach it to the dryer, an American type adapter is soldered into the polypropylene pipeline. It can consist of one part with a union nut, which is screwed directly onto the dryer connection pipes through sealing gaskets.

But more often they use an American one, consisting of two parts. When installing it, one fitting with an external thread is screwed to the heated towel rail, and then an American nut soldered into the polypropylene pipeline is screwed onto it.

In a similar way, using a composite unit, American women connect coils into the riser gap during sequential installation.

It is worth noting that different methods are used to connect the heated towel rail to the pipeline. Sometimes an American fitting is placed on its threaded pipes, the union nut of which is screwed onto a fitting with an external thread soldered into polypropylene pipes.

Rice. 14 Fitting kits for installation of dryers

Installation of a universal dryer

Most ladder dryers are made of a universal type with internal top and external (internal) bottom threads at the four ends of the vertical pipelines. A plug and Mayevsky tap are screwed into the upper pipes of the coil, and the lower ones are used for water supply through water sockets built into the wall.

Many ladders are supplied with corner adapters, equipped on one side with an American union nut, and on the other with an external thread for connection to water sockets. Installation of the dryer into the wall with this adapter is carried out in the following way:

- Screw the corner adapters into the water sockets with an adjustable wrench, using flax fiber, plumbing thread or anaerobic sealant to seal. The American union nut is located at the top.

- Place the dryer with the covered supports against the wall and screw the American nuts from the corner adapters onto its lower threaded pipes.

Rice. 15 Stages of installing a heated towel rail - installing the top fitting for connecting to a water outlet

- Mark the places where the supports are attached with a pencil and remove the heated towel rail by unscrewing the American nuts. By lightly tapping the hammer on the core or nail, the pencil marks are deepened, breaking through the top layer of enamel in the tile.

- Insert a Victory bit of the required diameter (usually 6 mm) into the hammer drill and use the drilling mode to make holes in the tile cladding. Then switch the power tool to perforation mode and deepen the holes to the length of the dowels. Carefully drive in the dowels with a hammer.

- Place the dryer in place again, securing it with American nuts. Fix the supports to the dowels with self-tapping screws.

It should be noted that the vast majority of manufacturers provide their elbow fittings with soft silicone or rubber gaskets. They must be replaced with fluoroplastic or hard paronite ones. This will allow you to use higher clamping force when tightening the nuts, prevent damage to soft gaskets and reduce the likelihood of possible leaks.

In the retail chain there are dryers that have short pipes for the bottom connection installed perpendicular to the plane of the heat exchanger.

In this case, one straight American fitting is screwed into the water sockets, the union nuts of which are screwed onto the dryer pipes. This installation method is considered the most reliable due to the smallest number of connections and gaskets in the docking unit.

Rice. 16 Installation of a heated towel rail step by step with all fittings - design of a ladder dryer

Related article:

Replacing pipes in the bathroom and toilet - choice of pipe material, tools, installation methods . If you need to install a heated towel rail step by step with all the fittings, and the pipes are old, then it may be interesting to read in a separate article how to change the pipes in the bathroom.

Connection to the boiler

Connecting a heated towel rail to a boiler is considered an exceptional option. The scheme is used only in cases where the implementation of other methods is impossible. For example, in the absence of hot water supply in a private house heated by a single-circuit boiler. The supply of cold water to the boiler and the supply of hot water to the “towel box” is carried out through flexible hoses. They are connected to the device using a stainless steel or bronze coupling. The temperature of the water, and therefore the heated towel rail, is set using the water heater thermostat.

The disadvantage of this scheme is the inconsistent heating of the dryer. The hot water circuit is connected through the device and the flow directed to the mixer first passes through the “towel box”. This means that the jumpers and racks will only be warm during selection - when the hot water tap is turned on. To avoid airing the system, a Mayevsky valve must be installed - accumulated air is periodically released through it.

Is shape important?

The type of connection of the device will depend on this characteristic, so it is considered to be a more or less important aspect

How to properly connect a ladder heated towel rail

Develop a plan and materials that will be useful to you. Read the instructions, which contain an individual approach. Despite this, there is a general phasing.

- Reproduction of dismantling a real dryer.

- Connection of pipes and equipment.

- Installation of taps.

- Jumper installation.

At the end of the work, you should remove all accumulated debris and check the capabilities of the updated device.

Connection diagram for a complex-shaped heated towel rail

In such a situation, you will have to take into account some features. The working pressure is 8 atm, however, it can experience up to 16 atm. For improved heating, there is a Mayevsky tap, then the air will leave the system. Installation occurs thanks to special bushings. They are mounted on the wall. When attaching the legs to the bushings, screws are used to securely fix the device.